Documente Academic

Documente Profesional

Documente Cultură

Appendix C - Welding Specification For Fabrication of Piping Systems

Încărcat de

ibnu.asad984Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Appendix C - Welding Specification For Fabrication of Piping Systems

Încărcat de

ibnu.asad984Drepturi de autor:

Formate disponibile

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 1 of 33

WELDING SPECIFICATION

FOR

FABRICATION OF PIPING SYSTEM

abc

Mott MacDonald Consultants (India) Pvt. Ltd.

Hindustan Petroleum Corporation Ltd

Kothari House, CTS No. 185

Viskaha Dispatch Station

Off Andheri - Kurla Road

VR-ATP Area, Naval Base Post

Andheri (East)

Visakhapatnam - 530 014

Mumbai 400 059

Andhra Pradesh

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 2 of 33

WELDING SPECIFICATION

FOR

FABRICATION OF PIPING SYSTEM

Client

HINDUSTAN PETROLEUM CORPORATION LTD.

MMCI Project No.

254625

Issue and Revision Record:

Rev

A

Date

08/05/09

Originator

HBS

Checked

SGN/JP

Approved

SNA

Description

Issued for Approval

Group Disclaimer

"This document has been prepared for the titled project or named part thereof and should not be relied upon or

used for any other project without an independent check being carried out as to its suitability and prior written

authority of Mott MacDonald being obtained. Mott MacDonald accepts no responsibility or liability for the

consequences of this document being used for a purpose other than the purposes for which it was commissioned.

Any person using or relying on the document for such other purpose agrees, and will by such use or reliance be

taken to confirm his agreement, to indemnify Mott MacDonald for all loss or damage resulting therefrom. Mott

MacDonald accepts no responsibility or liability for this document to any party other than the person by whom it

was commissioned."

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 3 of 33

List of Content

Page No

General

Applicable Codes & Standards

Base Metal

Welding Consumables

Shielding & Purging Gas

Equipments & Accessories

Welding Process

Edge Preparation

Alignment & Spacing

10

Weather Conditions

11

Welding Technique

12

Heat Treatment

13

Cleaning Of The Weld Joint

11

14

Inspection And Testing

11

15

Repairs Of Welds

14

16

Documents To Be Submitted By Contractor (4 Copies Each)

14

17

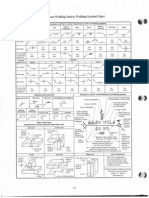

Welding Specification Charts

15

18

Annexure 1 : Suggested Formats

21

19.

Annexure 2 : Welding Sketches

27

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 4 of 33

Abbreviations

ASME

: American Society of Mechanical Engineers

Company

: Mott MacDonald Consultants(I) Pvt. Ltd.

ASNT

: American Society for Non-Destructive Testing

IQI

: Image Quality Indicator

SWG

: Standard Wire Gauge

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 5 of 33

General

This specification shall be followed for the fabrication of all types of welded piping joints of

piping system within the battery limits of the plant.

The following pipe joints shall include the following:

a) All pipe joints, longitudinal butt welds, circumferential butt welds, groove welds and fillet

welds.

b) Attachments for forging, flanges and other supports of pipes.

c) Welded manifold headers and other sub-assemblies.

d) Welded branch connections with or without reinforcing pads.

e) Joints in welded /fabricated piping components.

f) The attachments of smaller connections for vents, drain drips and other instrument tapping.

Any approval granted by the Company Site Representative or Owner/Companys inspectors shall

not relieve the contractor of his responsibilities and guarantee.

This specification shall not be applicable for welding of pipe lines for transportation of liquid

petroleum and other similar products.

Applicable Codes & Standards

All welding work, equipments for welding, heat treatment, other auxiliary functions and the

welding personnel shall meet the requirements of the latest editions of the following accepted

standards and procedures unless otherwise specified in the welding specification Chart and the

Technical Notes attached thereof. In the case of conflicting requirements, the requirements

mentioned in Welding Specification Chart/Technical Notes shall be applicable.

i)

ASME Code for Pressure Piping

ii)

ASME Boiler & Pressure Vessel Code, Sec II Part C, Material Specifications: Welding

Rods, Electrodes and Filler metals. ASME Sec II Part C (2007)

iii)

ASME Boiler & Pressure Vessel Code Section V, Non destructive examination.- ASME

Section V

iv)

ASME Boiler & Pressure Vessel Code Section VIII, Rules for construction of Pressure

Vessels.- ASME Section VIII

v)

ASME Boiler & Pressure Vessel Code Section IX, Welding and Brazing Qualification.ASME Section IX (2008)

vi)

The Indian Boiler Regulations

ASME B31.3 (2006)

I.B.R. (2000)

Note : All codes/standards mentioned above shall be the latest at the time of awarding of contract.

In the event of any differences due to additional requirements mentioned in this specification, over

and above those obligatory as per codes, this specification shall be binding.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 6 of 33

Base Metal

3.1

In general, use of carbon steel is envisaged. The details of the material specifications are given in

the Welding Specification Chart.

3.2

The Contractor shall provide the manufacturers test certificates for every heat of the materials

supplied by him.

Welding Consumables

4.1

The contractor shall provide, at his own expense, all the welding consumables necessary for the

execution of the job such as electrodes, filler wires, argon etc. and these should bear the approval

of the Company Site Representative.

4.2

The welding electrodes and filler wires supplied by the contractor shall conform to the class

specified in the Welding Specification Chart. The material shall be of the make approved by the

Company Site Representative.

4.3

Electrode qualification test records should be submitted in accordance with Suggested Format-A

(Annexure 1) in the respected of the electrodes tested by the contractor, for obtaining the approval

of the Company Site Representative.

4.4

The contractor shall submit batch test certificates, from the electrode manufactures, giving details

of physical and chemical tests carried out by them, for each batch of electrodes to be used.

4.5

All electrodes shall be purchased in sealed containers and stored properly to prevent deterioration.

The electrodes removed from the containers shall be kept in holding ovens at temperature. Out of

the oven time of electrodes, before they are consumed, shall not exceed the limits recommended

by the electrode manufacturer. The electrodes shall be handled with care to avoid any damage to

the flux covering.

4.6

All low hydrogen type of electrodes shall be rebaked at 350C for 1 hour minimum and stored in

ovens kept at 80-100C before use. Recommendation of the electrode manufacturer shall be

followed if available.

4.7

The electrodes, filler wires and flux used shall be free from rust, oil, grease, earth and other

foreign matter which affect the quality of welding.

