Documente Academic

Documente Profesional

Documente Cultură

D540A213064

Încărcat de

Kem RaiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

D540A213064

Încărcat de

Kem RaiDrepturi de autor:

Formate disponibile

Journal of Civil Engineering and Construction Technology Vol. 2(9), pp.

189-197, 2 September, 2011

Available online at http://www.academicjournals.org/jcect

ISSN 2141-2634 2011 Academic Journals

Review

Coconut fibre: A versatile material and its applications

in engineering#

Majid Ali

Structure Design Section, National Engineering Services Pakistan (NESPAK) Islamabad Office, Pakistan.

E-mail: majidonefive@gmail.com. Tel: +92-300-5148037.

Accepted 11 July, 2011

This paper presents the versatility of coconut fibres and its applications in different branches of

engineering, particularly in civil engineering as a construction material. Coconut fibre is one of the

natural fibres abundantly available in tropical regions, and is extracted from the husk of coconut fruit.

Not only the physical, chemical and mechanical properties of coconut fibres are shown; but also

properties of composites (cement pastes, mortar and/or concrete etc), in which coconut fibres are used

as reinforcement, are discussed. The research carried out and the conclusions drawn by different

researchers in last few decades are also briefly presented. Graphs showing the relationship between

different properties are shown in this paper. Coconut fibres reinforced composites have been used as

cheap and durable non-structural elements. The aim of this review is to spread awareness of coconut

fibres as a construction material in civil engineering.

Key words: Coconut fibres, construction material, composites, cement and concrete.

INTRODUCTION

Coconut fibre is extracted from the outer shell of a

coconut. The common name, scientific name and plant

family of coconut fibre is Coir, Cocos nucifera and

Arecaceae (Palm), respectively. Coconut cultivation is

concentrated in the tropical belts of Asia and East Africa

(Aziz et al., 1984).

There are two types of coconut fibres, brown fibre

extracted from matured coconuts and white fibres

extracted from immature coconuts. Coconut fibres are

stiff and tough and have low thermal conductivity

(Asasutjarit et al., 2005). Coconut fibres are commercial

available in three forms, namely bristle (long fibres),

mattress (relatively short) and decorticated (mixed fibres).

These different types of fibres have different uses

depending upon the requirement. In engineering, brown

fibres are mostly used (Aggarwal, 1992; Agopyan et al.,

2005; Asasutjarit et al., 2007; Aziz et al., 1981; 1984;

Corradini et al., 2006; Fernandez, 2002; Li et al., 2007;

Munawar et al., 2007; Paramasivam et al., 1984;

Ramakrishna and Sundararajan, 2005a, b; Rao et al.,

2007; Reis, 2006; Satyanarayana et al., 1990; Toledo et

al., 2005).

According to official website of International Year for

Natural Fibres 2009, approximately, 500 000 tonnes of

#

Also submitted in Second International Conference on Sustainable Materials

and Technologies, June 28-30, 2010.

coconut fibres are produced annually worldwide, mainly

in India and Sri Lanka. Its total value is estimated at $100

million. India and Sri Lanka are also the main exporters,

followed by Thailand, Vietnam, the Philippines and

Indonesia. Around half of the coconut fibres produced is

exported in the form of raw fibre.

Figure 1 show a coconut tree, coconut and coconut

fibres. Figure 2 shows the structure (longitudinal and

cross section) of an individual fibre cell (Abiola, 2008).

There are many general advantages of coconut fibres

e.g. they are moth-proof, resistant to fungi and rot, provide excellent insulation against temperature and sound,

not easily combustible, flame-retardant, unaffected by

moisture and dampness, tough and durable, resilient,

springs back to shape even after constant use, totally

static free and easy to clean.

PROPERTIES OF COCONUT FIBRES

Physical and mechanical properties

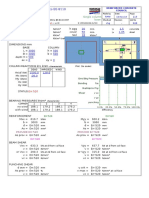

The physical and mechanical properties of coconut fibres

are presented in Table 1. The conditions specifically

mentioned by the researchers are given at the end of

Table 1. Coconut fibres were investigated by many

190

J. Civ. Eng. Constr. Technol.

commercial software ABAQUS. The author found that the

inner coconut fibre had a higher mechanical strength as

compared to that of outer fibre, but the outer coconut

fibre had a higher elongation property which could makes

it to absorb or with stand higher stretching energy as

compared to the inner coconut fibre.

Chemical properties

Figure 1. Coconut tree, coconut and coconut fibres.

Fig. 1. Coconut Tree, Coconut and Coconut fibres

researchers for different purposes.

