Documente Academic

Documente Profesional

Documente Cultură

Production of Starch From Mango (Mangifera Indica.l) Seed Kernel and Its Characterization

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Production of Starch From Mango (Mangifera Indica.l) Seed Kernel and Its Characterization

Drepturi de autor:

Formate disponibile

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 3, Issue 3 (May-June 2015), PP. 346-349

PRODUCTION OF STARCH FROM MANGO

(MANGIFERA INDICA.L) SEED KERNEL AND

ITS CHARACTERIZATION

Manisha Sonthalia1, Sikdar D C2

Department of Chemical Engineering,

Dayananda Sagar College of Engineering,

Bangalore, Karnataka, India

manishabiotech09@gmail.com, dulalsi@yahoo.co.in

Abstract Mango (Mangifera Indica.L) is the national

fruit of India. Peels and seeds are the by-products obtained

during processing of mango. The Mango seed possess disposal

problem if not handled properly therefore conversion of mango

seed kernel to starch is the solution of this problem. Starch is

used in food and pharmaceutical industry. These industries

depend on crops that are the primary source of food for the

human thus raising the food prices. Unlike the conventional

method of producing starch, this method totally uses raw waste.

The report showed the maximum yield of starch was 59.06

percent, the amylose content 16.3 percent and ash content

between 0.12 to 0.15 percent. The purity of the starch obtained

was 97.18 percent when compared to market starch which was

92.59 percent. Thus, it can be concluded that the starch obtained

from mango seed kernel can be used in food industry.

Index TermsMangifera indica, Seed, Kernel, Starch,

Adhesive.

I. INTRODUCTION

Starch is a carbohydrate consisting of large number of

glucose units which are linked by glycosidic bond. It is a food

reserve substance in plant and is widely used in pharmaceutical

industry. It is also used as a food additive usually as thickeners

and stabilizers. It can also be used to produce gel and ethanol.

Extensive research is done on the isolation of starch from

variety of food sources like potato, maize, corn and rice and

their application in food and non- food industry[1]. The

physicochemical properties of starch differ from source to

source of raw material. Very few literatures are available on

isolation of starch from non-conventional sources like the seeds

of fruits.

One such source for the production of starch is mango

(Mangifera indica) seed kernel. Mango belongs to the genus

Mangifera of the family Anacardiaceae. Mango is a tropical

fruit. As per the investigation of Kusuma D.K et. al, [2] India is

the largest producer of mango with 44.14% of the world total

production. Mango flesh are usually consumed or processed in

an industry thus disposing a large amount of seed as solid

waste. Approximately 4060% waste is generated during

processing of mango, out of which peel and kernel constitute

1215% and 1520%, respectively[3]. Mango kernel, on a dry

basis, contains 65% starch, 2.9% reducing sugars, 5.7%

proteins, 0.8% pectin, 9.3% fat and 1.1% tannins and rest is

moisture[4]. The kernel obtained after decortication of mango

seed is used as a supplement to wheat flour or for the extraction

of edible oil.[3]. The mango seed kernel flour can also be used

for edible purpose besides being used as an animal feed. Very

little information is present about the isolation of starch from

mango seed kernel. The mango seed kernel is a promising

seed because of its high level of carbohydrate and oil [5]. The

present study focuses on the isolation of starch from the raw

mango seed kernel and the study of physicochemical properties

of different varieties of mango.

II. MATERIALS AND METHODS

A. Materials/Instruments Used

The materials/instruments used for this work were,

Proportional-Integral-Derivative Controller (PID), hot air

oven, thermometer (0 to 100C), centrifuge, pH meter,

crucible and muffle furnace.

B. Sample Collection

Sindhoori, Totapuri and Bagenpalli mangoes are collected from

the local market of Bengaluru, Karnataka of the 2015 harvest.

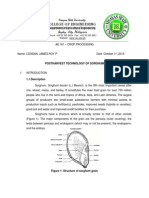

A sample of Sindhoori mango is shown in Fig 1.

Fig 1: Sindhoori Mango

C. Process of Starch Isolation

The mango seed is collected and sun dried for two days. Then

the mango seed kernel is manually separated from the hull and

cut into small pieces of 5-10mm size. A sample of mango seed

kernel and hull is shown in Fig 2.

Fig 2: Mango Seed along with the Kernel

10g of raw kernel sample is weighed and taken in a starch

isolation unit. To this, 80ml of 0.16% of Sodium Hydrogen

Sulphite solution is added. The temperature of the process is

maintained at 50C for 24hrs using a PID controller. Also the

content is agitated at an interval of 1hr with the help of glass

rod. This is called steeping process. The experimental setup of

starch isolation unit with PID controller is shown in Fig 3.

