Documente Academic

Documente Profesional

Documente Cultură

ULS Analysis

Încărcat de

Abdul HadhiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ULS Analysis

Încărcat de

Abdul HadhiDrepturi de autor:

Formate disponibile

5th GRACM International Congress on Computational Mechanics

Limassol, 29 June 1 July, 2005

ULTIMATE STRENGTH ANALYSIS OF ARBITRARY CROSS SECTIONS

UNDER BIAXIAL BENDING AND AXIAL LOAD

BY FIBER MODEL AND CURVILINEAR POLYGONS

Aristotelis E. Charalampakis and Vlasis K. Koumousis

Institute of Structural Analysis and Aseismic Research

National Technical University of Athens

NTUA, Zografou Campus GR-15773, Athens, Greece

e-mail: vkoum@central.ntua.gr, web page: http://users.ntua.gr/vkoum

Keywords: biaxial bending, fiber model, failure surface, composite structure.

Abstract. A fiber model algorithm for the analysis of arbitrary cross sections under biaxial bending and axial

load is presented. The method can be applied to complex cross sections of irregular shape and curved edges,

with or without openings and consisting of various materials. The only assumption is that plane sections remain

plane. The cross section is described by curvilinear polygons. The material properties are user defined; the

stress strain diagrams of all materials consist of any number of consecutive polynomial segments (up to cubic).

Various effects such as concrete confinement, concrete tensile strength, strain hardening of the reinforcement

etc. may be taken into account. Apart from ultimate strength analyses of cross sections, the algorithm can be

applied to other problems in which the Bernoulli Euler assumption is valid. Based on the proposed algorithm,

a computer program with full graphical interface was developed.

1 INTRODUCTION

The analysis of an arbitrary cross-section under biaxial bending and axial load has received extensive

attention in the literature lately [6], [4], [9]. With the advent of inexpensive computer systems, the generation of

the failure surface has been made possible using the fiber approach. This approach produces consistent results

that agree closely with experimental results [2].

The failure of the cross section corresponds to the top of the moment curvature diagram. However, the

conventional failure, defined by design codes, occurs when any of the materials reaches its predefined maximum

allowable compressive or tensile strain.

The results of such an analysis are important as they can be used in non-linear analyses of structures where

the plastic deformations of a structural element are functions of the load history and the distance of the load

vector from the surface. Moreover, it provides grounds for the damage analysis of the cross section.

2 GENERATION OF FAILURE SURFACE

There exist three different techniques to generate the failure surface of an arbitrary cross section: (1)

interaction curves for a given bending moments ratio, (2) load contours for a given axial load and (3) isogonic or

3D curves.

The first two techniques require the calculation of the exact position of the neutral axis. The set of

equilibrium equations are non-linear and coupled and an iterative approach such as the quasi-Newton method is

needed to determine the position of the neutral axis, as proposed by Yen [10]. These procedures are not

straightforward to implement and, in many cases, are sensitive to the selection of the origin of the reference

system. Moreover, these algorithms usually become unstable near the state of pure compression.

On the other hand, the third technique, which is used in the method presented, is more direct because the

direction of the neutral axis is assumed from the very beginning. The produced points describe a more complex

3D plot, because the meridians of the failure surface, in general, are not plane. This is due to the asymmetry of

the cross section, as described later.

3 CROSS SECTION

The curvilinear polygon is the only type of graphical entity that is used for the description of all cross

sections. A curvilinear polygon has edges that may be straight lines and/or circular arcs. Since these polygons can

be nested in any depth, it is obvious that almost any cross section can be described accurately. Circles are taken

Aristotelis E. Charalampakis and Vlasis K. Koumousis.

into account as two-sided curvilinear polygons with curved edges. Notice that even small objects, such as the

reinforcement bars, are treated as actual graphical entities and not dimensionless individual fibers.

