Documente Academic

Documente Profesional

Documente Cultură

Nail Up Insulated Ceilings: Site Handling Instructions

Încărcat de

peterTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Nail Up Insulated Ceilings: Site Handling Instructions

Încărcat de

peterDrepturi de autor:

Formate disponibile

June 2012

NAIL UP INSULATED CEILINGS

Heat gain in residential homes is largely through the roof structure. Insulated ceilings retard heat flow into

the living areas in summer, and contain generated heat in winter, providing a comfortable living environment.

Note that ventilation, window design and positioning of the building also affect

comfort in the dwelling. Consult the TIASA Code for Construction of Insulated

Dwellings (www.aaamsa.com)

Suggested Bill of Quantity Specification:

"IsoBoard high density 32-36kg/m3 rigid extruded polystyrene 100%

closed cell insulation board of __mm thickness and 600mm width, tackfixed with recommended adhesive at 200mm intervals to timber/steel

brandering installed at maximum 700mm centres transversely to trusses,

and edge- fixed with concealed ceiling clips screwed/pop-riveted to

timber/steel brandering. Boards to be secured to perimeter brandering

with drywall screws and washers at 300mm centres."

Nail-up Guidelines:

Order either bevelled edge or IsoPine.

Boards to run wall to wall: avoid butt joints

Brandering maximum 700mm spacing, with perimeter brandering around room.

Boards must be positively secured on ends.

Always use adhesive, screws and concealed clips as recommended for ceiling installation.

Ensure planned lighting is compatible with IsoBoard.

Paint with two coats of a good quality water based matt PVA

paint. Painting also prevents discolouration of boards by UV

rays (reflected sunlight).

Double fixing points where board is installed externally or

in windy areas.

Overlay IsoBoard with fibre products where sound insulation

is required.

Site Handling Instructions:

1. Store boards flat within original packaging until

required.

2. Boards are to be protected from adverse weather conditions and direct sunlight for the storage period.

3. Handle and install with care to prevent damage to

board edges and exposed surfaces.

4. IsoBoard is easily cut to length or trimmed using a

sharp knife or hack-saw.

5. Surface indentations and imperfections can be repaired

using a plasterkey and crack filler paste or by applying

a filler base coat.

6. Wipe boards with cloth and softened water solution to

clean as necessary, prior to painting two coats of good

quality PVA.

Bevelled Edge

Typical uses for IsoBoard in this application:

Residential housing installed as insulated ceiling. IsoPine

grooved and bevelled finishes are options.

In retail developments when no insulation is provided,

IsoBoard is frequently retrofitted to achieve comfort and

cost saving objectives, and protect the expected shelf life of

perishable produce.

Community housing, police stations, clinics, school projects

and Office developments.

IsoPine

Ordering Information:

IsoBoard thermal insulation is available in standard lengths

From 4.8m to 7,2m with 0,6m increments and in 8m and

halves for 25, 30, 40, 50mm boards. Tolerance 5mm.

Enquire availability of lengths of thicker board.

Thicknesses range from 25mm, 30mm, 40mm up to 80mm,

with board thicknesses of 50mm and above made to order

IsoBoard can be ordered with the Isopine surface finish, which

looks similar to a tongue and groove pine surface, having

grooves at 100mm centers down the length of the board, or,

with bevelled edge, to achieve a panelled look finish.

IsoBoard is always 600mm ( 2mm) wide, with a tongue and

groove edge profile so adjacent boards interlock.

Please consult a representative for the appropriate thickness for use in your region to comply with energy usage

requirements.

Retrofit Nail Up Installation

June 2012

NAIL UP INSULATED CEILINGS

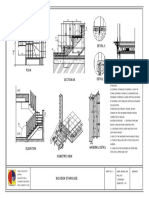

The recommended nail-up ceiling installation

method for IsoBoard:

1. Fit timber or steel brandering at maximum 700mm centres transversely

to the trusses, as well as all around the perimeter of each room. Increase

brandering x-sectional area where truss spacing exceeds 750mm.

2. IsoBoard sheets to be of sufficient length to span brandering transversely without butt jointing. Trim boards on site, allowing for a 5mm

gap to each wall.

3. Apply 5ml blobs of recommended adhesive at 200mm intervals along

the brandering.

4. Fix initial panel to perimeter brandering with screws and washers at

300mm intervals, such as to be concealed with cornice.