346 | P a g e

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 3, Issue 3 (May-June 2015), PP. 346-349

0.5N KOH is added to it. The suspension is mixed and then

transferred to a 100ml volumetric flask to make the final

volume to the mark with distilled water. 10ml of the test starch

is pipetted out and is transferred to a 50ml volumetric flask

and 5ml of 0.1N HCl is added followed by 0.5ml of iodine

reagent. The final volume is made to the mark by distilled

water and the absorbance is measured at 625nm. The amylose

content is determined using the following equation

Fig 3: Experimental Setup for Starch Isolation with PID

Controller

After the steeping process the solution is decanted to obtain the

steeped kernel. Then, the steeped kernel is grounded in a mixer

grinder by adding 50ml of distilled water to obtain brownish

white color slurry. Then this slurry is filtered using a muslin

cloth and filtrate is obtained. Thereafter, the filter cake is

washed with distilled water until unless clear wash water is

obtained. The filter cake is disposed and the obtained filtrate is

further centrifuged at 2800 rpm for 5 mins. The upper nonwhite layer is disposed and the white layer was re-suspended in

distilled water and again centrifuged. This is done for 4 times

and finally the starch is collected and dried in an oven for 6 hrs

at 50 C. A sample of isolated starch is shown in Fig 4.

Fig 4: Isolated Starch

This procedure of starch isolation is continued for three

varieties of mango seed kernel for different solid solvent ratio.

D. Physicochemical Properties Analysis of Starch Ash

Content (%)

Ash content was determined using AOAC method [6]. In a

pre-weighed empty crucible (W1) 5g of starch is taken and is

again weighed (W2). The crucible is then kept in a muffle

furnace for 5hours at 900C. The crucible is then allowed to

cool and weighed (W3). The ash content was determined using

the following equation

Ash content (%) = {(W3-W1) / (W2-W1)} X 100 ..(1)

pH

Priya.D.Patil et.al method is used for the pH determination [6].

5g of starch is taken in 20ml of distilled water and is mixed

thoroughly for 5 minutes. The starch is allowed to settle and

pH of the water phase is taken using a calibrated pH meter.

Average of three trials is taken.

Amylose content (%)

= (85.24 x A) - 13.19 (2)

Amylopectin content (%) = 100 - %amylose

(3)

Where,

A = Absorbance

E. Production of Adhesive

10grams of starch is added to 500ml of distilled water in 1000

ml beaker and is heated at 50C. 50 ml of 0.01M hydrochloric

acid is then added and the temperature of the solution is

brought up to 75C. The solution is heated and stirred until the

starch becomes gelatinized. The solution is then cooled to

room temperature. 6 grams of Borax (viscosity enhancer) is

added in the increments of 0.5 grams at a temperature of 80C.

Continuous heating and stirring is carried on until the desired

viscosity is obtained [9]. A sample of glue produced from

starch is shown in Fig 5.

Fig 5: Glue Produced from Starch

III. RESULTS AND DISCUSSION

A. Confirmation Test of Starch

Starch is a polysaccharide consisting of two fractionsamylose (10-20%) and amylopectin (80-90%). Amylose forms

a colloidal suspension in water whereas amylopectin is

completely insoluble.

Iodine - Potassium Iodide (KI) Reagent preparation: It is

also known as Lugols solution. Iodine is not very soluble in

water therefore to dissolve iodine with water potassium iodide

is added. As a result a linear triiodide ion complex is formed.

The obtained Lugols solution appears to be orange or yellow

colour.

Starch test: The lugol solution is added to the extracted

sample. The linear triiodide ion complex slips into the coil of

starch giving an intense blue-black colour indicating the

presence of starch. If no starch is present, the colour of the

solution remains the same. The confirmation test of isolated

starch is shown in Fig 6.

Amylose Content (%)

The method reported by Priya.D.Patil et.al [6] is used for

amylose determination. 20mg of starch is taken and 20ml of

347 | P a g e

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 3, Issue 3 (May-June 2015), PP. 346-349

Table 2: Percentage Yield of Starch

Mango

Amount Solid to Amount Percentage

varieties

of raw

solvent of starch

yield of

mango

ratio

obtained

starch (%)

seed

(g)

kernel

used (g)

Sindhoori

10

1:14

5.906

59.06

Totapuri

10

1:14

4.745

47.45

Bagenpalli

10

1:14

4.842

48.42

Fig 6: Starch Test Negative (Orange Yellow Color) for

Water and Positive (Blue Black color) for Starch

B. Determination of Optimum Solid-Solvent Ratio

10 grams of Sindhoori mango kernel is taken at different solidsolvent ratio to determine the optimum yield of starch.

D. Material Balance

The result produced is verified for 1:10 solid to solvent

ratio using material balance shown in the Fig.8.