In order to significantly reduce the expensive calculations required to identify the various regions in a

complex cross section with several materials, each curvilinear polygon is treated separately. Two material

properties are defined: the foreground material and the background material. The foreground material is

taken into account with a positive sign, whereas the background material is taken into account with a negative

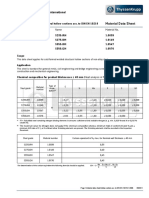

sign. Therefore, almost any cross section can be described, as shown in the example of Figure 1:

1

Entity

Number

of Nodes

16

None

Structural

steel

6 22

Reinforcement

23 41

Reinforcement

2

3

opening

4

5

6 - 22

23 - 41

Foreground

material

Unconfined

(outer) concrete

Confined

(inner) concrete

Structural

steel

Background

material

None

Unconfined

(outer) concrete

Confined

(inner) concrete

Structural

steel

Confined

(inner) concrete

Confined

(inner) concrete

Unconfined

(outer) concrete

Figure 1. Example of complex cross section consisting of various materials

4 MATERIAL PROPERTIES

The stress strain diagrams of all materials are composed of any number of consecutive segments. Each

segment is a polynomial expression (up to cubic), which is automatically defined by an appropriate number of

points; for example, a cubic segment is defined by four consecutive points. Therefore, the stress strain diagrams

of a certain kind of concrete and steel may be defined as shown in Figure 2:

cubic

linear

stress

linear

parabolic

stress

strain

(a) Example of stress - strain diagram (concrete)

strain

(b) Example of stress - strain diagram (steel)

Figure 2. Example of stress strain diagrams (tension positive)

5 CALCULATIONS

5.1 Rotation

We assume that the X axis is parallel to the central axis of the element. Any convenient point may be used as

the origin for the calculations. Since the direction of the neutral axis is assumed from the beginning, it is

convenient to express all coordinates in another YZ Cartesian system with Y axis parallel to the chosen direction

of the neutral axis. Therefore, the Cartesian system is rotated counter-clockwise around the origin by an angle ,

as shown in Figure 3. In this way, the strains and therefore the stresses vary only in Z axis.

Aristotelis E. Charalampakis and Vlasis K. Koumousis.

Z

Zc

Yc

Figure 3. Rotation of cross section

5.2 Decomposition of curvilinear polygons

The next step is the decomposition of all curvilinear polygons into curvilinear trapezoids. The top and bottom

edges of the curvilinear trapezoids are straight lines parallel to the neutral axis whereas the left and right edges

may be straight lines or arcs. This procedure is required only once for every direction of the neutral axis; this

basic set of trapezoids may be stored in memory and retrieved when needed.

Figure 4 shows an example of decomposition of a steel section and some of the produced curvilinear

trapezoids. Note that the section is described exactly by a 16-node curvilinear polygon:

Figure 4. Decomposition of a steel section into curvilinear trapezoids

For reasons of simplicity we will drop the term curvilinear for both the curvilinear polygons and the

curvilinear trapezoids.

5.3 Calculation of integrals

The next step is the calculation of the basic integrals of the trapezoids. These integrals are of the form ym zn,

where m, n, are specific integers (equation (1)). All expressions for the integrals are analytical. Again, the

integrals need to be evaluated only once for every direction of the neutral axis and the results can be stored in

memory for later use. Therefore, the overhead for using analytical expressions is minimal.

I jm , n

ym zn

trapezoid j

m, n

(1)

0, 0..4 , 1,1..4

This method is also used for the exact calculation of cross sectional properties, such as area, first moments of

area, centroids, moments of inertia, products of inertia, principal axes etc.

5.4 Strain distribution

As mentioned before, the main assumption is that plane sections remain plane. Therefore, three parameters

are needed to define the deformed plane, namely the direction of the neutral axis (angle ), the curvature k and

the strain 0 at the origin, as shown in Figure 5:

Aristotelis E. Charalampakis and Vlasis K. Koumousis.

