Documente Academic

Documente Profesional

Documente Cultură

The Construction Procedure and Advantage of The Rail Cable-Lifting Construction Method and The Cable-Hoisting Method

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

The Construction Procedure and Advantage of The Rail Cable-Lifting Construction Method and The Cable-Hoisting Method

Drepturi de autor:

Formate disponibile

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 3, Issue 4 (July-August 2015), PP. 21-23

THE CONSTRUCTION PROCEDURE AND

ADVANTAGE OF THE RAIL CABLE-LIFTING

CONSTRUCTION METHOD AND THE

CABLE-HOISTING METHOD

Ji Ce Zeng

School of civil engineering and architecture

Chongqing Jiaotong University

Chongqing, China

277199895@qq.com

AbstractThe cable-hoisting method and rail cable-lifting

suspended saddle and installing the main girder when beam

method are widely used in the construction of suspension bridge.

section is being installed saddle. It is also can be able to

This paper takes a suspension bridge in Hunan as an example,

reduce the lifting height of steel truss girder and improve

and expounds the two construction methods, and analyzes their

construction efficiency.

II. CABLE-HOISTING CONSTRUCTION METHOD

respective merits and disadvantages.

Key

words suspension

bridge

rail

A. Design of cable-hoisting system

cable-lifting

The main cable crane spans to 900m, the side span is

cable-hoisting

I. ENGINEERING SITUATION

155m in south shore, the side span is 258m in north shore,

The bridge is steel truss girder suspension bridge, the

both sides of the anchorage are anchored by gravity anchor.

main bridge spans to 900 meters, truss width is 27.0 meters,

The steel tower is assembled by steel tubes. The section

truss height is 8 meters, approach bridge(5*30m) is designed

weight of steel truss girder is calculated by 160t.

in south shore , another approach bridge(8*30m) is also

Working principle of the cable crane machine is along

designed in north shore; both sides of the Straits are used with

the cross bridge to arrange two sets of main cable, each main

gravity anchor, door-type reinforce concrete tower, dig

cable is composed of steel wire rope 10 Phi 60.5, both ends of

cast-in-place circular pile foundation.

which are anchored in the gravity anchor on both sides of

Deck to the bottom of the River, vertical distance is about

bridge. Each main cable respectively hangs the two supporting

200m, river width of maximum is 400m, accounting for the

car in midair. At both ends of the bridge, the traction winch

main cross 44.4%, average slope rate of gully length is about

and lift winch pull lifting trolley in the bearing cable to roll

0.66 (height / length).

and lift steel truss girder, which makes girder construction

Lifting saddle is arranged in perpetual suspended cable,

completed. There are 8 sports cars during the working frame

which dose not occupy the sling steel truss connecting holes.

of the cable crane, and the erection of each section of the steel

It is convenient for connection of cable head and segmental

truss girder is shared 4 sports cars (i.e., 4 lifting points) and

beam. Meanwhile, it can reduce operation steps of removing

hoisted synchronously

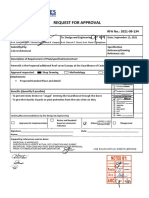

Suspension rope design and related parameters of single cable

Specification

Project

Unit weight

Breaking

rope

(kg.m)

tensionkN

1060.5

637S+IWR

1284.3

2075

10500

32

637S+IWR

389.0

546.5

10500

236

637S+IWR

437.0

701.9

10500

for wire rope

mm

Load-bearing cable

the sling

Traction cable

B. Cable crane tower

Modulus

form for wire

elasticity

MPa

Cable crane tower is used in scheme that assembles

21 | P a g e

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 3, Issue 4 (July-August 2015), PP. 21-23

steel pipe column in bridge tower, each tower with 4 Phi 600

highest safety risk coefficient. Its internal force changes

* 10 is made of seamless steel pipe column, flat joint by phi

complexly and shows different characteristics on various

300 x 8 of the seamless steel pipe, bracing by Phi 200 x 8

construction conditions, in order to meet need of its function

seamless steel tube composed of space lattice system, which

and have enough safety and operability, after calculating, the

plays a part in supporting in bridge cable tower, tower has

staff used Phi 60 wire rope galvanized and sealed.

height of 13m. tower is made of the total amount of 54t steel.

single, independent of each other, one end fixedly, one end

Its material is Q345 steel. Steel tube tower is connected with

through the pulley group + keeping four rail cable force

the tower frame, in order to increase the overall stability of

basically the same and remain constant with counterweight

the tower. At the same time, a transverse eight wind is

block.