P + O +T

Table 1: Effect of Solid-Solvent Ratio on Yield of Starch

Yield of starch/10g of kernel

Solid to

Trial 1

Trial 2 (g) Trial 3 (g)

Average

solvent

(g)

(g)

ratio

1:8

5.068

5.138

5.113

5.106

1:10

5.151

5.21

5.087

5.149

1:12

5.726

5.803

5.842

5.790

1:14

5.874

5.907

5.939

5.906

1:15

5.912

5.923

5.899

5.911

It is observed from table 1 that as the solid to solvent ratio

increases the yield of starch increases. The maximum yield is

obtained at 1:14 solid to solvent ratio after which there is no

much effect. This may be due to the reason that at low solid to

solvent ratio the solvent is not enough to steep the kernel

properly and the starch is not isolated effectively whereas at

higher solid solvent ratio the kernel is steeped properly so the

isolation of starch is obtained effectively.

R

Fig 8: Material Balance

Where,

Feed, F

Starch, S

Residue, R

Protein(P)

Oil(O)

Tannin(T)

= 10g

= 5.21g

= 4.477g

= 0.015g

= 0.029g

= 0.049g

Material In

= Material Out

F

10

10

Loss

=

=

=

=

S+R+P+O+T

5.21 + 4.477 + 0.015 + 0.029 + 0.049

9.78

0.22g

From the material balance it is observed that during

isolation of starch process 0.22g of loss occurs which is within

the permissible limit.

Fig 7: Effect of Solid Solvent Ratio on Starch Yield

A bar chart comparing the yield of starch/10g of kernel with

different solid solvent ratio is shown in Fig 7.

C. Percentage Yield of Different Variety of Mango

Different variety of mango i.e Sindhoori, Totapuri and

Bagenpalli are taken and the percentage yield of each variety

is calculated. Table 2 compares the percentage yield of starch

produced from different variety of mango. Sindhoori mango

shows the highest yield of starch followed by Bagenpalli and

Totapuri.

E. Physicochemical Properties of Starch

The pH, amylose content (%) and ash content (%) of

Sindhoori, Totapuri and Bagenpalli Starch is depicted in Table

3.

Table 3: Physicochemical Properties of Starch

Starch

pH

Amylose

Ash content

content (%)

(%)

Sindhoori

Totapuri

Bagenpalli

4.2

3.8

4.0

11.3

16.3

9.1

0.12

0.15

0.13

From the table 3 it is found that the values of the

physicochemical properties are comparable with the standard

value. Low ash content depicts low amount of minerals present

in the starch. Thus, it indicates that the starch is of good

quality.

348 | P a g e

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 3, Issue 3 (May-June 2015), PP. 346-349

F. Purity Test

results indicated that the starch is of good quality. The

The purity test is determined in Bangalore Test House as

physicochemical properties also reveals that the starch

per the IS: 4706 (Part II) 1978 method. The value obtained is

obtained can be used as both food and non-food purposes.

shown in Table 4.

Thus the results obtained are suggestive that Mango seed

kernel is a good source of starch and can be utilized for

industrial purposes.

Table 4: Comparison of Purity of Starch

Starch

Trail number

Percent purity

V. ACKNOWLEDGEMENT

Sindhoori

Trail 1

51.20

We thankfully acknowledge the help from Dr.

Trail 2

91.14

Ravishankar R, Prof. G.K Mahadevaraju, Dr. Muruthy

Trail 3

97.18

Shekhar, Prof. M.R. Rajani, Prof. Pradeep H.N, Prof. B.S.

Totapuri

Trail 1

69.38

Thirumalesh, Prof. Karthik K.V, Department of Chemical

Trail 2

97.82

Engineering, DSCE, and Bangalore. We would also like to

Bagenpalli

Trail 1

97.73

thank Dr.D. Hemachandra Sagar, Chairman, Dr. D.

Market

Trail 1

92.59

Premachandra Sagar, Vice-Chairman and Dr. S.C.Sharma,

Director, Dayananda Sagar College of Engineering, Bangalore

The purity obtained in trail 1 is comparatively very low.

for their encouragement and support for publishing this paper.

This is due to the reason that in Trail 1 one fold of muslin cloth

is used. Later on modification of the filtering process produced

more purity. The purity obtained in Bagenpalli Mango kernel

sample is highest.

G. Adhesive Produced

Table 5 shows the amount of Gelatinization Enhancer (HCl)

and Viscosity Enhancer (borax) added for the preparation of

adhesive.