Figure 5. Deformed plane (expressed in terms of strains)

Since the Cartesian system has been rotated by an angle , the strain is a function of z only (equation (2)):

z

Given k,

0,

k z

(2)

the neutral axis is defined as the line parallel to the Y axis at a distance given by equation (3):

0

zna

(3)

5.5 Calculation of stress resultants

The calculation of stress resultants will take place for an imposed deformed configuration defined by a set of

given values of the parameters , k, 0. In general, we assume that the segment of the stress strain diagram

covering the specific trapezoid is a cubic polynomial expression of the following form:

3

i 0

The coefficients

ai

(4)

are known from the properties of the material. Substituting relation (2) into (4) we obtain:

3

k, 0 , z

bi z i

i 0

3

b0

b1

b3

2

2

b2

0

0

3

3

k 2

k

2

2

0

0

(5)

The stress resultants of trapezoid j are calculated by integration of equation (5) as:

3

N xj

i 0

trapezoid j

3

M yj

trapezoid j

i 0

3

M zj

trapezoid j

i 0

bi z i

bi z i

bi z i

i 0

3

i 0

3

i 0

zi

bi

trapezoid j

zi

bi

zi y

trapezoid j

bi I j0,i

i 0

trapezoid j

bi

bi I j0,i

i 0

3

i 0

(6)

(7)

bi I 1,j i

(8)

Note that the integrals I(m,n)j have already been calculated and are independent of k, 0. By a simple

summation of the stress resultants of all trapezoids, the overall forces and bending moments required to impose

Aristotelis E. Charalampakis and Vlasis K. Koumousis.

the specific deformed configuration are obtained. Therefore, the steps to calculate the stress resultants are as

follows:

Pick k, 0.

For trapezoid j:

Calculate bi as functions of i (equations (5))

Calculate the stress resultants using the known values of I(m,n)j (equations (6) to (8)).

Sum the results from all trapezoids to obtain overall stress resultants NX, MY, MZ.

6 CONSTRUCTION OF MOMENT-CURVATURE DIAGRAM

For a specified axial load and direction of neutral axis (angle ), a full moment curvature diagram can be

constructed. After the initialization (rotation of cross section, decomposition of polygons into trapezoids,

calculation of the basic integrals of the trapezoids), small increments of k are applied as imposed curvature.

Since , k are given, the deformed plane is only a function of strain 0 at the origin. The algorithm calculates an

upper and lower bound of 0 and uses a fast Van Wijngaarden Dekker Brent method to calculate 0 in order to

achieve axial equilibrium to a specified accuracy.

As the curvature increases, the neutral axis moves perpendicular to its direction. This incremental procedure

continues until the moment reaches a maximum (failure), or until one of the materials reaches the maximum

compressive or tensile strain specified by the user (conventional failure). Thus, the complete moment curvature

diagram can be obtained, both for the primary moment MY and for secondary moment MZ. In general, the

secondary moment MZ, expressed by equation (8), is small as compared to the primary moment M . Finally, the

moments can be expressed in the global reference system with an inverse rotational transformation.

The algorithm uses a variable curvature step which is adjusted automatically; therefore, the final result is

independent of the initial curvature step (specified by the user). A small initial curvature step produces a smooth

moment curvature diagram.

7 CONSTRUCTION OF INTERACTION CURVES AND FAILURE SURFACES

By repeating the procedure described previously for different directions of the neutral axis in the range of 00

3600, we are able to construct the interaction curve for a given axial load. In addition, by constructing

interaction curves for various axial loads, we are able to construct the full failure surface of the cross section

equator by equator.

8 DEFORMED CONFIGURATION UNDER GIVEN LOADS

The algorithm can also be used for calculating the deformed configuration of a cross section under given

loads. The calculation is a trial and error procedure (Figure 6). The task is to calculate the parameters , k, 0 of

the deformed plane for which the cross section is in equilibrium with the external loads NXcT, MYcT, MZcT.

M Zc

N

T

M YcT , M Zc

T

Xc

II

M YcII , M Zc

II

I

I

M YcI , M Zc

0, 0

M Yc

I

0

M Yc0 , M Zc

Figure 6. Calculation of deformed configuration under given loads

Aristotelis E. Charalampakis and Vlasis K. Koumousis.