There is a huge difference in some properties, for

example, diameter of coconut fibres is approximately

same and magnitudes of tensile strength are quite

different, e.g. compare tensile strength of coconut fibres

mentioned by Ramakrishna and Sundararajan (2005a)

and Toledo et al. (2005) in Table 1.

Also, the range shown for a particular property is quite

wide; Toledo et al. (2005) mentioned the density of

coconut fibre as 0.67-10.0 g/cm3. These values seem to

be unrealistic, real values may be 0.67-1.00 g/cm3.

There are variations in properties of coconut fibres, and

this makes it difficult for their frequent use as construction

material. The purpose of compilation of data for the

properties of fibres is to get a guideline, but after

compilation, a huge variation is seen. There should be

some standards for such variations, just like we have

standards for sand and aggregates.

Figure 3 shows stress-strain relationship for coconut

fibres as reported by some researchers (Paramasivam et

al., 1984; Munawar et al., 2007; Satyanarayana et al.,

1990). Coconut fibre is the most ductile fibre amongst all

natural fibres. Coconut fibres are capable of taking strain

4-6 times more than that of other fibres as shown in

Figures 3b and 3c (Munawar et al., 2007; Satyanarayana

et al., 1990).

Fibre dimensions of the various individual cells are said

to be dependent on the type of species, location and

maturity of the plant. The flexibility and rupture of the fibre

is affected by the length to diameter ratio of the fibre and

this also determines the product that can be made from it.

The shape and size of central hollow cavity, lumen,

depends on (i) the thickness of the cell wall and (ii) the

source of the fibre. The hollow cavity serves as an

acoustic and thermal insulator because its presence

decreases the bulk density of the fibre (Flower et al.,

2006 as cited by Abiola, 2008).

Abiola (2008) evaluated the mechanical properties

(load-extension curves, stress-strain curves, Youngs

modulus, yield stress, stress and strain at break) of inner

and outer coconut fibres experimentally, and the results

were verified by finite element method using a

Coconut fibres contain cellulose, hemi-cellulose and

lignin as major composition. These compositions affect

the different properties of coconut fibres. The pre-treatment of fibres changes the composition and ultimately

changes not only its properties but also the properties of

composites. Sometimes it improves the behaviour of

fibres but sometimes its effect is not favourable. The

chemical composition of coconut fibres is presented in

Table 2.

Ramakrishna and Sandararajan (2005a) investigated

the variation in chemical composition and tensile strength

of four natural fibres (coconut, sisal, jute and hibiscus

cannabinus fibres), when subjected to alternate wetting

and drying and continuous immersion for 60 days in three

mediums (water, saturated lime and sodium hydroxide).

Chemical composition of all fibres changed for tested

conditions (continuous immersion was found to be

critical), and fibres lost their strength. But coconut fibres

were reported best for retaining a good percentage of its

original tensile strength for all tested conditions. The

effect of pre-treatment of coconut fibres is also

investigated by Asasutjarit et al. (2007) for light weight

cement boards.

PROPERTIES OF COCONUT FIBRE REINFORCED

COMPOSITES

Cement paste

Aziz et al. (1981) cited the work of Das Gupta et al.

(1978, 1979) who studied the mechanical properties of

cement paste composites for different lengths and

volume fractions of coconut fibres. The authors concluded that the tensile strength and modulus of rupture of

cement paste increased up to a certain length and

volume fraction; and further increase in length or volume

fraction decreased the strength of composite. Table 3

shows the tensile strength and modulus of rupture of

cement paste composite reinforced with different volume

fractions of 38 mm long coconut fibres ranging from 2 to

6 %. It can be easily observed that 4 % volume fraction of

coconut fibres had given the highest mechanical

properties amongst all tested volume fractions.

With 4% volume fraction, the authors also studied the

tensile strength of cement paste reinforced with different

lengths of coconut fibres. The reported tensile strengths

were 2.3, 2.8 and 2.7 MPa with lengths of 25, 38 and 50

mm, respectively. Thus coconut fibres with a length of 38

Ali

191

Figure 2. Longitudinal and cross-section of a fibre cell (Abiola, 2008).

Fig. 2. Longitudnal and Cross-section of a Fibre Cell [3]

mm and a volume fraction of 4% gave maximum strength

of cement paste composite

Cement sand mortar

Effect of fibre content

Slate (1976) investigated mechanical properties of coir

fibre reinforced cement sand mortar. The researcher

tested two different design mixes (cement sand ratio by

weight), first was 1:2.75 with water cement ratio of 0.54

and second was 1:4 with water cement ratio of 0.82.

