Documente Academic

Documente Profesional

Documente Cultură

Lab2-Analog Inputs and DC Motor Control

Încărcat de

BigMace23Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lab2-Analog Inputs and DC Motor Control

Încărcat de

BigMace23Drepturi de autor:

Formate disponibile

Name: ___________________________________

ME 1049 Lab 2

Analog Inputs and DC Motor Control on the Arduino

This assignment is to be done individually, and is due by the end of the lab period on

February 13. Steps preceded with _____ must be demonstrated to the lab instructor for

his initials.

In this lab you will use the Arduino analog input pins and wire an analog sensor as a

speed control input for a DC motor.

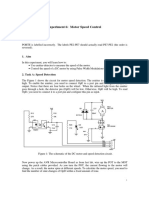

1) Wire five LEDs to five digital pins on the Uno board. Also wire an analog sensor (e.g.

potentiometer, thermistor, flex sensor, photo resistor, etc.) to one of the Unos

analog input pins. Note that most of these are resistive, and can be wired in a

voltage divider circuit as shown below.

2) Write a program that:

a) Causes the LEDs to blink in a linear fashion. That is, the light appears to scroll

along the row of LEDs from one to the next, then back around to the first one.

Repeat this pattern indefinitely.

b) The speed of scrolling LED should be proportional to the voltage read from the

analog sensor. Note that your sensor will likely not read the full 0-5V range, so

adjust the scrolling rate for your particular sensor range. If the voltage is at the

lowest value, turn all LEDs off. If the voltage is at the highest value, it should

take about 0.5 seconds for the light to scroll from one end of the LED row to the

other. For a voltage between min and max, set the scrolling proportionally.

________ 3) Upload your code to the Uno and run it. Once you have verified that it works

correctly, demonstrate the system to the lab instructor. Show what the voltage

range is for your sensor.

MEMS 1049 University of Pittsburgh wwc/1-20-15

Name: ___________________________________

In the following parts you will create a pulse-width modulation controller with which to

control the speed of a dc motor. The analog sensor created above will be used to set the

desired motor speed.

4) Using the P2N2222A transistor from the Arduino kit (dont confuse this with the

thermistor, as they look identical) as the power source wired as shown below (be

sure to include the diode across the motor), test your program by driving a dc

motor. (If you dont have a transistor and flyback diode, they will be provided in

the lab).

- Note that if you face the flat side of the transistor (that shows the part number),

the pins are from left-to-right: collector, base, emitter.

- Note the diode shown is a flyback diode that prevents unwanted voltage

spikes from the inductive coils in the motor to damage the circuit when the

current is rapidly changed in the motor. The black end of the diode is the

cathode and should be connected to the 5V source, while the opposite end

(anode) is connected to the collector of the transistor. When the cathode is

biased at lower voltage than the anode (so-called forward biasing), the diode

will conduct. Normally in this circuit the bias across the diode is in the opposite

direction and current flows through the motor. When the current is abruptly

stopped (when the PWM signal goes to zero), the collapsing magnetic field in

the motors armature produces a high voltage spike that forward biases the

diode and the transistor remains protected from the spike.

It is recommended that before continuing with the lab, you test the motor circuit

first by

i) simply connecting the transistors base to 5V or ground, to see the motor be

fully on or stopped, then

ii) write a simple on-off code to replicate that test with a digital pin from the

Arduino connected to the transistors base.

5) Write a program that produces a pulse-width modulated signal to control a motor. You

should test the signal using an oscilloscope. Be sure that different duty cycles can

be set across the full range from 0 to 100%.

6) Demonstrate that the motor speed can be varied from zero to a maximum by changing

the duty cycle of the PWM signal.

MEMS 1049 University of Pittsburgh wwc/1-20-15

Name: ___________________________________

7) Using the analog sensor of Parts 1)-3) as a speed control input to the motor,

combine your sensor, programs, and motor circuit such that the microcontroller reads

the analog voltage generated by the sensor and then sets the duty cycle based on that

value. When the sensor reads zero (or low voltage), the motor should be stopped

(zero duty cycle) and when a high voltage is read, the motor should run faster. Adjust

the sensor and/or your code so that you can control the motor speed between zero and

its maximum speed corresponding to the full range of the sensor (note that because of

dissipation factors in the motor, its speed will probably go to zero before the duty

cycle goes to zero, which is fine). Note that depending on the sensor used, you may

not observe a full 0-5V range from the sensor, but you MUST adjust the code so that

the motor can be adjusted over the full range of duty cycles (0-100) by using the input

sensor.

_____ 8) Demonstrate your final program and hardware setup. One should be able to use the

sensor to vary the motor speed from stopped to its max speed. While demonstrating

the motor in the lab, use an oscilloscope to show that the duty cycle of the motor

control signal is actually changing as the sensor voltage changes.

