Documente Academic

Documente Profesional

Documente Cultură

Foundry Manual - Part 3

Încărcat de

Khin Aung ShweDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Foundry Manual - Part 3

Încărcat de

Khin Aung ShweDrepturi de autor:

Formate disponibile

2/4/2016

FoundryManualPart3

Calendar:

WhattoVisit:

HowtoVisit:

Membership

AboutUs:

139

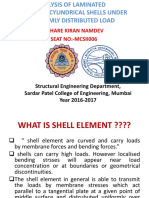

ChapterIX

POURINGCASTINGS

Pouringisacriticaloperationinthe

Aliningmixturewhichwillhavethedesired

productionofacastingandonewhichshould propertiescanbeobtainedbythoroughly

becarefullyconducted.Theladleequipment mixingthefollowingmaterialsinasand

shouldbedesignedforhighstructural

muller.

strengthand,inthecaseofgearedladles,for

foolproofmechanicaloperation.Becauseof

Usedsteelbacking

81.5percent

thehightemperaturesinvolved,areasonable sand(Allpurpose

factorofsafetyshouldbeusedwhenlininga backingsand

ladleorwhendecidingwhetheranoldlining chapterIV)

isfitforuse.

Silicaflour

15.0percent

Bentonite

2.0percent

Toavoidaccidents,frequentandcareful

1.5percent

inspectionshouldbemadeofallpartsofthe Dextrine

metalhandlingequipment(bowls,bails,

Water

5.0percentofthedry

trunnions,etc.)todetectbadlyscaledor

ingredients

crackedareas.Defectiveequipmentcauses

badcastings.Whengearedladlesareused,

Amixtureofsilicasandorganister,fireclay,

anyindicationoftroubleshouldbe

andwatercanalsobeusedwhenavailable.

immediatelycheckedbycarefullyexamining Thismixturecontains85to95percentof

allgearsforexcessivetoothwearorbroken silicasandorganistertherestisfireclay.The

teeth.Anyladleinadoubtfulcondition

exactpercentageofsilicasandorganisterand

shouldnotbeused.

fireclayaredeterminedbyhowworkablea

mixisdesired.Moreclaygivesamore

TYPESOFLADLES

workableandstickymixturebutincreasesthe

amountofshrinkagewhentheliningisdried.

Ladlesusedaboardrepairshipsareoftwo

Withalltypesofrefractorymixes,only

basictypes.Thelippouringladleisshownin enoughwatershouldbeaddedtomakethe

figure186andtheteapot,orbottompouring mixtureworkable.Anexcessofwater,

ladle,isshowninfigure187.Crucibles,such althoughmakingthemixtureeasiertohandle,

asshowninfigure188,areatypeoflip

causesmoreshrinkageandcracksinthe

pouringladle.Teapotcruciblesareshownin liningwhenitisdried.Forlowshrinkageand

figure189.

fewercracks,usesmallamountsofwaterand

clay.

Ladlebowlsareusuallyofweldedorpressed

steelconstruction.Trunnionsonthelarger

Beforerammingaliningintheladle,

ladlesareoftenattachedbybothrivetingand arrangementsmustbemadeforventingthe

weldingformaximumsafety.

liningduringdrying.Thisisdonebydrilling

3/16inchor1/4inchholesthroughthesides

http://maritime.org/doc/foundry/part3.htm

1/49

2/4/2016

FoundryManualPart3

LADLELININGS

andbottomoftheladleshellon3to4inch

centers.Ifthisisnotdone,dryingwilltake

Ladleliningshaveanimportantbearingon

toolong.Numerousinjuriestopersonnelhave

thecleanlinessofcastingsproduced.Ifnot

resultedfromtheuseofimproperlydried

sufficientlyrefractory,liningswillmeltand ladles.Whenmoistureispocketedunder

formslag,whichisdifficulttokeepoutofthe moltenmetal,alargevolumeofwatervapor

casting.Becauseofthehightemperature

israpidlyformedandthemetalisblownout

involved,thisismostapttooccurinpouring oftheladlewithexplosiveforce.Inaddition

steel.Slaggingoftheladleliningislesswith tothis,evenslighttracesofmoistureinladle

grayironandbronze,andnegligiblewith

liningswillcauseporosityandcasting

aluminum.

unsoundness.Themostpracticalwayto

determinewhenaladleisdryistoapplyheat

Iftheliningmaterialhasinsufficientdry

untilsteamflowsfromtheventholes,and

strength,itwillcrumblearoundtheupper

thencontinuetoapplyheatuntilthisflow

partoftheladle.Theupperpartofthelining stopscompletely.

isnotincontactwiththemoltenmetaland

doesnotdevelopstrengthbyfusingor

Withaproperlyventedladleshell,thelining

fluxing.Whentheladleistiltedtoapouring isthenrammedinplace.Itisbesttousea

position,partsofthecrumbledrimwillfall

woodormetalcoretoformtheinsideofthe

intothestreamofmetalenteringthemoldor ladle.Theformcanbemadewithtaperand

intoopenrisers.

allowanceforliningthickness.Afterthe

bottomoftheladleisrammedintoplace,the

formiscenteredwithwedgesandthesidesof

theliningrammed.Aharderandmoredense

liningcanbemadeandthewaterkepttoa

minimumwhen

140

aformisused.Also,thejobisaloteasier

ANYONEWHOPOURSMETALFROMA

thantryingtoramaliningagainstvertical

LADLEWITHADAMPLININGOR

walls.Whenrammingalininginlayers,be

DAMPPATCHCANEXPECTTOFIND

suretoroughenthetopofeachlayerbefore UNPLANNEDHOLESINHISCASTING.

ramminginthenextlayer.Afterthelining

hasbeenrammed,theformisrappedlightly Pouringlipsofladlesareafrequentsourceof

toloosenitandthendrawnfromtheladle.To troublebecausetheyareoftenpatchedand

makedrawingoftheformeasier,andtokeep thenproperdryingofthepatchisoverlooked.

theformfromabsorbingwaterfromthemix, Awetpatchonapouringlipwillputgasin

themetalandcauseblowholesinthecastings.

itshouldbecoveredwithathinlayerof

greaseorwithaluminumfoil.Ifaluminum

foilisused,itispeeledfromtheliningafter Patchingofaladleisbestdonewhenthe

liningiscold.Alladheringslagandmetal

thecorehasbeenremoved.Careshouldbe

exercisedsothataluminumfoildoesnotfold mustberemovedintheareatobepatched.If

possible,undercuttheoldliningtohelphold

andcauseadeepcrackinthelining.The

rammingoftheliningmustbeveryhardand thepatch.Brushloosedirtfromtheoldlining

andwettheliningthoroughly.Patchlarge

uniform.Iftheliningshowsatendencyto

crackintolayerswhentheformiswithdrawn, holeswiththesamemixtureusedforlining.

eachlayerwasnotroughenedenoughbefore Patchsmallholesandcrackswithamixture

thenextwasrammedin.Suchaladlecanbe offourpartscleansandandonepartfireclay.

DRYAPATCHTHESAMEASANEW

dangeroustouse.

LINING.

Thethicknessoftheliningvarieswiththe

metaltobehandledandwiththesizeofthe Infigure190areshownthevariousstepsin

theliningofateapotladle.Part(a)isa

http://maritime.org/doc/foundry/part3.htm

2/49

2/4/2016

FoundryManualPart3

ladle.Forexample,aladleforthepouringof

steelrequiresaheavierliningthanonefor

castiron,bronze,oraluminumbecausesteel,

atthehightemperaturesrequired,attacksthe

liningmaterialmuchmorerapidlythanany

oftheothermetals.

cutawayviewoftheladleshell.Thebottomis

rammed,theformssetinplace,andrefractory

rammedontheside.Manytimes,aheavy

dutyrefractorybrickisplacedinthebottom

ofanyladletotaketheforceofthemolten

metalstreamwhentheladleisfilled.This

reduceserosionoftheladlebottom.Part(b)

Aliningforaladletoholdandpour75

showsthesidespartlyrammedaftertheforms

poundsofsteelwillhaveathicknessofabout areset.Thecompletedliningwithformsstill

1inchonthebottomand1inchonthesides inplaceisshownin(c).Orderofwithdrawing

atthebottomandwilltapertoabout3/4inch theformsisshownin(d).

atthetopoftheladle.Thisthicknessisalso

satisfactoryforanyoftheothermetals.For

Ladlesforsteelarecommonlyusedonlyonce

thelowermeltingpointmetals,themain

perliningbecauseofthefluxingactionofthe

considerationindeterminingthethicknessof metalatthehightemperatures.Inan

liningisproperinsulationinordertoprevent emergency,ifgreatcareisusedinskimming

chillingofthemoltenmetalandtoavoid

slag,ladlesmaybeusedtwiceforsteel,butit

damagetotheladleshellsasaresultof

isnotgoodpractice.Thisdoesnotholdtrue

overheating.

fortheothermetals,however,andtheladles

maybeusedformanyheats.Careshouldbe

Dryingofaneworpatchedliningisan

takentoremoveallmetalandslagaftereach

operationthatcancausealotoftroubleifitis use,butitisimpossibletoremoveallofthe

notdoneproperly.Anewliningorpatch

debris.Therefore,ladlesshouldbeusedfor

shouldbeheatedgentlyatfirsttogetridof

onlyonemetal.Aseparateladleshouldbe

mostofthewaterwithoutblowingaholein usedforeachmetalorthemetalwillbecome

theliningorcrackingitbecauseofsteam

contaminatedandunfitforuse.

pressure.Aboardship,thiscanbestbedone

byfirstdryingtheladleinacoreovenand

POURINGTHEMOLD

thencompletingthedryingwithatorch.The

Theplacingofweightsandclampsonamold

torchshouldbepositioned,withrespectto

isonlyaminoroperationinthemakingofa

theladle,soastoinsurecomplete

castingbutonethatwillproducedefectsifnot

combustionofthegasanddeliveryof

maximumheattothelining.Ifanewliningis properlydone.Weightsareusedtoprevent

theforceofthemoltenmetalfromliftingthe

heatedtoofastatthestart,thewatertravels

copeasitfillsthemold,therebyproducinga

backtotheshellandmakesthatpartofthe

swelledcastingorarunout.Thepositionof

liningweakandsoggy.Aftertheliningor

theweightonthemoldshouldbedetermined

patchisthoroughlydriedslowly,the

temperaturecanbesafelyincreasedtoashigh andtheweightplacedonthemoldgently,

withoutanymovementoftheweightacross

asobtainable.Itisdesirabletomaintaina

newliningatredheatforseveralhoursbefore thetopofthecope.

usingit.Ifaslowlyheatednewliningcracks,

therammingmixturecontainedtoomuch

clayorwater.

