Documente Academic

Documente Profesional

Documente Cultură

Cajon-001 WPS

Încărcat de

Danem HalasTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cajon-001 WPS

Încărcat de

Danem HalasDrepturi de autor:

Formate disponibile

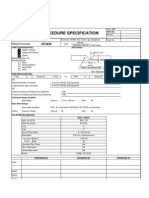

Fermi National Accelerator Laboratory

Technical Division-Machine Shop

Welding Procedure Specification

Welding Procedure Specification No.:

Revision No.:

Revision Date:

Welding Processes:

WPS Cajon/Orbital 001

Date: 12/29/2009**

Remarks:

Supporting PQR No.(s):

PQR Cajon/Orbital 001

GTAW/Automatic

(2)

(Manual, Automatic, Machine, Semi-automatic)

Joints (QW-402):

Joint Design: Groove

Retainer: Yes *** No

Joint Details:

Backing: Gas

Backing Material (Type): Argon Gas

Type: Non-Metallic *** Metallic (Non-fusing)

Remainder:

.035

.250

0.0to 0.002 opening

SA249 304/304L .035 x 0.250

Cajon Orbital Welding Machine (Autogenous only)

P-No.: 8 Group 1

TO

Base Metals (QW403):

Specification Type and Grade: SA 249 Type 304/304L

TO Specification Type and Grade: SA 249 Type 304/304L

OR Chemical Analysis and Mechanical Properties:

TO Chemical Analysis and Mechanical properties:

Thickness Range:

Process 1

Groove: .035

Fillet: Unlimited

Base Metal:

Groove:

.035

Fillet: Unlimited

Deposited Weld Metal:

Groove: .250 Minimum

Fillet: Unlimited

Pipe Diameter Range:

Other:

Filler Metals (QW-404)

Specification No. (SFA):

AWS No, (Class):

F-No.:

A No.:

Size of Filler Metals:

Deposited Weld Metal

Thickness Range:

Electrode-Flux (Class):

Flux Trade Name:

Consumable Insert:

P-No.:

8 Group 1

Process 2

Groove:

Groove:

Groove:

Process 1

Autogenous No Filler

Fillet:

Fillet:

Fillet:

Process 2

Groove:

Fillet: Unlimited

Groove:

Fillet:

Other:

Each Base Metal-Filler Metal Combination should be recorded individually

Page 1 of 2

12/29/09

Fermi National Accelerator Laboratory

Technical Division-Machine Shop

Welding Procedure Specification

Positions (QW-405

Positions of Groove:

Welding Progression

Positions of Fillet

Preheat (QW-408)

Preheat Temperature:

Interpass Temperature:

Preheat Maintenance:

Minimum Welding Temperature

Post Heat Treatment (QW-407)

Temperature Range:

None

Time Range

N/A

All

Upward & downward

All

Gas (QW-408)

% Composition

Minimum 50 F

Maximum-Not Recorded

None

32 F

Electrical Characteristics (QW-409)

Current AC or DC:

Direct Current

Tungsten Electrode:

Size: .040

Mode of Metal Transfer for GMAW:

N/A

Electrode Wire Feed Speed Range:

N/A

Shielding

Trailing

Backing

Polarity: Straight

EWCe-2

Gases

Argon

None

Argon

Mixture

99.9%

***

99.9%

Characteristics

Flow Rate

10-15 CFH

***

8-12 CFH

Pulsing

Technique (QW-410)

String or Weave Bead:

String

Orifice or Gas Cup Size:

Cajon Orbital Head CWS H5

Initial Interpass Cleaning (Brushing, Grinding, etc.):

Initial Solvent Clean***Wire brush between passes

Method of Back Gouging:

None

Oscillation:

None

Contact Tube to Work Distance:

N/A

Multiple or Single Pass (per side): Single

Multiple or Single Electrode(s):

Single

Travel Speed (Range):

As Required

Peening:

None

Other:

Sequence Chart: Cajon Welding Systems for .035 x SA249 304/304L

Impulse

41.0

Maintenance

11.0

Frequency

10

Duty Cycle

20

Start

40

Pre-purge

10

Dwell

10

Down-slope

15

Post Purge

30

Speed

82

Special Notes

ARC Length

.035

Gage Setting

.722

Material

304/304L

Wall Thickness

.035

Outside Diameter

1/4

Duration

15

Gas Settings

Type

Head

Tube

Head Model

Argon

12CFH

10CFH

5H

Power Supply

100D

Page 2 of 2

Date:

Welder: Harbacek #8

12/29/09

S-ar putea să vă placă și

- I-963 Welder Certificate Smaw-Gtaw-1Document1 paginăI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- 385 2 Internal Gtaw+SmawDocument2 pagini385 2 Internal Gtaw+Smawsubash1688Încă nu există evaluări