4.8 Tungsten electrodes used shall conform to ASME Sec.II C SFA 5.12 specification.

5

Shielding & Purging Gas

5.1

Argon gas used in GTA welding for shielding purposes shall be 99.995% pure. The purity of the

gas shall be certified by the manufacturer. The rate of flow for shielding purposes shall be

established through produced qualification tests. Normally this rate may be 12-20 CFH.

5.2

Argon gas with a purity level of 99.995% shall be used for purging.

5.3

When GTAW process alone or a combination of GTAW and SMAW processes is recommended

for the production of a particular joint, the purging shall be maintained during the root pass and

for the first filling pass to minimize oxidation on the inner side of the pipe, unless otherwise

specified in Welding Specification Chart.

5.4

Initial purging shall be maintained for sufficient period of time so that at least 4-5 times the

volume between the dams is displaced, in order to completely remove the entrapped air. In no case

should the initial purging period be less than 10minutes. High gas pressure should be avoided.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 7 of 33

5.5

After initial purging, the flow of the backing gas should be reduced to a point where only a slight

positive pressure prevails. For systems, which have a volume (up to 1/2 cubic foot) to be purged, a

gas flow rate of 6-CFH is usually adequate. Systems of larger volume may require higher flow

rates and these should be established during procedure qualification tests.

5.6

Gas backing (purging) is not required for socket type of welded joints.

5.7

Dams, used for conserving inert gas during purging, shall be removed after completion of the

welding, and shall be accounted for. Wherever, removal of dams is not possible after welding, use

of water-soluble dams should be made.

Equipments & Accessories

6.1

The Contractor should have the arrangement of sufficient number of welding and cutting

equipments, auxiliaries, and accessories of sufficient capacities so as to meet the target / schedule.

6.2

All the equipments for performing the heat treatment, including transformers, thermocouples,

pyro-meters, automatic temperature recorders (with suitable calibration arrangement etc.) shall be

provided by the Contractor at his own expenses and these should bear the approval of the

Company Site Representative.

6.3

Contractor shall make necessary arrangements at his own expense, for providing the radiographic

equipments, radiographic films, processing equipment all other darkroom facilities and all the

equipments/materials required for carrying out the liquid-penetrant / magnetic particle

test/ultrasonic testing for satisfactory and timely completion of the job.

6.4

Redoing of any work, necessitated by faulty equipments or operation used by the Contractor will

be done at his own expense.

Welding Process

7.1

Welding of various materials under this specification shall be carried out using one or more of the

following processes with the approval of the Company Site Representative.

-

Shielded Metal Arc Welding Process (SMAW).

Gas Tungsten Arc Welding Process (GTAW).

7.2

The welding processes to be employed are given in the Welding Specification Chart. Any

deviation desired by the Contractor shall be obtained through the express consent of the Company

Site Representative.

7.3

Automatic and semi-automatic welding processes shall be employed only with the express

approval of the Company Site Representative. The welding procedure adopted and consumables

used shall be specifically approved.

7.4

A combination of different welding processes could be employed for a particular joint only after

duly qualifying the welding procedure to be adopted and obtaining the approval of Company Site

Representative.

Edge Preparation

8.1 General

The edges to be welded shall be prepared to meet the joint design requirements by any of the

following methods recommended:

(a)

Carbon Steel

Gas cutting, machining or grinding methods shall be used. After gas cutting, oxides shall be

removed by chipping or grinding.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

8.2

Rev: A

abc

Page 8 of 33

Cleaning

(a)

The ends to be welded shall be properly cleaned to remove paint, oil, grease, rust, oxides,

sand, earth and other foreign matter. The ends shall be completely dry before the welding

commences.

(b)

On completion of each run, craters, welding irregularities, slag etc., shall be removed by

grinding and chiselling.

Alignment & Spacing

9.1

Components to be welded shall be aligned and spaced as per the requirements laid down in

applicable code. Special care must be taken to ensure proper fitting and alignment when the

welding is performed by GTAW process. Flame heating for adjustment and correction of ends is

not permitted unless specifically approved by the Company Site Representative.

9.2

A wire spacer of suitable diameter may be used for maintaining the weld root opening while

tacking, but it must be removed after tack welding and before laying the root bead.

9.3

For pipes of wall thickness 5 mm and above, the ends to be welded shall be secured in position

with the aid of couplers, yokes and C clamps, to maintain perfect alignment. Yokes shall be

detached after the completion of weld, without causing any surface irregularity. Any irregularity

caused on the pipe surface must be suitably repaired to the satisfaction of the Company Site

Representative.

9.4

Tack welds, for maintaining the alignment, of pipe joints shall be made only by qualified welders

using approved WPS. Since the tack welds become part of the final weldment they shall be

executed carefully and shall be free from defects. Defective tack welds must be removed prior to

the actual welding of the joints.

9.5

Tacks should be equally spaced. Minimum number of tacks shall be:

3 tacks

4 tacks

6 tacks

for 2 1/2and smaller dia. Pipes.

for 3 to 12 dia. Pipes.

for 14 and larger dia. Pipes.

9.6

Welding shall commence only after approval of fit-up by the Company Site Representative.

10

Weather Conditions

10.1 The part being welded and the welding personnel should be adequately protected from rain and

strong winds. In the absence of such a protection no welding shall be carried out.

10.2 During field welding using GTAW process, particular care shall be exercised to prevent any air

current affecting the welding process.

11

Welding Technique

11.1 Root Pass

a) Root pass shall be made with electrodes/filler wires recommended in the welding specification

chart. For fillet welding, root welding shall be done with consumables recommended for filler

passes. The preferred size of the electrodes is 2.5 mm diameter (12 SWG) but in any case not

greater than 3.25 mm (10 SWG).

b) Upward technique shall be adopted for welding pipe held fixed with its axis horizontal.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 9 of 33

c) The root pass of butt joints should be executed so as to achieve full penetration with complete

fusion of the root edges. Weld projection inside the pipe shall be as per applicable code. It

shall be limited 3mm gap. When the applicable code does not place any restriction.

d) Any deviation desired from the recommended welding technique and electrodes indicated in

the welding specification chart should be adopted only after obtaining explicit approval of the

Company Site Representative.

e) Welding shall be uninterrupted.

f) While the welding is in progress care should be taken to avoid any kind of movement of the

components, shocks, vibrations and stresses to prevent occurrence of weld cracks.

g) Peening shall not be used.