MEMS 1049 University of Pittsburgh wwc/1-20-15

S-ar putea să vă placă și

- Lab 3Document6 paginiLab 3Vu LeÎncă nu există evaluări

- CISE 204 Digital System Design Lab Manual PDFDocument44 paginiCISE 204 Digital System Design Lab Manual PDFEng-Mohammed KayedÎncă nu există evaluări

- Spectrometer Interfaced With ArduinoDocument7 paginiSpectrometer Interfaced With ArduinoAgung Arif Nur WibowoÎncă nu există evaluări

- Experiment 11Document8 paginiExperiment 11Mihai BogdanÎncă nu există evaluări

- Servo Encoder LabDocument8 paginiServo Encoder LabGoran MiljkovicÎncă nu există evaluări

- Arduino Workshop 03 - Output: ActuatorsDocument13 paginiArduino Workshop 03 - Output: ActuatorsDardan BelaÎncă nu există evaluări

- Arduino Model Train ControllerDocument9 paginiArduino Model Train ControlleritzanhÎncă nu există evaluări

- Lab Report 910Document14 paginiLab Report 910fu MozaÎncă nu există evaluări

- Experiment 6: Motor Speed Control: ErratumDocument5 paginiExperiment 6: Motor Speed Control: ErratumBambang PrasetyoÎncă nu există evaluări

- Microprocessors and Microcontrollers DesignDocument8 paginiMicroprocessors and Microcontrollers DesignBittu VermaÎncă nu există evaluări

- Arduino DC Motor ControlDocument4 paginiArduino DC Motor ControlKathryn WorkmanÎncă nu există evaluări

- DC Motor ArduinoDocument40 paginiDC Motor ArduinoBodo De La BuernoÎncă nu există evaluări

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsDe la EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsÎncă nu există evaluări

- Session 4Document2 paginiSession 4Manoj GudiÎncă nu există evaluări

- Accident Detection SystemDocument62 paginiAccident Detection SystemKarthik KingstarÎncă nu există evaluări

- Vanderbilt University ES 140x EE Introduction To Engineering Electrical Engineering Module Fall 2021Document3 paginiVanderbilt University ES 140x EE Introduction To Engineering Electrical Engineering Module Fall 2021Siyuan ChenÎncă nu există evaluări

- Final SDocument8 paginiFinal SChetanModiÎncă nu există evaluări

- Lab 2 Analog Encoder PWM R9Document5 paginiLab 2 Analog Encoder PWM R9subairiÎncă nu există evaluări

- INTELLIGENT MANAGEMENT OF ELECTRICAL SYSTEMS IN INDUSTRIES - FinalDocument9 paginiINTELLIGENT MANAGEMENT OF ELECTRICAL SYSTEMS IN INDUSTRIES - FinalAbishek ReddyÎncă nu există evaluări

- Technical Research Paper Microcontroller Based Fault DetectorDocument8 paginiTechnical Research Paper Microcontroller Based Fault DetectorM S Daniel WesliyÎncă nu există evaluări

- Wesleyan FULL PDF - 210516 - 222709-115-118Document4 paginiWesleyan FULL PDF - 210516 - 222709-115-118Ajaykrishna R.CÎncă nu există evaluări

- Arduino ppt-1Document25 paginiArduino ppt-1Aman NaikyaÎncă nu există evaluări

- Reg-Sv: Light Dimming RegulationDocument8 paginiReg-Sv: Light Dimming Regulationkaushik4endÎncă nu există evaluări

- Traffic Light Control SystemDocument12 paginiTraffic Light Control SystemVinay ReddyÎncă nu există evaluări

- IR TachometerDocument10 paginiIR TachometerMohammed Abdulrahman MossaÎncă nu există evaluări

- Instrumentation: Submitted By-Debaraj Kakati ECE-12/16 DuietDocument27 paginiInstrumentation: Submitted By-Debaraj Kakati ECE-12/16 DuietRajÎncă nu există evaluări

- Line Follower Robot Using LabVIEWDocument6 paginiLine Follower Robot Using LabVIEWTrần Huy Vinh QuangÎncă nu există evaluări

- Magnetically Levitated BallDocument4 paginiMagnetically Levitated BallthaisubÎncă nu există evaluări

- Dkg-329 Automatic Transfer Switch With Uninterrupted Transfer and Multiple Genset SupportDocument43 paginiDkg-329 Automatic Transfer Switch With Uninterrupted Transfer and Multiple Genset SupportLuis Fernando CuaspudÎncă nu există evaluări

- Team 4 Technical ReportDocument12 paginiTeam 4 Technical Reportabdelrahmanmoataz0Încă nu există evaluări