141

Anysuchmovementcancausethecopeto

SPEEDOFPOURING

breakorforcesandintothegatingsystemor

openrisers.

Thepouringbasinshouldbefilledquicklyto

preventnonmetallicsandslagfromentering

Clampsservethesamepurposeasweights

themoldcavityandmustbekeptfull.Inorder

andareusedtoclampthecopeanddrag

todothis,theladlestreammustbecontrolled

togetherwhenthecastingispouredinthe

carefully.Oncepouringhasstarted,itmust

http://maritime.org/doc/foundry/part3.htm

3/49

2/4/2016

FoundryManualPart3

flask.Inplacingtheclamps,awoodwedgeis

usuallyusedtotightentheclampdownonthe

flask.Beforeplacingtheclamp,theareanext

totheclampshouldbecleanedofexcesssand

topreventmolddamagewhentheclampis

set.Thewedgeshouldbeplacedbetweenthe

clampandthetopedgeoftheflask,theclamp

broughtupsnug,andthentightenedby

drivingthewedge.Caremustbetakentohit

thewedgeandnottheclamporflask.

continuewithoutinterruptionuntilthemoldis

filled.Oneallowableexceptionistostop

pouringthroughthespruewhenthemetalhas

filled1/3ofatopriser.Theriseristhenfilled

lastwithhotmetaltoimprovefeeding.This

exceptionappliesonlytotoprisers.Withside

risers,themoldmightnotbefullwhenmetal

isseenintheriser.

Slagonthemetalshouldbeskimmed

carefullypriortoandduringpouring.Ifa

steelorironslagistoofluidtobeskimmed

properly,drysilicasandshouldbespread

acrossthesurfaceofthemoltenmetalto

thickentheslag.Drymetalrodsorspecial

metalskimmersshouldbeusedforskimming

orstirringmetal.Woodskimmersorstirrers

shouldneverbeusedbecausethewood

containsmoisturewhichoftenproduces

unsoundnessincastings.

Closecontrolofpouringtemperaturesis

essentialtotheconsistentproductionofgood

castings.Animmersionpyrometerandan

opticalpyrometerarefurnishedfor

temperaturedetermination.Becauseofthe

hightemperatureinvolved,theimmersion

pyrometerisnotusedforironorsteel.The

ChromelAlumelimmersionthermocouples

arelimitedtotemperaturesof2,500F.The

opticalinstrumentisimpracticalfor

nonferrousmetalsbecausetheirpouring

Theuseofapouringbasinandplugtoget

moreuniformpouringisshowninfigure193.

Althoughclampsandweightsareusedforthe Part(a)showsthebasinreadytoreceivethe

samepurpose,clampsaremuchmore

metal.In(b)thebasinispartiallyfilled.When

dependable.Itistooeasytounderestimate

thebasinisproperlyfilled,theplugis

theliftingpowerofthemetalandtousetoo withdrawnasin(c).Theuseofapouring

fewweights.Ontheotherhand,toomany

basinpermitsbettercontrolofthemetal

weightscancrushamold.

enteringthegatingsystem.Anothervariation

ofthismethodistoputathinsheetofthe

Withtheladlethoroughlydried,preheatedto metalbeingpouredoverthesprueopening.It

aredheat,andsecurelyinthebail,molten

willmeltoutwhenthebasinisfilledwithhot

metalfromthefurnaceistappedintoit.

metal.Keepthebasinfullofmetalatall

Fillingtheladletoitsbrimisunwisefromthe times.

standpointofsafetyandfortheproductionof

goodcastings.Fillingtheladletoitsbrim

Whenpouringametalthatformsdross

shouldbedoneonlywhenabsolutely

(especiallyaluminum,aluminumbronze,or

necessary,andthenextremecautionshould magnesium),everyeffortmustbemadeto

beexercisedinhandlingtheladleand

avoidturbulententryofthemetalintothe

pouring.

mold.Itisparticularlyimportantinsuchcases

thatthelipoftheladlebeasclosetothe

Iftheladleisfilledtoabout3/4ofits

pouringbasinaspossible.Thespruemustbe

capacity,metalwillnotflowoverthelipuntil filledquicklyandkeptfullsothatthe

theladleisinclinedtoanangleof

tendencyfordrossandentrappedairtoenter

approximately60fromthehorizontal.This themoldwillbeataminimum.Hereagain

permitsagoodcontrolofthestream,making thepouringbasinandplugcanbeusedto

itpossibletokeeptheladlequitelowand

advantage.Theuseofskimgatesor

thus,keeptheheightoffallofthemetallow. perforatedcoresplacedinthesprueor

Thislessensmolderosion,entrapmentofair, pouringbasin(asshowninfigures194and

formationofoxides,andmetalspills.

195)aidsinremovingdrossfromthemetal

andpreventingitsentranceintothecasting

Figure191showsthepropermethodof

cavity.Agitationofthemoltenmetalwhileit

pouring,whilefigure192showspoorpouring isbeingtransportedtothemoldalsoincreases

technique.Inthegoodpouringtechnique,

drossformationandgasabsorption.

noticethatthelipoftheladleisascloseas

possibletothemold.

POURINGTEMPERATURE

http://maritime.org/doc/foundry/part3.htm

4/49

2/4/2016

FoundryManualPart3

temperaturesaretoolow.

142

Theoperationofanimmersionpyrometerisa toresult.Properpouringtemperaturesfora

simplematter.Theinstrumentsareusuallyof givenmetalvarywiththecastingsize,design,

twotypesaselfcontainedunitortheunitin anddesiredrateofpouring.Forthisreason,

whichtheimmersionunitisconnectedby

thepouringrangesgivenbelowshouldbe

wirestothereadinginstrument.Beforeuse, takenasageneralguideonly:

thepyrometershouldbecheckedtomake

Metal

Pouring

surethattheimmersionpartoftheinstrument

Temperature

isclean.Leadwirepyrometersshouldbe

Range

checkedforanybreaksorlooseconnections Steel

2850F.to2950F.

inthewire.Whentakingareading,the

Grayiron

2300F.to2600F.

immersiontipshouldbesubmergedinthe

Aluminum

1250F.to1400F.

moltenmetaltoadepthofapproximately3

inchesandmovedslowlybackandforthorin Manganesebronze 1875F.to1975F.

acircle.Afterthetemperaturereachesafairly CompositionsG& 2000F.to2200F.

steadyreading,itshouldberecorded.The

M

immersiontipshouldthenbewithdrawnfrom

themelt.Immersionpyrometersshouldbe

Ingeneral,thinwalledcastingsarepouredon

handledwithcareandperiodicinspections

thehighsideoftherangeandthickwalled

madeforproperupkeep.Wheneverpossible, castingsonthelowside.

theinstrumentsshouldbecheckedand

calibratedforgoodoperation.

SUMMARY

Theopticalpyrometeroperatesbymatching

theintensityoflightfromthemoltenmetal

withthatofastandardlightsourcewithinthe

instrument.Exactoperatingproceduresare

availablewiththeinstruments.Generally,the

fieldofvisionwillbeuniform,asshownin

figure196a,whentheinstrumentissetatthe

propertemperature.Iftheinstrumentisset

toohigh,theinnercircleofthefieldwillbe

brighterasin(b).Iftheinnercircleisdarker,

theinstrumentissetattoolowareading.

Thisinstrumentshouldbehandledwithcare

andgivenperiodicchecksandcalibrationsfor

properoperation.

Excessivepouringtemperatures(thatis,

temperaturesabovethoserequiredforthe

properfillingofthemold)resultinexcessive

oxideordrossformation,segregation,rough

anddirtycastingsurface,unnecessarilyhigh

liquidshrinkage,coarsegrainmetalstructure,

andincreaseddangerofcavities,tearsand

porosity.Figure197showstheincreasein

grainsizethatresultedwithincreasedpouring

temperaturesforacopperbasealloy.Notice

thatthehighpouringtemperatureresultedin

http://maritime.org/doc/foundry/part3.htm

Theimportantfactorsinpouringacastingare

summarizedasfollows:

1.Ladleequipmentmustbekeptingood

repair.

2.Allladleliningsmustberammeduniformly

hardandbeoftheproperthickness.

3.Allladlesmustbethoroughlydriedandata

redheatforsometimebeforeusewiththe

highmeltingpointalloys.

4.Ladlesshouldnotbefilledtomorethan3/4

oftheircapacity.

5.Metalshouldbeskimmedfreeofallslagor

drossbeforepouring.

6.Inpouring,theladleshouldbeascloseto

thepouringcuporsprueaspossible.

7.Oncepouringhasstarted,thestreamshould

notbeinterrupted.Asteadyrateofpouring

shouldbeusedandthesprueshouldbekept

fullatalltimes.

5/49

2/4/2016

FoundryManualPart3

averycoarsegrainstructure.

8.Themetalshouldbepouredatthecorrect

temperature,neithertoohighnortoolow.

Ifthepouringtemperaturesaretoolow,

entrappedgasanddross,misruncastings,or

castingswithsurfacelaps(coldshuts)are

likely

143

Figure188.Lippouringcrucibles.

Figure186.Lippouringladle.

Figure189.Teapotcrucibles.

Figure187.Teapotladle.

Figure190.Liningateapotpouringladle.

http://maritime.org/doc/foundry/part3.htm

6/49

2/4/2016

FoundryManualPart3

144

Figure191.Properpouringtechnique.

Figure194.Skimcoreindowngate.

Figure192.Poorpouringtechnique.

Figure195.Skimcoreinpouringbasin.

Figure193.Useofpouringbasinandplug.

Figure196.Pyrometerfieldwhenatcorrect

temperature,toohighasetting,andtoolowa

setting.

145

http://maritime.org/doc/foundry/part3.htm

7/49

2/4/2016

FoundryManualPart3

Figure197.Effectofpouringtemperatureongrainsize.

146

Thispageisblank.