All calculations are performed with axial load equal to NXcT. The origin can be any point; therefore, we first

have to calculate the bending moments MYc0, MZc0 required for a deformed plane with no curvature (k=0). Since

curvature is always increased from zero until failure, this bending moment vector is the first result for any

direction of the neutral axis. Therefore, the paths of all analyses stem from (MYc0, MZc0). The target vector

connects (MYc0, MZc0) with (MYc , MZc ).

As first attempt (I), we set the direction I of the neutral axis equal to the direction of the target vector T. As

curvature is increased, the path of the analysis deviates because of the secondary moment MZ; when the norm

reaches the norm of the target vector, the analysis stops and the result (MYcI, MZcI) may differ from the target

values (MYc , MZc ). The direction of the neutral axis is then corrected by the difference I found in the first

iteration. In the second attempt, the results (MYcI , MZcI ) are much closer to the target values. The procedure

stops when a specified accuracy is achieved.

8 COMPUTER IMPLEMENTATION

A computer program, called myBiAxial, which implements the method proposed, has been developed. The

program features a full graphical interface. Some screen shots are shown in Figure 7:

(a)

(b)

Figure 7. MyBiAxial computer program

9 VALIDATION - EXAMPLES

9.1 Example 1

Eurocode 2 provides design charts for common reinforced concrete cross sections. These charts provide

combinations of axial loads and their respective ultimate bending moment capacities for a range of longitudinal

reinforcement expressed by the mechanical reinforcement percentage .

The axial load and bending moment are in a non-dimensional form with respect to the concrete properties and

the cross sectional dimensions; therefore, a single chart covers all cases for a certain steel grade.

Eurocode 2 specifies the value of 0.020 as the ultimate strain limit for longitudinal steel reinforcement. Also,

for large compressive axial loads, it reduces the ultimate curvature capacity by imposing the rotation of the strain

profile around point C which is located at a distance 3/7 h from the most compressed fiber and has a strain of 0=0.002. This restriction is included easily in the algorithm; however, it is of little practical interest since large

compressive axial loads in concrete cross sections must be avoided for other reasons i.e. creep.

The developed computer program was used to calculate pairs of axial loads and bending moments for the

rectangular cross section of Figure 8a. The characteristic strengths and partial safety factors for concrete and

reinforcement bars were taken as follows: fck=20MPa, c=1.5, fy=500MPa, r=1.15.

Five different cases of longitudinal reinforcement were considered, i.e. =0.00, 0.50, 1.00, 1.50, 2.00. The

computed results follow the corresponding curve exactly, as shown in Figure 8c.

Aristotelis E. Charalampakis and Vlasis K. Koumousis.

Z

100

800

1000

100

500

(a)

(b)

(c)

Figure 8. (a) Rectangular reinforced concrete cross section (distances in mm) (b) Corresponding EC2 design

chart (steel grade S500) (c) Results from proposed algorithm superimposed over the design chart

9.2 Example 2

This is an example presented by Chen et al. [2], which invokes the polygonal composite column cross section

of Figure 9. The cross section consists of a concrete core, an asymmetrically placed H shaped steel section, 15

reinforcement bars of diameter 18mm and a circular opening.

Figure 9. Composite column cross section

Chen et al. use a quasi Newton method [10] to analyze the cross section. However, the convergence of the

iterative process invoked by this algorithm cannot be guaranteed when dealing with large axial loads i.e. loads

that approach the axial load capacity under pure compression. In order to ensure the stability of Chens

algorithm, the plastic centroid must be used as the origin of the Cartesian system. In this case, the coordinates of

the plastic centroid with respect to the bottom left corner are [2] Ypc=292.2mm, Zpc=281.5mm.

The stress strain curve for concrete (CEC 1994) which consists of a parabolic and a linear (horizontal) part

was used in the calculation, with fcc=0.85 fck/ c, 0=0.002 and cu=0.0035. The Young modulus for all steel

sections was 200GPa while the maximum strain was u=0.010. The characteristic strengths and partial safety

factors for concrete, structural steel and reinforcement bars were taken as follows: fck=30MPa, c=1.5,

fs=355MPa, s=1.1, fy=460MPa, r=1.15. The analysis was carried out with an angle step of 5 degrees and an

initial curvature step of 1e-05.