Four

designed, wind-bearing wire rope with 4 Phi 32 per bank is

D. Crane

selected. In order to reduce the longitudinal direction of the

The bridge had two sets of hydraulic loading crane for

bridge tower deviation, unilateral set Phi 60.5 pressure

lifting type cable, a cable carrier crane by a steel truss beam,

tower wire rope.

two pedrail-walking mechanism on the main cable, two sets

C. Hoisting construction

of hydraulic lifting equipment (including lifting and traction

Steel truss girder in assembling field is assembled,

jacks, hydraulic pump station, control system and steel wire

when steel truss girder ships load- segment, with floating

take-up device), with a lifting pole beam, power generation

box controlling the water-level, the top of floating box lies

equipment parts.

alongside the wharf, and pressure from the ship's load levels

E. Construction Procedure

system position. At the same time, the floating box and

The installation and construction method of flexible

wharves should be fixed and connected, waiting for flat car

cable net steel truss beam is used for erection of steel truss

on board.

beam in the section of hoisting. The main construction steps

III. RAIL CABLE-LIFTING CONSTRUCTION

METHOD

are:

1.

The main cable and permanent slings are used for

A. Equipment And Assembling

supporting, horizontal cable is set up , with

The equipment mainly composed of the following parts:

anchored in the rock mass.

beam-transporting trolley, saddle, cable, crane, zenith trolley,

2.

a winch etc.

on both sides, steel truss girder assembling

The beam-transporting trolley is the most core

platform is made of Bailey platform and the rest

equipment in this project, which composed of the pulley

group, the triangular distribution beam and the rectangular

space of pile cap.

3.

distribution beam.

carriage beam trolley.

4.

will convert load from cable to cable. The design of crane

saddle incorporate characteristics of pin type sling, with

After lifting section that has been assembled, and

then those sections are suspended under the

B. Saddle

The effect of cable saddle is to provide support, and

A steel pipe Bailey platform is built at the pile cap

Transporting vertically to the corresponding sling

by rail sling

5.

The section of the steel truss girder is suspended

moving the saddle to the direction of top and using the cable

from the cable borne crane, and the carriage beam

clamp as a fulcrum to place it at the top, which make saddle

carriage is exited.

not occupy space of connecting hole of the lower cable

clamp.

6.

It also uses both sides of the longitudinal

positioning lock to ensure the lateral stability and it is

Adjusting spatial position of the segment, and beam

butt has been installed, and pin sling.

7.

The beam in mid of bridge is first installed and then

convenient for construction. The saddle is composed of a

symmetrically installed from mid of bridge to the

longitudinal beam and a saddle beam.

sides of bank until the full bridge is linked.

C. Cable

The advantages of rail cable-lifting construction method

Rail cable is considered as beam-transporting orbit and

and cable-hoisting method

the lifeline of the whole system, it is also the parts that has

1.

The assembling field of the steel truss is arranged

22 | P a g e

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 3, Issue 4 (July-August 2015), PP. 21-23

REFERENCES

on the platform. Compared with the cable hoisting,

2.

it can reduce the lifting height of the steel truss

[1]. Jianhui Lv. Hui Zhang. long span concrete filled steel tube

girder and the construction time, and improve the

arch bridge cable-hoisting construction technology [J] -

safety of the construction. At the same time, two

Science and technology and engineering 2009,9 (4)

pieces of steel truss girder can be installed, which

[2]. Shiming Liu. Yongjian Liu. Xiaorong Yao. concrete filled

can shorten the construction time and bring the

steel tubular arch bridge cable- hoisting construction

recessive economic benefits.

optimization [J] - Highway Traffic Science and technology

Transport and erection of the steel truss girder have

in 2012, 29 (7)

high construction efficiency, cost savings.

3.

[3]. Jinming Huang. cable hoisting system in steel truss arch

The rail cable is used as the main cable as the

bridge hook in construction application [journal article] -

support, with the good wind stability, the quality of

the western traffic science and technology 2012 (2)

construction can be controllable

4.