Fibres content was 0.08, 0.16 and 0.32 % by total weight

of cement, sand and water. The mortars for both design

mixes without any fibres were also tested as reference.

Cylinders having size of 50 mm diameter and 100 mm

height and beams having size of 50 mm width, 50 mm

depth and 200 mm length were tested for compressive

and flexural strength. The curing was done for 8 days

only. ASTM standards were used (C196-72, C78-64,

C39-71 and C109-73).

It was found that all strengths were increased in case of

fibre reinforced mortar as compared to that of plain

mortar for both mix design with all fibre contents.

However, a decrease in strength of mortar was also

observed with an increase in fibre content.

Effect of fibre pre-treatment

Li et al. (2006) studied untreated and alkalized coconut

fibres with two lengths of 20 and 40 mm in cementitious

composites as reinforcement materials. Mortar was

mixed in a laboratory mixer at a constant speed of 30

rpm, with cement: sand: water: super plasticizer ratio of

1: 3: 0.43: 0.01 by weight and fibres were slowly put into

the running mixer. Australian standards AS 1012.8.12000 and 1012.8.2-2000 were used.

The resulting mortar had better flexural strength, higher

energy absorbing ability and ductility, and lighter than the

conventional mortar. Good results were achieved with the

addition of a low percentage of coconut fibres and

chemical agents in cementitious matrix.

Concrete

Epoxy polymer concrete

Reis (2006) investigated the mechanical characterization

(flexural strength, fracture toughness and fracture

energy) of epoxy polymer concrete reinforced with natural

fibres (coconut, sugarcane bagasse and banana fibres).

RILEM standards TC-113/PC2, TC 89-FMT, TC50-FMC

and TC-113/PCM-8 were followed.

Fracture toughness and fracture energy of coconut

fibre reinforced polymer concrete were higher than that of

other fibres reinforced polymer concrete. And flexural

strength was increased up to 25 % with coconut fibre

only.

Effect of fibre volume fraction

Baruah and Talukdar (2007) investigated the static

properties of plain concrete (PC) and fibre reinforced

concrete (FRC) with different fibre volume fractions

ranging from 0.5 to 2 %. Fibres used were steel, artificial

and natural fibres (jute and coir fibres only). Here,

discussion is limited only to PC and the coir fibres

reinforced concrete (CFRC).

The mix design (cement: sand: aggregates) for plain

concrete was 1: 1.67: 3.64 with water cement ratio of

0.535. Per cubic meter of concrete mix was cement = 350

kg, fine aggregates = 568.40 kg, coarse aggregate =

1239.40 kg and water = 182 kg. The maximum size of

aggregates was 20 mm. Coir fibres having length of 4 cm

and diameter of 0.4 mm with volume fraction of 0.5, 1, 1.5

and 2% were added to prepare CFRC. The sizes of

specimens were (1) 150 mm diameter and 300 mm

height for cylinders (2) 150 mm width, 150 mm depth and

700 mm length for beams, and (3) 150 mm cubes having

a cut of 90 60 mm in cross-section and 150 mm high for

L-shaped shear test specimens. All specimens were

cured for 28 days.

The investigated properties,

compressive strength (), splitting tensile strength (STS),

modulus of rupture (MOR) using four point load test and

shear strength (), are shown in Table 4 for PC and

CFRC. It can be noted that CFRC with 2 % fibres showed

better results amongst all volume fractions.

The compressive strength, splitting tensile strength,

modulus of rupture and shear strength of coir fibre

reinforced concrete with 2% fibres by volume fraction

were increased up to 13.7, 22.9, 28.0 and 32.7%,

respectively as compared to those of plain concrete. It is

also noted from their research that all these properties

were also improved for CFRC with all other tested

volume fractions of fibres (0.5, 1 and 1.5%). These

properties were increased up to only 1.3, 4.9, 4.0 and

192

J. Civ. Eng. Constr. Technol.

Diameter (mm)

Length (mm)

Tensile strength (MPa)

Specific Tensile strength (MPa)

Average Tensile Modulus (GPa)

Specific Tensile Modulus (GPa)

Tensile Strain (%)

Elongation (%)

Youngs Modulus (GPa)

Specific Youngs Modulus (GPa)

Toughness (MPa)

Permeable Void (%) **

Moisture Content (%)

Water Absorption Saturation (%) *

Elastic Modulus (GPa)

Density (Kg/m3)

Table 1. Physical and mechanical properties of coconut fibres.