Table 5: Adhesive Produced

Trail

Number

Amount

of

starch

added

(g)

Volume

of

0.01M

HCl

added

(g)

Volume

of

0.01M

HCl

added

(g)

Amount

of Glue

obtained

(g)

Water

evaporated

(ml)

10

50

25

41

The amount of glue produced during the process is verified

using the material balance. Using mass balance, the water

evaporated can be calculated as,

Mass in

= mass out

Wstarch + VHCl + WBorax = Wglue + Wevap

10 + 50 + 6

= 25 + Wevap

Water evaporated, Wevap = 41ml

IV. CONCLUSION

The disposal of mango seed kernel can be overcome by

producing starch from the kernel. At a solid to solvent ratio of

1:14 maximum yield of starch is obtained. Sindhoori mango

shows the maximum yield of 59.06% starch. The purity test

also reveals that the starch produced from mango seed kernel

is 97.82% when compared to the market starch that is 92.59%.

Even though there are some difference in physicochemical

properties of the starch of different variety of mango the

REFERENCES

[1] Singh, J., & Singh, N. Studies on the morphological and

rheological properties of granular cold water soluble corn and

potato starches. Food Hydrocolloids, 17, 6372(2003).

[2] D.K Kusuma, and H. Basavaraja stability analysis of mano

export markets in India: Markov China approach, Karnataka

J.Agric. Sci, 27(1): (36-39), 2014.

[3] Maninder Kaur, Narpinder Singh, Kawaljit Singh Sandhu and

Harmeet Singh Guraya,

Physicochemical, morphological,

thermal and rheological properties of starches separated from

kernels of some Indian mango cultivars (Mangifera indica L.),

Food Chemistry 85131140,2004

[4] Garg, N., & Tandon, D. K. Amylase activity of A. oryzae

grown on mango kernel after certain pretreatments and aeration.

Indian Food Packer, 51(5), 2629 (1997).

[5] Kittiphoom.S, Utilization of Mango seed, International Food

Research Journal 19(4): 1325-1335 (2012)

[6] Priya D. patil, M.V. Gokhale and N.S.Chavan, Mango starch: its

use and future prospects, Innovare Journal of Food Science, Vol

2, Issue 1, (2014).

[7] L.G Hassam, A.B. Muhammad, A.B. Muhamma, R.U. Aliyu,

Z.M. Idris, T. Izuagie, K.J. Umar and N.A.Sani, Extraction and

characterisation of starches from four varieties of Mangifera

indica seeds, IOSR Journal of Applied Chemistry, Vol. 3, Issue

6, pp 16-23,2013

[8] L.A. Bello Perez, A. Aparicio-Saguilan, G. Mendez-Montealvo,

J. Solorza-Feria and E. Flores-Huicochea, Isolation and partial

characterization of mango (Mangifera indiaca L) Starch:

Morphological, Physicochemical and functional studies, Plant

Foods for Human Nutrition 60(2005).

[9] Peter Okoromi OZEMOYA, Emmanuel Sunday Akin Ajisegiri

and Peter Aba Idah , Production of Adhesives from Cassava

Starch , of Chemical Engineering and Department of

Agricultural Engineering, Federal University of Technology,

P.M.B. 65, Minna, Niger State.

349 | P a g e

S-ar putea să vă placă și

- Optimization of The Process of Drying of Corn Seeds With The Use of MicrowavesDocument10 paginiOptimization of The Process of Drying of Corn Seeds With The Use of MicrowavesShania GintingÎncă nu există evaluări

- Cacao BalansagDocument5 paginiCacao BalansagCrystal Ann Monsale Tadiamon0% (1)

- Introduction To RecommendationsDocument31 paginiIntroduction To RecommendationsRobert Andree LabadanÎncă nu există evaluări

- Effect of Seaweed Extracts On The Growth of Tomato Plant FINALDocument9 paginiEffect of Seaweed Extracts On The Growth of Tomato Plant FINALMint XÎncă nu există evaluări

- The Processing and Storage of Guinea Corn (Sorghum) in Donga Local Government Area of Taraba State.Document29 paginiThe Processing and Storage of Guinea Corn (Sorghum) in Donga Local Government Area of Taraba State.Joshua Bature Sambo100% (3)

- AIC Organic Fertilizer For CacaoDocument4 paginiAIC Organic Fertilizer For CacaoGene Gregorio100% (1)

- Biodegradability of Bioplastics from Rice, Potato and Mung Bean StarchDocument4 paginiBiodegradability of Bioplastics from Rice, Potato and Mung Bean StarchYanhyÎncă nu există evaluări

- PHD Research Proposal OutlineDocument2 paginiPHD Research Proposal Outlinemariam murtazaÎncă nu există evaluări

- Theoretical FrameworkDocument3 paginiTheoretical FrameworkHannah MeloÎncă nu există evaluări

- 05-Postharvest Handling of AvocadoDocument14 pagini05-Postharvest Handling of AvocadolangtuduongsonttÎncă nu există evaluări

- Science InveCornstarch (Amylum) As Additives in Concrete Masonary Unit (CMU) BIO-PLASTIC CMU StigatoryDocument27 paginiScience InveCornstarch (Amylum) As Additives in Concrete Masonary Unit (CMU) BIO-PLASTIC CMU StigatoryAlmer Chris Calma TuayonÎncă nu există evaluări