5. Break out tongue or top of groove at each intersection of board edge and

brandering to accept concealed clip into edge of IsoBoard sheet. Screw

or pop rivet clip into brandering, pressing up to ensure adhesive contact.

Fit subsequent IsoBoard panels, using the tongue and groove joint.

6. Trim the final board and fit to complete the installation.

7. Fit polystyrene cornice.

8. Sand grooves lightly, fill any indentations with a plasterkey and crack

filler paste.

9. Wipe surface clean. Finish with two coats good quality matt acrylic

paint, of which we recommend the first coat to be an acrylic filler-coat,

to cover minor surface indentations and imperfections.

10. Contact with ANY solvents or solvent-based products will damage

the boards. Only water-based cleaners, adhesive and paints to be used.

Isometric View

Blobs of recommended adhesive at

200mm spacing

Concealed clip inserted at each

junction with brandering see

Detail 1

38mm x38 mm brandering at

700mm centers maximum

Roof Truss

IsoBoard ceiling

Cross sectional detail

38mm Brandering

Concealed Clip

IsoBoard ceiling

5mm bevel

Cove Cornice Detail

Roof Truss

38mm perimeter brandering

40mm from the walls

IsoBoard fixed with screws

IsoBoard ceiling

Cornice adhesive

Using IsoBoard externally under eaves and verandas and in

windy areas:

Cornice

Halve the brandering spacings and double the number of clips/screws and

adhesive fixing points where IsoBoard is installed externally or in windy

areas. This is to accommodate the effect of wind and air pressure differences.

Painting is required to avoid discolouration.

Wall

Cornice adhesive

Concealed Clip Detail

Concealed Clip

Sound Insulation:

IsoBoard is a thermal insulator and should not be used in isolation to achieve

noise reduction. Please consult a specialist with respect to noise reduction

systems. (Generally a wool blanket will reduce sound transmission.)

Lighting and IsoBoard ceilings

Lamp holders fixed through Isoboard should be fitted with lamps generating

heat not exceeding temperatures of 70C. Above this temperature Isoboard

will soften and retract from the heat source.

Space fluorescent lamp holders (with fitted ballast) approximately 3mm away

from IsoBoard using washers, and fix to supporting brandering or trusses.

Use Energy Saver lamps when installing other lamp fittings in close proximity

to IsoBoard. Heavier light fittings should always be hung from timber fixed

above the IsoBoard.

Downlighters:

Lamp fittings to be of swivel type.

We only recommend Energy Saver or LED lamps be used. For 12V installations, position transformers off the board on battens/truss and 200mm

away from the lamp fittings. Allow a minimum of 150mm airspace above

the IsoBoard for sufficient ventilation.

Flush look ceilings are not recommended due to the special skills and time it takes

to achieve an aesthetically pleasing result. Please consult with IsoBoard before

attempting this finish.

t. 012 653 8204

f. 012 653 0782

northsales@isoboard.com

Cape Sales

t. 021 983 1140

f. 021 981 6099

southsales@isoboard.com

KwaZulu Natal Sales t. 031 700 3525

f. 031 700 2573

dbnsales@isoboard.com

Gauteng Sales

www.isoboard.com

S-ar putea să vă placă și

- Over Rafter Thermal InsulationDocument2 paginiOver Rafter Thermal InsulationpeterÎncă nu există evaluări

- Clearly Safe and Strong: The High Performance Glazing That'S Built Tough To Keep You SafeDocument2 paginiClearly Safe and Strong: The High Performance Glazing That'S Built Tough To Keep You Safeapuhapuh_153349Încă nu există evaluări

- How To Build A Partition Wall: 0845 274 1000 Wickes - Co.ukDocument4 paginiHow To Build A Partition Wall: 0845 274 1000 Wickes - Co.ukRenganathan V SankaranÎncă nu există evaluări

- HOW To BUILD YOUR OWN DIY Treated Pine PERGOLADocument8 paginiHOW To BUILD YOUR OWN DIY Treated Pine PERGOLAJohn EvansÎncă nu există evaluări

- ALS PolycarbonateInstallationInstructions Laserlite Dec2011Document3 paginiALS PolycarbonateInstallationInstructions Laserlite Dec2011patlolanugmailcomÎncă nu există evaluări

- 9 - Ceilings, Partitions and Access FloorsDocument4 pagini9 - Ceilings, Partitions and Access FloorsmozÎncă nu există evaluări