- WPS GTAW Stainless SteelDocument2 paginiWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- PQR Sample PrintoutDocument2 paginiPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 paginăPQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraÎncă nu există evaluări

- Composite Construction Design (ULS Only)Document93 paginiComposite Construction Design (ULS Only)CawanNeroMiranio100% (1)

- Mathematics Paper I: Question-Answer BookDocument11 paginiMathematics Paper I: Question-Answer BookTO ChauÎncă nu există evaluări

- Science: Modified Strategic Intervention MaterialDocument32 paginiScience: Modified Strategic Intervention MaterialMar Angelo TangcangcoÎncă nu există evaluări

- 004 Gtaw P5aDocument16 pagini004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Engine Number Guide (2-Page)Document2 paginiEngine Number Guide (2-Page)Abdul KhaliqÎncă nu există evaluări

- PQR-WPS-WPQR XXX Rev 0Document6 paginiPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- WPS RegisterDocument2 paginiWPS RegisterdaveswinburneÎncă nu există evaluări

- WeldingofStainlesssSteelandotherJoiningMethods 9002Document0 paginiWeldingofStainlesssSteelandotherJoiningMethods 9002jvs11021102Încă nu există evaluări

- WPS FormatDocument2 paginiWPS FormatAmit SarkarÎncă nu există evaluări

- WPS002 312Document2 paginiWPS002 312proxywarÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 paginiQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Încă nu există evaluări

- Manual Joints (QW - 402) : Page 1 of 12Document12 paginiManual Joints (QW - 402) : Page 1 of 12miteshpatel191Încă nu există evaluări

- 254-SmoDocument12 pagini254-SmoDanem Halas100% (1)

- WPQ Template (Asme Ix) No LogoDocument4 paginiWPQ Template (Asme Ix) No LogorcpretoriusÎncă nu există evaluări

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 paginiTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanÎncă nu există evaluări

- Wps Magi Tig ExempleDocument6 paginiWps Magi Tig ExempleDanem HalasÎncă nu există evaluări

- WPS PQR Checklist 2014Document2 paginiWPS PQR Checklist 2014Sebastian Rajesh100% (1)

- WPS PQR Checklist 2014Document2 paginiWPS PQR Checklist 2014Sebastian Rajesh100% (1)

- Clad PQRDocument5 paginiClad PQRRinshadÎncă nu există evaluări

- WPS 2014-002 006 - 6G PipeDocument3 paginiWPS 2014-002 006 - 6G PipejeswinÎncă nu există evaluări

- Format WPQDocument2 paginiFormat WPQAkash Singh TomarÎncă nu există evaluări

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 paginăPt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RÎncă nu există evaluări

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 paginiIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- Ut Proceduregeneral 141118232235 Conversion Gate02Document24 paginiUt Proceduregeneral 141118232235 Conversion Gate02Danem HalasÎncă nu există evaluări

- WPS Resrvoire Sous Pression Smaw SawDocument6 paginiWPS Resrvoire Sous Pression Smaw SawDanem HalasÎncă nu există evaluări

- TopCoreBelco 101 FCDocument9 paginiTopCoreBelco 101 FCCesar ArellanoÎncă nu există evaluări

- Ami-001 WPSDocument2 paginiAmi-001 WPSPramod Athiyarathu100% (1)

- Design Guide UPSDocument18 paginiDesign Guide UPSVictor BitarÎncă nu există evaluări

- WPS BhelDocument2 paginiWPS BhelpradhankruhsnaÎncă nu există evaluări

- Joints (Qw-402) DetailsDocument3 paginiJoints (Qw-402) DetailsNaqqash SajidÎncă nu există evaluări

- Tacom Weld Code SteelDocument165 paginiTacom Weld Code SteelAles Kubat0% (1)

- Template BUTTDocument1 paginăTemplate BUTTDylan TriggÎncă nu există evaluări

- Ami-003 WPSDocument2 paginiAmi-003 WPSBenjamin BrownÎncă nu există evaluări

- WSS Welding Handbook 2013 Full Lowres PDFDocument552 paginiWSS Welding Handbook 2013 Full Lowres PDFsridharchowdary3490% (1)

- WPQ-1083 3G PDFDocument2 paginiWPQ-1083 3G PDFduendex360100% (1)

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 paginiWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanÎncă nu există evaluări

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pagini163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Wps Mma PipeDocument2 paginiWps Mma PipeDimitris NikouÎncă nu există evaluări

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 paginiCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONÎncă nu există evaluări

- Alu WpsDocument4 paginiAlu WpsdselvakuuÎncă nu există evaluări

- WPQ WeldCanada PDFDocument1 paginăWPQ WeldCanada PDFAhmad DanielÎncă nu există evaluări

- WPS List For Piping: (Asme Section Ix)Document2 paginiWPS List For Piping: (Asme Section Ix)Ali MoosaviÎncă nu există evaluări