11.2 Joint Completion

a) Joint shall be completed using the class of electrodes, recommended in the Welding

Specification Chart.

b) Two weld beads shall not be started at the same point in different layers.

c) Butt joints shall be completed with a cover layer that would affect good fusion at the joint

edges and a gradual notch free surface.

d) Each weld joint shall have a workmanship like finish. Weld identification work shall be

stamped clearly at each joint, just adjacent to the weld. Metal stamping shall not be used on

thin pipe having wall thickness less than 3.5mm. Suitable paint shall be used on thin wall

pipes for identification.

e) Rust preventive/protective painting shall be done after the weld joint has been approved.

11.3 Dissimilar Welds

Where welds are to be produced between carbon steels and alloy steels, preheat and post weld heat

treatment requirements shall be those specified for corresponding alloy steels and filler

wire/electrodes shall correspond to ER 70 S-G or AWS E-7016/7018 type. For welds between two

dissimilar Cr-Mo low alloy steels, preheat and post weld heat treatments shall be those specified

for higher alloy steel and electrodes used shall correspond to those specified for steel of lower

alloy content. For carbon steel welds, use of filler wire/electrodes E/ER-309/E-310/E NiCr Fe-3

shall be made. The welding procedure, electrodes/filler wires to be used shall be approved by the

Company Site Representative.

12

Heat Treatment

12.1 Preheating

a) No welding shall be performed without preheating the joint to 10C (50F) when the ambient

temperature is below 10C

b) Preheating requirements for the various materials shall be as per the Welding Specification

chart attached.

c) Preheating shall be performed using resistance or induction heating methods. Preheating by

gas burners, utilizing oxy-acetylene or oxy-propane gas mixtures, with neutral flame may also

be carried when permitted by the Company Site Representative.

d) Preheating shall extend uniformly to at least three times the thickness of the joint, but not less

than 50 mm, on both sides of the weld.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 10 of 33

e) Preheating temperature shall be maintained over the whole length of the joint during welding.

Temperature recorders shall be provided by the Contractor to record the temperature.

12.2 Post Heating

In case of alloy steel materials such as Cr-Mo steels, if the post weld heat treatment is not

performed immediately after welding, the weld joint and adjacent portion of pipe, at least 50 mm

on either side of weld, shall be uniformly heated to 300C. This temperature shall be maintained

for half an hour minimum, and then wrapped in asbestos or insulation before allowing it to cool to

room temperature. If the Post Heating temperature specified in the welding specification Charts

exceeds 300C, the same shall be followed. Similarly, if the welding specification chart specifies

post-heat time, the same shall be carried out later on.

12.3 Post Weld Heat Treatment

a) Post weld heat treatment, wherever required for joints between pipes, pipes and fittings, pipe

body and supports shall be carried out as per the welding specification chart, applicable codes

standards and the instructions of the Company Site Representative.

b) The Contractor shall submit for the approval of the Company Site Representative, well before

carrying out actual heat treatment, the details of the post weld heat treatment procedure as per

Suggested Format-B (Annexure 1), that he proposes to adopt for each of the

materials/assembly/part involved.

c) Post weld heat treatment shall be done in a furnace or by using an electric resistance or

induction-heating equipment, as decided by the Company Site Representative.

d) While carrying out local post weld heat treatment, technique of application of heat must

ensure uniform temperature attainment at all points of portion being heat-treated. Care shall be

taken to ensure that width of heated band over which specified post weld heat treatment

temperature attained is at least that specified in the relevant applicable standards/codes.

e) Throughout the cycle of heat treatment, the portion outside the heated band shall be suitably

wrapped under insulation so as to avoid any harmful temperature gradient at the exposed

surface of pipe. For this purpose temperature at the exposed surface should not be allowed to

exceed 50% of the peak temperature.

f) The temperature attained by the portion under heat treatment shall be recorded by means of

thermocouple pyrometers. Adequate number of thermocouples should be attached to the pipe

directly at equally spaced location along the periphery of the pipe joint. The minimum number

of thermocouples attached per joint shall be 1 up to 6 dia., 2 up to 10 dia. and 3 for 12 dia.

and above. However, the Company Site Representative can increase the required number of

thermocouples to be attached if found necessary.

g) Automatic temperature recorders, which have been suitably calibrated, should be employed

for measuring & recording the temp. The time-temp graph shall be submitted to Company Site

Representative immediately on completion of S.R. The calibration chart of each recorder

should be submitted to Company Site Representative prior to starting the heat treatment

operations and his approval should be obtained.

h) Manufacturers test certificate shall be submitted for the thermocouple materials.

i)

Immediately on completion of the Heat Treatment, the Post Weld heat Treatment

chart/records along with the hardness test results on the weld points, wherever required as per

the Welding Specification Chart, shall be submitted to Company Site Representative for his

approval.

j)

Each joint shall bear an identification number, which shall be maintained in the piping sketch

to be prepared by the contractor. The joint identification number should appear on the

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 11 of 33

corresponding post weld heat treatment charts. The chart containing the identification

numbers and piping sketch shall be submitted to the Company Site Representative in suitable

folders.

13

Cleaning Of The Weld Joint

All weld joints shall be free from adherent weld spatters slag, sward, dirt or foreign matter. This

can be achieved by brushing.

14

Inspection And Testing

14.1 General

a)

The Owner/Companys inspector shall have free access to all concerned areas, where the

actual work is being performed. The contractor shall also accord the Owners Inspector all

means and facilities necessary to carry out inspection.

b)

The Owner/Company is entitled to depute his own inspector to the shop or field where

prefabrication and erection of pipe lines is in progress for (but not limited to) the following

objectives:

i)

To check the conformance to relevant standards and suitability of various welding

equipments and the welding performance.

ii) To witness the welding procedure qualification.

iii) To witness the welder performance qualification.

iv) To check whether shop/field welding being executed is in conformity with the relevant

specifications and codes of practice followed in piping construction.

c)

Contractor shall intimate sufficiently in advance the commencement of qualification tests,

welding works and acceptance tests, to enable the Owner/Companys inspector to be present

to supervise them.