- Rosabelle 1Document55 paginiRosabelle 1ken Janray PujadasÎncă nu există evaluări

- Utilization of Winter Squash and Sweet Potato Waste for Bioplastic ProductionDocument8 paginiUtilization of Winter Squash and Sweet Potato Waste for Bioplastic ProductionPatricia PascualÎncă nu există evaluări

- Cassava Trends in Asia Production Processing MarketsDocument38 paginiCassava Trends in Asia Production Processing MarketsMohamad IkhwanÎncă nu există evaluări

- Group 3 Rice Farming Practices of Local Agusan FarmersDocument124 paginiGroup 3 Rice Farming Practices of Local Agusan FarmersPAUL STEPHEN MALUPAÎncă nu există evaluări

- Horticulture 22Document19 paginiHorticulture 22Jodelyn JumadasÎncă nu există evaluări

- Trend Analysis and Other Data Analytics For BambooDocument19 paginiTrend Analysis and Other Data Analytics For BambooAnne CuadernoÎncă nu există evaluări

- Cassava ProductionandprocessingDocument41 paginiCassava Productionandprocessingadebo_yemiÎncă nu există evaluări

- ResearchDocument22 paginiResearchKish PabbssÎncă nu există evaluări

- Bioplastics and Biocomposites for Food PackagingDocument5 paginiBioplastics and Biocomposites for Food PackaginglleiÎncă nu există evaluări

- Organic Agriculture and Inputs GuideDocument100 paginiOrganic Agriculture and Inputs GuideManish PatelÎncă nu există evaluări

- Synthesis of Bioplastic of Cassava StarchDocument3 paginiSynthesis of Bioplastic of Cassava StarchIjan HeyÎncă nu există evaluări

- Characterization of Banana Peel Briquettes With The Variation of Binder ConcentrationDocument19 paginiCharacterization of Banana Peel Briquettes With The Variation of Binder ConcentrationSuriati Eka PutriÎncă nu există evaluări

- Minimum Requirements For Conversion To Organic Agriculture: What Will You LearnDocument9 paginiMinimum Requirements For Conversion To Organic Agriculture: What Will You LearnRoma QuiochoÎncă nu există evaluări

- Chemical Composition of SeedDocument51 paginiChemical Composition of SeedBramesty Laras HanifÎncă nu există evaluări

- Poster CakkkomDocument1 paginăPoster CakkkomJihan MutiahÎncă nu există evaluări

- Das & Jana. Pond Fertilization Regimen - State-Of-The-ArtDocument32 paginiDas & Jana. Pond Fertilization Regimen - State-Of-The-ArtJTheron58Încă nu există evaluări

- Postharvest Technology of SorghumDocument17 paginiPostharvest Technology of SorghumJames RoyÎncă nu există evaluări

- Kwon 2014Document11 paginiKwon 2014restyayuyo50% (2)

- Improving Food Security and Income For Smallholder Farmers - Prof Kwame AfrehDocument67 paginiImproving Food Security and Income For Smallholder Farmers - Prof Kwame AfrehFrançois StepmanÎncă nu există evaluări

- BioplasticDocument5 paginiBioplasticclaire bernadaÎncă nu există evaluări

- CRPT1 - Lecture 1. Introduction To Crop Protection and Major Groups of Crop PestsDocument41 paginiCRPT1 - Lecture 1. Introduction To Crop Protection and Major Groups of Crop PestsMenard NavaÎncă nu există evaluări

- Establishing Static Soil Testing-NABARDDocument8 paginiEstablishing Static Soil Testing-NABARDSachin V TiwadeÎncă nu există evaluări

- Enzyme ProductionDocument15 paginiEnzyme ProductionAlejandra Lopez100% (1)

- Paper Review 3Document5 paginiPaper Review 3Earl CarreraÎncă nu există evaluări

- FGAS as Alternative Protein Source in Tilapia DietsDocument9 paginiFGAS as Alternative Protein Source in Tilapia DietsGabriel BermudezÎncă nu există evaluări

- 2 - CHAPTER-Iv2 0Document30 pagini2 - CHAPTER-Iv2 0GodisGood AlltheTimeÎncă nu există evaluări

- Using Lemongrass Oil as a Natural Ant RepellentDocument25 paginiUsing Lemongrass Oil as a Natural Ant RepellentFlory Alon HernandezÎncă nu există evaluări

- BISU Ecological Agriculture Learning PlanDocument6 paginiBISU Ecological Agriculture Learning PlanRosebelle GocoÎncă nu există evaluări

- What are bioplasticsDocument15 paginiWhat are bioplasticsRCA_CONSULTORESÎncă nu există evaluări