Figure 10a shows the interaction curve produced by the proposed algorithm for compressive axial load

4120kN. The image is superimposed over the results taken from [2]; it is obvious that the curves almost coincide.

Aristotelis E. Charalampakis and Vlasis K. Koumousis.

The same figure also shows the paths of the analyses and the directions of the neutral axes that correspond to

each spike. Note that the data for each spike becomes denser near failure; this is because the curvature step is

decreased in order to achieve accuracy. By repeating this procedure for various axial loads we obtain the

complete failure surface of Figure 10b.

(a)

(b)

Figure 10. (a) Interaction curve for compressive axial load 4120 kN (b) Complete failure surface

10 CONCLUSIONS

A generic algorithm for the analysis of arbitrary cross sections under biaxial bending and axial load is

presented. The algorithm has some unique features as compared to the literature. The cross section is described

by curvilinear polygons, i.e. closed polygons with straight or curved edges; the material stress strain diagrams

are fully user defined as piecewise functions of polynomial segments; the integration of the stress field is

analytical. Apart from producing interaction curves and failure surfaces, the algorithm can be used for the

calculation of the deformed state of the cross section under given loads.

The algorithm has proved to be very stable and fast, while providing accurate results for non-linear analysis.

REFERENCES

[1] Bonet, J.L., Romero, M.L., Miguel, P.F., Fernandez, M.A. (2004), A fast stress integration algorithm for

reinforced concrete sections with axial loads and biaxial bending, Computers and Structures 82 213-225

[2] Chen, S. F., Teng, J. G., Chan, S. L. (2001), Design of biaxially loaded short composite columns of

arbitrary cross section, J. Struct Engng, ASCE; 127(6):678-685.

[3] De Vivo, L, Rosati, L. (1998), Ultimate strength analysis of reinforced concrete sections subject to axial

force and biaxial bending, Comput. Methods Appl. Mech. Engrg. 166:261-287.

[4] Fafitis, A (2001), Interaction surfaces of reinforced-concrete sections in biaxial bending, J Struct Engng,

ASCE; 127(7):840-6

[5] Press, W. H., Teukolsky, S. A., Vetterling, W. T., Flannery, B. P. (2002), Numerical recipes in C++: the

art of scientific computing, Cambridge University Press.

[6] Rodriguez, J. A., Aristizabal-Ochoa, J. Dario (1999), Biaxial interaction diagrams for short RC columns of

any cross section, J Struct Engng, ASCE; 125(6):672-683.

[7] Rodriguez, J. A., Aristizabal-Ochoa, J. Dario (2001), M-P- diagrams for reinforced, partially and fully

prestressed concrete sections under biaxial bending and axial load, J Struct Engng, ASCE; 127(7):763773.

[8] Rodriguez, J. A., Aristizabal-Ochoa, J. Dario (2001), Reinforced, partially and fully prestressed concrete

columns under biaxial bending and axial load, J Struct Engng, ASCE; 127(7):774-783.

[9] Sfakianakis, M. G. (2002), Biaxial bending with axial force of reinforced, composite and repaired concrete

sections of arbitrary shape by fiber model and computer graphics, Advances in Engineering Software 33

227 - 242.

[10] Yen, J. Y. R. (1991), Quasi-Newton method for reinforced concrete column analysis and design, J Struct

Engng, ASCE; 117(3):657-666.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Arizona EPMDocument385 paginiArizona EPMJames Lynch100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Dematic WMSDocument20 paginiDematic WMSkrystyinÎncă nu există evaluări

- STAADPro Verification Manual PDFDocument378 paginiSTAADPro Verification Manual PDFAbdul HadhiÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Fujifilm EP-6000 Processor - Service Manual PDFDocument445 paginiFujifilm EP-6000 Processor - Service Manual PDFjames100% (1)