147

ChapterX

CLEANINGCASTINGS

Afterthecastinghassolidified,itshouldbe itisadvisabletopreheatto700F.orhigher.

allowedtocoolinthemolduntilithas

Thedesiredcuttingtemperaturemaybethat

reachedatemperaturewhichwillpermitsafe retainedduringcoolingoritmaybeobtained

handling.Thetimerequiredforthiswillvary byreheatingthecastinginafurnace.

withthemetal,typeofmold,andthesizeand

CastIron.Thegatesandrisersoncastiron

designofthecasting.Asageneralguide,

castingsshouldnotbeshakenoutuntilthey mayberemovedbyflogging,sawing,or

chipping.Theuseofcuttingtorchesisnot

havecooledtoatleastthefollowing

practical.Floggingisthesimplestmethodand

temperatures:

isentirelysatisfactory.Toflog,thegateor

Steel

1200F.

riserisfirstnotchedonallsidestokeepthe

Castiron

1000F.

breakfromleadingintothecastingoranotch

Manganesebronze

1000F.

iscastintothejunctionofriserorgateandthe

CompositionsGandM 1000F.

casting.Thegateorrisershouldbestruck

sharplysothattheblowisgoingawayfrom

Aluminum

500F.

thecasting,ratherthantowardit.Thiswill

Afterthecastingisshakenfromthemold,all helptokeepbreaksfromleadingintothe

adheringsandshouldberemovedwithwire casting,andwillpreventdamagetothe

castingifthehammermissesthegateorriser.

brushesorchippinghammersbeforethe

http://maritime.org/doc/foundry/part3.htm

8/49

2/4/2016

FoundryManualPart3

castingiscleanedbywater,sand,orshot

blastingmethods.Thecastingshouldnot

havealotofexcesssandleftonitbeforeitis

shotblasted.Thesandcontaminatesthemetal

shot.Iftheexcesssandisremovedfromthe

casting,therewillalsobemuchlessdustto

beextractedbythedustarrestingequipment.

Abrasivecutoffwheelscanalsobeused.

Sawingwithahacksaworhandsawis

practicalifthecastingiseasytogrip.Stubs

remainingonthecastingareremovedby

grindingorchipping.

Brass,Bronze,andAluminum.Themost

commonmethodsforremovinggatesand

risersfromnonferrouscastingsarebyband

saw,highspeedhacksaw,abrasivecutoff

wheel,orbyshearing,dependingonthetype

ofequipmentavailableforthispurpose.

REMOVINGGATESANDRISERS

Thefollowingmethodsareusedtoremove

gatesandrisersfromcastings.

Steel.ForGradeBandforlowalloysteel,

flamecuttingwiththeoxyacetylene,

oxyhydrogen,oroxypropanetorchisthebest

methodtouse.Thoroughcleaningofthe

castingisimportanttomakeiteasiertostart

thecutandtoassureauniformcut.Thegates

andrisersshouldbecutaboutthreesixteenths

orthreeeighthsofaninchfromthecasting.

Theremainingstubisremovedbygrindingor

bychippinghammers.

GRINDINGANDFINISHING

Chippingfollowedbygrindingorfinishingis

usedtoremovetheroughmetalremainingon

acastingafterthegatesandrisershavebeen

removed.Manytimes,grindingcanbeusedto

salvageacastingwhichhassmallfinsor

localizedroughspotsonthesurface.

Whenusinganytypeofgrinder,thewheel

shouldbeprotectedandtheoperatorshould

Forstainlesssteelcastings,thegatesand

weargoggles.Glovesareahazardbecause

riserscannotberemovedbyflamecutting.

theymaybecomecaughtinthewheel.The

Theymustberemovedbymechanicalmeans operatorshouldalsoavoidlooseclothing.

suchassawing,chipping,orshearing,with

Beforeagrindingwheelisused,itshouldbe

anabrasivecutoffwheel,orbymeltingoff

strucklightlybutsharplywithahammer

withanelectricarcfromaweldingmachine. handletodeterminewhetherthewheelhasa

Inmeltingoff,caremustbetakentoleavea highpitchedring.Adullthudindicatesthat

stubof1/4to1/2inchonthecastingtoavoid thewheelmaybecrackedandmayflyapart

crackingormetallurgicalchangesinthe

duringuse.DONOTUSEAGRINDER

castingasaresultofthehightemperature

UNLESSYOUAREWEARINGGOGGLES.

wherethecutismade.

Grindersavailableaboardshipareoftwo

Ifcastingsshowatendencytocrackduring

types,standandportable.Theportable

cutting,risersshouldberemovedwhilethe

grindersareairorelectricdriven.Thestand

castingsareatatemperatureofatleast

grinderiselectricandisusedforcastings

400F.Forriserslargerthansixinchesin

whichcanbeeasilymanipulatedbyhandat

diameter,

thefaceofthe

45260505811

148

grinder.Grindingonlargecastingsmustbe heatingwithpossiblecrackingofthecasting,

donewiththeportablegrinders.

unnecessarywearonthegrindingwheel,and

dangertotheoperator.Thispracticeorthe

Manyofthegrindingoperationsdonewith

useofleverstodeliverhighpressuremay

thestandgrinderusebodilycontactwiththe causethewheeltobreakandinjurethe

castingtoprovidetherequiredpressureand operator.

stability.Suchbodilycontactcausesthe

operatortoreceivealotofvibrationduring

WELDING

http://maritime.org/doc/foundry/part3.htm

9/49

2/4/2016

FoundryManualPart3

grinding.Reinforcedleatherapronsareuseful

forreducingthephysicalstrainonthe

operatorduringgrinding.Theyreducethe

vibrationtransmittedtotheoperator.For

grindingoperationsrequiringalongperiodof

time,areinforcedapronorasimilarpieceof

safetyequipmentisanecessity.Theapron

notonlyservesthepurposeofreducing

fatigueintheoperator,butalsomayprevent

seriousinjuryincasethecastingbecomes

snaggedbetweenthetoolrestandthe

grindingwheel.

Manydefectivecastingsmaybesalvagedby

welding.Whenrepairsbyweldingare

required,referenceshouldbemadetothe

"GeneralSpecificationsforShipsofthe

UnitedStatesNavy,"SectionS91,

"Welding,"forgeneralguidance.Theactual

weldingshouldbedonebytrainedpersonnel

andnotattemptedbyunqualifiedpersonnel.

Anotheruseforweldingisintheassemblyof

twoormoresimplecastingsintoa

complicatedpart.Quiteoften,anemergency

castingcanbemostsimplymadebymaking

twoormoresimplecastingsandthenwelding

themtogether.Anotherschemeistomake

somepartsofanassemblybycastingandto

completethestructurebyweldingwrought

metaltothecasting.

Theportablegrindersarenormallyusedfor

lightergrindingoperations,butaboardship

theymustbeusedforheaviergrindingon

largecastings.Smallportablegrindersare

usefulforcleaningupminorsurfacedefects

inacasting.

SUMMARY

Whenusingeithertypeofgrinder,anattempt

shouldalwaysbemadetousetheentireface

ofthegrindingwheel.Movingtheworkback

andforthacrossthefaceofastandgrinder,or

movingaportablegrinderbackandforth

acrossthecasting,willhelpinobtaining

uniformwearofthewheelface.Agrinding

wheelisdifficulttousewhentheface

becomesgroovedbecauseofimproperuse.It

ispoorpracticetosnagacastingbetweenthe

grinderrestandthewheelinanattemptto

applymorepressureandgetfastergrinding.

Thiscauseslocalizedover

Cleaningandgrindingofcastingsisa

relativelysimpleoperationcomparedwiththe

otheroperationsinvolvedinmakingacasting.

Itisasimportantasanyoftheother

operationsbecausecarelessnessinfinishing

mayruinanotherwiseacceptablecasting.The

productionofgoodcastingsdependsonthe

useofcorrecttechniquesinallofthe

operationsandnotinjustafewofthem.

149

ChapterXI

CAUSESANDCURESFORCOMMONCASTINGDEFECTS

Defectsincastingsdonotjusthappen.They whenpouringisinterruptedsothatthemetal

arecausedbyfaultyprocedure(1)inoneor doesnotfusetogetherproperly.

moreoftheoperationsinvolvedinthecasting

process,(2)intheequipmentused,or(3)by Metalpenetrationcausesroughcastings.

Themetalseepsinbetweenthesandgrains

thedesignofthepart.Acastingdefectis

andgivesaroughsurfaceonthecasting.Such

oftencausedbyacombinationoffactors

castingsaredifficulttocleanbecausesand

whichmakesrapidinterpretationand

grainsareheldbylittlefingersofmetal.

correctionofthedefectdifficult.

Castingdefectsarisefrommanycausesand

havemanynames.Oneofthemost

prominentcausesofdefectsdoesnotappear

onanyformallistofdefects,itis

CARELESSNESS.Itsremedyisobvious.

http://maritime.org/doc/foundry/part3.htm

Astickeroccurswhensandstickstothe

pattern,asthepatternisdrawnfromthemold.

Arunout,bleeder,orbreakthroughisa

castinginwhichthemoldhasfailedsothat

themetalrunsoutbeforethecastingissolid.

10/49

2/4/2016

FoundryManualPart3

NAMESOFDEFECTS

Acutorwashiserosionofthesandbythe

streamofmoltenmetal.Itoftenshowsupasa

Thetableinthesummaryofthischapterlists patternaroundthegatesandusuallycauses

themostcommontypesofcastingdefects,

dirtinsomepartofthecasting.

theircauses,andtheircures.Causesand

curesarediscussedinmoredetaillaterinthis Aswellisanenlargedpartofacasting

chapter.Thenamesofcommondefectsare

resultingfrequentlyfromsoftramming.Itis

explainedasfollows.

oftenfoundinconnectionwithmetal

penetration.

Abloworblowholeisasmoothcavity

causedbygasinthemoltenmetal.Apinhole Acrushordropoccurswhenpartofthesand

isatypeofblowthatisunusualbecauseofits moldiscrushedordropsintothemoldcavity.

smallsize.Itiscommontofindasinglelarge Itusuallycausesdirtinsomeotherpartofthe

gashole(orblow)inacasting,butpinholes casting.

usuallyoccuringroups.

Ashiftisamismatchingofcopeanddragor

Ashrinkorshrinkagecavityisarough

ofmoldandcores.

cavitycausedbycontractionofthemolten

Hotcracksorhottearsareusuallyirregular

metal.Itisquiteoftenimpossibletotell

andoxidizedsothatthefractureappearsdark.

whetheraparticularholeinacastingisa

shrinkorablow.Gaswillaggravateashrink Adarkfractureusuallyshowsthatthecrack

ortearoccurredwhilethecastingwasstillhot

defect,andshrinkagewillaggravateagas

andcontracting.Abrightfractureindicates

defect.Thedistinctioncanusuallybemade

thatgaspressuregivesacavitywithsmooth thatthebreakoccurredwhenthecastingwas

cold.

sides(blow)andcontractionorlackof

feedinggivesacavitywithroughsides

Afinisathinprojectionofmetalusually

(shrink).Wheneitherabloworshrink

occurs,itisagoodideatocorrectforbothif foundatcoreprintsorpartinglines.Finsare

commononcastingsandnottooharmfulif

thecausecannotbedeterminedforsure.

small.Iflarge,theycancausearunout,or

Arattail,buckle,andscaballoriginatein smallshrinkagecavitiesatthejunctionofthe

finwiththecasting.

thesamewayanddiffermainlyindegree.