14.2 Welding Procedure Qualification

Welding procedure qualification shall be carried out in accordance with the relevant requirements

of ASME Sec. IX latest edition or other applicable codes and job requirements. The contractor

shall submit the welding procedure specification in format as per QW-482, ASME Section IX

(latest edition) immediately after the receipt of the order. Owner/Companys inspector will review,

check and approved the welding procedure submitted and shall release the procedure for

qualification tests. The procedure qualification test shall be carried by the Contractor at his own

expense. A complete set of test results in the format as per QW-483, ASME Section IX (latest

edition) shall be submitted to the Owner/Companys inspector for his approval immediately after

completing the procedure qualification test at least 2 weeks before the commencement of actual

work. Standard test as specified in the code shall be carried out in all cases. In addition to these

tests, other tests like macro/micro examination, hardness tests, dye penetrant examination, charpy

V notch, Corrosion tests, impact tests etc. shall be carried out on specimens depending upon the

type of base material, operating conditions and requirements laid down in the detailed drawings

and specifications. It shall be the responsibility of the contractor to carry out all tests required to

the satisfaction of the Owner/Companys inspector.

14.3 Welders Qualification

a) Welders shall be qualified in accordance with the ASME Section-IX or other applicable

codes. The Owner/Companys inspector shall witness the test and certify the qualification of

each welder separately. Only those welders who have been approved by the

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 12 of 33

Owner/Companys Inspector shall be employed for welding. Contractor shall submit the

welder qualification test reports in the format as per QW-484, ASME Section IX (latest

edition) and obtained express approval before commencement of work. It shall be the

responsibility of the contractor to carry out the qualification tests of welders. For welding of

steam piping, falling under the purview of Indian Boiler Regulation only those welders with

IBR Certification, qualified by Boiler Inspectorate, and acceptable to the local Boiler

Inspector authority shall be employed.

b) The welders shall always have in their possession the identification card as shown in

Suggested Format-D (Annexure 1) and shall produce it on demand by the Owner/Companys

inspectors. It shall be the responsibility of the Contractor to issue the identify cards after it has

been duly certified by the Inspector.

c) No welder shall be permitted to work with out the possession of identify card.

d) If a welder is found to perform a type of welding or in a position for which he is not qualified,

he shall be debarred from doing any further work. All welds performed by an unqualified

welder shall be cut and redone by a qualified welder at the expense of the Contractor.

14.4 Visual Inspection

Inspection of all welds shall be carried out as per the latest edition of the applicable codes and

specifications. All finished welds shall be visually inspected for parallel and axial alignment of the

work, excessive reinforcement, concavity of welds, shrinkage cracks, inadequate penetration,

unrepaired burn-through, under cuts, dimensions of the weld, surface porosity and other surface

defects. Undercutting adjacent to the completed weld shall not exceed the limits specified in the

applicable standard / code.

14.5 Radiographic Examination

a) Contractor shall appoint agency for carrying out the radiography works at site from the list of

agency (ies) enclosed in the bid document or separately supplied by Owner/Company.

b) The radiographic Examination procedures to be adopted shall be submitted by the contractor

as per QW-484, ASME Section IX (latest edition) and shall be got approved from the

Owner/Companys Inspector prior to employment. A person qualified to ASNT Level-II in

Radiographic testing shall prepare to procedure. The Radiographic Procedure shall be

established to demonstrate that require sensitivity can be consistently achieved under the most

unfavourable parameters (e.g. source to film distance, geometric unsharpness, thickness etc.).

The radiographic technique and procedure adopted shall conform of the requirements

mentioned in Article 2 as well as Article 22 (SE 94, 142, 747, 999 & 1025) of ASME Sec.V.

The IQI sensitivity obtained shall be equal to or better than the requirements mentioned in

Article 2 of ASME Sec.V. Source side penetrameter shall be used in establishing radiographic

procedure/technique. The acceptance criteria shall be as per the relevant codes of Fabrication

and over riding requirements if mentioned elsewhere in the technical specifications of the

contract. The contractor shall be responsible for carrying out Radiography; rectification of

defects and re-radiography of welds repaired/rectified at his cost.

c) The extent of Radiography shall be as per specifications to be supplied to the Contractor. For

welds between dissimilar materials, the extent of Radiographic Examination shall be the more

stringent of the two recommended for the materials being welded. Wherever random

Radiography is called for, in a particular piping class, the dissimilar materials weld joints shall

essentially be included.

d) Type of Radiation source and film to be used shall be as per Suggested Format-E (Annexure

1) for carrying out radiographic examination. However if specifications (as given elsewhere

in the contract) for some critical material require usage of X-Radiation, then Radiography

shall be done using X-Rays only.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 13 of 33

e) The Contractor shall fulfil all the statutory and Owner/Companys safety requirements while

Handling X- ray Gamma-ray equipment.

f) The joints for Radiography shall be selected by the Owner/Companys Inspector and the

Radiography shall be performed in his presence, if he instructs the contractor to do so. The

contractor shall furnish all the radiographs, to the Owner/Companys inspector immediately

after processing along with evaluation by a person qualified to ASNT Level-II in

Radiographic testing, inline with clause T- 292 of article 2 of ASME Sec.V. The certificate of

ASNT Level-II (RT) personal shall be submitted to Owner/Companys inspector for his

approval prior to start of job.

g) The Contractor shall provide the Owner/Companys Inspector all the necessary facilities at

site such as a dark room with controlled temperature, illuminator (viewer) suitable for varying

densities, a duly calibrated electronic densitometer with batteries, magnifying glass, tracing

paper, ruler marking pencils etc. to enable him to review the radiographs.

h) Where random radiography is specified, the first weld of each welder shall be completely

radiographed. In the case of pipe size 6 and below, the first two welds shall be completely

radio graphed.

i)

For each weld performed by a welder found unacceptable, two additional checks shall be

carried out on welds performed by the same welder. This operation is iterative and the of two

additional welds for each welds deemed unsatisfactory shall be continued till such time that

two consecutive welds of satisfactory quality are found for every defective weld.

j)

The Contractor shall carry out these additional radiographic testing at his own expense. To

avoid the possibility of too many defective welds by a single welder remaining undetected for

a long period to time, the Contractor shall promptly arrange for Radiographic Examination so

that there is no accumulation of defective joints.

k) Contractor shall quote rates for X- ray as well as Gamma Ray for joints indicated to be radio

graphed by X-ray in Table of Suggested Format-E (Annexure 1).

14.5.1

Check shots

a) Owner/Company shall select 5% of the total joints radiographed on a day for check shots.

Contractor shall carry out check shots as directed.

b) Weld profiled of check shot shall be compared with weld profile observed in the earlier

Radiographs. In the event of any one variation in the check shots and earlier Radiographs,

contractor shall re-shoot the entire lot of joints radiographed by particular Radiography

agency on the particular date. All the re-shot films shall be compared with the originally

submitted films.