- Auto-Pilot: Simplified Block DiagramDocument8 paginiAuto-Pilot: Simplified Block Diagrammmishra914100% (1)

- Structural Design of Steel Latticed TowersDocument13 paginiStructural Design of Steel Latticed Towersskumaran1100% (11)

- TG20-13 Supplement 1Document4 paginiTG20-13 Supplement 1Abdul Hadhi100% (1)

- 2 Way SlabDocument22 pagini2 Way SlabAhmed Al-AmriÎncă nu există evaluări

- Glossary of Safety ScaffoldsDocument48 paginiGlossary of Safety Scaffoldsmp_babu_2100% (1)

- HSS DimensionsDocument28 paginiHSS DimensionsRichard StratulakÎncă nu există evaluări

- Three Dimensional Static and Dynamic Analysis of StructuresDocument423 paginiThree Dimensional Static and Dynamic Analysis of StructuresUsman SiddiquiÎncă nu există evaluări

- Using European Standards for Temporary Works DesignDocument24 paginiUsing European Standards for Temporary Works Designcarlosfilipegomes3994Încă nu există evaluări

- 6.2 Board DATA - 1Document7 pagini6.2 Board DATA - 1Abdul HadhiÎncă nu există evaluări

- British Codes ReferencesDocument1 paginăBritish Codes ReferencesAbdul HadhiÎncă nu există evaluări

- Title Design, Erect, and Dismantle Advanced Cantilevers Level 5 Credits 15Document6 paginiTitle Design, Erect, and Dismantle Advanced Cantilevers Level 5 Credits 15Abdul HadhiÎncă nu există evaluări

- Hollow Section Acc. To 10219Document3 paginiHollow Section Acc. To 10219Abdul HadhiÎncă nu există evaluări

- Scaffolds Scaffolding Work General Guide 1Document16 paginiScaffolds Scaffolding Work General Guide 1Mohamad SafwanÎncă nu există evaluări

- 2016 CHH Futurebuild HyPLANKBrochure AU v0.12 PDFDocument8 pagini2016 CHH Futurebuild HyPLANKBrochure AU v0.12 PDFAbdul HadhiÎncă nu există evaluări

- Ipe BeamDocument1 paginăIpe Beamdoshi78Încă nu există evaluări

- Steel W-Shape Section DataDocument7 paginiSteel W-Shape Section DataNelson MendozaÎncă nu există evaluări

- Ensuring best fixings practiceDocument15 paginiEnsuring best fixings practiceAbdul Hadhi100% (1)

- Murphy Scaffold Plank Technical GuideDocument4 paginiMurphy Scaffold Plank Technical GuideAbdul HadhiÎncă nu există evaluări

- HAKI International Component List 140904 PDFDocument64 paginiHAKI International Component List 140904 PDFAbdul Hadhi100% (1)

- HAKI International Component List 140904 PDFDocument64 paginiHAKI International Component List 140904 PDFAbdul Hadhi100% (1)

- Bolts DetailsDocument1 paginăBolts DetailsAbdul HadhiÎncă nu există evaluări

- Popper 02Document19 paginiPopper 02Abdul HadhiÎncă nu există evaluări

- Layher ScaffDocument28 paginiLayher ScaffAbdul HadhiÎncă nu există evaluări

- Article On FE Slab AnalysisDocument1 paginăArticle On FE Slab AnalysisAbdul HadhiÎncă nu există evaluări

- Wind Loads and Anchor Bolt Design For Petrochemical Factories PDFDocument84 paginiWind Loads and Anchor Bolt Design For Petrochemical Factories PDFAbdul HadhiÎncă nu există evaluări

- CH 01Document10 paginiCH 01Abdul HadhiÎncă nu există evaluări

- Wandering About in A Dark Labyrinth: The Role of Mathematics in The Sciences and EngineeringDocument17 paginiWandering About in A Dark Labyrinth: The Role of Mathematics in The Sciences and EngineeringAbdul HadhiÎncă nu există evaluări