- C T I/O P: Hapter Hree RocessingDocument22 paginiC T I/O P: Hapter Hree RocessingMohamed OmarÎncă nu există evaluări

- Organizer Resource Person: Department of ECE Aliah University Kolkata, IndiaDocument41 paginiOrganizer Resource Person: Department of ECE Aliah University Kolkata, IndiaK K SHUKLAÎncă nu există evaluări

- Lab 9Document13 paginiLab 9Abu BakarÎncă nu există evaluări

- Eye Blink DocumentDocument38 paginiEye Blink Documentpavani13Încă nu există evaluări

- FinalDocument36 paginiFinalyashÎncă nu există evaluări

- Chapter One Controlling The Operation of Wind-Solar Hybrid Power System Using Arduino-Based Hybrid MPPT ControllerDocument48 paginiChapter One Controlling The Operation of Wind-Solar Hybrid Power System Using Arduino-Based Hybrid MPPT ControllerOdebunmi NathanielÎncă nu există evaluări

- MDD PPT Keerti Third ReviewDocument20 paginiMDD PPT Keerti Third Reviewkeeru mbsÎncă nu există evaluări

- Arduino Wattmeter - Measure Voltage, Current and Power ConsumptionDocument9 paginiArduino Wattmeter - Measure Voltage, Current and Power ConsumptionMihai BogdanÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Working Principle: 1) System CheckDocument8 paginiWorking Principle: 1) System CheckHans IngoleÎncă nu există evaluări

- Circuits Docs Labs Lab3 First and Second Order ResponsesDocument8 paginiCircuits Docs Labs Lab3 First and Second Order ResponsesCesar Santiago Bolaño SalazarÎncă nu există evaluări

- Arduino WattmeterDocument6 paginiArduino WattmetersalmanÎncă nu există evaluări

- Fiber Optic Telemetry System Using Ne555Document10 paginiFiber Optic Telemetry System Using Ne555Rajesh VeerabadranÎncă nu există evaluări

- LabBJTandH BridgeDocument12 paginiLabBJTandH BridgeAndrew BuckleyÎncă nu există evaluări

- Differential Transformer ProtectionDocument14 paginiDifferential Transformer ProtectionChetanModiÎncă nu există evaluări

- 273-Article Text-474-1-10-20171230Document5 pagini273-Article Text-474-1-10-20171230Jinsha CÎncă nu există evaluări

- Arduino Lab 1 - The Voltage DividerDocument8 paginiArduino Lab 1 - The Voltage DividerRahmat PrihartonoÎncă nu există evaluări

- ELEC30x0 Lab8Document6 paginiELEC30x0 Lab8Lûtwàmä JôëÎncă nu există evaluări

- DOC-202317Document23 paginiDOC-202317nittinmohanty.nmÎncă nu există evaluări

- Ir Remote Based Stepper Motor Control PDFDocument70 paginiIr Remote Based Stepper Motor Control PDFsanoopmk100% (1)

- Servicing PLC 120V I/O Modules: 0 CommentsDocument49 paginiServicing PLC 120V I/O Modules: 0 CommentsrajuanthatiÎncă nu există evaluări

- Chequeo de Sensores AutomovilDocument7 paginiChequeo de Sensores AutomovilBryan RzÎncă nu există evaluări

- Robotics 17Document27 paginiRobotics 17setsindia3735Încă nu există evaluări

- ArduinoDocument19 paginiArduinoAbiral BharillÎncă nu există evaluări

- T'REX Robot Controller Instruction Manual1Document14 paginiT'REX Robot Controller Instruction Manual1mariachi1980Încă nu există evaluări

- CPE400 Lab8 ARCONADO DEVELLES 2 PDFDocument10 paginiCPE400 Lab8 ARCONADO DEVELLES 2 PDFKimÎncă nu există evaluări

- TheftDocument12 paginiTheftEmeka Nelson OffornedoÎncă nu există evaluări

- A Remote Electricity Billing SystemDocument9 paginiA Remote Electricity Billing SystemHemant PatelÎncă nu există evaluări

- Electric Motor: Project DescriptionDocument20 paginiElectric Motor: Project DescriptionAllen LeeÎncă nu există evaluări

- Fundamentals of GearsDocument56 paginiFundamentals of GearsBigMace23Încă nu există evaluări

- Business Format Writing DetailsDocument3 paginiBusiness Format Writing DetailsBigMace23Încă nu există evaluări

- ENGR0022 Syllabus Fall2013Document2 paginiENGR0022 Syllabus Fall2013BigMace23Încă nu există evaluări

- ANTH0536 Syllabus 2013Document12 paginiANTH0536 Syllabus 2013BigMace23Încă nu există evaluări

- TEC 2000 User ManualDocument80 paginiTEC 2000 User ManualAndrew N. Irangi100% (1)