14.6 Liquid Penetrant and Magnetic Particle Examination

a) Whenever such tests are specified, the tests shall be carried out on joints chosen by the

Owner/Companys inspector, as per ASME Section V article 6 and 7 respectively.

14.7 Hardness Test

Hardness requirements for weld shall be as per the Welding Specification Chart (attached).

Hardness testing shall be carried out by Vickers Hardness Tester during welding procedure

qualification and shall be cross sectional. In all other cases, hardness testing may be carried out by

portable shore Seleroscope hardness tester. Contractor shall produce documentary

evidence/calibration certificate to the Owner/Companys Inspector and obtain approval of the

equipment.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

Rev: A

abc

Page 14 of 33

14.8 Proof Tests

Hydrostatic and pneumatic tests shall be performed as per the requirements laid down by

respective flushing and Testing specification/applicable codes to demonstrate the soundness of the

welds. The tests shall be conducted after fulfilling the requirement of visual examinations

radiography etc., and after the entire work has been certified by the Owner/Companys inspector

to be fit for being subjected to such tests.

15

Repairs Of Welds

a) Defects ascertained, through the inspection methods, which are beyond acceptable limits shall

be removed after the joint is completely radiographed by the process of chipping and grinding.

b) When the entire joint is judged unacceptable, the welding shall be completely cut and edges

suitably prepared as per required alignment tolerance. The re-welded joint shall again be

examined following standard practices.

c) No repair shall be carried out without prior permission of the Owner/Companys inspector.

d) Repairs and/or work of defective welds shall be done in time to avoid difficulties in meeting

the construction schedules.

16

Documents To Be Submitted By Contractor (4 Copies Each)

(a)

Electrode and welding consumable qualification Records as per Suggested Format-A

(Annexure 1), for the Welding Consumables tested and approved for the work.

(b)

Batch Test Certificates, for the Electrodes used, obtained from the Electrode manufacturers.

(c)

Proposed Heat Treatment Procedure as per Suggested Format-B (Annexure 1).

(d)

Heat Treatment Charts.

(e)

Weld joint hardness test results.

(f)

Welding Procedure Specifications as per QW-482, ASME Section IX (latest edition)

immediately after receipt of the order.

(g)

Welding Procedure Qualification records as per QW-484, ASME Section IX (latest edition)

.

(h)

Welder Performance Qualification records as per QW-483, ASME Section IX (latest

edition) immediately after conducting Welder Qualification Tests.

(i)

Radiography Procedure as per Suggested Format-C (Annexure 1) and other NDT

procedures.

(j)

Radiographic test Report along with Radiographs and other NDT reports.

(k)

Piping Sketch (Isometric) giving all the details regarding the pipe specifications, welded

joints, joints radiographed, magnetic particle tested, ultrasonic tested, penetrant tested, joints

heat treated, WPS used, welders identification number, etc.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

17

Rev: A

abc

Page 15 of 33

Welding Specification Charts

PIPING CLASS:

A09A1, A09A2, B09A2

MATERIAL

SPECIFICATIONS

PIPES

FITTINGS

FLANGES

OTHERS

BASE METAL 'P'

NO

ASTM A106 GR.B, API 5L Gr B PSL 1, ASTM A 672 GR. B60 CL12

ASTM A105, ASTM A234 GR. WPB, ASTM A GR. WPB-W

ASTM A105

1

GROOVE JOINTS

BUTT

WELDING

PROCESS

ROOT PASS

SMAW

GTAW

(NOTE-4)

FILLER

PASS

SMAW

ROOT PASS

OTHER THAN BUTT

FILLER PASS

SMAW

FILLET JOINTS / SOCKET JOINTS

SMAW

SMAW

GROOVE JOINTS

ROOT PASS

WELDING

MATERIALS

BACKING RING

JOINT PREPN.

BUTT

E6010/E6013

(NOTE 2)

ER70 SG/ER

70S-2

FILLER

PASS

E7016/E7018

(NOTE 4)

FILLET JOINTS / SOCKET JOINTS

-

ROOT PASS

OTHER THAN BUTT

E6010/E6013

FILLER PASS

(NOTE 2)

E7016/E7018

E7016/E7018

CONSUMABLE INSERT

ASME B31.3

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

GASES

GAS

COMPOSITION

PURGING

PREHEATING

CONTINUITY OF

WELDING AND

PREHEAT

POST WELD

HEAT

TREATMENT

NOTE - 1

PREHEAT TEMP

Rev: A

PURGING

10 MIN/ 100C (FOR

THK>=25.4MM)

abc

Page 16 of 33

SHIELDING

ARGON

SHIELDING

99.995%

POST HEATING

HOLDING TEMP

RATE OF HEATING

HOLDING TIME

MIN HOLDING TIME

METHOD OF COOLING

RATE OF COOLING

MECH. PROPERTY REQUIREMENTS CHARPY 'V' NOTCH IMPACT TEST VALUE

AT TEMPERATURE

HARDNESS

MIN

AVERAGE

CODE OF FABRICATION

ASME B31.3

TECHNICAL NOTES:

1 HEAT TREATMENT SHALL BE DONE AS PER ASME B31.3 FOR WALL THICKNESS EXCEEDING 19MM

2 E6013 MAY BE USED FOR ROOT PASS PROVIDED UNIFORM ROOT PENETRATION IS OBTAINABLE AND IS DEMONSTRATED

THROUGH PROCEDURE QUALIFICATION

3 PREHEAT TEMPERATURE AT LEAST 50O C SHALL BE PROVIDED FOR THE FIRST TWO PASSES FOR THK >=12.7MM & <25.4MM

4 GTAW SHALL BE EMPLOYED FOR THE ROOT PASS WELDING FOR SMALL BORE PIPING OF DIAMETER 2" AND SMALLER

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

PIPING CLASS:

A09B0

MATERIAL

SPECIFICATIONS

PIPES

FITTINGS

FLANGES

OTHERS

BASE METAL 'P' NO

Rev: A

abc

Page 17 of 33

ASTM A 106 GR.B

ASTM A105, ASTM A234 GR. WPB

ASTM A105

-

GROOVE JOINTS

ROOT PASS

WELDING PROCESS

SMAW

GTAW

NOTE-4

BUTT

FILLER

PASS

SMAW

ROOT PASS

FILLET JOINTS / SOCKET JOINTS

WELDING

MATERIALS

OTHER THAN BUTT

SMAW

FILLER PASS

SMAW

SMAW

GROOVE JOINTS

BUTT

OTHER THAN BUTT

ROOT PASS

E6010/E6013

FILLER

ER7016/

ROOT PASS E6010/

FILLER PASS E7016/E7018

PASS

NOTE-2

E7018

E6013

ER70

SG/ER70S-2

NOTE 4

NOTE 2

FILLET JOINTS / SOCKET JOINTS

E7016/E7018

BACKING RING

CONSUMABLE INSERT

-

JOINT PREPN.