- CBB1443 How To Timber DeckDocument2 paginiCBB1443 How To Timber DeckTuroyÎncă nu există evaluări

- 12 Pitched RoofsDocument3 pagini12 Pitched Roofshkalloli@gmail.comÎncă nu există evaluări

- Timber Cladding Installation Instructions MinDocument3 paginiTimber Cladding Installation Instructions MinMarko NakicÎncă nu există evaluări

- Building Works Specification: Two Storey HouseDocument12 paginiBuilding Works Specification: Two Storey HouseKhalid AwanÎncă nu există evaluări

- Build A Pergola. Mitre 10Document12 paginiBuild A Pergola. Mitre 10John EvansÎncă nu există evaluări

- Multi-Wall Polycarbonate Installation Instructions: Bending/Burying Bending/Burying Bending/Burying Bending/BuryingDocument5 paginiMulti-Wall Polycarbonate Installation Instructions: Bending/Burying Bending/Burying Bending/Burying Bending/BuryingreyromanyÎncă nu există evaluări

- Rooftiles Unicoppo Installation GuideDocument6 paginiRooftiles Unicoppo Installation GuideJessica SandersÎncă nu există evaluări

- BOQ-Acoustic Work at IIIDEM 31.01.2020Document10 paginiBOQ-Acoustic Work at IIIDEM 31.01.2020Kirti BaliÎncă nu există evaluări

- Installation Manual HVAC Pipework and Ductwork 2012 PDFDocument24 paginiInstallation Manual HVAC Pipework and Ductwork 2012 PDFsasan490% (1)

- Construction Methodologies Ceiling FinishesDocument6 paginiConstruction Methodologies Ceiling FinishesDonita DaquizÎncă nu există evaluări

- 1 37753 BR Egger-Holzbau enDocument28 pagini1 37753 BR Egger-Holzbau enstefan hergheligiuÎncă nu există evaluări

- Gypsum PlasterboardDocument7 paginiGypsum PlasterboardJerusalemsÎncă nu există evaluări

- Baison 1Document24 paginiBaison 1mohanty_anantakumar6332Încă nu există evaluări

- Wood Cement BoardDocument15 paginiWood Cement BoardpiangphetÎncă nu există evaluări

- Alubond Method of StatementDocument2 paginiAlubond Method of StatementHaneefa ChÎncă nu există evaluări

- BISON PANEL Product GuideDocument24 paginiBISON PANEL Product Guideg_periwal_pune9635Încă nu există evaluări

- Method Statement For Drywall Work: Installation GuideDocument2 paginiMethod Statement For Drywall Work: Installation GuideMacaÎncă nu există evaluări

- Seminar On: By-Monika SmritiDocument26 paginiSeminar On: By-Monika SmritiJaishree BaidÎncă nu există evaluări

- Lacing Anchors & Hooks... Oct.2018Document1 paginăLacing Anchors & Hooks... Oct.2018Parag PanditÎncă nu există evaluări

- False Ceilings & PartitionsDocument114 paginiFalse Ceilings & PartitionsTanmay BhaleraoÎncă nu există evaluări

- Requirements of A Good PartitionDocument11 paginiRequirements of A Good PartitionShraddha Bahirat100% (1)

- Fiber Cement BoardDocument6 paginiFiber Cement BoardFavorSea Industrial Channel Limited, Building Materials DivisionÎncă nu există evaluări

- Flat RoofDocument2 paginiFlat RoofHarry ThienÎncă nu există evaluări

- KrovoviDocument0 paginiKrovovipeckalicamnÎncă nu există evaluări

- STEICO Floor Deck Fixing en IDocument4 paginiSTEICO Floor Deck Fixing en IClaudiu BaditaÎncă nu există evaluări

- SarfDocument51 paginiSarfSantosh ThakurÎncă nu există evaluări

- Placi Osb Catalog General en 49632 PDFDocument28 paginiPlaci Osb Catalog General en 49632 PDFbermisuÎncă nu există evaluări

- Construction of Linings, Finishes and StairsDocument29 paginiConstruction of Linings, Finishes and StairsAlbert LiuÎncă nu există evaluări

- Oofing: A Guide To Fibreglass R Installation Things To Consider and AdviceDocument22 paginiOofing: A Guide To Fibreglass R Installation Things To Consider and AdviceIoan PiuÎncă nu există evaluări