- Sugarcane Bagasse Paper with Aratiles SeedsDocument4 paginiSugarcane Bagasse Paper with Aratiles SeedsArvie Karl NabiÎncă nu există evaluări

- My Project 2021 Chap 2Document31 paginiMy Project 2021 Chap 2Godwin NkwoÎncă nu există evaluări

- Status of Cacao (Production: Its Challenges and Prospect in Zamboanga Del Norte Province in The PhilippinesDocument21 paginiStatus of Cacao (Production: Its Challenges and Prospect in Zamboanga Del Norte Province in The Philippinesmark patalinghug100% (1)

- Uses of UreaDocument3 paginiUses of UreaKrisnawati AyÎncă nu există evaluări

- Fermented Plant JuiceDocument6 paginiFermented Plant JuiceRaven ShadeÎncă nu există evaluări

- Full Thesis in PDFDocument139 paginiFull Thesis in PDFOben Oben ObenÎncă nu există evaluări

- My NarrativeDocument28 paginiMy NarrativeGauis Laurence CaraoaÎncă nu există evaluări

- Bioplastic production from soybean hullsDocument17 paginiBioplastic production from soybean hullsAlberto Suarez100% (1)

- Outline NaomiDocument27 paginiOutline NaomiAlieza Del Socorro100% (1)

- Dry SeasonDocument14 paginiDry SeasonJoshua GbaderoÎncă nu există evaluări

- Industrial Uses of WheatDocument6 paginiIndustrial Uses of Wheatmedkarthik100% (1)

- Effect of Different Processing Methods On The Proximate Composition of Cassava PeelsDocument7 paginiEffect of Different Processing Methods On The Proximate Composition of Cassava PeelsPremier PublishersÎncă nu există evaluări

- Project Proposal On Enhancing The Variety and Quality of Sweet Potato in Selected Area of Mimbalot, Buru-Un, Iligan CityDocument14 paginiProject Proposal On Enhancing The Variety and Quality of Sweet Potato in Selected Area of Mimbalot, Buru-Un, Iligan CityChristian Lumactod Embolode100% (1)

- EFFECT OF DRUMSTICK TREE (Moringa Oleifera) LEAF EXTRACT THROUGH DRINKING WATER ON THE GROWTH PERFORMANCE OF JAPANESE QUAIL (Coturnix Japonica) FED WITH COMMERCIAL RATIONSDocument57 paginiEFFECT OF DRUMSTICK TREE (Moringa Oleifera) LEAF EXTRACT THROUGH DRINKING WATER ON THE GROWTH PERFORMANCE OF JAPANESE QUAIL (Coturnix Japonica) FED WITH COMMERCIAL RATIONSs.abella.keanuÎncă nu există evaluări

- Pest and Diseases of CacaoDocument39 paginiPest and Diseases of CacaoVimarce CuliÎncă nu există evaluări

- Growth and Yield of Tomato (Lycopersicon EsculentumDocument12 paginiGrowth and Yield of Tomato (Lycopersicon EsculentummikdarmuÎncă nu există evaluări

- Benefits of Banana PeelDocument1 paginăBenefits of Banana PeelChicken WingzÎncă nu există evaluări

- PS T 04 Silica Rich Rice Oryza Sativa Hull Ash For Wood Adhesive Bond FortificationDocument42 paginiPS T 04 Silica Rich Rice Oryza Sativa Hull Ash For Wood Adhesive Bond FortificationToni Chinita100% (1)

- Agricultural Development in The PhilipppinesDocument4 paginiAgricultural Development in The PhilipppinesJon Te100% (1)

- Pests of Field Crops and Pastures: Identification and ControlDe la EverandPests of Field Crops and Pastures: Identification and ControlÎncă nu există evaluări

- Sumita PDFDocument5 paginiSumita PDFInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Pod-Pwm Based Capacitor Clamped Multilevel InverterDocument3 paginiPod-Pwm Based Capacitor Clamped Multilevel InverterInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Sumita PDFDocument5 paginiSumita PDFInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Postponement of Scheduled General Surgeries in A Tertiary Care Hospital - A Time Series Forecasting and Regression AnalysisDocument6 paginiPostponement of Scheduled General Surgeries in A Tertiary Care Hospital - A Time Series Forecasting and Regression AnalysisInternational Jpurnal Of Technical Research And Applications100% (2)

- Energy Gap Investigation and Characterization of Kesterite Cu2znsns4 Thin Film For Solar Cell ApplicationsDocument4 paginiEnergy Gap Investigation and Characterization of Kesterite Cu2znsns4 Thin Film For Solar Cell ApplicationsInternational Jpurnal Of Technical Research And Applications100% (1)