ASME B31.3 & IBR

GASES

GAS COMPOSITION

PURGING

PURGING

SHIELDING

SHIELDING

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

ARGON

99.995%

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

PREHEATING

NOTE 3

CONTINUITY OF

WELDING AND

PREHEAT

PREHEAT

TEMP

POST WELD HEAT

TREATMENT

NOTE - 1

HOLDING TEMP

RATE OF HEATING

METHOD OF COOLING

Rev: A

10 MIN/ 100C (FOR

THK>=25.4MM)

POST HEATING

600+ 20 DEG C

200 DEG C /HR MAX.

CONTROLLED

HOLDING TIME

MIN HOLDING TIME

RATE OF COOLING

CODE OF FABRICATION

TECHNICAL NOTES:

2

3

4

MECH. PROPERTY REQUIREMENTS CHARPY 'V' NOTCH IMPACT TEST VALUE

AT TEMPERATURE

HARDNESS

abc

Page 18 of 33

MIN

AVERAGE

1 HR PER INCH THICKNESS

1 HOUR

200 DEG C /HR MAX.

-

ASME B31.3 & IBR

HEAT TREATMENT SHALL BE DONE AS PER IBR FOR WALL THICKNESS EXCEEDING 19MM

E6013 MAY BE USEDE FOR ROOT PASS PROVIDED UNIFORM ROOT PENETRATION IS OBTAINABLE AND DEMONSTRATED THROUGH

PROCEDURE QUALIFICATION

PREHEAT TEMPERATURE OF AT LEAST 50 DEG C SHALL BE PROVIDED FOR THE FIRST TWO PASSES FOR THK. >=12.7MM & <25.4MM

GTAW SHALL BE EMPLOYED FOR THE ROOT PASS WELDING FOR SMALL BORE PIPING OF DIAMETER 2" AND SMALLER

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

PIPING CLASS:

A09A0

MATERIAL

SPECIFICATIONS

PIPES

FITTINGS

FLANGES

OTHERS

BASE METAL 'P' NO

Rev: A

abc

Page 19 of 33

IS 1239 (Black)

ASTM A105, ASTM A234 GR. WPB

ASTM A105

-

GROOVE JOINTS

ROOT PASS

BUTT

SMAW

WELDING PROCESS

FILLER

PASS

SMAW

ROOT PASS

FILLET JOINTS / SOCKET JOINTS

OTHER THAN BUTT

SMAW FILLER PASS

SMAW

SMAW

GROOVE JOINTS

WELDING

MATERIALS

ROOT PASS

BUTT

E6010/E6013

FILLER

PASS

E6013

E7016

E7018

ROOT PASS

FILLET JOINTS / SOCKET JOINTS

BACKING RING

JOINT PREPN.

OTHER THAN BUTT

E6010/ FILLER PASS

E6013

E6013/E7016

E7018

E6013/E7016/E7018

CONSUMABLE

INSERT

ASME B31.3

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT BLACK OIL TERMINAL

Doc No.:254625-300-SP-PIP-015

GASES

GAS COMPOSITION

PREHEATING

NOTE 3

PURGING

PURGING

PREHEAT TEMP

10 C MIN

CONTINUITY OF

WELDING AND

PREHEAT

POST WELD HEAT

TREATMENT

Rev: A

abc

Page 20 of 33

SHIELDING

SHIELDING

POST HEATING

HOLDING TIME

MIN HOLDING TIME

RATE OF COOLING

HOLDING TEMP

RATE OF HEATING

METHOD OF COOLING

MECH. PROPERTY REQUIREMENTS CHARPY 'V' NOTCH IMPACT TEST VALUE

AT TEMPERATURE

HARDNESS

CODE OF FABRICATION

TECHNICAL NOTES:

MIN

ASME B31.3

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015 Rev A.doc

AVERAGE

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

18

Annexure 1

Rev: A

Page 21 of 33

Suggested Formats

Suggested Format-A

Electrode Qualification Test Record

A:

Tested at (Site name)

Manufacturers Name

:

Brand Name

Batch Number & Size tested

:

Classification & Code

Intended for welding in position

:

In combination with (if any)

:

Code of Reference (used for testing) :

Special Requirements (if any)

:

B:

All weld Tensile Test

Base Material used

Pre-heat temperature

Post weld heat treatment details

Visual examination

Radiographic examination results

Tensile test results

Identification No.

Date:

:

:

:

:

:

:

U.T.S.

Yield Point

Elongation

Remarks

1.

2.

C.

Impact Test Results

Test Temperature

:

Type of Specimens (Charpy) :

Specimen No

1

2

3

4

5

D.

Impact Value

Chemical Analysis Results

Electrode Size Results

Batch No.

%C

%S

Notch in

Size of Specimens

%P

:

:

Average

:

:

%Si

%Mn

%Cr

%Ni

%Mo

Other

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 22 of 33

Fracture in

E.

Fillet Weld Test Results

Welding Positions

Base Materials

Size of electrode used

Visual Inspection Results

Macro Test Results

Fracture Test Results

Remarks

:

:

:

:

:

:

:

:

F.

Other Test Results

1.

Transverse tensile test

In combination with

Base material used

Position weld heat treatment

Preheat temperature

Post weld heat treatment

Radiography

Identification No.

:

:

:

:

:

:

:

:

U.T.S.

2.

Guided Bend test

Position

Identification

No.

1

2

3

4

5

Root, Face or Side

Bend

G.

Any other tests

H.

Conclusions

____________________

PREPARED BY

_______________________

REVIEWED BY

Remarks

Remarks

______________________

APPROVED BY

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 23 of 33

Suggested Format-B

Stress Relief Heat Treatment Procedure Specification

Contractor

__________________________________________________

Name of the Heat treater :

__________________________________________________

Name of the project

__________________________________________________

Specification

__________________________ Reference No. : ___________

___________________________________________________________________________

1.