- ENG Technish Grill HD StijlDocument6 paginiENG Technish Grill HD StijlBoyko IzoffÎncă nu există evaluări

- Insulation Method StatementDocument4 paginiInsulation Method StatementShanoor AS100% (1)

- Roof Concrete Brochure Zephyr Vent PDFDocument4 paginiRoof Concrete Brochure Zephyr Vent PDFHRroofingÎncă nu există evaluări

- Brochure BraceboardDocument12 paginiBrochure Braceboardchancer2Încă nu există evaluări

- Boq and Specifications For Civil, Interior, Furnishing, Electrical and Air-Conditioning Works of DSH Office at First Floor of Panna Main BranchDocument21 paginiBoq and Specifications For Civil, Interior, Furnishing, Electrical and Air-Conditioning Works of DSH Office at First Floor of Panna Main BranchRadwan Noman100% (1)

- Boq PDFDocument21 paginiBoq PDFnohaÎncă nu există evaluări

- Cavity Wall Insulation Is An Effective Way To Save EnergyDocument3 paginiCavity Wall Insulation Is An Effective Way To Save EnergyAbishaTeslinÎncă nu există evaluări

- Sips Erection GuideDocument12 paginiSips Erection GuideKalibabaÎncă nu există evaluări

- Thermobreak Tube Installation InstructionsDocument8 paginiThermobreak Tube Installation Instructionssurya325kiranÎncă nu există evaluări

- Know Your Associate 0Document12 paginiKnow Your Associate 0sarveshrathiÎncă nu există evaluări

- AAC Blocks Construction Tips PDFDocument7 paginiAAC Blocks Construction Tips PDFBharath Reddy ChinthiReddyÎncă nu există evaluări

- B - R - PR - 2 - Loft Conversion - Room in RoofDocument20 paginiB - R - PR - 2 - Loft Conversion - Room in Roofhrpwmv83Încă nu există evaluări

- SUSPENDED CEILING - MDocument28 paginiSUSPENDED CEILING - MGunjan Uttamchandani100% (1)

- General Guidelines InsulationDocument56 paginiGeneral Guidelines InsulationPadmanaban SoundirarajanÎncă nu există evaluări

- SB07 Decorative Effects 04Document14 paginiSB07 Decorative Effects 04Mohamed AliÎncă nu există evaluări

- PARTITION WALL - Room Divider: What Is Parttion WallDocument5 paginiPARTITION WALL - Room Divider: What Is Parttion WallShraddha BahiratÎncă nu există evaluări

- Installing Gyprock Plasterboard: How To Install Gyprock Plasterboard Walls and CeilingsDocument4 paginiInstalling Gyprock Plasterboard: How To Install Gyprock Plasterboard Walls and CeilingsAjay DattÎncă nu există evaluări

- Flat RoofDocument9 paginiFlat RoofAdrian Mosquisa100% (1)

- PVC False CeilingDocument12 paginiPVC False Ceilingprakriti goyalÎncă nu există evaluări

- Technical Documentation Linear enDocument8 paginiTechnical Documentation Linear enmualk91Încă nu există evaluări

- L8 - 17080 - Via - 13501 - Mix DetailsDocument38 paginiL8 - 17080 - Via - 13501 - Mix Detailsakhileshsharma94Încă nu există evaluări

- AA Unideck PDFDocument2 paginiAA Unideck PDFDouglas TaylorÎncă nu există evaluări

- Family Handyman Quick & Easy ProjectsDe la EverandFamily Handyman Quick & Easy ProjectsFamily HandymanÎncă nu există evaluări

- Family Handyman Whole House Storage & OrganizingDe la EverandFamily Handyman Whole House Storage & OrganizingFamily HandymanÎncă nu există evaluări

- Ukuqonda Math Gr7 Teacher GuideDocument353 paginiUkuqonda Math Gr7 Teacher GuideM. Adil NasirÎncă nu există evaluări

- Social Sciences Gr7 TRBDocument65 paginiSocial Sciences Gr7 TRBpeterÎncă nu există evaluări

- Lessons Gr. 7 Mathematics Term 1 Week 1,2,3 Whole NumbersDocument59 paginiLessons Gr. 7 Mathematics Term 1 Week 1,2,3 Whole NumberspeterÎncă nu există evaluări

