Documente Academic

Documente Profesional

Documente Cultură

Geotechnical Exploration Shahabi Dam FINAL2

Încărcat de

TuroyDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Geotechnical Exploration Shahabi Dam FINAL2

Încărcat de

TuroyDrepturi de autor:

Formate disponibile

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

1. INTRODUCTION

1.1 Authorization

This investigation was undertaken according to the contract

signed on May 2009 between the client, General Commission

for Dams and Reservoirs of the Ministry of Water Resources, and

the contractor, Engineering Consultancy Bureau, University of

Al-Mustansiriya.

.

1.2 Site Location

The area of the present study is located in Wassit Governorate in

the south east of Baghdad. The city of Kut, centre of Wassit, is

located about 170 km south east of Baghdad. An earth dam,

Shahabi Dam, is proposed for construction in this location.

Google earth program is used to show a scale picture for the job

site area as shown in Fig. 1.

Fig. 1 Dam Location with respect to the Kut City

(Earth Google Picture with Scale)

1.3 Purpose of Soil Investigation

The main purpose of the site exploration is to determine

1

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

subsurface conditions at the project site, evaluate these

conditions with respect to the proposed construction and to

make engineering recommendations for site preparation,

and foundations. Furthermore, to obtain soil design

parameters that may be used in the civil and structural

design of facilities at the project site. Consequently, the

purposes of the exploration program can be summarized

as follows:

1. To identify the subsoil engineering, physical and

chemical properties up to certain predetermined depth.

2. To estimate the allowable bearing capacity and the

compressibility of the soil for the purpose of the most

safe and economic foundation design.

3. To suggest the pile type and to estimate the pile

capacity if piles are found to be a suitable alternative for

the foundation in the site.

4. To investigate the validity of the site as a foundation to

support the proposed structure.

5. To fid out the suitable areas to be used as quarries for

the construction of embankments and earth dams.

2. FIELD EXPLORATION

2.1

Boreholes location

The purpose of the present project is to find out the nature

and engineering properties of the soil strata beneath the

proposed dam, also to investigate the soil properties of the

proposed quarries. To achieve this purpose, six boreholes

were drilled in each site. They are numbered 1 to 6. The

depth of the boreholes ranged from 15 to 25 m. Ten test pits

were excavated, three in a site proposed for a quarry

containing gravel, three in a site proposed for a quarry

2

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

containing sand and four in a site proposed for a quarry

containing clay. Figure 2 shows a layout of the holes in the

dam site.

Fig. 2 Boreholes Location with respect to the Shahabi River

(Earth Google Picture with Scale)

Fig. 2-B Boreholes Location with respect to the Dam Axis

The G.P.S coordination of each borehole is indicated in

Table 1.

3

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

Table 1. G.P.S Coordination of the Six Boreholes

B.H No.

1

2

3

4

5

6

2.2

G.P.S Coordination

E

N

o

o

46 17.751 32 50.647

46o17.734 32o50.687

46o17.780 32o50.720

46o17.715 32o50.720

46o17.670 32o50.772

46o17.670 32o50.754

Method of Drilling and Sampling

Core rotary driving was used for advancing the hole. Thin

walled samplers, 102 mm diameter (Shelby tubes) as well

as cores were employed for obtaining undisturbed samples

of high quality when a clayey material is encountered. The

tubes were hydraulically jacked into the ground. Disturbed

samples were collected from the auger.

The Shelby tubes were covered from both ends with wax;

disturbed and undisturbed samples were labeled and

placed in wooden boxes.

The core recovery percent (C.R. %) was used earlier to

indicate the quality of rock (Bowles, 1996). Recently the

Rock Quality Designation (RQD %) is being used as an

index of the quality of a rock mass. However these

measures are not used for clay and sand. The ground layers

encountered in the present investigation were silty sand

and silty clay with some gravel. Therefore the C.R. % and

the RQD % were not of significance.

Description of soils (Visual - Manual Procedure) has been

carried out in accordance with local codes and ASTM D

2488.

The test pits were excavated to a depth of around 3 m using

both mechanical and manual methods. Samples were

extracted from the pits in intervals of 1 m in depth.

Photographs of field work are available in Appendix E.

4

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

2.3

Field Tests

2.3.1 Field Permeability tests

Constant Head Test

A constant head is maintained through an open end pipe

casing as shown in Fig. 3. The test is begun by adding clear

water through a metering system to maintain gravity flow at

a constant head. In tests above the water table (Fig 3-B)

stable, constant level is rarely obtained and a surging of the

level within a few tenths of a foot at a constant rate of flow

for about 5 minutes is considered satisfactory.

If it is desired to apply pressure to the water entering the

hole, the pressure, in units of head, is added to the gravity

head. Measurements of constant head, constant rate of flow

into the hole, size of casing pipe, and elevations of top and

bottom of casing are recorded.

However, in the present procedure the permeability test

was conducted successively during drilling stages. The

water was confined between the hole end and the bottom

level of the casing therefore the following equation was

used to calculate the permeability;

Q

L

L 10r

k

ln

2LH r

where

k = permeability

Q = constant rate of flow into the hole

r = internal radius of casing, and

H = differential head of water

L = length of portion of the hole tested

Table below presents classification of the range of

permeability by various degree adopted after Terzaghi and

Peck.

5

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

Degree of Permeability

Range Coefficient of

Permeability , k, cm/s

> 10-3

High

Medium

10 -1 10-3

Low

10-3 10-5

Very Low

10-5 10-7

Impervious

< 10-7

Appendix -D- presents the field permeability tests records.

2.3.2 Standard Penetration Test (SPT)

The test is standardized as ASTM D 1586. Technical details

on the equipment are available elsewhere. The procedure

is summarized as:

1) Driving the standard spilt-barrel sampler of dimensions

51mm (OD) a distance of 460 mm (18in) into the soil at the

bottom of the boring using a falling mass.

2) Counting the number of blows to drive the sampler the

last 305 mm (12 in) to obtain the N number.

3) Using a 63.5 kg (140 1b) driving mass (or hammer)

falling free from a height of 760 mm (30 in).

6

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

The boring log shows refusal and the test is halted if

1- 50 blows are required for any 150 mm increment.

2- 100 blows are obtained.

3- 10 successive blows produce no advance.

The results of this test are widely correlated to the various

soil properties. Bowles (1996) reported that 85 to 90 percent

of conventional foundation design in North and South

America is made using the SPT.

2.4 Standards

Table (2) presents the standards that have been adopted for

field works.

Table (2) Standards for Field Exploration

Work description

Practice for using hollow stem

augers for Geotechnical

Exploration and Sampling

ASTM D-6151

Test method for penetration Test

and Split-Barrel sampling of soil

ASTM D-1586

Practice for thin walled tube

Sampling of cohesive soils

ASTM D-1587

Practice of Preserving and

Transporting soil samples

ASTM D-4220

Practice for description and

Identification of soils

ASTM D-2488

Field permeability tests in

boreholes

3.