- A 6 - A 6m - 02 QtytmdiDocument63 paginiA 6 - A 6m - 02 QtytmdiDanem HalasÎncă nu există evaluări

- A 6 - A 6m - 02 QtytmdiDocument63 paginiA 6 - A 6m - 02 QtytmdiDanem HalasÎncă nu există evaluări

- WPS & PQRDocument24 paginiWPS & PQRtulasirao.nammiÎncă nu există evaluări

- WPS Sa 335 P91 PipeDocument3 paginiWPS Sa 335 P91 Pipecsankarananth50% (2)

- Office: Printout Sample - ASME WPSDocument2 paginiOffice: Printout Sample - ASME WPSDanem HalasÎncă nu există evaluări

- Office: Printout Sample - ASME WPSDocument2 paginiOffice: Printout Sample - ASME WPSDanem HalasÎncă nu există evaluări

- Welder ID Card BRE KarahaDocument5 paginiWelder ID Card BRE KarahaHerruSetiawan100% (1)

- Welding Procedure Specification For GTAW & GMAWDocument4 paginiWelding Procedure Specification For GTAW & GMAWanh thoÎncă nu există evaluări

- Wps For Aluminium WeldingDocument8 paginiWps For Aluminium WeldingMohammed MusaÎncă nu există evaluări

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pagini2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanÎncă nu există evaluări

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 paginăD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Încă nu există evaluări

- ASME P-NumbersDocument2 paginiASME P-NumbersAnonymous XwaOunGK100% (1)

- WPQR2Document3 paginiWPQR2Thanasis KyrgiazoglouÎncă nu există evaluări

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 paginiSample Wps Carbon Steel GTAW SMAW PDFirwanÎncă nu există evaluări

- Weld Decay 2Document8 paginiWeld Decay 2Ahmed M. HashimÎncă nu există evaluări

- Weld RepairDocument2 paginiWeld RepairAnurag YadavÎncă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- WPS SampleDocument182 paginiWPS Sampleaymenfr23Încă nu există evaluări

- Interpretations: ASME Boiler and Pressure Vessel Code Section IxDocument48 paginiInterpretations: ASME Boiler and Pressure Vessel Code Section Ixjuan ninaÎncă nu există evaluări

- Welding Procedure Data SheetDocument2 paginiWelding Procedure Data SheetAmanSharmaÎncă nu există evaluări

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 paginiWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniÎncă nu există evaluări

- PQR Editable SampleDocument2 paginiPQR Editable SampleKoya ThangalÎncă nu există evaluări

- AUT-1023 A2 Multitrac PEKDocument1 paginăAUT-1023 A2 Multitrac PEKcarlosÎncă nu există evaluări

- New Microsoft Excel WorksheetDocument6 paginiNew Microsoft Excel Worksheetravi00098Încă nu există evaluări

- PQR - PipeDocument3 paginiPQR - PipeAdvanced Quality Centre AQC100% (1)

- Painting Procedure 4288 Danem 28-04-13Document24 paginiPainting Procedure 4288 Danem 28-04-13Rejoy baby100% (1)

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 paginiProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabÎncă nu există evaluări

- WPQ CS SmawDocument1 paginăWPQ CS Smawniket0Încă nu există evaluări

- Fcaw 16 THKDocument5 paginiFcaw 16 THKAnonymous Ij6VfaÎncă nu există evaluări

- Consignation HTDocument6 paginiConsignation HTDanem HalasÎncă nu există evaluări

- TWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDocument26 paginiTWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDanem HalasÎncă nu există evaluări

- Chapter 13 - Designing For Quality: PTTE 434 Jim Wixson - InstructorDocument72 paginiChapter 13 - Designing For Quality: PTTE 434 Jim Wixson - InstructorPrabhat SharmaÎncă nu există evaluări

- Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocument3 paginiCarbon Steel Girder Rails of Plain, Grooved, and Guard TypesDanem HalasÎncă nu există evaluări

- CV Ait KoufiDocument3 paginiCV Ait KoufiDanem HalasÎncă nu există evaluări

- Crane SafetyDocument12 paginiCrane SafetymytheeÎncă nu există evaluări

- Inspection & Test Plans 1 of 50Document49 paginiInspection & Test Plans 1 of 50jok1974Încă nu există evaluări

- 13 L1 L2 Reactor DesignDocument48 pagini13 L1 L2 Reactor DesignStan LouisÎncă nu există evaluări

- Construction IssuesDocument50 paginiConstruction IssuesDanem HalasÎncă nu există evaluări

- WPQRDocument27 paginiWPQRJayaram MVÎncă nu există evaluări

- MT Training SpecifiqueDocument4 paginiMT Training SpecifiqueDanem HalasÎncă nu există evaluări