- WorksheetsDocument58 paginiWorksheetspeterÎncă nu există evaluări

- Social Sciences Worksheets gr7Document50 paginiSocial Sciences Worksheets gr7peterÎncă nu există evaluări

- Math ENG Gr7 B2Document166 paginiMath ENG Gr7 B2Matthew AprilÎncă nu există evaluări

- MasterConsole Z User Guide 0C EDocument34 paginiMasterConsole Z User Guide 0C EpeterÎncă nu există evaluări

- Lesson Plan Gr. 7 Mathematics Term 1 Week 6 Common FractionsDocument13 paginiLesson Plan Gr. 7 Mathematics Term 1 Week 6 Common FractionspeterÎncă nu există evaluări

- Lesson Plan Gr. 7 Mathematics Term 1 Week 5 Common FractionsDocument22 paginiLesson Plan Gr. 7 Mathematics Term 1 Week 5 Common FractionspeterÎncă nu există evaluări

- Grade 7 Social Sciences Platinum Navigation PackDocument58 paginiGrade 7 Social Sciences Platinum Navigation PackLinda ManuelÎncă nu există evaluări

- Lesson Plan SP Grade 7 SS Geography T1 W1Document5 paginiLesson Plan SP Grade 7 SS Geography T1 W1peterÎncă nu există evaluări

- GRD 7 History Notes T 1 2018 ApprovedDocument20 paginiGRD 7 History Notes T 1 2018 ApprovedpeterÎncă nu există evaluări

- Instamaths gr7Document30 paginiInstamaths gr7peterÎncă nu există evaluări

- Grade 8 Social Sciences Platinum Navigation PackDocument66 paginiGrade 8 Social Sciences Platinum Navigation PackNtsako OraciaÎncă nu există evaluări

- En Ac-cnc2019-1d-Mega r1.x Diagram JogwheelDocument4 paginiEn Ac-cnc2019-1d-Mega r1.x Diagram JogwheelpeterÎncă nu există evaluări

- 2020 November Exam Paper GR7 MathsDocument11 pagini2020 November Exam Paper GR7 MathspeterÎncă nu există evaluări

- IBUCDocument293 paginiIBUCgermancho81Încă nu există evaluări

- Woodcraft Magazine - Issue #072 - Aug, Sept 2016 - My First Chair PDFDocument68 paginiWoodcraft Magazine - Issue #072 - Aug, Sept 2016 - My First Chair PDFKen Lock100% (3)

- Woodcraft Magazine TruePDF-August September 2019 PDFDocument76 paginiWoodcraft Magazine TruePDF-August September 2019 PDFpeter100% (1)

- Solutions For All Social Sciences GradeDocument49 paginiSolutions For All Social Sciences Gradesibusiso dzivaÎncă nu există evaluări

- Silicon Chip June 2011Document108 paginiSilicon Chip June 2011peterÎncă nu există evaluări

- Minilink BasDocument174 paginiMinilink BaspeterÎncă nu există evaluări

- En Manual AC-2018-7 REV05Document9 paginiEn Manual AC-2018-7 REV05peterÎncă nu există evaluări

- Woodcraft Magazine TruePDF-August September 2019 PDFDocument76 paginiWoodcraft Magazine TruePDF-August September 2019 PDFpeter100% (1)

- WSmithSpets TheBestOfWoodsmithShop PDFDocument128 paginiWSmithSpets TheBestOfWoodsmithShop PDFpeter100% (3)

- WSmithSpets AllTimeFavoriteProjects PDFDocument143 paginiWSmithSpets AllTimeFavoriteProjects PDFpeter100% (1)

- WOOD Magazine TruePDF-March 2020Document88 paginiWOOD Magazine TruePDF-March 2020peterÎncă nu există evaluări

- Woodcraft Magazine TruePDF-August September 2019 PDFDocument76 paginiWoodcraft Magazine TruePDF-August September 2019 PDFpeter100% (1)

- WSmithSpets MustHaveHandTools PDFDocument119 paginiWSmithSpets MustHaveHandTools PDFpeter100% (1)

- WSmith 240Document70 paginiWSmith 240peter100% (3)

- 4 Wooden StaircaseDocument1 pagină4 Wooden StaircasecharuÎncă nu există evaluări

- Lesson 8 - BLDG FRMG SystemsDocument11 paginiLesson 8 - BLDG FRMG SystemsCher EpondolanÎncă nu există evaluări

- Staircases 161104110549 PDFDocument136 paginiStaircases 161104110549 PDFDharshan KÎncă nu există evaluări