5.

[4]. Dong liang Zhou. Construction control study [J] highway

Compared to the cables, rail cable needs less

and 2012 trucks hoisting of long span arch bridge (1)

bearing steel wire rope.

Huaqiang

When using cable-hoisting method, it needs more

[5]. Jian gen Lv. The main span of 368m Zhang Hui lifting

operators, and cable-hoisting system technology is

Maocaojie Bridge Construction Technology [J] 2009 rib

complex, it has high demands for the operation and

arch construction technology, 40 (2)

personnel quality . Rail cable has a high degree of

[6]. Zheng zhou Cao. Yu tao Feng. Chongqing Chaoyang

automation, it needs less operators when moving

complex bridge hoisting cable tower, tower integration

the beam. Construction technology is stable, the

research [J] 2010 (07) of bridge construction.

impact

of

environment

is

small,

easy

to

standardized operation.

bridge construction control [J] highway and automotive

IV. CONCLUSION

Rail

cable-lifting

construction

[7]. Jun wei Tian. large span concrete filled steel tubular arch

2012 rib hoisting (1)

method

and

[8]. Hong tian Du. Zhong Ming. concrete filled steel tube arch

cable-hoisting construction method is more and more mature,

bridge arch rib hoisting process temperature change on Rib

but there are still many places should be improved,

Alignment Effect [J] - Railway Standard arch design 2008

such as

whether rail cable-lifting construction method can cancel

(3)

cable carrying crane or not, in terms with controlling the

[9]. Jian hong LI . Jing Sheng. cable hoisting method of

main cable wire linearity in cable-hoisting construction

reinforced concrete arch bridge construction error analysis

method

[J] - Sichuan building 2009,29 (6)

23 | P a g e

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Energy Gap Investigation and Characterization of Kesterite Cu2znsns4 Thin Film For Solar Cell ApplicationsDocument4 paginiEnergy Gap Investigation and Characterization of Kesterite Cu2znsns4 Thin Film For Solar Cell ApplicationsInternational Jpurnal Of Technical Research And Applications100% (1)

- Sumita PDFDocument5 paginiSumita PDFInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Exponential Smoothing of Postponement Rates in Operation Theatres of Advanced Pediatric Centre - Time Series Forecasting With Regression AnalysisDocument7 paginiExponential Smoothing of Postponement Rates in Operation Theatres of Advanced Pediatric Centre - Time Series Forecasting With Regression AnalysisInternational Jpurnal Of Technical Research And Applications100% (2)

- Postponement of Scheduled General Surgeries in A Tertiary Care Hospital - A Time Series Forecasting and Regression AnalysisDocument6 paginiPostponement of Scheduled General Surgeries in A Tertiary Care Hospital - A Time Series Forecasting and Regression AnalysisInternational Jpurnal Of Technical Research And Applications100% (2)

- Study of Nano-Systems For Computer SimulationsDocument6 paginiStudy of Nano-Systems For Computer SimulationsInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Sumita PDFDocument5 paginiSumita PDFInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Qualitative Risk Assessment and Mitigation Measures For Real Estate Projects in MaharashtraDocument9 paginiQualitative Risk Assessment and Mitigation Measures For Real Estate Projects in MaharashtraInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Digital Compressing of A BPCM Signal According To Barker Code Using FpgaDocument7 paginiDigital Compressing of A BPCM Signal According To Barker Code Using FpgaInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Aesthetics of The Triumphant Tone of The Black Woman in Alice Walker's The Color PurpleDocument30 paginiAesthetics of The Triumphant Tone of The Black Woman in Alice Walker's The Color PurpleInternational Jpurnal Of Technical Research And Applications100% (2)