Theyarecausedbyuncontrolledexpansionof

thesand.Iftheconditionisnottoobad,arat Inclusionsordirtarejustwhatthename

implies.Theyareoftenaccompaniedbyother

tailisformed.Thesurfaceofthesand

bucklesupinanirregularlinethatmakesthe defectswhichprovideloosesandinthemold.

castinglookasthougharathasdraggedhis

DESIGN

tailoverit.Ifsandexpansionisevengreater,

thedefectiscalledabuckle.Ifitisstillworse

Themostcommondefectscausedbycasting

sothatmoltenmetalcangetbehindthe

designarehottearsandhotcracks.Ahottear

buckledsand,itisascab.

isusuallyrecognizedbyitsjaggeddiscolored

Amisrunorcoldshutoccurswhenthemold fracture.Itoccurswhenthestresses

doesnotcompletelyfillwithmetal,or

150

inthecastingaregreaterthanthestrengthof

metalshortlyafterthecastinghassolidified.

Ahotcrackoccursbythesamemethod

exceptthatittakesplaceafterthecastinghas

cooledconsiderably.Ahotcrackisalso

recognizedbyadiscoloredfracture,butis

http://maritime.org/doc/foundry/part3.htm

coreprintandadequateventing,andtheuse

ofcorecoatings.

Sharpcornersinthecopeoronprotruding

sectionsmaybecomeweakenedduringthe

drawingofthepatternandcausedrops.This

11/49

2/4/2016

FoundryManualPart3

smooth,ascornparedwiththejagged

fractureofthehottear.

Hottearsandhotcracksbotharecausedby

improperdesignthatdoesnotprovide

adequatefilletsatthejunctionofsectionsor

thatjoinssectionsofdifferentthicknesses

withoutprovidingagradualchangeinsection

sizebytapering.Inadequatefillets(sharp

corners)produceplanesofweaknessatthe

junctionsofthesectionsandcausefailureat

thesepoints.Failurefromimproperjoiningof

heavyandthinsectionsiscausedbytheearly

solidificationofthethinsectionbeforethe

heavysectionhassolidified.Thecontraction

ofthethinsectionproducesastresswhichis

greaterthanthestrengthofthepartially

solidifiedheavysection.Somethinghasto

giveitisusuallytheheavysection.

Thecureforhotcracksandhottearscaused

bypoorcastingdesignistoprovideadequate

filletsatalljunctionsandtousetapered

sectionswheresectionsofdifferent

thicknessesmustbejoined.RefertoChapter

2,"DesigningaCasting."

iscorrectedbytheuseoffillets,increased

draftonthepattern,androundedcorners.

Deeppocketsoroverhangingsectionsinthe

copecausedropsbecauseoftheweightofthe

sand.Ifthesecannotbeovercomeby

changingthepositionofthepatterninthe

flask,reinforcementsmustbeusedtogivethe

sandadequatesupport.Sharpcornersalso

causescabsbecausetheyaggravatethe

conditionsinlargeflatsurfaces,whichcause

scabs.Theuseoffilletsandroundcorners

willminimizetheeffectofsharpcornerson

scabformation.Tominimizecastingdefects

causedbyimproperdesign,maintain(1)the

castingassimpleaspossible,(2)tapered

sectionstopromotedirectionalsolidification,

(3)cornersroundedorfilleted,and(4)plenty

ofdraftonthepattern.

PATTERNEQUIPMENT

Themostcommondefectwhichcanbetraced

topatternequipmentistheshift.Ashiftis

easilyrecognizedbythemismatchingofthe

copeanddragsectionsofthecastingatthe

parting.Thistypeofshiftiscausedbyworn

patternequipment.Looseorworndowelpins

inapatternwillpermitmovementofthe

patternpartsduringmoldingandcauseashift

inthecasting.Ashiftcausedbyadefective

patterncanonlybecorrectedbyrepairingthe

pattern.Goodpatternmaintenancewillgoa

longwaytowardminimizingtheoccurrence

ofshiftsduetowornpatterns.Therecognition

ofthisdefectisespeciallyimportantinrepair

shipworkbecausethegreatmajorityof

castingsaremadewithloosepatterns.

Shrinkagecavities,misruns,coldshuts,

pinholes,blows,drops,scabs,andmetal

penetrationcanalsobecausedbypoor

castingdesignaswellasbyotherfactors.

Shrinkagecavitiesmaybecausedbyusing

filletslargeenoughtoproduceasectionthat

cannotbeproperlyfed,orbyheavysections

thataresolocatedinthecastingthatthey

cannotbeproperlyfed.Thelattercondition

shouldbecorrectedbyredesigningthe

casting,theuseofchillsonheavysections,or

bymakingthepartastwocastingswhichcan Anotherdefectfrequentlycausedbyapoor

beweldedtogether.

patternisthesticker.Astickerisduetoa

poorpatternsurface,whichcausesthesandto

Misrunsandcoldshutsarecausedbyalow sticktothepattern.Poorpatternsurfacecan

pouringtemperatureforthesections

beremediedbysmoothingtheroughspots

involved,inadequategating,orinadequate

andrefinishingthepattern.Astickerwhichis

ventingofthemold.Redesigningfortheuse notnoticedinthemoldingoperationwillhave

oftaperedsectionscanbeusedtoeliminate theappearanceofadropinthecompleted

thesedefects.Pinholescanbecausedby

casting.

nonuniformsectionsize.Ahighpouring

temperaturenecessarytoovercomecoldshuts Otherdefectsthatmaybecausedbypattern

andmisrunsinthinsectionsmayresultin

equipmentincludemisruns,coldshuts,drops,

pinholesintheheaviersections.This

andmetalpenetration.Wornpattern

situationrequiresredesignforuniform

equipment,whichcausessectionstobe

sectionthickness,regatingtopermitlower

thinnerthandesigned,mayproducemisruns

pouringtemperatures,ortheuseofchillson andcoldshutsinthecasting.Adropwillbe

heavysections.

causedbyapatternhavinginsufficientdraft.

Improperdraftwillcausethesandtocrack

http://maritime.org/doc/foundry/part3.htm

12/49

2/4/2016

FoundryManualPart3

Glowsduetodesigncanoftenbetracedto

insufficientmeansfortheescapeofcoregas.

Thismaybeduetoacoreprintwhichistoos

mallorinadequatelyvented.Corrective

measurescallforanincreaseinthesizeofthe

whenthepatternisdrawn,andwillcausea

dropbecauseoftheweakenedconditionof

thesand.Increaseinthedraftofthepatternis

thecureforthisdefect.

151

Metalpenetrationmayoccurbecausean

Metalpenetration(roughsurfaceofthe

irregularpartinglinehaspreventedproper

casting)iscausedbyrammingthemoldtoo

rammingofthesand.Metalpenetrationof

soft,aswhenthereistoolittlespacebetween

thistypecanbecorrectedbyremakingthe

thepatternandtheflask.Alargerflaskwill

patternwithaflatterpartingline.

permitharderrammingbetweenthepattern

andtheflaskandreducepenetrationofthe

FLASKEQUIPMENTANDRIGGING metalbetweenthegrainsofsand.

Crushesandshiftsarethedefectsmost

commonlycausedbydefectiveflask

equipmentandrigging.Adisplacementof

sandinthemoldafterithasbeenmade

causesacrush.Improperlyalignedflask

equipment,warpedorunevenflaskjoints,

badfittingjackets,andbadbottomboardsall

resultinanunequalpressureonthemold,

withtheresultingdisplacementofsandwhich

producesthecrush.Properlymaintained

equipmentistheonlysolutiontocrushesof

thistype.

Shiftsarealsocausedbydefectiveflask

equipment.Wornpinsordefectivebushings

inaflaskallowmovementofthecopeto

occurwhenclosingthemold.Proper

maintenanceofequipmentagainisthe

solutionforthisdefect.

Stickersareoftencausedbyfaultyflask

equipment.Thedefectiveflaskpreventsa

cleanpatterndrawand,asaresult,somesand

stickstothepattern.Thestickershownin

figure198wascausedbyloosepinsand

bushings.

Hottearsandhotcrackscanoftenbetracedto

alackofcollapsibilityinsandwhichhasbeen

excessivelyreinforced.Excessive

reinforcementpreventsthesandfrom

collapsingandobstructsfreecontractionof

thecasting.Rememberthatmetalscontract

whentheysolidifyandthatthemoldmustbe

weakenoughtoallowthecastingtocontract.

Ifthemoldistoostrong,thecastingmay

crack.Reinforcementwhichisplacedtoonear

asprueorriserhasanevengreatereffectthan

thatmentionedabove.Thereinforcementin

thiscaserestrainsthesprueandriserfromany

freemovementwiththecastingandisalmost

suretocausehottearsorhotcracks.Ifhot

tearsorhotcracksoccurnearthepointwhere

risersorspruesareattachedtothecasting,the

reinforcementofthemoldshouldbechecked

asapossiblecause.

GATINGANDRISERING

Shrinkagecavities,inclusions,cuts,and

washesarethedefectsmostfrequentlycaused

bygatingandrisering.Ifariseristoosmall

forthesectiontobefed,therewillnotbe

enoughmetaltofeedthesectionandashrink

Swells,fins,runouts,bleeders,metal

willoccurinthecasting.Thegrossshrink

penetration,hottears,andhotcrackscan

showninfigure199wascausedby

oftenbetracedtofaultyequipmentand

inadequatefeeding.Surfaceshrinkscausedby

rigging.Swellsandfinsarelikelytooccur

improperfeedingareshowninfigures200

whenthemoldweightsarenotheavyenough and201.Improperlocationofgatesandrisers

forthecastingbeingpoured.Becauseofthe fordirectionalsolidificationcanalsoleadto

lightweightofsand,themoltenmetalisable shrinks.Figure202showsaninternalshrink

todisplacethesandandproduceaswellin

whichwasexposedwhentheriserwas

thecasting.Ifthisdisplacementoccursatthe removed.Thisdefectresultedfroman

partinglineoracoreprint,themoltenmetal impropergatingsystemwhichresultedincold

http://maritime.org/doc/foundry/part3.htm

13/49

2/4/2016

FoundryManualPart3

isabletopenetratethejointandafinisthe

result.Swellsandfinscanberemediedby

usingenoughmoldweightsorclampsto

resisttheferrostaticforceofthemolten

metal.Rememberthatiron,steel,brass,and

bronzeareheavierthansand,sothecopewill

tendtofloatoffwhenthesemetalsareused.