- UTKARSHDocument20 paginiUTKARSHprosperity facilitationÎncă nu există evaluări

- Quantity Surveying - SpecificationDocument39 paginiQuantity Surveying - SpecificationAndrew MwambaÎncă nu există evaluări

- Gree Vatrshni TelaDocument403 paginiGree Vatrshni TelaNikolay KapitanovÎncă nu există evaluări

- Technical Submittal - FP330 Pipe Collar - 050723 - Rev0 - CompressedDocument176 paginiTechnical Submittal - FP330 Pipe Collar - 050723 - Rev0 - CompressedAngelo Carlo MalabananÎncă nu există evaluări

- Typical Foundation Plan-ModelDocument1 paginăTypical Foundation Plan-ModelkapilÎncă nu există evaluări

- Smacna Duct ConstructionDocument23 paginiSmacna Duct ConstructionKaustubh Bidkar100% (2)

- MFID-18-80138.1 OTTV Glass Summary As 9mmDocument2 paginiMFID-18-80138.1 OTTV Glass Summary As 9mmShinji JrÎncă nu există evaluări

- Etabs - Column Calculation ReportDocument1 paginăEtabs - Column Calculation Reportkhlee.mitraÎncă nu există evaluări

- Bosch ASD DesignDocument2 paginiBosch ASD DesignChowKC03Încă nu există evaluări

- CE 316 IntroductionDocument34 paginiCE 316 IntroductionPLABON SENÎncă nu există evaluări

- 2 Case StudiesDocument18 pagini2 Case StudiesolaÎncă nu există evaluări

- SECTION 09 29 00 Gypsum BoardDocument10 paginiSECTION 09 29 00 Gypsum BoardRima Baz FadousÎncă nu există evaluări

- BCA - Builder's Guide On Measuring Productivity 2012Document86 paginiBCA - Builder's Guide On Measuring Productivity 2012lwin_oo243567% (3)

- DSSS PDFDocument2 paginiDSSS PDFBrij AkabariÎncă nu există evaluări

- Quantity Surveying Lecture NotesDocument8 paginiQuantity Surveying Lecture NotesSam SamÎncă nu există evaluări

- Renaissance ArchitectureDocument11 paginiRenaissance ArchitectureIonut Popescu100% (1)

- Steel and Refurbishment in AAVV FeaturinDocument14 paginiSteel and Refurbishment in AAVV FeaturindiogolafaiaÎncă nu există evaluări

- Viollet Le Duc by Bhavani and ShaziyaDocument17 paginiViollet Le Duc by Bhavani and ShaziyaBhavani U KulkarniÎncă nu există evaluări

- GOVERNMENT OF PUNJAB Building by Law PDFDocument45 paginiGOVERNMENT OF PUNJAB Building by Law PDFniki niksÎncă nu există evaluări

- Detailing The Differential: Tricky Transitions in Commercial RoofingDocument49 paginiDetailing The Differential: Tricky Transitions in Commercial RoofingTower GodÎncă nu există evaluări

- Axial Shortening of Columns in Tall BuildingsDocument5 paginiAxial Shortening of Columns in Tall BuildingsAnil kumar RÎncă nu există evaluări

- The Subsidiary Temple of Nekhtnebef at Tell El-BalamunDocument18 paginiThe Subsidiary Temple of Nekhtnebef at Tell El-BalamunLudwigRossÎncă nu există evaluări

- Structural Glass & Spider Glazing Curtain WallsDocument19 paginiStructural Glass & Spider Glazing Curtain WallsAndrei NedelcuÎncă nu există evaluări

- 2022 - 12 - 29 - JN - Main HT Panel Foundation GA & Details - R4 - ApprovedDocument1 pagină2022 - 12 - 29 - JN - Main HT Panel Foundation GA & Details - R4 - ApprovedHemal PatelÎncă nu există evaluări

- Aama-Wdma-Csa 101 PDFDocument6 paginiAama-Wdma-Csa 101 PDFGino TironiÎncă nu există evaluări

- Model BQ Explanatory Notes 2017 2ndrevDocument12 paginiModel BQ Explanatory Notes 2017 2ndrevSiu EricÎncă nu există evaluări

- Est. Repair Raha Toll PlazaDocument42 paginiEst. Repair Raha Toll PlazaBilal A Barbhuiya100% (1)