- Duplex 2101Document6 paginiDuplex 2101Anonymous AlhzFE9EVNÎncă nu există evaluări

- Part2 Notice 1Document21 paginiPart2 Notice 1Danem Halas100% (1)

- En Metalwork Gas Tungsten Arc WeldingDocument48 paginiEn Metalwork Gas Tungsten Arc WeldingadammzjinÎncă nu există evaluări

- WLD 290 Submerged Arc WeldingDocument52 paginiWLD 290 Submerged Arc WeldingDanem HalasÎncă nu există evaluări

- 8a Codes and Q & CDocument35 pagini8a Codes and Q & CDanem HalasÎncă nu există evaluări

- Welding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDocument7 paginiWelding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDanem HalasÎncă nu există evaluări

- 2.basic Electrical Engineering PDFDocument152 pagini2.basic Electrical Engineering PDFkandavel71Încă nu există evaluări

- Chapter 9 Powerpoint Notes 2008Document39 paginiChapter 9 Powerpoint Notes 2008Umar AsimÎncă nu există evaluări

- QEI - MCap II - UG1065 PDFDocument113 paginiQEI - MCap II - UG1065 PDFJohanes Nugroho Adhi PrakosaÎncă nu există evaluări

- Milpass - Catalogo Alluminio EN PDFDocument174 paginiMilpass - Catalogo Alluminio EN PDFStefanus AndreÎncă nu există evaluări

- Chemistry Question Bank For JEE Advance Part 1Document55 paginiChemistry Question Bank For JEE Advance Part 1gfffdssseÎncă nu există evaluări

- Sensor Presión Keller Pa26y - 3852Document2 paginiSensor Presión Keller Pa26y - 3852benditasea3352Încă nu există evaluări

- NEMA TS2 - OverviewDocument22 paginiNEMA TS2 - OverviewAdalberto MesquitaÎncă nu există evaluări

- Unit 1 - Homework Assignment 2: The Hydrogen AtomDocument2 paginiUnit 1 - Homework Assignment 2: The Hydrogen Atom周子暄Încă nu există evaluări

- Project - Silicon Solar Cell-CoDocument55 paginiProject - Silicon Solar Cell-CoSudheer SebastianÎncă nu există evaluări

- GMAT QUANT TOPIC 3 (Inequalities + Absolute Value) SolutionsDocument46 paginiGMAT QUANT TOPIC 3 (Inequalities + Absolute Value) SolutionsBhagath GottipatiÎncă nu există evaluări

- WDM2 LOCO REPORT - Manoj Kr. KataraDocument23 paginiWDM2 LOCO REPORT - Manoj Kr. KataraAbhinav AgarwalÎncă nu există evaluări

- Application of Vehicle Interior Noise SimulationDocument7 paginiApplication of Vehicle Interior Noise Simulationprashanth_1008Încă nu există evaluări

- AC O& M City Mall Version 1.0Document12 paginiAC O& M City Mall Version 1.0yewminyun6098Încă nu există evaluări

- Roof Beam Design CalculationDocument11 paginiRoof Beam Design CalculationArnold VercelesÎncă nu există evaluări

- Antena Tipo LazoDocument2 paginiAntena Tipo LazoMarllory CobosÎncă nu există evaluări

- BC 107Document3 paginiBC 107Sreerag Kunnathu SugathanÎncă nu există evaluări

- B SafeunitDocument4 paginiB SafeunitSabariyantoÎncă nu există evaluări

- B Boehler-Fox-Cel Se en v1Document1 paginăB Boehler-Fox-Cel Se en v1tacosanchezbrayanÎncă nu există evaluări

- PWM DC Motor ControllerDocument11 paginiPWM DC Motor ControllerSanthosh Kumar100% (1)

- Gestión de Formación Profesional Integral Procedimiento Desarrollo Curricular Guía de Aprendizaje 1. Identificación de La Guia de AprenizajeDocument9 paginiGestión de Formación Profesional Integral Procedimiento Desarrollo Curricular Guía de Aprendizaje 1. Identificación de La Guia de AprenizajeMilena Sánchez LópezÎncă nu există evaluări

- Adobe Scan Feb 10, 2021Document4 paginiAdobe Scan Feb 10, 2021Filip SalekÎncă nu există evaluări

- Internship Report Sample 5Document35 paginiInternship Report Sample 5SUMIT KUMARÎncă nu există evaluări

- Class Test Question Paper Kinematics of Machinery - 21-22 - FinalDocument3 paginiClass Test Question Paper Kinematics of Machinery - 21-22 - FinalRavi PatilÎncă nu există evaluări

- GasCalc Module enDocument2 paginiGasCalc Module ensppramÎncă nu există evaluări

- Colin MaclaurinDocument6 paginiColin MaclaurinChristian David PecsonÎncă nu există evaluări