Fordoublesecurity,usebothmoldweights

andclamps.

metalintheriser.Whenthecastingwasgated

soastoputhotmetalintheriser(asshownin

figure203),theshrinkdefectwaseliminated.

Connectionswhichfreezeofftooearly

betweenariserandcastingproduceashrink

bythesamemethodasasmallriserbecause

thereisnomoltenmetalavailabletofeedthe

casting.Insuchacase,theconnectionsshould

bemadelarger.Thelocationoftheriserwith

Runoutsandbleedersoccurwhenthemolten respecttothesectionitisfeedingcanalso

metalpenetratesthepartinglineandreaches causeashrinkasshowninfigure204.Inthis

theoutsideofthemold.Abreakoutmay

casting,thelocationoftheingateprevented

occuranywhereonthemoldandmaybe

properfeedingofthecastingeventhoughthe

causedbyinsufficientsandbetweenthe

risercontainedmoltenmetal.

patternandtheflask,orbysoftramming.

Inclusionsarecausedwhenthegatingsystem

Runoutsandbleedersatthepartinglineare

oftencausedbyunevenmatchingofthecope permitsdirt,slag,ordrosstobecarriedinto

thecasting.Themethodofeliminating

anddrag.Thismismatchmaybecausedby

badpinsandbushings,dirtintheflaskjoint,

badbottomboards,orunevenclamping.The

curesareselfevident.

152

inclusionsistoprovideachokingactionat Thelocationofgatesandriserscancausehot

thebaseofthespruebyusingataperedsprue tearsandhotcracks.Ifthegatesandrisers

ofcorrectcrosssectionalarea.Ifitis

restrictthecontractionofthecasting,hottears

impossibletoprovideproperchokingaction andcrackswilloccur.Ifthedefectsarenear

inthegatingsystem,askimcoreshouldbe

theingatesandrisers,thiscauseshouldbe

usedatthebaseofthespruetotrapdirtand investigatedasapossibletroublespot.

slag.Drossinclusionsinafractured

Swells,fins,runouts,andbleedersmayalso

aluminumcastingareshowninfigure205.

becausedbyimpropergating.Riserswhich

Cutsandwashesaredefectswhicharealso

aretoohighcauseanexcessiveferrostatic

causedbythegatingsystem.litheingatesofa forcetoactonthemold,withtheresultthat

moldarelocatedsothatthemetalentering

thesedefectsoccur.Areductionincope

themoldimpingesorstrikesdirectlyoncores heightwillcorrectdefectsofthistype.Run

oramoldsurface,thesandwillbewashed

outsandbleedersmayalsooccurifanypart

awaybytheerodingactionofthestreamof ofthegatingorriseringsystemistoocloseto

moltenmetal.Thedefectwillthenappearon theoutsideofthemold.Insuchasituation,

thecastingasaroughsection,usuallylarger thereisinsufficientsandbetweenthegates,

thanthedesignedsectionthickness.Sand

runners,risers,andflasktopermitproper

inclusionsareusuallyassociatedwithcuts

ramming.Thisresultsinweaksandwhich

andwashesasaresultofthesanderodedand cannotwithstandtheforceofthemolten

carriedtootherpartsofthecastingbythe

metal.Theselectionofflasksofpropersize

streamofmetal.

forthecastingbeingmadeisthemethodof

overcomingthesedefects.

Improperriseringandgatingcanalsocause

blows,scabs,metalpenetration,hottears,hot Misrunsandcoldshutsarecausedbyanypart

cracks,swells,fins,shifts,runouts,bleeders, ofthegatingandriseringsystemwhich

misruns,andcoldshuts.Blowsorgasholes preventsthemoldfromfillingrapidly.Gates

arecausedbyaccumulatedorgeneratedgas orrunnerswhicharetoosmallrestrictthe

http://maritime.org/doc/foundry/part3.htm

14/49

2/4/2016

FoundryManualPart3

orairwhichistrappedbythemetal.Theyare

usuallysmoothwalledroundedcavitiesof

spherical,elongated,orflattenedshape.Ifthe

sprueisnothighenoughtoprovidethe

necessaryferrostaticheattoforcethegasor

airoutofthemold,thegasorairwillbe

trappedandablowwillresult.Anincreasein

theheightofthesprueorbetterventingofthe

moldarecuresforablowofthistype.A

similarblowmayalsooccuriftheriser

connectiontothecastingfreezesofftoosoon

andthemetalheadintheriserisprevented

fromfunctioningproperly.Tocurethis

situation,theconnectionsshouldbemade

larger,placedclosertothecasting,orthe

connectionareashouldbecheckedfor

possiblechillingfromgaggersorimproperly

placedchills.

flowofmoltenmetalandpermitittocool

beforefillingthemold.Improperlylocatedin

gateswillhavethesameresult.Ifthepressure

headofacastingistoolow,themoldwillnot

fillcompletelyandacoldshutwillresult.

Increasingthesizeofthegatingsystemand

relocationofingatesaremethodsusedto

correctdefectsduetothegatingsystem.

Increasingtheheightofthespruewill

produceagreaterpressureheadandhelpto

fillthemoldrapidly.

SAND

Byitself,themoldingsandcancauseallof

thecastingdefectsthatamolderwill

encounter.Thisisoneofthereasonsthatitis

difficulttodeterminethecauseofsome

defects.Blowscanbecausedbysandthatis

toofine,toowet,orbysandthathaslow

permeabilitysothatgascannotescape.Ifthe

sandcontainsclayballsbecauseofimproper

mixing,blowswillbeapttooccurbecausethe

clayballsarehighinmoisture.Ablowcaused

inanaluminumcastingbyhighmoisture

contentofthesandisshowninfigure206.To

remedythissituation,thesandshouldbe

mulledtobreakuptheclayballs.Ifthesand

containstoomanyfines,itwillhavealow

permeabilityandthemoistureorgaswillhave

adifficulttimeflowingthroughthesandaway

fromthecasting.Finesshouldbereducedby

addingnewsands.

Scabscanbecausedbythegatingsystemif

thegatingarrangementcausesanuneven

heatingofthemoldbythemoltenmetal.The

cureforascabfromthiscauseistoregatethe

castingtoobtainauniformdistributionof

metalenteringthemold.

Metalpenetration(roughsurfaceonthe

casting)occursifthesandisexposedtothe

radiantheatofthemoltenmetalfortoolonga

timesothatthebinderisburnedout.An

increaseinthenumberofingatestofillthe

moldmorerapidlywillcorrectthissituation.

Anygatingarrangementswhichcausethe

sandtobedriedoutbyexcessiveradiation

willresultinmetalpenetration.Asprue

whichistoohighwillcauseahighferrostatic

pressuretoactonthemoldsurfacesand

causemetalpenetration.Metalpenetrationof

thistypecanbecuredbydecreasingthe

heightofthecope.

Toohighamoisturecontentinthesand

makesitdifficulttocarrytheexcessive

volumesofwatervaporawayfromthe

casting.Useof

153

thecorrectmoisturecontentsandthecontrol greenstrengthandalowdrystrengthmay

ofmoisturecontentbyroutinetestswithsand alsoleadtocutsandwashes.Theseproperties

testingequipmentisthebestwaytocorrect

arecorrectedbyincreasingthebinder.A

thiscause.Whenthepermeabilityofsandis defectcloselyrelatedtocutsandwashesisthe

low,itisdifficultforevensmallamountsof erosionscab.Itisalsocausedbyamolding

moisturetoescapethroughthesand.The

sandhavingalowhotstrength.A

additionofnewsandsandareductioninclay combinationofotherfactorssuchashigh

contentserveto"openup"asandand

moistureandhardrammingcanalsocausean

increaseitspermeability.

erosionscabsuchasshowninfigure208.

Hardrammingmakestheescapeofmoisture

http://maritime.org/doc/foundry/part3.htm

15/49

2/4/2016

FoundryManualPart3

Dropsareoftencausedbylowgreenstrength.

Suchsanddoesnothavethenecessary

strengthtomaintainitsshape,sopiecesfall

off.Correctivemeasurescallforanincrease

inbinder,increaseinmixingtime,oran

increaseinbothbinderandmixingtime.

Don'toverlookthepossibilityofreinforcinga

weaksectionofamoldwithwires,nails,or

gaggers.

Ascabwillbecausedonacastingwhenthe

sandmoldcannotexpanduniformlywhenit

isheatedbymoltenmetal.Theindividual

sandgrainshavetoexpand.Ifthemolddoes

not"give,"thesurfaceofthemoldhasto

buckleandcauseascab.Anexpansionscab

isshowninfigure207.Themaincauseofa

sandbeingunabletoexpandproperlyisthe

presenceoftoomanyfinesinthesand.These

finescausethesandtopackmuchharderso

thatitsexpansionisrestricted.Additionof

newsandstoproperlybalancethesandgrain

distributionandreducethepercentageof

finesisusedtoobtainbettersandproperties.

Anotherremedyistoaddsomethingtothe

sandtoactasacushion.Cerealflour,wood

flour,andseacoalareallusedforthis

purpose.

Amoldingsandmayyhaveacceptable

thermalexpansionproperties,butalowgreen

strengthmayalsocauseanexpansionscab.

Thecureinthissituationistoincreasethe

claycontent.Ahighdrystrengthandahigh

hotstrengthcanalsocauseexpansionscabs.

Thesandwillbetoorigidbecauseofthehigh

strengths,andproperexpansionofthesand

willberestricted.Areductionintheclayor

binderswhichcausethehighstrengthswill

correctscabsduetothesecauses.Ifascabis

presentonacastingsurfacewheresand

shakeoutandcleaningwasdifficult,highhot

strengthofthesandwasprobablythecause.

Thebindershouldbereduced,cushioning

materialsadded,orfinesreducedbyadding

coarsersand.

difficultwhenhotmetalispouredintothe

mold.Asaresult,theexpandingvapor

loosensthesandgrainsandtheyarewashed

awaybythemoltenmetal.Sandinclusionsin

somepartofacastingarealwaysfoundwhen

expansionscabsoccur.