- An Experimental Study On Separation of Water From The Atmospheric AirDocument5 paginiAn Experimental Study On Separation of Water From The Atmospheric AirInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Study of Nano-Systems For Computer SimulationsDocument6 paginiStudy of Nano-Systems For Computer SimulationsInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Digital Compressing of A BPCM Signal According To Barker Code Using FpgaDocument7 paginiDigital Compressing of A BPCM Signal According To Barker Code Using FpgaInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Exponential Smoothing of Postponement Rates in Operation Theatres of Advanced Pediatric Centre - Time Series Forecasting With Regression AnalysisDocument7 paginiExponential Smoothing of Postponement Rates in Operation Theatres of Advanced Pediatric Centre - Time Series Forecasting With Regression AnalysisInternational Jpurnal Of Technical Research And Applications100% (2)

- Scope of Replacing Fine Aggregate With Copper Slag in Concrete - A ReviewDocument5 paginiScope of Replacing Fine Aggregate With Copper Slag in Concrete - A ReviewInternational Jpurnal Of Technical Research And Applications100% (1)

- Aesthetics of The Triumphant Tone of The Black Woman in Alice Walker's The Color PurpleDocument30 paginiAesthetics of The Triumphant Tone of The Black Woman in Alice Walker's The Color PurpleInternational Jpurnal Of Technical Research And Applications100% (2)

- Modelling The Impact of Flooding Using Geographic Information System and Remote SensingDocument6 paginiModelling The Impact of Flooding Using Geographic Information System and Remote SensingInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- A Study On The Fresh Properties of SCC With Fly AshDocument3 paginiA Study On The Fresh Properties of SCC With Fly AshInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Qualitative Risk Assessment and Mitigation Measures For Real Estate Projects in MaharashtraDocument9 paginiQualitative Risk Assessment and Mitigation Measures For Real Estate Projects in MaharashtraInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Implementation of Methods For Transaction in Secure Online BankingDocument3 paginiImplementation of Methods For Transaction in Secure Online BankingInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Time Efficient Baylis-Hillman Reaction On Steroidal Nucleus of Withaferin-A To Synthesize Anticancer AgentsDocument5 paginiTime Efficient Baylis-Hillman Reaction On Steroidal Nucleus of Withaferin-A To Synthesize Anticancer AgentsInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Li-Ion Battery Testing From Manufacturing To Operation ProcessDocument4 paginiLi-Ion Battery Testing From Manufacturing To Operation ProcessInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- The Construction Procedure and Advantage of The Rail Cable-Lifting Construction Method and The Cable-Hoisting MethodDocument3 paginiThe Construction Procedure and Advantage of The Rail Cable-Lifting Construction Method and The Cable-Hoisting MethodInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Effect of Trans-Septal Suture Technique Versus Nasal Packing After SeptoplastyDocument8 paginiEffect of Trans-Septal Suture Technique Versus Nasal Packing After SeptoplastyInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Evaluation of Drainage Water Quality For Irrigation by Integration Between Irrigation Water Quality Index and GisDocument9 paginiEvaluation of Drainage Water Quality For Irrigation by Integration Between Irrigation Water Quality Index and GisInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- An Inside Look in The Electrical Structure of The Battery Management System Topic Number: Renewable Power Sources, Power Systems and Energy ConversionDocument5 paginiAn Inside Look in The Electrical Structure of The Battery Management System Topic Number: Renewable Power Sources, Power Systems and Energy ConversionInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Open Loop Analysis of Cascaded Hbridge Multilevel Inverter Using PDPWM For Photovoltaic SystemsDocument3 paginiOpen Loop Analysis of Cascaded Hbridge Multilevel Inverter Using PDPWM For Photovoltaic SystemsInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Overview of TCP Performance in Satellite Communication NetworksDocument5 paginiOverview of TCP Performance in Satellite Communication NetworksInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Performance Analysis of Microstrip Patch Antenna Using Coaxial Probe Feed TechniqueDocument3 paginiPerformance Analysis of Microstrip Patch Antenna Using Coaxial Probe Feed TechniqueInternational Jpurnal Of Technical Research And Applications100% (1)

- Physico-Chemical and Bacteriological Assessment of River Mudzira Water in Mubi, Adamawa State.Document4 paginiPhysico-Chemical and Bacteriological Assessment of River Mudzira Water in Mubi, Adamawa State.International Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Investigation of Coverage Level and The Availability of GSM Signal in Ekpoma, NigeriaDocument6 paginiInvestigation of Coverage Level and The Availability of GSM Signal in Ekpoma, NigeriaInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Structural and Dielectric Studies of Terbium Substituted Nickel Ferrite NanoparticlesDocument3 paginiStructural and Dielectric Studies of Terbium Substituted Nickel Ferrite NanoparticlesInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Parametric Modeling of Voltage Drop in Power Distribution NetworksDocument4 paginiParametric Modeling of Voltage Drop in Power Distribution NetworksInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Study of Carbohydrate Metabolism in Severe Acute Malnutrition and Correlations of Weight and Height With Pp-Sugar and BmiDocument9 paginiStudy of Carbohydrate Metabolism in Severe Acute Malnutrition and Correlations of Weight and Height With Pp-Sugar and BmiInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Determining Trace Bromate in Water by Ion Chromatography and Optimized Post-Column DerivatizationDocument3 paginiDetermining Trace Bromate in Water by Ion Chromatography and Optimized Post-Column DerivatizationKhanza26Încă nu există evaluări