The Standard

Earth Manual

Designation E-18

LABORATORY TESTING

3.1 Types of Tests

The soil tests were selected to cover the information

required for adequate design of the dam. Soil

characteristics such as, index properties, grading, shear

7

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

strength, compressibility, compaction and chemical

contents were obtained using the following types of testing:

1) Classification tests

- Liquid Limit (L.L)

- Plastic Limit (P.L)

fine- grained soil

-Hydrometer testing

- Sieve testing

- Water content (w) and density () determination

2) Consolidation (compressibility) test (for fine-grained

soil)

3) Shear strength tests

- Unconfined compressive test (qu) (for finegrained soil)

4) Chemical tests

- CaCO3 content

- Organic matter content (OM)

- Gypsum Content

- Total Soluble Salts

5) Compaction tests (only for samples from the test pits).

Photographs of Laboratory work are available in Appendix

E.

3.2 Standards

Laboratory tests were carried out in accordance with the

standards given in Table (3)

Table (3) Standards for Laboratory Testing.

Test

Naturel Moisture Content (wc)

Unit Weight (wet , dry ).

Specific Gravity ( GS)

Liquid and Plastic Limits ( L.L ,

P.L )

Grain Size Analysis

One- Dimensional

Consolidation (e , cc , cr , Pc )

Unconfined Compression Test

Organic content

SO3

CO3

August, 2009

The Standard

ASTM D-2488

ASTM D-2488

ASTM D-854

ASTM D-4318

ASTM D-422

ASTM D-2435

ASTM D-2166

ASTM D-2974

BS 1377

ASTM D4373

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

3.3 Presentation of Test Results

A description of the type of soil encountered together with

the values of the measured permeability and the standard

penetration resistance is given in the Borehole Logs of

Appendix A. A soil profile (geological section) is also given.

The test results for each borehole are presented in the form

of a data sheet (table) and given in Appendix B.

4. ANALYSIS of RESULTS

4.1 Subsurface Condition

The relative density of sand and the consistency of clay

(Table 4) are determined using SPT results in accordance

with the recommendation of Terzaghi and Peck.

Table (4) Correlation of N- Values with Soil Properties

Sands

No. of

blows per

30 cm (1 ft)

0-4

4-10

10-30

30-50

>50

Relative

Density

Very loose

Loose

Medium

Dense

Very

Dense

Clays

No. of blows

per 30 cm (1

Consistency

ft)

0-2

Very soft

2-4

Soft

4-8

Medium

8-15

Stiff

15-30

Very Stiff

>30

Hard

Figure 2 shows that Bhs 1, 2, 4, and 5 are located on the dam

axis; BH6 is slightly shifted toward the downstream whereas

BH3 is located in the upstream area. The borehole logs of

Appendix A indicate that the soil layers beneath the dam

axis are characterized by heterogeneity. While the silty

clay (with sand) dominates the ground in the location of BH1

with the permeability (k) slightly higher than 10-5 cm/s,

sandy silt and silty sand (with gravel) take over in the

location of BHs 2 and 4 with k in the range of approximately

10-3 to 10-5 cm/s. Silty clay (with sand) appears again in the

9

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

location of BHs 6 and 5 with k approximately in the range of

10-4 to 10-6 cm/s. The designer should take this

heterogeneity beneath the axis into account. Cement

injection may be carried out in the zones where k is less

than 10-4 cm/s. The soil profile along the dam axis, given in

Appendix A, demonstrates a clear picture of this

configuration.

In the upstream the picture is different, down to 10 m depth

the soil is either "silty gravel with sand" or "silty sand with

gravel" with permeability (k) in the range of approximately

10-2 to 10-3 cm/s. As it is generally known, if the coefficient

of permeability of the soil lies between about 10-4 and 10-6

cm/sec, no injection procedure is satisfactory; this indicates

that cement injection should be considered in the upstream

area. However, the employment of an impermeable

upstream blanket is recommended to further reduce the

seepage underneath the dam. Any measure designed to

lengthen the seepage path will result in a partial reduction

in under seepage. In the depth 10 to 15 m the soil upstream

is silty clay (with sand and gravel) with k about 10-6 cm/s.

The SPT results reflected the same heterogeneity noted

above. On right and left of the dam axis (zones dominated

by silty clay) the SPT count (N) is mostly higher than 50

marking a hard consistency. Mid of the dam axis (zones

dominated by silty sand), the value of N is in the range of 13

to 38 marking a medium to dense continuum

A filter should be used in the downstream end to act as an

interceptor, keeping the downstream slope in an

unsaturated state. The use of a clay core is highly

dependent on the dam size, head and the detailed design.

The difference between water table depths is attributed to

the difference between the natural ground elevations

between boreholes. In addition, it appears that the

measured water level does not always represent a true

underground water level. The existence of pockets of low

permeability may cause the confinement of water at

different levels.

10

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

4.2 Test Results

The tables of test results are given in Appendix B.

The unified soil classification of the tested ground at the left

and right of the dam axis is mostly of the CL (clay of low

plasticity) type. At the middle of the axis the ground is

mostly of the SM (silty sand) type. Upstream, the ground is

mostly of the SM and GM (silty gravel) type

The grading details are given in the tables besides the

Atterberg limits. The values of the plasticity index do not

indicate significantly expansive clay specially when taken

into consideration that the Atterberg limit tests are

conducted on the clayey part excluding the gravels.

The carbonate content is generally within 10% except few

locations where it exceeded 20% which indicates that the

soil is somewhat calcareous. The total soluble salts are

generally within 10%; this may cause slight gradual

subsidence during the service life of the dam.

. The percents of organic material are acceptable.

Therefore, future creep (secondary compression) is not

expected. However, tie beams for isolated shallow

foundations, if required, are recommended to account for

environmental changes or accidents which may cause

differential settlement.

In reference to gypsum content, BHs 2, 3, 4 and 5 did not

show appreciable content. However, at depths of 10 and15

m in BH 1, the laboratory Engineer noted pockets of

accumulated white material which upon testing appeared to

be gypsum (up to 56.9%). Other tested samples in the same

hole did not reveal significant content except at 13.5 m

where the content was 12.47%. High amounts of gypsum

(e.g. 27.5% at 10 m and 45.5% at 19.5 m) are also noted in

BH 6 but not all the tested specimens. It appears that only

the clayey soil showed localities of high gypsum content. It

is not possible to judge if the gypsum exists or not in the

zone between the present boreholes unless more holes are

executed or may be relied to some geophysical

procedures. The latter are not accurate for this purpose.

11

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

It is recommended to use sulphate-resisting cement for

foundation work.

The high gypsum content, the ground heterogeneity and

the total soluble sulphate, all these lead us to the

recommendation of employing an advanced monitoring

system to record the movements of the dam during the

service life.

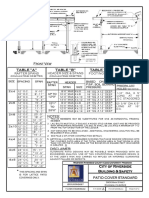

4.3 Bearing Capacity

The standard penetration results of all boreholes have been

considered. As mentioned in section 4.1 the values of N at

the middle of the dam are less than those at the right and

left, reasonable representative value should be adopted.

The value of (N) has been employed to calculate the

allowable bearing capacity (qa) using the chart of Terzaghi

and Peck given below (Fig. 4). The obtained value has been

incorporated with the value calculated from Terzaghi

Theory based on the angle of internal friction () as

estimated from the value of N using the correlation chart

also shown below.