Ametalpenetrationdefectoccurswhenthe

moltenmetalpenetratesintothesandand

producesanenlarged,roughsurfaceonthe

casting.Ifthemetalpenetrationisnottoo

deep,itmayhavetheappearanceofaswell.

Coarsesand,highpermeability,andlowmold

hardnessaretheprincipalsandproperties

whichcausemetalpenetration.Asandthatis

toocoarsewillhavelargeropeningsbetween

sandgrains(thisaccountsforthehigh

permeability).Becauseoftheopenings,the

moltenmetaldoesnothaveanydifficultyin

penetratingintothesand.Alowmold

hardnessiscausedbysoftrammingofthe

mold.Thisconditionoffersasoftsurfaceto

themoltenmetalwhich,again,caneasily

penetrateintothesand.Tocorrectpenetration

duetocoarsesandandhighpermeability,fine

sandmustbeaddedtothebasesandtogeta

finersanddistributionandreducethe

permeability.Harderandimprovedramming

techniqueisthecureformetalpenetration

causedbylowmoldhardness.Ifpermeability

ofthesandcannotbereduced,amoldwash

maybeusedtoeliminatepenetration.An

exampleofmetalpenetrationisshownin

figure209.Theleftsideofthecastinghasa

goodsurfacetheresultofusingamoldwash

topreventpenetration.

Veiningisshowninfigure209.Itiscaused

whenthesandcracksandthecrackisfilled

bythemoltenmetal.Asandthatcollapses

rapidlyundertheheatofmoltenmetalwill

produceveining.Thiscanbecorrectedbythe

additionofmorebinderorsilicaflourtothe

sand.

Hottearsandhotcracksareusuallycausedby

poorsandproperties.Ahighpercentageof

Theprincipalcauseforcutsandwashesis

finesandahighhotstrengtharetheprincipal

lowhotstrength.Whenthesandisheatedby causes.Ahighpercentageoffinesandgrains

themoltenmetal,itdoesnothavethe

producesamorecloselypackedsand,withthe

necessarystrengthtoresisttheerodingaction resultthatitcannotcontractproperlywhen

oftheflowingmetalandiswashedaway.If thecastingitselfcontractsduringandafter

anincreaseintheamountofbinderdoesnot solidification.Thereductionoffinescanbe

curecutsandwashes,adifferenttypeof

accomplishedbyadditionsofcoarsesand.A

bindermayberequired.Anadditionofsilica highhotstrengthwillalsopreventthesand

http://maritime.org/doc/foundry/part3.htm

16/49

2/4/2016

FoundryManualPart3

flourmayalsobeusedtocorrectlowhot

strength.Alow

fromcontractingorcollapsingproperly.A

reductioninthecontentoffinesisalsoa

correctivemeasure

154

forhotcracksandtearsduetoahighhot

leadstocutsandwashes),andhottears

strength.Areductioninthebindercontent

(whicharecausedbycoreshavinglow

mayberequiredtocorrectahighhot

collapsibility).Figure215showsacasting

strength.Aseverehottearisshowninfigure thatcrackedbecausethecorewastoohard.

210.

Thebakingofcorescanalsocausecasting

Pinholesarecausedbyahighmoisture

defects.Anunderbakedcorewillstillcontain

contentinthesand.Pinholesarerecognized alargeamountofcoreoil,whichmaycausea

bytheirsmallsizeandlocationonthecasting blowwhenthecastingispoured.Suchablow

surfaceasshowninfigure211.Thecurefor canbecuredbybakingthecoreproperlyand

pinholesistousethecorrectamountof

byusingthecorrectamountofbinder.

moisture.Thiscanbedeterminedbyproper

Overbakingofcorescausesdefectsbecauseit

sandtestingandcontrol.Thereareother

minorcausesofpinholes,buthighmoisture resultsinburnedoutbinders.Anoverbaked

corewillhaveaweakandsoftsurface.Cuts,

contentinthesandisbyfarthegreatest

washes,andmetalpenetrationresultfrom

sourceoftrouble.

overbaking.Correctbakingtimeforthetype

Anexpansionofthesandsothatapartofthe ofbinderusedandforthesizeofthecoreis

moldsurfaceisdisplacedinanirregularline themethodforcorrectingthesedefects.

producesarattaildefect.Thesedefectsare

showninfigures212and213.Rattailsdonot Anothercontributingfactortotheoccurrence

ofhottearsmaybeoverreinforcement.This

alwaysoccurasseverelyasshowninthese

isespeciallytrueoflargercoreswhere

twoexamples.Theymaybeasfineas

hairlinesonthesurfaceofacasting.Asand reinforcementisnecessary.Theuseof

ofimpropergrainsizedistribution,highhot reinforcingwiresandrodsonlywhentheyare

strength,andthathasbeenrammedhardare requiredandonlyinamountsnecessaryisthe

themajorcontributingcausestorattails.To waytoovercomehottearsfromover

curethissituation,greatercaremustbetaken reinforcement.

toramthemoldtomakeauniformmold

Coreshiftscauserunouts,bleeders,misruns,

surfaceofcorrecthardness.Thehighhot

coldshuts,andcastingsthataredimensionally

strengthcanbecorrectedbyreducingthe

inaccurate.Ifcoresareimproperlyfittedin

binder.Betterexpansionpropertiescanbe

obtainedbypropergrainsizedistributionin thecoreprint,moltenmetalcanrunin

thesand,orbyaddingcushioningmaterials. betweenthecoreandthemoldandcausea

bleederorrunout.Moltenmetalmayalsofill

theventandcauseablow.Incorrectlypasted

Bucklesaresimilartoexpansionscabsand

rattails.Whenanexpansionscabisremoved cores,coreswithventstooclosetothe

fromthesurfaceofacasting,anindentation surface,andcoreswithinertbackingmaterial

inthecastingsurfacewillberevealed.This tooclosetothesurfaceprovideaneasypath

indentationisabuckleandisshowninfigure forthemoltenmetaltorunoutofthemold.

Correctfittingandpastingofcores,relocation

214.Arattailissometimescalledaminor

buckle.Thecureforabuckleisthesameas ofventstowardthecenterofthecore,and

centrallocationofinertbackingmaterialare

foranexpansionscab.

thestepsrequiredtocorrectrunoutsand

Stickersduetosandarecausedbytoohigha bleedersfromthesecauses.Acoreshiftmay

moisturecontentorbyalowgreenstrength. reducethesectionthicknessofamoldwith

Ahighmoisturecontentwillcausethesand theresultthatthesectionwillnotbe

http://maritime.org/doc/foundry/part3.htm

17/49

2/4/2016

FoundryManualPart3

tosticktothepattern.Areductioninthe

moisturecontentisnecessarytoovercome

stickersfromthiscause.Ifthegreenstrength

islow,thesandwillnothavethenecessary

strengthtopermitdrawingfromapocketor

alongaverticalsurface.Additionsofbinder

orimprovementofthemixingprocedureby

usingamullertoproduceamoreuniform

distributionofbinderarecorrectivemeasures

whichcanbetakentoeliminatestickersof

thistype.Properuseofpartingcompounds

willminimizesticking.

completelyfilled.Amisruncausedbyacore

shiftisshowninfigure216.Tocorrectsucha

defect,itisnecessarytoprovidebetter

supportforthecore,eitherbyabetter

designedcoreprintorbytheuseofchaplets.

MOLDINGPRACTICE

Moldingpractice,alongwiththeother

operationsinvolvedinfoundrywork,

contributestocastingdefectsifnotproperly

done.Blowsarecausedbyacombinationof

hotsandandcoldcoresandflasks.This

combinationcausesmoisturetocondenseand

togivealocalizedconcentrationofmoisture

whichcausesablow.Topreventthistypeof

blow,sandshouldbecoolbeforemakinga

mold.Donotusehotsand.

CORES

Themoldingsandconditionswhich

contributetocastingdefectsalsoapplyto

cores.Amongtheseconditionsarelow

permeability(whichcausesblows),low

bindercontent(which

155

Hardrammingofthesandcancauseblows morethanoneladleofmetalwillberequired

andexpansionscabsasshowninfigure217. topouramold.Insuchacase,pouringwith

Theblowsoccurbecausemoistureis

thesecondladleshouldstartbeforethefirst

preventedfromescapingbytheclosely

ladlehasbeenemptied.Otherwisetheshort

packedsand.Expansionscabsoccurbecause intervalallowedforthestartofpouringfrom

thehardrammedsandexpandsandbuckles. asecondladleissufficienttochillthemetal

Thecastingshowninfigure217wasofsuch inthemoldandtocauseacoldshut,orslag

adesignthathardrammingcouldnotbe

inclusions.

avoided.Inthiscase,woodflouradditions

weremadetoprovideacushionforthehard Slowpouringmayproduceunevenheatingof

rammedsandsothatitwouldexpandwithout amoldsurfacebytheradiantheatfromthe

moltenmetalandcauseascab.Fasterpouring

buckling.

willfillthemoldmorerapidlyandminimize

Figure218showsastickerthatwascaused

theradiantheatingeffectsinthemoldcavity.

byhardramminginthepockets.Improved

Pouringshouldalwaysbeasfastasthesprue

techniquecorrectedthisdefect.

willpermit.ifaslowerorfasterpouringrate

Metalpenetrationcantakeplacebecauseof isindicated,adifferentspruesizeshouldbe

softorunevenramming,whichproducesa

used.

softmoldsurface.Harderandmoreuniform

Pouringfromhighabovethemoldresultsin

rammingisthecureforthistypeofdefect.

anincreasedmetalvelocityinthemolduntil

Softrammingmayalsoresultinswellsor

fins.Thesandissoftatthemoldsurfaceand thesprueisfullandcanleadtowashing

cannotretainitsshapeagainstthepressureof defects.Also,pouringfromaladlewhichis

heldhighabovethemoldpermitseasypickup

themoltenmetal,withtheresultthatthe

ofgasesbythemoltenmetal,aswellas

moldcavityisforcedoutofshapeandthe

agitationinthestreamofmetal.

defectoccurs.

Poormoldingpracticeisprobablythemajor

causeforcrushes.Carelessclosingofamold

http://maritime.org/doc/foundry/part3.htm

MISCELLANEOUS

18/49

2/4/2016

FoundryManualPart3

willresultindisplacedsandorcores,which

inturnresultinthecrush.Ifthebottomboard

isnotproperlybedded,ahighspotofsandon

theboardwillcausepressureagainstthe

moldandadisplacementofsandinthemold

cavity.Thisagainwillcauseacrush.