- An Experimental Study On Separation of Water From The Atmospheric AirDocument5 paginiAn Experimental Study On Separation of Water From The Atmospheric AirInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Modelling The Impact of Flooding Using Geographic Information System and Remote SensingDocument6 paginiModelling The Impact of Flooding Using Geographic Information System and Remote SensingInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Overview of TCP Performance in Satellite Communication NetworksDocument5 paginiOverview of TCP Performance in Satellite Communication NetworksInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Pod-Pwm Based Capacitor Clamped Multilevel InverterDocument3 paginiPod-Pwm Based Capacitor Clamped Multilevel InverterInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Li-Ion Battery Testing From Manufacturing To Operation ProcessDocument4 paginiLi-Ion Battery Testing From Manufacturing To Operation ProcessInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Open Loop Analysis of Cascaded Hbridge Multilevel Inverter Using PDPWM For Photovoltaic SystemsDocument3 paginiOpen Loop Analysis of Cascaded Hbridge Multilevel Inverter Using PDPWM For Photovoltaic SystemsInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Implementation of Methods For Transaction in Secure Online BankingDocument3 paginiImplementation of Methods For Transaction in Secure Online BankingInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Scope of Replacing Fine Aggregate With Copper Slag in Concrete - A ReviewDocument5 paginiScope of Replacing Fine Aggregate With Copper Slag in Concrete - A ReviewInternational Jpurnal Of Technical Research And Applications100% (1)

- A Study On The Fresh Properties of SCC With Fly AshDocument3 paginiA Study On The Fresh Properties of SCC With Fly AshInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Time Efficient Baylis-Hillman Reaction On Steroidal Nucleus of Withaferin-A To Synthesize Anticancer AgentsDocument5 paginiTime Efficient Baylis-Hillman Reaction On Steroidal Nucleus of Withaferin-A To Synthesize Anticancer AgentsInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Evaluation of Drainage Water Quality For Irrigation by Integration Between Irrigation Water Quality Index and GisDocument9 paginiEvaluation of Drainage Water Quality For Irrigation by Integration Between Irrigation Water Quality Index and GisInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Physico-Chemical and Bacteriological Assessment of River Mudzira Water in Mubi, Adamawa State.Document4 paginiPhysico-Chemical and Bacteriological Assessment of River Mudzira Water in Mubi, Adamawa State.International Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Performance Analysis of Microstrip Patch Antenna Using Coaxial Probe Feed TechniqueDocument3 paginiPerformance Analysis of Microstrip Patch Antenna Using Coaxial Probe Feed TechniqueInternational Jpurnal Of Technical Research And Applications100% (1)

- An Inside Look in The Electrical Structure of The Battery Management System Topic Number: Renewable Power Sources, Power Systems and Energy ConversionDocument5 paginiAn Inside Look in The Electrical Structure of The Battery Management System Topic Number: Renewable Power Sources, Power Systems and Energy ConversionInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Effect of Trans-Septal Suture Technique Versus Nasal Packing After SeptoplastyDocument8 paginiEffect of Trans-Septal Suture Technique Versus Nasal Packing After SeptoplastyInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Parametric Modeling of Voltage Drop in Power Distribution NetworksDocument4 paginiParametric Modeling of Voltage Drop in Power Distribution NetworksInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Investigation of Coverage Level and The Availability of GSM Signal in Ekpoma, NigeriaDocument6 paginiInvestigation of Coverage Level and The Availability of GSM Signal in Ekpoma, NigeriaInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Production of Starch From Mango (Mangifera Indica.l) Seed Kernel and Its CharacterizationDocument4 paginiProduction of Starch From Mango (Mangifera Indica.l) Seed Kernel and Its CharacterizationInternational Jpurnal Of Technical Research And Applications100% (1)

- Study of Carbohydrate Metabolism in Severe Acute Malnutrition and Correlations of Weight and Height With Pp-Sugar and BmiDocument9 paginiStudy of Carbohydrate Metabolism in Severe Acute Malnutrition and Correlations of Weight and Height With Pp-Sugar and BmiInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Structural and Dielectric Studies of Terbium Substituted Nickel Ferrite NanoparticlesDocument3 paginiStructural and Dielectric Studies of Terbium Substituted Nickel Ferrite NanoparticlesInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- LISTA Nascar 2014Document42 paginiLISTA Nascar 2014osmarxsÎncă nu există evaluări

- Black BookDocument28 paginiBlack Bookshubham50% (2)

- Effective Communication LeaderDocument4 paginiEffective Communication LeaderAnggun PraditaÎncă nu există evaluări

- RFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonDocument8 paginiRFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonSteven MoietÎncă nu există evaluări