Terzaghi equation takes the form;

q u cN c 0.5BN DN q

where q u ultimate bearing capacity

c cohesion

density

N c , N and N q are bearing capacity factors

B footing width

D footing depth

The calculated values should be considered in conjunction

with engineering judgment and taking into account the site

heterogeneity and the existence of gypsum.

The value of the recommended net allowable bearing

capacity is:

qa = 120 kN/m2 ~ 12 Ton/m2

12

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

However, it is also recommended for all the main shallow

foundations to be placed below 1.5 m depth otherwise strict

measures should be taken to ensure the rigidity of the

foundations.

45

o

40

35

30

25

10

20

30

40

50

60

Approximate relation between N and

Fig. 4 Correlations for estimation of allowable bearing capacity

from SPT

4.4 Soil Compressibility and Collapsibility

SPT results indicate that the encountered layers possess

significantly varied strength ranging from hard clayey soil

to medium sandy soil. Thus, immediate settlement may

vary along the dam axis.

It is known that the SPT allowable bearing pressure chart is

based on settlement considerations. The immediate

settlement will then remain less than 25 mm as far as the

pressure is less than that specified in the chart unless salt

dissolution takes place.

Immediately after construction and application of loads the

differential settlement will primarily depend on the rigidity

of the structure. For isolated footings the differential

settlement primarily depends on the tie beams. However,

most building codes specify the tolerable differential

13

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

settlement as being more than 25 mm. Such a value is not

presently expected because the total settlement is already

less than 25 mm.

Time after construction differential settlement may result

due to leak of water from tanks or broken pipes, thereby

high maintenance performance should be provided.

The values of the compression index obtained from the

consolidation tests are low; therefore the consolidation

settlement is not expected to be significant. Also, the soil

has no indication of significant swelling characteristics.

The collapsibility of the soil results from the existence of

cementing materials which softens or dissolves on the

arrival of water. Collapsible behavior may take place due to

the existence of high gypsum content in certain zones.

Therefore, movements of the dam should be monitored in

order to take fast actions, when necessary, like soil grouting

during the service life of the dam.

5. QUARRIES

In order to ascertain the existence of nearby raw materials

for the construction of the dam, an investigation was

conducted to find out the available quarries near the dam.

The number of quarries test pits was ten. The depth of each

pit was bout 3m. Gravelly, sandy and clayey quarries were

found.

Samples were extracted every 1m. Grading tests have been

conducted on all the samples. In addition, compaction and

chemical tests have been performed on the clay in order to

determine the maximum dry density and optimum moisture

content and ascertain the suitability of the material. The test

results are given in Appendix C. The designer of the dam

may review this information in order to approach an

economical design according to the requirements of each

dam. Fig. 5 below shows the location of gravel, sand and

clay quarries and their approximately area with respect to

the shahabi dam location.

14

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

Fig. 5 Quarries Location with respect to the Shahabi Dam

(Earth Google Picture with Scale)

15

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

6. CONCLUSIONS AND RECOMMENDATIONS

1) The ground of the dam site is characterized by

heterogeneity. Both the type of soil and the strength

varies significantly along the dam axis. Hard silty

clay dominates on the right and left whereas medium

to dense silty sand dominates on the middle of the

dam axis.

2) The permeability coefficient also varies along the

dam axis but generally of low value. Differently the

upstream permeability is in the range of

approximately 10-2 to 10-3 cm/s with the ground

being sandy and gravelly.

3) Cement injection should be considered particularly

in the upstream area.

4) It is recommended to use an impermeable upstream

blanket extending a sufficient distance on the

upstream side.

5) The net allowable bearing capacity of the site may be

taken as 120 kN/m2. The depth of main footings is

preferably deeper than 1.5 m.

6) In two of the boreholes the gypsum content is high,

up to 56.9 %, at certain depths below the dam axis.

The total soluble salts are generally within 10%.

7)

It is recommended to employ an advanced

monitoring system to record the movements of the

dam during the service life.

8) It is recommended to use sulphate-resisting cement

for foundation work; the shallow foundation in contact

with soil may also be protected using two layers of

tar coat. The strength (fc`) of the used concrete is

preferably not less than 30 MPa.

16

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / AlMustansirya University

9) Near to the site of each dam, clayey, sandy and

gravelly quarries are found.

10) No significant amount of gypsum was found in the

clay quarries soil. Therefore; may the quarries

material be used, as convenient.

Geotechnical Eng.

Gitath A. S. Al-Sharifi

Geotechnical Eng.

Mohammed H. Al-Dahalki

Prof. Geotecnical Eng.

Dr. Raid R. Al-Omari

7. REFERENCES

1. American Society for Testing Materials (ASTM),

1989.

2. Peck, R., Hansen, W. and Thornburn, T. Foundation

Engineering. John Wiley & Sons, 1974.

3. Bowles, J.E., Foundation Analysis and Design, 5th

Edition, 1996.

4. Lambe, T.W.and Whitman, R.V., Soil Mechanicals

John Wiley & Sons, Inc., 1969.

5. Teng,W.C. " Foundation Design ", Prentice Hall ,

New Jersey , 1974.

6. Terzaghi , K.and Peck , R.,B.,"Soil Mechanics in

Engineering Practice" ,1967

7. Tomlinson, M.J., Foundation Design & Construction,

Pitman, 3rd Edition, 1975.

10. Singh, B. and Prakash, S. (1970). Soil mechanics

and Foundation Engineering. New Chand and Bros

Rookee.

11. Earth Manual (1980) U.S. Department of the Interior

Water and Power Resources Service.

12. "Dam Foundations" Commission International des

Grands. Bds Haussmann, 75008 Paris, 2000.

17

August, 2009

Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

APPENDIX A

Borehole Logs

(Boreholes + Quarries)

&

Geological Cross Section

for Dam Axis

A0

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A1

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A2

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A3

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A4

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A5

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A6

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A7

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A8

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A9

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A10

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A11

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A12

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A13

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A14

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A15

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A16

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A17

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

A18

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

APPENDIX B

Tables of Test Results

BOREHOLES (1-6)

&

SPT Records

U Undisturbed Sample

D- Disturbed Sample

SS- Split Spoon Sample

C Core Sample

B0

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Borhole No. :1

Depth:25

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Sample

Depth

(m)

Typ

e

0.0-1.5

1.5-3.0

3.0-3.5

3.5-4.0

4.0-5.5

5.5-6.0

6.0-6.5

6.5-8.0

8.0-9.5

9.5-10

10-11.5

11.5-13

13-13.5

13.5-15

15-16.5

16.5-17

17-18.5

18.5-20

20-20.5

20.5-22

22-23.5

23.5-24

24-25.5

C

C

US

SS

C

US

SS

C

C

SS

C

C

SS

C

C

SS

C

C

SS

C

C

SS

C

Index properties

L.L

P.I

USCS

%

%

w.c

%

Dry

Density

kN/m3

Gs

46.81

40.32

45.24

38.86

39.62

39.93

40.86

40.84

34.84

-

15.3

17.1

-

16.74

17.07

-

2.66

2.69

2.68

2.67

2.68

2.67

2.67

2.68

2.68

-

25.01

20.9

23.08

20.66

20.72

19.82

21.04

20.18

17.54

-

SM

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

Grain size analysis

Grav. San Silt Cla

%

d

%

y

%

%

0

0

0

0

0

0

0

-

65.2

34.8

12.6 55.6 31.8

12.4

87.6

41.4

58.6

23.5

76.5

33.6

66.4

28.2 36.4 35.4

44.9

55.1

7.1

92.9

12.1 48.6 39.3

5.4

94.6

6.7

93.3

W.T = 12.0 m

qu

kPa

Chemicals tests

T.S.S CaCo3 O.M Gyp.