Incorrectlyplacedchaplets,orchapletsof

incorrectsize,willalsoresultinpressure

beingexertedeitheronthemoldoronthe

coreandcauseacrush.Anydefectdueto

poormoldingpracticecanbecorrectedby

onlyonemethodimprovethemolding

technique.Careandattentiontothevarious

operationsinvolvedcangoalongway

towardminimizingdefectscausedby

moldingpractice.

Theuseofrustyordampchillsandchaplets

almostalwayscausesblows.Theruston

chillsandchapletsreactsreadilywiththe

moltenmetalandalargeamountofgasis

producedinthecastingatthispoint.The

localizedhighgascontentcannotescapeand

ablowisproduced.Asimilarsituationis

broughtaboutbytheuseofdampchillsor

chaplets.Themoistureonthechillsor

chapletsformssteamwhichresultsinablow.

Figure220showsablowwhichwascausedin

analuminumcastingbyusingabadchill.

Carelesshandlingofamoldcanresultin

wastedeffortonthepartofthemolder.Rough

treatmentmayresultindrops.Thecareless

placingofmoldweightscanalsoresultin

POURINGPRACTICE

dropsfromexcesspressureonthecope.A

dropduetoroughhandlingofthemoldis

Thedefectscausedmostoftenbypouring

showninfigure221.Theleftsideofthe

practiceareblows,misruns,coldshuts,and

figureshowsthecopesideofthecasting.The

slagordrossinclusions.Blowsarecausedby roughlumpofmetalwhichfilledthecavity

usinggreenladlesorladleswithwetpatches. bythedisplacedsandcaneasilybeseen.The

Severeblowscausedbyuseofagreenladle rightsideofthefigureshowsthedragsideof

areshowninfigure219.Adefectfromthis

thecastingwiththeholeatthecentercore

causeisremediedbyusingladleswhichare causedbythesandwhichdroppedfromthe

thoroughlydriedafterliningandafterany

cope.Thesandthatdroppedmayfloatin

patchingisdone.Misrunsandcoldshutsare heavymetalcastingsandcauseasecond

causedbypouringwhenthemetalistoocold defectinthecope.

orbyinterruptingthepouringofthemold.

Withimmersionandopticalpyrometersin

Cracksandtearscanbecausedbyshakingout

properoperatingcondition,misrunsand

thecastingtooearly.Thiscauseschillingof

coldshutsduetocoldmetalareminimized.If thecastingandhighstressesareproduced.

eitherofthesedefectsoccurwhen

Thecastingusuallyhasalowstrengthwhen

temperaturereadingsindicatehotmetal,a

hot.Dumpingofhotcastingsintowetsand

defectiveinstrumentisindicated.Sometimes canalsocausecracksandtears.Careless

grindingof

156

thecastingmaycauselocalizedoverheating,

SUMMARY

highstresses,andcracks.SeeChapter10,

"CleaningCastings,"forcorrectgrinding

Whendeterminingthecauseofcasting

techniques.

defects,itmustalwaysbekeptinmindthat

Theuseofmoist,dirty,orrustymeltingtools defectsaremoreoftenduetoacombination

maycausetheintroductionofmoistureinto ofcausesratherthantooneisolatedcause.

themelt.Thissourceofmoisturecanresultin Theuseofproperlykeptrecordsofprevious

castings,goodsandcontrol,anddevelopment

pinholesinthecompletedcasting.Every

ofagoodmoldingprocedurecangofarin

effortshouldbemadetomaintaingood

makingthejobofeliminatingcastingdefects

meltingpracticetopreventtherejectionof

castingbecauseofcarelessnessinthemelting aneasierone.Acharthasbeenincluded

whichindicatesthecausesofthevarious

operation.

defectsandpossiblecuresandshouldbeused

http://maritime.org/doc/foundry/part3.htm

19/49

2/4/2016

FoundryManualPart3

asaconvenientreference.

Thefollowingoversizetablesareonseparatepages.

SummaryofCastingDefectsPage157

SummaryofCastingDefectsPage159

SummaryofCastingDefectsPage161

SummaryofCastingDefectsPage163

SummaryofCastingDefectsPage165

SummaryofCastingDefectsPage167

SummaryofCastingDefectsPage169missing

SummaryofCastingDefectsPage171

173

Figure198.Sticker.(Causedbyloosepinsandbushings)

Figure199.Grossshrink.

(Causedbyinadequatefeeding)

Figure200.Surfaceshrink.(Causedbyimproperfeeding)

http://maritime.org/doc/foundry/part3.htm

20/49

2/4/2016

FoundryManualPart3

Figure201.Surfaceshrink.(Causedbyimproperfeeding.)

(Crackresultedfrombreakingthecastingforexamination.)

174

Figure202.Internalshrink.

(Causedbycoldmetalriserarrangement)

Figure205.Grossinclusions.

(Revealedbyfracturedaluminumcasting)

Figure203.Gatingandriseringthatcorrected

internalshrinkinfigure202.

Figure206.Blow.(Causedbyhighmoisture

content)

http://maritime.org/doc/foundry/part3.htm

21/49

2/4/2016

FoundryManualPart3

Figure207.Expansionscab.(Causedbytoo

manyfinesinthesand)

Figure204.Grossshrink.

(Causedbyimproperlocationofingate.)

175

Figure208.Erosionscabandinclusions.

http://maritime.org/doc/foundry/part3.htm

22/49

2/4/2016

FoundryManualPart3

Figure210.Hottear.(Causedbytoohighhot

strengthofthemoldingsand)

Figure211.Pinholes.(Causedbyhighmoisture

contentofthesand)

Figure209.Metalpenetrationandveining.

(Penetrationcausedbyanopensandveining

causedbymetalpenetrationintocracked

sand)

176

Figure214.Buckle.

http://maritime.org/doc/foundry/part3.htm

23/49

2/4/2016

FoundryManualPart3

Figure215.Crackedcasting.(Causedbyahard

core)

Figure212.Rattails.(Sandlackedgood

expansionproperties)

Figure216.Misrun.(Causedbyacoreshift)

Figure213.Rattails.(CausesameasforFig.

207)

177

http://maritime.org/doc/foundry/part3.htm

24/49

2/4/2016

FoundryManualPart3

Figure218.Sticker.(Causedbyhardramming

inpockets)

Figure217.Blowandexpansionscab.

(Causedbyhardrammingofthesand)

Figure219.Blows.(Causedbymoisturepickupfromadampladle)

178

http://maritime.org/doc/foundry/part3.htm

25/49

2/4/2016

FoundryManualPart3

Figure220.Blow.(Causedbyabadchill)

Figure221.Drop.(Causedbyroughhandlingofthemold)

179

ChapterXII

HEATTREATMENTOFCASTINGS

Themostcommontypesofheattreatment

hardness.Temperatureandtimeoftreatment

appliedtocastingsareasfollows:

dependsontheparticularalloy.

http://maritime.org/doc/foundry/part3.htm

26/49

2/4/2016

FoundryManualPart3

IRONANDSTEELCASTINGS

SOLUTIONHEATTREATMENT

STRESSRELIEFANNEAL

Hightemperaturetreatment.Usuallyfor

aluminumforprolongedperiods,generallyjust

Lowtemperaturetreatmenttoimprove

belowthesolidustemperaturetohomogenize

dimensionalstabilityandincreaseavailable thestructure,followedbyquenchinginwarm

strengthbydecreasingresidualstresses.Can water.Temperatureandtimeoftreatment

beappliedtoallcastings.Requiresslow

dependsontheparticularalloy.Thistreatment

coolinginthefurnace.Usuallyhaslittleeffect producesthesoftestmostductilecondition.Itis

onhardness.

generallyfollowedbyartificialaging.

FULLANNEAL

AGING

Hightemperaturetreatmenttohomogenize

thecaststructure.Improvesmechanical

propertiesormachinability.Requiredforsteel

castingsthatarenotnormalized.Desirablefor

castironwhere"chill"ispresentandcastings

mustbemachined.Requiresslowcoolingin

thefurnace.

Alowtemperaturetreatmentfollowingsolution

heattreatmenttoproducemaximumhardness

andyieldstrength.

TEMPER

Asecondimportantreasonforheattreatmentis

fortheremovalofresidualstressesthatarethe

resultofcastingdesign,solidification,orlackof

freecontractionbecauseofsandproperties.See

Chapter1,"HowMetalsSolidify,"Chapter2,

"DesigningaCasting,"andChapter4,"Sandfor

MoldsandCores."Stressreliefheattreating

involvesheatingfollowedbyslowcooling.

REASONSFORHEATTREATMENT

Thereareseveralreasonsforheattreating

castings.Thepropertiesofsomealloyssuchas

NORMALIZE

heattreatablebronzes,heattreatablealuminum

alloys,varioussteels,andcastironscanbe

Hightemperaturetreatmentforsteel

improvedbyheattreatment.Improvementof

castingsthatarenotannealed.Improves

mechanicalpropertiesisthemainreasonforthe

structureandductility.Requirescoolinginair. heattreatmentofcastings.

Lowtemperaturetreatmentfollowing

normalizingorquenching.Similartostress

reliefannealbutinvolvescoolinginair.

Resultsinsofteningofnormalizedsteelor

ironcastings.

QUENCHING

Fastcoolingofcastingsfromhigh

temperaturesbyimmersingtheminquenching

oil,water,orbrine.Resultsinhardeningof

ironandsteelcastings.Involvesconsiderable

riskofcrackingthecasting.Detailsof

quenchingareoutsidethescopeofthis

manual.Quenchingmustalmostalwaysbe

followedbytempering.

NONFERROUSCASTINGS

STRESSRELIEFANNEAL

Lowtemperaturetreatmenttoimprove

dimensionalstabilityandincreasethe

availablestrengthbydecreasingresidual

stresses.Canbeappliedtoallcastings.May

increasethe

Anotherreasonforheattreatingistomake

ferrouscastingssofterthantheywereintheas

castcondition,sothattheywillbeeasierto

machine.Also,itmaybenecessarytoreduce

thehardnessthatmayhavebeencausedby

chilling,suchasmayoccurwithgrayirons.

Suchheattreatmentiscalledannealing.

Becauseoftheslowcoolinginsand,many

castingswillhaveacoarsegrainstructurethat

doesnotprovidethebestproperties.Thiscanbe

correctedbyaheattreatmentthatwillcausethe

solidifiedmetaltorecrystallizeandformsmaller

grains.Thisrecrystallizationwillproduce

improvedpropertiesinthecasting.