General Details

Name o f the

Equipment:

Other Details

________________________

Type of Heating: Elec. Res /

Induction

(Tick mark applicable method)

Maximum Permissible Temp at

Uncovered Parent Metal___________

Width of heated band _____________

Width of Insulation ______________

Material :

_____________________

Type of Thermo couples

3.

No. of Themo couples (dia wise)

___________________________

___________

Heat Treatment Cycle Details

Charging Temp C

:__________________________________________________

Rate of heating C Hr : __________________________________________________

Soaking Temp C

: __________________________________________________

Soaking Time Hrs

: _________________________________________________

Rate of Cooling C/Hr : _________________________________________________

Method of Cooling

4.

: _________________________________________________

Other details, if any

:

______________________________________________________________________

______________________________________________________________________

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 24 of 33

Suggested Format-C

Radiographic Procedure Qualification Record for Pipe Welding

1.

Location

2.

Date of Testing

3.

Name of the Contractor / Agency

4.

Material: Carbon Steel

4A. Technique: DWSI / SWSI / DWDI

5.

Diameter & Thickness :

6.

Type of Weld Joint:

7.

Radiation Source:

8.

Intensifying Screens / Lead Screens :

9.

Geometric Relationship:

10.

Limit of Film Coverage:

11.

Film Type and Make :

12.

Exposure Time :

13.

Processing :

14.

Density :

15.

Sensitivity :

16*. Type of penetrameter:

(Source side)

17*. Type of penetrameter:

(Film side)

___________________________________

Signature of Contractor / Agency with Seal

_________________________

Approval of MMCIs Inspector

*

Ref. Para regarding recommended practice on placement on penetrameters Article 22,

SE 142, ASME Sec. V.

For Random Radiography lines placement of penetrameters as per Article 2, ASME,

Sec. V is permitted

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 25 of 33

Suggested Format-D

Welders Identification Card

1.

Name:

2.

Identification:

3.

Date of Testing:

4.

Process :

5.

Thickness range :

6.

Diameter range :

7.

F. No.:

8.

Date of approval of welding

9.

Position

Approved by:

Photograph

Employers Signature with Seal

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 26 of 33

Suggested Format-E

Type of Source and Films to be used for Radiography

NOMINAL WALL

THICKNESS (T) IN mm

SHOP WELDED JOINTS

FIELD WELDS

SOURCE

SOURCE

FILM

AGFA D7 or

19 T

All Materials

Gamma Ray

AGFA D7 or

Gamma Ray

Equivalent

Equivalent

AGFA D5 or

Carbon Steel

FILM

Gamma Ray

AGFA D5 or

Gamma Ray

Equivalent

Equivalent

8T<19

AGFA D4 or

All other Materials

Gamma Ray

Carbon Steel

Other than

<8

AGFA D4 or

Gamma Ray

Equivalent

Equivalent

AGFA D4 or

AGFA D4/D2 or

Equivalent

Gamma Ray

Equivalent

Gamma Ray

Inspection

Class IV *

All other material

and Carbon Steel

of Inspection Class

IV*

X-Ray

AGFA D5 or

equivalent

X-ray with AGFA D5 or

Equivalent to be used. Gamma

Ray with AGFA D4 / D2 or

Equivalent may be allowed only if

in the opinion of the owners

inspector Joints are inaccessible for

X-ray equipment and radiographic

sensitivity is achieved.

Notes: Integral to above table

1.

Joints welded in field on Ground Level shall be consider as shop welded joints.

2.

Very fine grain (High contrast) film slower than the above may have to be used, if

required radiographic sensitivity is not achieved consistently.

3.

AGFA means AGFA GAEVERTS.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

19. Annexure 2

Rev: A

Page 27 of 33

Welding Sketches

Figure 1: Butt Weld Details

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 28 of 33

Figure 2: Welding Details for Branch Connections (Stub-in)

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 29 of 33

Figure 3: Branch Connection (Breaking into)

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 30 of 33

Figure 4: Branch Connection (Not Breaking into)

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 31 of 33

Figure 5: Fillet Weld Details

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 32 of 33

Figure 6: Butt-Weld End Preparation Details

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

254625-300-SP-PIP-011

Rev: A

Page 33 of 33

Figure 7: Welding of Pipes with Different Thicknesses

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\Procurement\Roads & Drains\31.07.09\254625-300-SP-PIP-015

Rev A.doc

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Basics of Automobiles: EmmisionDocument76 paginiBasics of Automobiles: EmmisionRavindra Joshi100% (1)

- MIP Thickener DesignDocument3 paginiMIP Thickener DesignHatem SalahÎncă nu există evaluări

- Nike Case StudyDocument6 paginiNike Case Studyapi-361156846100% (1)

- Kiln Thruster LogicDocument3 paginiKiln Thruster LogicSameer kumar GOGOI0% (1)

- Cassette y Piso-Techo InverterDocument186 paginiCassette y Piso-Techo InverterDarwin Samir Silva Bautista0% (1)

- Science8 q1 Mod3 Potential-And-kinetic-Energy v2Document23 paginiScience8 q1 Mod3 Potential-And-kinetic-Energy v2Keith Genesis Ruiz AglubaÎncă nu există evaluări

- School Calendar: Queensland State SchoolsDocument1 paginăSchool Calendar: Queensland State Schoolsibnu.asad984Încă nu există evaluări

- 2016 Timetabling CalendarDocument1 pagină2016 Timetabling Calendaribnu.asad984Încă nu există evaluări

- 2016 Liturgical Calendar: Liturgy OfficeDocument8 pagini2016 Liturgical Calendar: Liturgy Officeibnu.asad984Încă nu există evaluări

- Recomm2015 2016Document2 paginiRecomm2015 2016ibnu.asad984Încă nu există evaluări

- 2016 Monthly CalendarDocument12 pagini2016 Monthly Calendaribnu.asad984Încă nu există evaluări

- 2016 Liturgical Calendar: Liturgy OfficeDocument8 pagini2016 Liturgical Calendar: Liturgy Officeibnu.asad984Încă nu există evaluări

- 1221 Hot Gas and Extrusion Welding Jan 2016Document2 pagini1221 Hot Gas and Extrusion Welding Jan 2016ibnu.asad984Încă nu există evaluări

- 13 BridgeDocument25 pagini13 Bridgeibnu.asad984Încă nu există evaluări

- February 2016: Sun Mon Tue Wed Thu Fri SatDocument1 paginăFebruary 2016: Sun Mon Tue Wed Thu Fri SatWilly ChandraÎncă nu există evaluări