%

%

%

%

134

145

-

8.02

7.82

13.04

12.05

9.08

-

Consolidation Test

eo

Pc,

kPa

Cc

Cr

0.576

115

0.102

0.009

0.534

121

0.113

0.012

24.03

10.71

7.12

13.65

8.34

-

2.31

1.73

6.0

2.36

1.81

-

B1

August, 2009

Al-Shahabi Dam / Wassit Governorate

1.93

2.08

28.2

12.47

56.9

6.77

1.30

-

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Borhole No. :2

Depth:20

Sample

Index properties

No.

Depth

(m)

Typ

e

L.L

%

P.I

%

USCS

w.c

%

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

0.0-1.5

1.5-3.0

3.0-3.5

3.5-5.0

5.0-6.5

6.5-7.0

7.0-8.5

8.5-10

10-10.5

10.5-12

12-13.5

13.5-14

14-15.5

15.5-17

17-17.5

17.5-19

19-20.5

C

C

SS

C

C

SS

C

C

SS

C

C

SS

C

C

SS

C

C

36.32

-

18.78

-

SM

SM

SM

SM

SM

SM

SM

SM

SM

SM

SM

SM

SM

CL

CL

CL

CL

Grain size analysis

Dry

Density

kN/m3

Gs

2.66

2.67

2.67

2.68

2.68

-

Grav.

%

2.9

30.0

8.5

1.2

15.2

29.6

24.8

-

Sand

%

Silt

%

Clay

%

51.2

48.8

78.3

18.8

79.6

20.4

56.6

15.4

75.4

16.1

76.3

23.7

77.1

21.7

73.4

26.6

74.4

25.6

62.6

22.2

11.2

32.8

26.4

9.4

65.8

W.T = 5.20 m

eo

-

Consolidation

Test

Pc,

Cr

Cc

kPa

-

qu

kPa

-

Chemicals tests

T.S.S

%

CaCo3

%

O.M

%

Gyp.

%

7.19

9.53

7.66

-

8.32

9.43

13.65

-

2.05

0.71

1.82

-

4.73

2.61

1.91

-

B2

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Borhole No. :3

Depth:15

No.

Sample

Depth

(m)

Typ

e

1

2

3

4

5

6

7

8

9

10

11

12

13

0.0-1.5

1.5-3.0

3.0-3.5

3.5-5.0

5.0-6.5

6.5-7.0

7.0-8.5

8.5-10

10-10.5

10.5-12

12-13.5

13.5-14

14-15.5

C

C

SS

C

C

SS

C

C

SS

C

C

SS

C

Index properties

L.L

P.I

USCS

%

%

39.99

-

20.91

-

GM

SM

GM

SM

GM

GM

SM

SM

SM

CL

CL

CL

CL

w.c

%

Dry

Density

kN/m3

Gs

2.68

2.68

Grain size analysis

Grav. Sand Silt Clay

%

%

%

%

47.3

37.1

41.6

31.4

43.7

42.5

50.8

45.2

56.1

39.9

10.2

12.1

13.2

12.5

-

16.4

33.6

45.5

20.9

17.2

14.8

33.3

34.7

15.3

14.6

70.1

13.1

13.8

34.1

39.0

W.T = At the Ground Surface

Consolidation Test

Pc,

Cr

eo

Cc

kPa

-

qu

kPa

-

T.S.S

%

8.04

7.61

9.27

-

Chemicals tests

CaCo3 O.M Gyp.

%

%

%

11.01

8.73

10.66

-

0.52

1.28

1.05

-

B3

August, 2009

Al-Shahabi Dam / Wassit Governorate

1.02

3.71

2.06

-

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Borhole No. :4

Depth:15

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Sample

Depth

Type

(m)

Index properties

L.L

P.I

USCS

%

%

0.0-1.5

1.5-3.0

3.0-3.5

3.5-5.0

5.0-6.5

6.5-7.0

7.0-8.5

8.5-10

10-10.5

10.5-12

12-13.5

13.5-14

14-15.5

36.20

37.42

-

C

C

SS

C

C

SS

C

C

SS

C

C

SS

C

18.31

19.01

-

SM

SM

SM

SM

SM

SM

SM

GM

SM

CL

CL

CL

CL

w.c

%

Dry

Density

kN/m3

Gs

2.68

2.68

Grain size analysis

Grav. Sand Silt Clay

%

%

%

%

39.1

51.2

9.7

37.8

48.9

13.3

35.6

49.6

14.8

47.1

40.2

12.7

42.5

41.3

16.2

33.2

52.3

14.5

34.5

52.4

13.1

52.7

39.1

8.2

23.6

33.6

42.8

6.8

18.3

43.7

31.2

8.9

14.8

46.7

29.6

W.T = At the Ground Surface

Consolidation Test

Pc,

Cr

eo

Cc

kPa

-

qu

kPa

-

T.S.S

%

7.91

8.24

6.28

5.13

-

Chemicals tests

CaCo3

O.M

%

%

8.33

4.02

7.41

24.99

-

0.83

1.01

1.15

3.00

-

B4

August, 2009

Al-Shahabi Dam / Wassit Governorate

Gyp.

%

2.09

3.62

2.03

1.72

-

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Borhole No. :5

Depth:25

No

.

Sample

Depth

(m)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

0.0-1.5

1.5-3.0

3.0-3.5

3.5-4.0

4.0-5.5

5.5-7.0

7.0-7.5

7.5-8.0

8.0-9.5

9.5-11

11-11.5

11.5-12

12-13.5

13.5-15

15-15.5

15.5-16

16-17.5

17.5-19

19-19.5

19.5-21

21-22.5

22.5-23

23-24.5

24.5-25

25-25.5

Typ

e

C

C

US

SS

C

C

US

SS

C

C

US

SS

C

C

US

SS

C

C

SS

C

C

SS

C

US

SS

Index properties

L.L

P.I

USCS

%

%

w.c

%

Dry

Density

kN/m3

36.62

35.35

42.91

44.96

39.9

36.47

41.5

-

12.4

21.7

20.7

21.2

23.4

-

18.01

16.63

16.92

16.16

-

19.21

18.76

22.65

23.98

20.1

18.85

21.05

-

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

SM

SM

CL

CL

CL

CL

CL

CL

CL

CL

CL

Gs

2.68

2.66

2.69

2.68

2.67

2.68

2.69

2.66

2.67

2.69

2.66

2.68

2.67

Grain size analysis

Grav Sand Silt Cla

%

%

%

y

%

0

0

0

0

0

0

0

0

0

0

0

0

0

21.3

49.2 29.5

33.4

66.6

22.7

77.3

20.8

45.8 33.4

6.7

53.0 40.3

12.9

87.1

14.3

45.5 40.2

17.4

82.6

54.7

45.3

20.4

43.8 35.8

22.7

77.3

25.0

44.2 30.8

38.1

40.3 21.6

W.T = 6.50 m

Consolidation Test

eo

Pc,

kPa

Cc

Cr

qu

kPa

0.449

0.581

0.554

0.627

-

88

109

138

154

-

0.101

0.138

0.147

0.176

-

0.008

0.011

0.010

0.012

-

100

141

176

196

-

Chemicals tests

T.S.S CaCo3 O.M Gyp.