- Exp 6Document6 paginiExp 6MsShu93100% (1)

- Lab Report ChemDocument6 paginiLab Report Chemapi-334645637Încă nu există evaluări

- ConclusionDocument2 paginiConclusionHannah HermickÎncă nu există evaluări

- Iodine TestDocument5 paginiIodine Testsyenikeyev3220Încă nu există evaluări

- Vitamin C Determination by IodineDocument4 paginiVitamin C Determination by IodineGrace Emphasis100% (3)

- Clock ReactionDocument3 paginiClock ReactionDoom RefugeÎncă nu există evaluări

- Iodine, Iodide, Triiodide Equilibrium (Rev'D 3/25/06) : 1 3 I I I EQDocument4 paginiIodine, Iodide, Triiodide Equilibrium (Rev'D 3/25/06) : 1 3 I I I EQJan HuesÎncă nu există evaluări

- Vitamin C Determination by Iodine Titration 606322Document11 paginiVitamin C Determination by Iodine Titration 606322Khánh HuânÎncă nu există evaluări

- CHM270 Report 6 - KineticsDocument6 paginiCHM270 Report 6 - KineticsGeorges MaaloufÎncă nu există evaluări

- Vitamina C FructeDocument5 paginiVitamina C FructePopescu DragosÎncă nu există evaluări

- Lab Report GuidlineDocument7 paginiLab Report Guidlineapi-327831991Încă nu există evaluări

- StarchDocument6 paginiStarchPatrice CampbellÎncă nu există evaluări

- Iodine Clock ReactionDocument11 paginiIodine Clock ReactionsanchitaÎncă nu există evaluări

- Chemistry Lab ReportDocument20 paginiChemistry Lab Reportapi-350436359Încă nu există evaluări

- Materials Letters: Chao Du, Bo Liu, Jian Hu, Hailong LiDocument4 paginiMaterials Letters: Chao Du, Bo Liu, Jian Hu, Hailong LiJOSE AURELIO SOSA OLIVIERÎncă nu există evaluări

- Lab ReportDocument10 paginiLab Reportapi-335117665Încă nu există evaluări

- Describe The Structure of Starch and State Which Structural Feature Is Key To The Colour Change in The Iodine Test For StarchDocument9 paginiDescribe The Structure of Starch and State Which Structural Feature Is Key To The Colour Change in The Iodine Test For StarchFelix AlfonsoÎncă nu există evaluări

- AdditionalDocument7 paginiAdditionalIN MaulizaÎncă nu există evaluări

- Reducing and Non-Reducing Sugars Test: Lab Activity in Preparation For Practical Exam AS Level BiologyDocument36 paginiReducing and Non-Reducing Sugars Test: Lab Activity in Preparation For Practical Exam AS Level BiologyAmisha JuraiÎncă nu există evaluări

- Production of Starch From Mango (Mangifera Indica.l) Seed Kernel and Its CharacterizationDocument4 paginiProduction of Starch From Mango (Mangifera Indica.l) Seed Kernel and Its CharacterizationInternational Jpurnal Of Technical Research And Applications100% (1)

- Iodine Test For StarchDocument2 paginiIodine Test For StarchNoora MubarakÎncă nu există evaluări

- Method Analytical ColouringDocument4 paginiMethod Analytical ColouringNOMKHULEKO ALICEÎncă nu există evaluări

- Sak Bosnar2012Document5 paginiSak Bosnar2012Syahidah Fitria AmaliaÎncă nu există evaluări

- Triiodide Ion FormationDocument2 paginiTriiodide Ion FormationMc Jason LaureteÎncă nu există evaluări

- Iodine Clock ReactionDocument2 paginiIodine Clock ReactionDina Mohd HalidiÎncă nu există evaluări

- Equilibrium Constant of Triiodide Ion FormationDocument5 paginiEquilibrium Constant of Triiodide Ion FormationJericho LakampuengaÎncă nu există evaluări

- PROCEDURESDocument19 paginiPROCEDURESBala ShriÎncă nu există evaluări

- LabchemistryDocument10 paginiLabchemistryapi-295783327Încă nu există evaluări

- Redox Titration of Ascorbic AcidDocument7 paginiRedox Titration of Ascorbic AcidKong KianliangÎncă nu există evaluări