- Welded Excutive SummDocument36 paginiWelded Excutive Summibnu.asad984Încă nu există evaluări

- Welding Application Spring 2016Document10 paginiWelding Application Spring 2016ibnu.asad984Încă nu există evaluări

- Competitive Programs For CanadaDocument41 paginiCompetitive Programs For Canadaferoz_bilalÎncă nu există evaluări

- Fab-Welding Supervisors and Inspector Dates and InformationDocument2 paginiFab-Welding Supervisors and Inspector Dates and Informationibnu.asad984Încă nu există evaluări

- WeldDocument2 paginiWeldibnu.asad984Încă nu există evaluări

- Tws School CatalogDocument76 paginiTws School Catalogibnu.asad984Încă nu există evaluări

- p24 Course Description Welding Technology Courseplan 2016Document3 paginip24 Course Description Welding Technology Courseplan 2016ibnu.asad984Încă nu există evaluări

- 2016 Training Materials CatalogDocument24 pagini2016 Training Materials Catalogibnu.asad984Încă nu există evaluări

- Highly Competitive Programs Chart 2015-2016Document3 paginiHighly Competitive Programs Chart 2015-2016ibnu.asad984Încă nu există evaluări

- MC2034 Weld Rods - v4Document2 paginiMC2034 Weld Rods - v4ibnu.asad984Încă nu există evaluări

- 2015 Programs Book List PricesDocument13 pagini2015 Programs Book List Pricesibnu.asad984Încă nu există evaluări

- MC2034 Weld Rods - v4Document2 paginiMC2034 Weld Rods - v4ibnu.asad984Încă nu există evaluări

- CCC 2015 2016 Fee ChartDocument5 paginiCCC 2015 2016 Fee Chartibnu.asad984Încă nu există evaluări

- WeldingDocument4 paginiWeldingibnu.asad984Încă nu există evaluări

- 16 17 Dept Flow Charts v2 0Document17 pagini16 17 Dept Flow Charts v2 0ibnu.asad984Încă nu există evaluări

- AWS Weld Symbol ChartDocument1 paginăAWS Weld Symbol ChartExsan OthmanÎncă nu există evaluări

- New Technologies 112515Document29 paginiNew Technologies 112515ibnu.asad984Încă nu există evaluări

- FIEA Events 2016 One Page FlyerDocument1 paginăFIEA Events 2016 One Page Flyeribnu.asad984Încă nu există evaluări

- h2020 wp1617 Fet - enDocument41 paginih2020 wp1617 Fet - enibnu.asad984Încă nu există evaluări

- Gs 16 1 Distributed Ledger TechnologyDocument88 paginiGs 16 1 Distributed Ledger Technologyibnu.asad984Încă nu există evaluări

- Motion in A Plane PDFDocument38 paginiMotion in A Plane PDFaman btechÎncă nu există evaluări

- Data Acquisition TechniquesDocument25 paginiData Acquisition TechniquesZarWinÎncă nu există evaluări

- Article Review CSR 7Document2 paginiArticle Review CSR 7Gwendoline BoucherÎncă nu există evaluări

- Lecture 2Document17 paginiLecture 2Physicist91Încă nu există evaluări

- JEE ChemistryDocument4 paginiJEE Chemistryrjpatil19Încă nu există evaluări

- Samsung LPC 247sm-06sDocument2 paginiSamsung LPC 247sm-06saboalghadbÎncă nu există evaluări

- Model C-30Hdz: Operations & Parts ManualDocument106 paginiModel C-30Hdz: Operations & Parts ManualGerardo MedinaÎncă nu există evaluări

- KSG 5K DMDocument2 paginiKSG 5K DMGirasolar solarÎncă nu există evaluări

- 5.4.1 INV5.4.1HessLawLab - Sem2 2017-HaleemMohamedAli EditDocument7 pagini5.4.1 INV5.4.1HessLawLab - Sem2 2017-HaleemMohamedAli EditHaleem MohamedÎncă nu există evaluări

- Casio Forester 5170Document1 paginăCasio Forester 5170embarerÎncă nu există evaluări

- Split Phase LV5048Document1 paginăSplit Phase LV5048A CermenoÎncă nu există evaluări

- VLSI Design Unit-2 Mosfet TransistorDocument5 paginiVLSI Design Unit-2 Mosfet Transistorselvi0412Încă nu există evaluări

- CIE IGCSE Forces Hookes Law OnlyDocument22 paginiCIE IGCSE Forces Hookes Law Onlyh aÎncă nu există evaluări

- Omnicomm LLS 4 Fuel Level Sensors: User Manual 18.12.2018Document20 paginiOmnicomm LLS 4 Fuel Level Sensors: User Manual 18.12.2018Giovanni QuinteroÎncă nu există evaluări

- Chapter8 PDFDocument54 paginiChapter8 PDFJoseph Constantino T. Fagel JrÎncă nu există evaluări

- SerieAK-2020 GBDocument120 paginiSerieAK-2020 GBAndré SilvaÎncă nu există evaluări

- Chemcad FeaturesDocument39 paginiChemcad FeaturesMOHAMED ESSALHIÎncă nu există evaluări

- The Effect of Using An Ethanol Blended Fuel On Emissions in An SI EngineDocument6 paginiThe Effect of Using An Ethanol Blended Fuel On Emissions in An SI EngineVinay GowdaÎncă nu există evaluări

- M Arch (LA) PDFDocument27 paginiM Arch (LA) PDFmonsÎncă nu există evaluări

- Pages From 0625 - s16 - QP - 43-10Document2 paginiPages From 0625 - s16 - QP - 43-10lelon ongÎncă nu există evaluări

- Climatronic 1.6 ltr.-74 KW Simos, Engine Code AEH, 1.6 ltr.-74 KW Simos, Engine Code AKL PDFDocument8 paginiClimatronic 1.6 ltr.-74 KW Simos, Engine Code AEH, 1.6 ltr.-74 KW Simos, Engine Code AKL PDFAlex SinatoviciÎncă nu există evaluări

- DS CatalogueDocument6 paginiDS CatalogueDMA ASIAÎncă nu există evaluări

- Our Technology Background Framo Cargo Pumping SystemDocument199 paginiOur Technology Background Framo Cargo Pumping SystemSorescu Radu VasileÎncă nu există evaluări

- Mechanical EngineeringDocument1 paginăMechanical EngineeringManjunatha EikilaÎncă nu există evaluări