%

%

%

%

8.66

8.71

7.74

9.75

4.52

17.07

7.57

12.31

10.02

9.72

28.42

18.87

2.01

1.02

1.25

2.06

2.33

1.39

B5

August, 2009

Al-Shahabi Dam / Wassit Governorate

3.03

1.51

2.19

1.31

1.29

15.98

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Borhole No. :6

Depth:20

Sample

Index properties

Depth Typ L.L

P.I

USCS

(m)

e

%

%

0.0-1.5

1.5-3.0

3.0-3.5

3.5-4.0

4.0-5.5

5.5-7.0

7.0-7.5

7.5-8.0

8.0-9.5

9.5-10

10-11.5

11.5-13

13-13.5

13.5-14

14-15.5

15.5-16

16-17.5

17.5-19

19-19.5

19.5-21

21-21.5

21.5-22

C

C

US

SS

C

C

US

SS

C

SS

C

C

US

SS

C

SS

C

C

SS

C

US

SS

32.98

44.94

48.16

42.58

48.67

37.99

39.82

-

16.18

22.84

23.92

21.97

24.56

19.79

20.11

-

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

SM

CL

CL

SM

SM

SM

SM

w.c

%

Dry

Density

kN/m3

Gs

14.8

24.9

23.7

23.6

-

16.61

15.73

16.15

-

2.68

2.67

2.68

2.69

2.67

2.69

2.70

2.69

2.68

-

Grain size analysis

Grav. Sand Silt Clay

%

%

%

%

0

0

0

0

0

0

0

0

0

0

0

0

28.1

13.2

11.8

10.5

38.8

20.1

22.2

51.4

31.8

59.6

51.9

Consolidation Test

Pc,

eo

Cc

Cr

kPa

71.9

86.8

61.2 38.2

51.2 37.0

89.5

61.2

49.8 30.1

77.8

48.6

68.2

40.4

48.9

0.577

97

0.101

0.007

0.665

90

0.175

0.011

0.640

86

0.151

0.010

qu

kPa

Chemicals tests

T.S.S CaCo3 O.M Gyp.

%

%

%

%

115

101

95

-

7.54

8.25

15.87

20.22

16.37

8.22

6.31

20.7

12.03

11.81

1.59

2.5

2.4

0.98

1.47

W.T = 6.70 m

B6

August, 2009

Al-Shahabi Dam / Wassit Governorate

1.29

27.5

11.39

45.5

12.04

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

SPT - Records

B.H. No

Depth m

S.P.T Number

3.5-4.0

6.0-6.5

9.5-10

13-13.5

16.5-17

20-20.5

23.5-24

3.0-3.5

6.5-7.0

10-10.5

13.5-14

17-17.5

3.0-3.5

6.5-7.0

10-10.5

13.5-14

46

51

57

74

51

83

82

28

13

28

26

33

22

27

29

32

B.H. No

4

Depth m

S.P.T Number

3.0-3.5

6.5-7.0

10-10.5

13.5-14

3.5-4.0

7.5-8.0

11.5-12

15.5-16

19-19.5

22.5-23

25-25.5

27

29

38

34

34

54

70

41

78

80

87

3.5-4.0

7.5-8.0

9.5-10

13.5-14

15.5-16

19-19.5

21.5-22

39

60

40

34

37

69

53

B7

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

APPENDIX C

Tables of Test Results

QUARRIES (1-10)

U Undisturbed Sample

D- Disturbed Sample

SS- Split Spoon Sample

C Core Sample

C0

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Table -1- Gravel quarries

% Finer

Diameter

Quarry N0.1

Quarry N0.2

Quarry N0.3

mm

Depth1 Depth Depth Depth Depth Depth Depth Depth Depth

m

2m

3m

1m

2m

3m

1m

2m

3m

75

100

100

100

100

82.69

100

100

100

100

50

87.45

93.94 91.15 87.36 66.56 82.38

87.9

84.18 94.37

25

62.32

85.84 63.47 74.58 46.85 60.44 79.17 48.24

70.1

9.5

31.97

56.84 24.26 46.94 26.98 35.21 50.07 25.92

38

4.75

20.5

30.53 11.78 27.16 15.98

21.3

34.27 15.46 21.56

2.36

14.06

17.85

7.87

17.89

9.84

14.78 24.47 10.21 14.04

0.3

3.09

5.47

3.85

8.12

3.42

5.34

7.67

3.99

5.65

0.075

0.47

0.99

0.32

0.54

0.42

0.38

0.81

0.64

0.46

C1

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Table -2- Sand quarries

% Finer

Diameter.

Quarry N0.1

Quarry N0.2

Quarry N0.3

mm

Depth1 Depth Depth Depth Depth Depth Depth Depth Depth

m

2m

3m

1m

2m

3m

1m

2m

3m

25

100

100

100

100

100

100

100

100

100

9.5

98.47

98.3

98.35 98.55 99.27

99

98.81 98.68

98.5

4.75

78.6

85.66 82.53

83

84.82 78.18 84.93 86.41 79.34

2.36

66.52

77.84 73.89 75.52

74.2

63.35 76.52 77.92 65.87

1.18

60.19

72.41 68.31 69.42 67.98 55.88 68.49 70.67 58.07

0.6

51.82

61.14 50.76 52.69 56.99 46.64 55.48 55.58 45.75

0.3

19.5

23.47 15.26 17.56 21.18 15.28 19.72 20.63 26.25

0.15

4.17

5.12

3.61

3.63

3.83

3.29

4.19

3.12

6.81

0.075

2.5

2.91

1.71

2.02

1.71

1.33

2.04

0.81

3.48

C2

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Table -3- Clay quarries

Properties

Consolida

tion Test

Triaxi

al

Test

Max. dry

density kN/m3

O.M.C%

L.L%

P.L%

P.I%

c,

kPa

qu kPa 238

eo

Pc

Cc

Cr

F.S,

Swelling %

Char.