- Frequency Selective Channel Equalization For Filter Bank Multi-Carrier ModulationDocument8 paginiFrequency Selective Channel Equalization For Filter Bank Multi-Carrier Modulationskh_1987Încă nu există evaluări

- KDS 7X ManualDocument26 paginiKDS 7X ManualDutchstylerÎncă nu există evaluări

- Umts CpichDocument2 paginiUmts CpichAlfredoÎncă nu există evaluări

- Linear IC TrainerDocument2 paginiLinear IC TrainerAdvanceElectronicesÎncă nu există evaluări

- 6360 - User Manual Lifepo4 Prismatic Battery 12.8v 40ah (512wh, 30a)Document8 pagini6360 - User Manual Lifepo4 Prismatic Battery 12.8v 40ah (512wh, 30a)maxonetÎncă nu există evaluări

- Starter Kit 2.4 GHZ Base Stations FCC Regulated 2011Document4 paginiStarter Kit 2.4 GHZ Base Stations FCC Regulated 2011SaudÎncă nu există evaluări

- The Art of The Possible: Overview of Public Broadband OptionsDocument46 paginiThe Art of The Possible: Overview of Public Broadband OptionsEsme VosÎncă nu există evaluări

- Haier: Color TelevisionDocument27 paginiHaier: Color TelevisionJohn Freddy LopezÎncă nu există evaluări

- UHF SatcomDocument3 paginiUHF SatcomalimahhassanÎncă nu există evaluări

- Transimpedance Amplifier With Mic PDFDocument23 paginiTransimpedance Amplifier With Mic PDFChanderKishoreJoshiÎncă nu există evaluări

- Quadrature Amplitude Backscatter Modulator For Passive Wireless SensorsDocument8 paginiQuadrature Amplitude Backscatter Modulator For Passive Wireless SensorsJunaidÎncă nu există evaluări

- GSM-EDGE Repeater Manual Preliminary Version 2Document265 paginiGSM-EDGE Repeater Manual Preliminary Version 2divxns100% (1)

- 5G Wireless Technology Seminar ReportDocument27 pagini5G Wireless Technology Seminar Reportprashantkumar2806Încă nu există evaluări

- ECA - VIVA QuestionsDocument2 paginiECA - VIVA QuestionsEdukondalu DuggeboinaÎncă nu există evaluări

- Business CommunicationDocument2 paginiBusiness CommunicationKaran Veer SinghÎncă nu există evaluări

- Fundamentals of Mechatronics 1st Edition Jouaneh Solutions ManualDocument15 paginiFundamentals of Mechatronics 1st Edition Jouaneh Solutions Manualqefoni100% (1)

- Airotronics-050 TGMLDocument2 paginiAirotronics-050 TGMLSergiSerranoÎncă nu există evaluări

- Bedienungsanleitung / Owner'S Manual: High End Class A/B 2-Channel AmplifierDocument28 paginiBedienungsanleitung / Owner'S Manual: High End Class A/B 2-Channel AmplifierDanyÎncă nu există evaluări

- IEEE Xplore Full-Text PDFDocument10 paginiIEEE Xplore Full-Text PDFpshyciÎncă nu există evaluări

- Acoustica Premium Edition 4: User GuideDocument85 paginiAcoustica Premium Edition 4: User GuideMatthew ThomasÎncă nu există evaluări

- Ultra-Wideband Low Noise Amplifier Using A Cascode Feedback TopologyDocument3 paginiUltra-Wideband Low Noise Amplifier Using A Cascode Feedback TopologyAsad AsadiÎncă nu există evaluări

- Network Analysis-Measurement Science Poster 2018 2Document1 paginăNetwork Analysis-Measurement Science Poster 2018 2joaomsonÎncă nu există evaluări

- Frequency - Division MultiplexingDocument11 paginiFrequency - Division MultiplexingZain Chaudhry100% (1)

- A Novel Scheme To Eliminate Common Mode Voltage in Multilevel InvertersDocument4 paginiA Novel Scheme To Eliminate Common Mode Voltage in Multilevel InvertersJavier MaldonadoÎncă nu există evaluări

- Ad 9954Document40 paginiAd 9954neelu_khÎncă nu există evaluări

- How To Replace An Iphone 5S Display AssemblyDocument10 paginiHow To Replace An Iphone 5S Display Assemblyama130230Încă nu există evaluări

- RLC and Band PassDocument4 paginiRLC and Band PasscuamiÎncă nu există evaluări

- ML 5510 6510 Error CodesDocument98 paginiML 5510 6510 Error CodesAlessandro Carneiro de AraujoÎncă nu există evaluări

- p7000 YammyDocument2 paginip7000 YammyAlloush86Încă nu există evaluări