- Design of Steel Beam ConnectionsDocument524 paginiDesign of Steel Beam ConnectionsAbdul HadhiÎncă nu există evaluări

- Zebradesigner XML Release Notes v2509427Document13 paginiZebradesigner XML Release Notes v2509427atacaraÎncă nu există evaluări

- Files - MC-WP-012 5 Key Factors To Consider When Selecting An Embedded Testing Tool - 5Document22 paginiFiles - MC-WP-012 5 Key Factors To Consider When Selecting An Embedded Testing Tool - 5Rafael R QueirozÎncă nu există evaluări

- Step To Clear Common Error MHF Client Side-1Document20 paginiStep To Clear Common Error MHF Client Side-1Arya Stygian EditionÎncă nu există evaluări

- Hacking Module 11Document53 paginiHacking Module 11Chye HengÎncă nu există evaluări

- Design and Analysis of AlgorithmDocument15 paginiDesign and Analysis of AlgorithmswathisaipragnyaÎncă nu există evaluări

- Jeemain - Ntaonline.in Frontend Web Advancecityintimationslip Admit-CardDocument4 paginiJeemain - Ntaonline.in Frontend Web Advancecityintimationslip Admit-Cardnani7013445101Încă nu există evaluări

- Cloud Computing Course and Project GuidesDocument2 paginiCloud Computing Course and Project GuidesWow BollywoodÎncă nu există evaluări

- Node JSDocument4 paginiNode JS12002040701186Încă nu există evaluări

- Business ON - App-New Guideline-EnglishDocument3 paginiBusiness ON - App-New Guideline-EnglishMuhammad UsmanÎncă nu există evaluări

- Modernize and Simplify Operations With IBM Managed Security Services - InfographicDocument1 paginăModernize and Simplify Operations With IBM Managed Security Services - InfographicJonas KhohÎncă nu există evaluări

- TR1 234Document4 paginiTR1 234Rocha MartinÎncă nu există evaluări

- Cny 17Document9 paginiCny 17Krista TranÎncă nu există evaluări

- Technical Specifications SSDDocument2 paginiTechnical Specifications SSDFelisha FebryÎncă nu există evaluări

- Ivent101 Operator'S ManualDocument184 paginiIvent101 Operator'S ManualTrang PhạmÎncă nu există evaluări

- RC4 Basics PresentationDocument14 paginiRC4 Basics PresentationKiruthikaBalasubramanianÎncă nu există evaluări

- ECC 602 Computer Communication Network exam modulesDocument2 paginiECC 602 Computer Communication Network exam modulesRatnakar YadavÎncă nu există evaluări

- Binary DecoderDocument7 paginiBinary DecoderAlinChanÎncă nu există evaluări

- Timothy Mo: Sour SweetDocument3 paginiTimothy Mo: Sour SweetSimion FloryÎncă nu există evaluări

- Oilfield Equipment Manual Connection and SealingDocument28 paginiOilfield Equipment Manual Connection and SealingIgor Ungur100% (2)

- Kotlin Coroutines Cheat Sheet PDFDocument1 paginăKotlin Coroutines Cheat Sheet PDFgeiledeutscheÎncă nu există evaluări

- Capri - Capri+ Trouble-Shooting Guide-L3Document53 paginiCapri - Capri+ Trouble-Shooting Guide-L3Jonatan Antonio Da SilvaÎncă nu există evaluări

- Help - Mens Work Jacket Mock UpDocument8 paginiHelp - Mens Work Jacket Mock UpMuhammad Zen WawazerÎncă nu există evaluări

- Tutorial Mobius BandDocument10 paginiTutorial Mobius BandOrlando AriasÎncă nu există evaluări

- Emergency mic and handheld micsDocument2 paginiEmergency mic and handheld micskmleongmyÎncă nu există evaluări

- APV Monitoring ReportDocument83 paginiAPV Monitoring ReportLeah MoscareÎncă nu există evaluări

- Kerem Kemik CV - Family Doctor ProfileDocument3 paginiKerem Kemik CV - Family Doctor ProfileKerem KemikÎncă nu există evaluări