S.P.,

kPa

USCS

Gravel %

Sand %

Silt & Clay

T.S.S %

CaCo3%

O.M %

Gyp. %

Quarry N0.1

Quarry N0.2

Quarry N0.3

Quarry N0.4

Depth1 Depth Depth Depth Depth Depth Depth Depth Depth Depth Depth Depth

1m

2m

3m

1m

2m

3m

1m

2m

3m

1m

2m

3m

1.761

1.848

1.791

1.698

1.799

1.779

1.658

1.844

1.908

1.865

1.868

1.881

18.10

45.65

23.89

21.76

15.48

31.54

15.01

16.53

17.07

41.55

20.04

21.51

18.02

48.02

24.66

23.36

16.61

36.49

16.56

19.93

17.43

38.46

18.05

20.41

18.13

54.22

26.71

27.51

13.23

34.87

16.81

18.06

12.20

33.01

16.02

16.81

14.04

32.81

15.88

16.93

14.12

33.03

17.32

15.71

13.18

28.65

14.23

14.42

208

225

205

218

188

193

131

3.8

285

0.439

178

0.096

0.010

262

-

278

-

3.1

226

0.500

142

0.116

0.014

0.628

119

0.132

0.017

7.6

-

8.3

-

5.5

0.426

123

0.084

0.009

5.7

-

9.8

10.3

8.7

7.8

13.5

10.8

24.2

17.6

21.4

33.7

19.5

CL

5.4

9.3

85.3

-

CL

12.3

87.7

7.81

7.02

1.35

1.75

CL

8.7

10.2

81.1

-

CL

3.8

96.2

-

CL

1.4

98.6

7.22

5.60

2.53

1.94

CL

4.9

95.1

-

CH

0.9

99.1

-s

CL

23.7

76.3

5.27

11.9

2.90

2.06

CL

22.2

77.8

-

CL

14.9

85.1

-

CL

15.2

84.8

8.93

7.01

1.54

2.79

CL

39.2

60.8

-

C3

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

100

100

90

90

Gravel quarry No.2

Gravel quarry No.1

80

Depth = 1 m

Depth = 1 m

70

Depth = 2 m

70

Depth = 2 m

60

Depth = 3 m

60

Depth = 3 m

% Finer

% Finer

80

50

50

40

40

30

30

20

20

10

10

0

0

0.01

0.10

1.00

Graine Diameter mm

10.00

100.00

0.01

0.10

1.00

Graine Diameter mm

10.00

100.00

C4

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

100

100

90

90

Gravel quarry No.3

Sand Quarry No.1

Depth = 1 m

80

70

Depth = 2 m

70

60

Depth = 3 m

60

% Finer

% Finer

80

50

40

Depth = 1 m

Depth = 2 m

Depth = 3 m

50

40

30

30

20

20

10

10

0

0.01

0.10

1.00

Graine Diameter mm

10.00

100.00

0

0.01

0.10

1.00

Grain Diameter mm

10.00

100.00

C5

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

100

100

90

90

Sand Quarry No.2

70

% Finer

60

Sand Quarry No.3

80

Depth = 1 m

70

Depth = 2 m

Depth = 3 m

60

% Finer

80

50

40

30

30

20

20

10

10

0

0.10

1.00

Grain Diameter mm

10.00

100.00

Depth = 2 m

Depth = 3 m

50

40

0.01

Depth = 1 m

0.01

0.10

1.00

Grain Diameter mm

10.00

100.00

C6

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

APPENDIX D

Field Permeability Tests Records

BOREHOLES (1-6)

D0

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Permeability Test

Sample of calculations

B.H. No. 2 depth 19-20 m

H =5.2 m

(deferential head of water)

L = 1.0 m

(Length of the portion of hole tested)

r = 6.35 cm

(radius of hole)

Q = 0.42 liter/5min. (Constant rate of flow)

k = Q/(2 x 3.14 x L x H) ln (L/r)

k = (0.42x 1000/60)/(2x3.14x100x520) ln(100/6.35)

= 1.18 x 10-5 cm /s

D1

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

B.H. No. 1

Test No. (1)

Tested depth- 4 to 5m

Head = 6.5m

Time

Discharge

"minute"

"liter"

0-5

15.8

5-10

10.5

10-15

4.3

15-20

3.1

20-25

2.5

25-30

2.3

Test No. (2)

Tested depth- 9 to 10m

Head = 6.5m

Time

Discharge

"minute"

"liter"

0-5

4.1

5-10

3.2

10-15

2.1

15-20

1.8

20-25

1.44

25-30

1.30

Test No. (3)

Tested depth- 14 to 15m

Head = 7.5m

Time

Discharge

"minute"

"liter"

0-5

3.1

5-10

2.5

10-15

1.5

15-20

1.2

20-25

0.94

25-30

0.91

Test No. (4)

Tested depth- 19 to 20m

Head = 7.5m

Time

Discharge

"minute"

"liter"

0-5

2.1

5-10

1.5

10-15

1.3

15-20

1.1

20-25

0.76

25-30

0.61

Test No. (5)

Tested depth- 24 to 25m

Head = 6.5

Time

Discharge

"minute"

"liter"

0-5

1.8

5-10

1.6

10-15

0.8

15-20

0.9

20-25

0.65

25-30

0.60

k (cm/s) = 5.40 x 10-5

k (cm/s) = 3.08 x 10-5

k (cm/s) = 1.81 x 10-5

k (cm/s) = 1.34 x 10-5

k (cm/s) = 1.41 x 10-5

D2

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

B.H. No. 2

Test No. (1)

Tested depth- 4 to 5m

Head = 6.5m

Time

Discharge

"minute"

"liter"

0-5

75.3

5-10

50.4

10-15

33.8

15-20

25.7

20-25

21.5

25-30

18.6

Test No. (2)

Tested depth- 9 to 10m

Head = 5.2m

Time

Discharge

"minute"

"liter"

0-5

40.8

5-10

29.6

10-15

23.9

15-20

18.3

20-25

19.8

25-30

17.3

Test No. (3)

Tested depth- 14 to 15m

Head = 6.2m

Time

Discharge

"minute"

"liter"

0-5

18.5

5-10

19.7

10-15

16.8

15-20

15.1

20-25

13.4

25-30

12.9

Test No. (4)

Tested depth- 19 to 20m

Head = 6.2m

Time

Discharge

"minute"

"liter"

0-5

2.4

5-10

0.8

10-15

1.1

15-20

0.3

20-25

0.4

25-30

0.4

k (cm/s) = 4.51 x 10-4

k (cm/s) = 5.22 x 10-4

k (cm/s) = 3.10 x 10-4

k (cm/s) = 1.18 x 10-5

D3

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

B.H. No. 3

Test No. (1)

Tested depth- 4 to 5m

Head = 2.0m

Time

Discharge

"minute"

"liter"

0-5

157

5-10

155

10-15

149

15-20

139

20-25

142

25-30

137

Test No. (2)

Tested depth- 9 to 10m

Head = 2.0m

Time

Discharge

"minute"

"liter"

0-5

46.9

5-10

47.8

10-15

45.3

15-20

42.9

20-25

41.8

25-30

43.2

Test No. (3)

Tested depth- 14 to 15m

Head = 2.0m

Time

Discharge

"minute"

"liter"