Inmanyalloys,itisdifficulttoproducea

uniformstructureinthecastingbecauseofthe

45260505812

http://maritime.org/doc/foundry/part3.htm

27/49

2/4/2016

FoundryManualPart3

180

alloyitself,orbecauseoftheconditions

Intheheattreatmentofmostalloys,a

controllingsolidificationofthecasting.In

preliminarystepknownassolutiontreatmentis

suchacase,heattreatmentcanbeusedto

necessary.Solutiontreatmentmeanstochange

obtainauniformhomogeneousstructure.

thestateofthealloyintothatofasolidsolution.

Asolidsolutionalloyisoneinwhichthealloys

Allofthechangesinpropertiesobtainedby aresolubleineachotherinthesolidstate.

heattreatingofmetalsoralloysdependonthe Underamicroscope,asolidsolutionalloy

movementoftheatomsofmetal.Whena

wouldhavetheappearanceofapuremetal.It

metaloralloysolidifies,itformsinadefinite wouldbeuniform,withoutanyindicationofthe

patternofatoms.Thispatterndeterminesits presenceofmorethanonemetal.Thiswouldbe

crystalstructure.Heattreatmentoften

incontrasttootheralloysinwhichthepresence

producesarearrangementoftheatomsto

ofmorethanonealloyisshownbytwoormore

producethedesiredproperties.Movementof characteristicphases.

theatomstoaccomplishthisrearrangementis

calleddiffusion.

BRASSANDBRONZE

Diffusiontakesplaceinametaloralloywhen Thereareonlyafewcopperbasealloysthatcan

itisheatedtoacertaincriticaltemperature

beheattreatedtoimprovetheirmechanical

whichpermitstheeasymovementofthe

properties.Formostcopperbasealloysonlya

variousatoms.Thiscriticaltemperatureat

stressreliefannealingtreatmentisusedto

whichrapiddiffusionstartsisknownasthe

removeresidualstresses.

activationtemperature.Belowthis

temperature,diffusiondoestakeplacebutis STRESSRELIEFANNEAL

soslowthatheattreatmentattheselower

temperatureswouldbeimpractical.Theold Tinbronzescanbestressrelievedbyheatingat

atemperaturebetween700F.and800F.forat

fashionedpracticeof"aging"castingsfor

monthsbystoringthematroomtemperature least1hour.Thecastingsarethencooledinair

fromthistemperature.Whereextreme

isanexampleofalowtemperatureheat

dimensionalstabilityisrequired,thecasting

treatmentwhichrequiresalongtime,but

whichcanbespeededuptoamatterofseveral shouldberoughmachinedbeforestress

relieving.

hoursbyproperheatingofthecasting.

Asimpleexampleofdiffusionandtheeffect

oftemperaturecanbeshownwithwateranda

dye.Ifthewaterisfrozenintoiceandadrop

ofdyeplacedonitssurface,thedyewill

maintainitsdropshapeandpossiblypenetrate

averyshortdistanceintotheice.Withthe

applicationofheat,theicewillreachits

meltingpoint.Asitmelts,thedyecanbeseen

movingthroughthewaterandtintingit.This

movementofthedyeisdiffusion.Themelting

temperatureoftheice(whichresultedin

water)istheactivationtemperature.

Theprocessbywhichtheatomsdiffuseto

producesmallergrainsisknownas

recrystallization.Theformationofthenew

crystaltakesplaceatnucleiwhichmaybe

centersofhighconcentrationofaparticular

element,impuritiesinthemetal,idealatom

http://maritime.org/doc/foundry/part3.htm

Manganesebronzecanbestressrelievedby

heatinginatemperaturerangeof600800F.(1

hourforeachinchofcastingthickness)andair

orfurnacecooling.

Copperbasecastingsingeneralcanbestress

relievedbyheatingat700F.to800F.(one

hourforeachinchofcastingthickness)andthen

cooledinair.

SOFTENINGANDHARDENING

Certainaluminumbronzealloyscanbeheat

treatedtoobtainhigherstrengthandhardness.

Thisheattreatmentconsistsofsofteningthe

alloybyasolutionheattreatment,followedby

anagingtreatmentthathardensittothedesired

strength.Classes2,3,and4aluminumbronze

alloysfallintothisgroup.Theexactheat

treatingcycleisdeterminedbythecomposition

28/49

2/4/2016

FoundryManualPart3

arrangements,orevencentersofhighstressin ofthealloyandthepropertiesdesired.Castings

thecasting.Whatevertheircause,theyserve shouldbeheatedtoatemperaturebetween

thesamepurposeasthenucleidescribedin

1,600F.and1,650F.,waterquenched,and

Chapter1,"HowMetalsSolidify."Theyactas agedbetween1,000F.and1,150F.Agood

centersofcrystalgrowth.Theonlydifference generalruleforholdingtimeattheheattreating

betweenrecrystallizationandsolidification,so temperatureistoholdfor1hourforeachinch

farascrystalgrowthisconcerned,isthat

ofsectionthickness.

duringsolidificationtheatomsformthe

crystalsfromaliquidstateandinre

crystallization,thenewcrystalsareformedby

thediffusionoftheatomsthroughthesolid

metal.

181

GENERALHEATTREATMENTS

ALUMINUM

Aluminumalloysinclasses1,3,4,7,and8can

beheattreated.Theheattreatmentinvolvesa

softeningofthealloysbyasolutionheat

Aluminumalloysarenotusuallyheattreated treatmentfollowedbyquenchinginwarmwater

forremovalofcastingstresses.Whenitis

followedbyanappropriateagingtreatmentto

desirabletoreducetheresidualstressesinan hardenit.

intricatecastingsoastomakeitstronger,less

susceptibletocracking,ormorestable

Exactinformationonheattreatingprocedures

dimensionally,heatthecastingtoabout

shouldbeobtainedfromtheBureauofShips.

600F.,holditfromtwotosevenhours,and

thenaircool.(T2).Additionaldataisgiven

Sometypicalheattreatmentsofaluminum

under"GeneralHeatTreatments."

castingalloysareasfollows:

STRESSRELIEFANNEAL

GENERALHEATTREATMENTOFALUMINUMALLOYS

AlloyType Condition

SolutionHeatTreatment

a

Desired Timeat Temp.b Quenching

Temp.

Media

F.

hours

Aluminum T2

(Notheattreatableandseldom

Silicon

used)

Aluminum T4

12

960

Boiling

Copper

water

(orAl

T6

12

960

Ditto

CuSi)

Aging

Annealing

Time, Temp.b Time, Temp.b

hours F.

hours F.

2to4 600

3to5 310

Aluminum T4

Magnesium

Aluminum T5

Magnesium T6

Silicon

12

810

Ditto

12

980

3to5 310

7to9 440

T7

12

980

Boiling

water

Ditto

7to9 440

http://maritime.org/doc/foundry/part3.htm

29/49

2/4/2016

FoundryManualPart3

aT2Annealed.

T4Solutionheattreatedformaximumsoftnessandductility.

T5Stressrelieved.

T6Solutionheattreatedandagedformaximumstrengthandhardness.

T7Solutionheattreatedandoveragedformaximumdimensionalstabilitycombinedwithgood

strengthandhardness.

bFurnacesmustgenerallybeaircirculatingtypeandcontrolledto3F.

ClassAcastingsandClassBcastingsunder

IRONANDSTEEL

SpecificationMILS15083shallbeannealedor

heattreatedinaccordancewiththespecification

STEEL

requirements.Heattreatmentshouldbe

accomplishedwithadequateandcalibrated

Caststeelhasacoarsemicrostructure.

pyrometricequipment.Castingsshouldbe

Castingsplacedinserviceinthiscondition

chargedsothatthelightercastingswillbe

mayfailbecauseofthebrittlenatureofthe

shieldedfromtheheatofthefurnacebythe

material.Therefore,steelcastingsmustbe

heaviercastings,placingthecastinglooselyand,

heattreatedtorefinethegrainsby

ifpossible,afewinchesoffthefloorofthe

recrystallization,tohomogenizethestructure, furnace,sothatthehotgaseswillhavefree

andtoimprovethephysicalproperties.Two circulationthroughoutthecharge.Large

typesofheattreatmentare(1)annealing,and castingsmustbeproperlysupportedunder

(2)normalizingfollowedbytempering.Steel heavysectionstominimizedistortion.

castingsthathavebeenweldedorworked

shouldbestressrelievedbeforeuse.The

detailsofthesetreatmentsareasfollows:

182

Annealing.NavyspecificationsforClassB BendTest.Abendtestmaybeusedasashop

andlowalloysteelcastingsrequirethatthe

testforcheckingthequalityofasteelandthe

castingsshallbeplacedinafurnace,the

effectivenessofheattreatment.Bendtest

temperatureofwhichisnotmorethan500F. specimensaremachinedtoabout6incheslong

abovethatofthecastingsandshallbe

witharectangularcrosssectionof1by1/2

uniformlyheatedatacontrolledratetoa

inchesandwiththelongedgesroundedtoa

temperatureof1600F.orabove.Thecastings radiusofnotover1/16inch.

shallbeheldattheannealingtemperaturefor

aperiodofatleast1hourperinchofthickest Arectangularbarwhichhasbeenadequately

crosssection,butinnocaselessthan1hour. gatedandriseredtoensuresoundnessandwhich

issuitableformachiningtotheabove

Thetemperaturedifferencebetweenthe

hottestandcoldestpartofthechargeduring dimensionsshouldbepouredfromeachheatof

steel.Thebendtestbarshouldbegiventhe

theholdingperiodshallnotbegreaterthan

75F.Thecastingsshallbecooledslowlyin sameheattreatmentasthatusedforthecastings

andthenmachined.

thefurnacefromtheheattreating

temperature.Whenthetemperatureofthe

hottestpartofthechargehasfallento500F. Ifthesteelhasbeenproperlymadeandheat

abovetheambienttemperature,thecastings treated,thespecimenshouldwithstandcold

mayberemovedfromthefurnaceandcooled bendingarounda1inchdiameterpinthrough

instillair.Wheretimeisafactor,thecooling anangleofapproximately120F.withoutc

rateofsmallcastings,suchaspipefittingsor racking.Thisisanindicationofsatisfactory

ductility.

thosewheredimensionalstabilityisnota

controllingfactor,maybeacceleratedwhen

CASTIRON

thetemperatureofthecastinghasfallento