- COVID Immunization Record Correction RequestDocument2 paginiCOVID Immunization Record Correction RequestNBC 10 WJARÎncă nu există evaluări

- Fire and Life Safety Assessment ReportDocument5 paginiFire and Life Safety Assessment ReportJune CostalesÎncă nu există evaluări

- Singapore Electricity MarketDocument25 paginiSingapore Electricity MarketTonia GlennÎncă nu există evaluări

- Part A Plan: Simple Calculater Using Switch CaseDocument7 paginiPart A Plan: Simple Calculater Using Switch CaseRahul B. FereÎncă nu există evaluări

- Sun Hung Kai 2007Document176 paginiSun Hung Kai 2007Setianingsih SEÎncă nu există evaluări

- TNCT Q2 Module3cDocument15 paginiTNCT Q2 Module3cashurishuri411100% (1)

- 7373 16038 1 PBDocument11 pagini7373 16038 1 PBkedairekarl UNHASÎncă nu există evaluări

- Integrated Building Managemnt SystemDocument8 paginiIntegrated Building Managemnt SystemRitikaÎncă nu există evaluări

- Consultancy Services For The Feasibility Study of A Second Runway at SSR International AirportDocument6 paginiConsultancy Services For The Feasibility Study of A Second Runway at SSR International AirportNitish RamdaworÎncă nu există evaluări

- Introduction To Radar Warning ReceiverDocument23 paginiIntroduction To Radar Warning ReceiverPobitra Chele100% (1)

- SCHEDULE OF FEES - FinalDocument1 paginăSCHEDULE OF FEES - FinalAbhishek SunaÎncă nu există evaluări

- A.2 de - La - Victoria - v. - Commission - On - Elections20210424-12-18iwrdDocument6 paginiA.2 de - La - Victoria - v. - Commission - On - Elections20210424-12-18iwrdCharisse SarateÎncă nu există evaluări

- Simplified Concrete Modeling: Mat - Concrete - Damage - Rel3Document14 paginiSimplified Concrete Modeling: Mat - Concrete - Damage - Rel3amarÎncă nu există evaluări

- How To Attain Success Through The Strength of The Vibration of NumbersDocument95 paginiHow To Attain Success Through The Strength of The Vibration of NumberszahkulÎncă nu există evaluări

- BSL-3 Training-1Document22 paginiBSL-3 Training-1Dayanandhi ElangovanÎncă nu există evaluări

- Fcode 54 en El SytucDocument2 paginiFcode 54 en El SytucAga MenonÎncă nu există evaluări

- CE5215-Theory and Applications of Cement CompositesDocument10 paginiCE5215-Theory and Applications of Cement CompositesSivaramakrishnaNalluriÎncă nu există evaluări

- Fact Pack Financial Services KenyaDocument12 paginiFact Pack Financial Services KenyaCatherineÎncă nu există evaluări

- CEC Proposed Additional Canopy at Guard House (RFA-2021!09!134) (Signed 23sep21)Document3 paginiCEC Proposed Additional Canopy at Guard House (RFA-2021!09!134) (Signed 23sep21)MichaelÎncă nu există evaluări

- NCR Minimum WageDocument2 paginiNCR Minimum WageJohnBataraÎncă nu există evaluări

- A Study On Effective Training Programmes in Auto Mobile IndustryDocument7 paginiA Study On Effective Training Programmes in Auto Mobile IndustrySAURABH SINGHÎncă nu există evaluări

- Immovable Sale-Purchase (Land) ContractDocument6 paginiImmovable Sale-Purchase (Land) ContractMeta GoÎncă nu există evaluări

- MSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)Document10 paginiMSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)ANNaÎncă nu există evaluări

- Coursework For ResumeDocument7 paginiCoursework For Resumeafjwdxrctmsmwf100% (2)

- Solved - in Capital Budgeting, Should The Following Be Ignored, ...Document3 paginiSolved - in Capital Budgeting, Should The Following Be Ignored, ...rifa hanaÎncă nu există evaluări

- 6mm Superlite 70 40t Clear +16as+6mm ClearDocument1 pagină6mm Superlite 70 40t Clear +16as+6mm ClearNav JavÎncă nu există evaluări