0-5

0.93

5-10

0.26

10-15

0.31

15-20

0.19

20-25

0.10

25-30

0.11

k (cm/s) = 1.02 x 10-2

k (cm/s) = 3.11 x 10-3

k (cm/s) = 7.81 x 10-6

D4

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

B.H. No. 4

Test No. (1)

Tested depth- 4 to 5m

Head = 2.0m

Time

Discharge

"minute"

"liter"

0-5

77.3

5-10

82.2

10-15

78.8

15-20

71.2

20-25

71.6

25-30

70.9

Test No. (2)

Tested depth- 9 to 10m

Head = 2.0m

Time

Discharge

"minute"

"liter"

0-5

32.1

5-10

35.9

10-15

29.7

15-20

24.9

20-25

25.4

25-30

25.8

Test No. (3)

Tested depth- 14 to 15m

Head = 2.0m

Time

Discharge

"minute"

"liter"

0-5

1.10

5-10

0.61

10-15

0.81

15-20

0.35

20-25

0.28

25-30

0.27

k (cm/s) = 5.21 x 10-3

k (cm/s) = 1.87 x 10-3

k (cm/s) = 2.01 x 10-5

D5

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

B.H. No. 5

Test No. (1)

Tested depth- 4 to 5m

Head = 6.5m

Time

Discharge

"minute"

"liter"

0-5

12.3

5-10

5.2

10-15

3.1

15-20

1.0

20-25

0.83

25-30

0.84

Test No. (2)

Tested depth- 9 to 10m

Head = 6.5m

Time

Discharge

"minute"

"liter"

0-5

2.2

5-10

0.93

10-15

1.21

15-20

0.77

20-25

0.49

25-30

0.51

Test No. (3)

Tested depth- 14 to 15m

Head = 7.5m

Time

Discharge

"minute"

"liter"

0-5

5.8

5-10

3.9

10-15

4.3

15-20

3.7

20-25

3.5

25-30

3.5

Test No. (4)

Tested depth- 19 to 20m

Head = 7.5m

Time

Discharge

"minute"

"liter"

0-5

0.91

5-10

1.20

10-15

0.56

15-20

0.66

20-25

0.48

25-30

0.45

Test No. (5)

Tested depth- 24 to 25m

Head = 6.5

Time

Discharge

"minute"

"liter"

0-5

0.72

5-10

0.69

10-15

0.77

15-20

0.59

20-25

0.54

25-30

0.57

k (cm/s) = 1.88 x 10-5

k (cm/s) = 1.12 x 10-5

k (cm/s) = 6.82 x 10-5

k (cm/s) = 9.11 x 10-6

k (cm/s) = 1.25 x 10-5

D6

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

B.H. No. 6

Test No. (1)

Tested depth- 4 to 5m

Head = 6.5m

Time

Discharge

"minute"

"liter"

0-5

5.5

5-10

4.1

10-15

1.8

15-20

1.21

20-25

0.77

25-30

0.81

Test No. (2)

Tested depth- 9 to 10m

Head = 6.7m

Time

Discharge

"minute"

"liter"

0-5

4.55

5-10

2.81

10-15

3.35

15-20

2.92

20-25

2.07

25-30

2.10

Test No. (3)

Tested depth- 14 to 15m

Head = 7.7m

Time

Discharge

"minute"

"liter"

0-5

1.53

5-10

1.21

10-15

0.81

15-20

0.66

20-25

0.40

25-30

0.40

Test No. (4)

Tested depth- 19 to 20m

Head = 7.7m

Time

Discharge

"minute"

"liter"

0-5

5.5

5-10

4.1

10-15

4.5

15-20

3.2

20-25

3.1

25-30

2.9

k (cm/s) = 6.48 x 10-4

k (cm/s) = 3.80 x 10-4

k (cm/s) = 4.70 x 10-4

k (cm/s) = 3.62 x 10-4

D7

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Appendix E

Documentation of

Field

&

Laboratory Works

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

1 Field Works:

Plate # 1: View for the Job Site Area

Plate # 2: Another View for the Job Site Area showing

Soil Section

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Plate # 3: Shahabi River

Plate # 4 : Site Preparation for Boring

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Plate # 5: Site Preparation for Boring and Drilling Setting

Plate # 6: Drilling Process with Core Chopping Pit

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Plate # 7: Double Core used in Core Samples Extraction

Plate # 8: Drilling Process Setting

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Plate # 9: Standard Penetration Test (S.P.T)

Plate # 10: Core Sample Using Double Core Technique

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Plate # 11: Split Spoon Sampler (S.P.T)

Plate # 12: Core Samples for visual inspection in laboratory

Under Geologist Supervision

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Plate # 13: Samples collected Spread for Visual Testing

Plate # 14: Core Samples for visual insection in laboratory

Under Geologist Supervision

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

2 Laboratory Works

Plate # 15: Samples Extruder

Plate # 16: Sieve Analyses using Shaker

August, 2009

Al-Shahabi Dam / Wassit Governorate

Engineering Consultancy Bureau / College of Engineering / Al-Mustansirya University

Plate # 17: OneDimensional Consolidation Test

Plate # 18 : Triaxial Test (Unconfined Compression Test)

August, 2009

Al-Shahabi Dam / Wassit Governorate

S-ar putea să vă placă și

- Common Problems With Coordinate System Configurations - Trimble GeospatialDocument12 paginiCommon Problems With Coordinate System Configurations - Trimble GeospatialTuroyÎncă nu există evaluări

- Wind Design of Timber Panelised Roof Structures de-Panelized-Roof-WindDocument40 paginiWind Design of Timber Panelised Roof Structures de-Panelized-Roof-WindTuroyÎncă nu există evaluări

- Foundation Design Using Standard Penetration Test (SPT) N-ValueDocument39 paginiFoundation Design Using Standard Penetration Test (SPT) N-Valueneilmark undagÎncă nu există evaluări

- Biochemical Oxygen DemandDocument4 paginiBiochemical Oxygen DemandHutapeaReynoldHamonanganChristoffelÎncă nu există evaluări

- Bioremediated Ground ImprovementDocument26 paginiBioremediated Ground ImprovementTuroyÎncă nu există evaluări

- Mitek 6kN Pile FixingDocument2 paginiMitek 6kN Pile FixingTuroyÎncă nu există evaluări

- 038Document8 pagini038Divya Dev C MÎncă nu există evaluări

- BBSC 433 Jessica Bennett Wind Design GuideDocument34 paginiBBSC 433 Jessica Bennett Wind Design GuideTuroyÎncă nu există evaluări

- Soil Liquefaction - Presentation June 2009Document27 paginiSoil Liquefaction - Presentation June 2009TuroyÎncă nu există evaluări

- Considerations in Wind Design of Wood StructuresDocument9 paginiConsiderations in Wind Design of Wood StructuresTuroyÎncă nu există evaluări

- Triggering of Liquefaction Recurring Questions 10-BoulangerDocument30 paginiTriggering of Liquefaction Recurring Questions 10-BoulangerTuroyÎncă nu există evaluări

- Mitek 12kN Pile FixingDocument2 paginiMitek 12kN Pile FixingTuroyÎncă nu există evaluări

- SLIDE Water ModellingDocument10 paginiSLIDE Water ModellingTuroyÎncă nu există evaluări

- Grout Epcon c6Document8 paginiGrout Epcon c6TuroyÎncă nu există evaluări

- Door and Window Standard Sizes WANZ Test Size Configurations - July 2007Document1 paginăDoor and Window Standard Sizes WANZ Test Size Configurations - July 2007TuroyÎncă nu există evaluări

- Differences Between Autocad and Autocad LTDocument2 paginiDifferences Between Autocad and Autocad LTTuroyÎncă nu există evaluări

- Design of Chinese steel TV towers: Analysis of wind and seismic loadsDocument6 paginiDesign of Chinese steel TV towers: Analysis of wind and seismic loadsTuroyÎncă nu există evaluări

- Australia:: What Makes A Home Relocatable?Document2 paginiAustralia:: What Makes A Home Relocatable?TuroyÎncă nu există evaluări

- Reproducing The REal Pressure CoefficientsDocument8 paginiReproducing The REal Pressure CoefficientsTuroyÎncă nu există evaluări

- Options For A WInd Loading CodeDocument10 paginiOptions For A WInd Loading CodeTuroyÎncă nu există evaluări

- Foundations On Expansive Clays and RocksDocument6 paginiFoundations On Expansive Clays and RocksTuroyÎncă nu există evaluări

- Raft Technical ManualDocument24 paginiRaft Technical ManualTuroy100% (1)

- Dashcam Number of HrsDocument9 paginiDashcam Number of HrsTuroyÎncă nu există evaluări

- Engineers Briefing Invitation 20 May 2016Document2 paginiEngineers Briefing Invitation 20 May 2016TuroyÎncă nu există evaluări

- Discussion On Swelling SoilDocument4 paginiDiscussion On Swelling SoilTuroyÎncă nu există evaluări

- Driven Piles in Central Texas Expansive SoilsDocument10 paginiDriven Piles in Central Texas Expansive SoilsTuroyÎncă nu există evaluări

- Foundations On Expansive Soils Sudan Experience - XXDocument13 paginiFoundations On Expansive Soils Sudan Experience - XXTuroyÎncă nu există evaluări

- Engineers Briefing Invitation 20 May 2016Document2 paginiEngineers Briefing Invitation 20 May 2016TuroyÎncă nu există evaluări

- Computer Program For Simulation of Wall Construction SequenceDocument90 paginiComputer Program For Simulation of Wall Construction SequenceTuroyÎncă nu există evaluări

- Patio Cover Standard DrawingDocument2 paginiPatio Cover Standard DrawingTuroyÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- A-08g-7 South Line GD Report FINALDocument104 paginiA-08g-7 South Line GD Report FINALNitaiGauranga108Încă nu există evaluări

- My Fun Science Corner - Plant System How Do Plants Store Food Article 2Document2 paginiMy Fun Science Corner - Plant System How Do Plants Store Food Article 2api-243322195Încă nu există evaluări

- Geometrical Optics (Univ of Physics)Document43 paginiGeometrical Optics (Univ of Physics)punitha100% (1)

- Idealism PaperDocument3 paginiIdealism PaperUbong UdokaÎncă nu există evaluări

- The Borage Family Boraginaceae S STRDocument25 paginiThe Borage Family Boraginaceae S STRJeremy BrewerÎncă nu există evaluări

- Group VII - Smooth Muscle ContractionDocument7 paginiGroup VII - Smooth Muscle ContractioniqbalÎncă nu există evaluări

- EclipsesDocument45 paginiEclipsesKATRINA MARIE AmayÎncă nu există evaluări

- NullDocument40 paginiNullapi-25923204Încă nu există evaluări

- (Sri Guru) LESSON 13 Using Progressions in Jyotish2Document25 pagini(Sri Guru) LESSON 13 Using Progressions in Jyotish2gift108Încă nu există evaluări

- Dimba Chakra Saptarishis Astrology BWDocument16 paginiDimba Chakra Saptarishis Astrology BWGarga100% (3)

- Map ReadingDocument2 paginiMap ReadingSafwan SamsudinÎncă nu există evaluări

- ASI2020 Instrumentation and TechniquesDocument5 paginiASI2020 Instrumentation and TechniquesHemachander JuniÎncă nu există evaluări

- Geology of Labuan - 1852Document13 paginiGeology of Labuan - 1852Martin LavertyÎncă nu există evaluări

- What Are Annular EclipsesDocument4 paginiWhat Are Annular EclipsesabcSDÎncă nu există evaluări

- Proceedings of The International Conference On Earthquake Engineering and Structural Dynamics PDFDocument510 paginiProceedings of The International Conference On Earthquake Engineering and Structural Dynamics PDFzdravac9220100% (1)

- Bhāskara IIDocument1 paginăBhāskara IIRavi PatodiyaÎncă nu există evaluări

- Dr. Freddy Liew Yu Shin Post at UNIMASDocument4 paginiDr. Freddy Liew Yu Shin Post at UNIMASFreddy Liew Yu ShinÎncă nu există evaluări

- Rashi Character - Virgo Kanya - FDocument3 paginiRashi Character - Virgo Kanya - FRaju GovindÎncă nu există evaluări

- SILVA, C. M. ARBILLA, G. Antropoceno: Os Desafios de Um Novo MundoDocument29 paginiSILVA, C. M. ARBILLA, G. Antropoceno: Os Desafios de Um Novo MundoWagner Vinicius AmorimÎncă nu există evaluări

- Takahashi Temma Equatorial Mounts With Wireless GotoDocument9 paginiTakahashi Temma Equatorial Mounts With Wireless Gotokhs0722Încă nu există evaluări

- English 5 Quarter 3 Week 7 Las 2Document1 paginăEnglish 5 Quarter 3 Week 7 Las 2Cristine Joy Villajuan AndresÎncă nu există evaluări

- Hora Sarvam - Albert Einstein's Horoscope - Some ObservationsDocument4 paginiHora Sarvam - Albert Einstein's Horoscope - Some Observationsbharanivldv9Încă nu există evaluări

- Waking Up in Time by Peter RussellDocument3 paginiWaking Up in Time by Peter RussellVenkat Ram ReddyÎncă nu există evaluări

- 1Document8 pagini1yos29Încă nu există evaluări

- Wavelength by GratingDocument7 paginiWavelength by Gratingprateekjain0150% (2)

- Física - Alonso, Finn - Fundamental University Physics Vol.3 - Quantum and Statistical Physics PDFDocument305 paginiFísica - Alonso, Finn - Fundamental University Physics Vol.3 - Quantum and Statistical Physics PDFFelipe Mascarenhas0% (1)

- Hevelius Star Catalog Comparison to HipparcosDocument22 paginiHevelius Star Catalog Comparison to HipparcosLurzizare100% (1)

- Resume Hugo HuamaniDocument2 paginiResume Hugo Huamanihugoluis_hÎncă nu există evaluări

- IT ReportDocument78 paginiIT ReportGabriel100% (1)

- Introduction to Engineering GeologyDocument21 paginiIntroduction to Engineering GeologyBEENAYEK AdHIKARIÎncă nu există evaluări