Reference

0.40- 0.10

60- 250

15- 327

75

Ramakrishna and

Sundararajan, 2005a

0.21 a, b

0.3

107e

69.3f

37.7d, e

-

56.6- 73.1

-

93.8- 161.0

-

2.8e

2.0

1104- 1370

1140

50.9 g

17.6g

180 h

1000

0.27 0.073

0.11 0.53

0.12 0.005

50 10

-

142 36

108- 252

137 11

158

24 10 k

13.7 41n

-

3.7 0.6

4.2

21.5 2.4

10 m

-

24

85.0- 135.0

-

2.0 0.3

2.50- 4.50

-

670- 1000

870

500

0.43q

2.50

2.17q

20

11.4p

1150

0.1- 0.4

0.1-0.4

0.10- 0.45

50- 250

-

175

174

100 - 130

106 - 175

30

10 - 25

10- 26

17- 47

4-6

4-6

130 - 180

-

16-26

19-26

-

1200

145- 280

1150

Agopyan et al., 2005 c

Paramasivam et al., 1984

Ramakrishna and

Sundararajan, 2005bi

Li et al., 2007

Toledo et al., 2005

Munawar et al., 2007 0

Rao and Rao, 2007

Fernandez, 2002

Reis, 2006

Aggarwal, 1992

Satyanarayana et al., 1990

e

Coefficients of variation frequently over 50 % - Determinations of thickness by scanning electron microscopy - Brazilian Standard NBR-9778 - Elongation on rupture Authors took other

f

g

h

i

researchers data - Ultimate value - (Unit: mm) Maximum Value and it do not agree with the general accepted value which may be due to the test conditions adopted by [4] In 24hrs used natural

j

k

l

m

n

o

dry condition of fibres - width - At break - Water absorption ratio (100 % humidity) - At 20 C - Strain at failure Data for mechanical properties are given as averages and 95 % confidence

p

q

-3

interval - Percentage moisture present on weight basis at normal atmospheric condition MPa / (Kg m ) **By Vol. *By mass

4.7%, respectively for CFRC with 0.5 % fibres by

volume fraction.

APPLICATIONS

TECHNOLOGY

IN

CIVIL

ENGINEERING

Plaster

John et al. (2005) studied the coir fibre reinforced

low alkaline cement taken from the internal and

external walls of a 12 year old house. The panel

of the house were produced using 1:1.5:0.504

(binder: sand: water, by mass) mortar reinforced

with 2% of coconut fibres by volume.

Fibres removed from the old samples were

reported to be undamaged. No significant

difference was found in the lignin content of fibres

removed from external and internal walls.

Roofing material

Effect of fibre length and volume fraction

Cook et al. (1978) reported the use of randomly

distributed

coir

fibre

reinforced

cement

composites as low cost materials for roofing. The

studied parameters were fibre lengths (2.5, 3.75

and 6.35 cm), fibre volumes (2.5, 5, 7.5, 10 and

Ali

composite with a fibre length of 3.75 cm, a fibre volume

fraction of 7.5% and cast at pressure of 1.67 MPa. Cost

comparison revealed that this composite was substantially cheaper than the locally available roofing materials.

50

Stress (MPa)

40

Coconut

fibre

30

Effect of weather conditions

20

10

0

(a)

Stress (MPa)

800

4

Strain (%)

Ramie bast

Pineapple

Sansevieria

Abaca

Sisal

600

400

200

Coconut

(b)

Stress (MPa)

800

193

4

6

Strain (%)

Pineapple

8

24

Agopyan et al. (2005) studied coconut and sisal fibres as

replacement for asbestos in roofing tiles. 2 % total fibre

volume fraction was used. The dimensions of the tiles

were 487 x 263 x 6 mm (frame measures) with

consumption of 12.5 pieces / m 2 and format very similar

to ceramic Roman tiles. Three-point bend test specimen

(span = 350 mm, deflection rate = 5 mm/min) was

employed for determination of maximum load. The tiles

were exposed in a rack facing North with 30 of inclination and submitted to natural ageing under environmental

condition in a rural area at Pirassununga, State of Sao

Paulo, Brazil (21 59 S of latitude), for up to 16 and 60

months. The main long-term climate conditions for the

region were: average maximum temperature for January=

30.1C, average minimum temperature for July= 9.5C,

average maximum relative humidity for January/February

= 77%, average minimum relative humidity for August =

63% and average rainfall = 1363 mm/year. After the

ageing period of 16 and 60 months, the maximum load

taken by coir tile were 235 and 248 N, respectively while

that by sisal tiles were 237 and 159 N, respectively. The

major benefit of reinforced tiles was the at least 22%

higher energy absorption than that of the unreinforced

tiles which could help to avoid fragile rupture of tiles in

the short-term under transportation or installation.

600

Banana

400

Sisal

Slabs

Effect of fibre length and volume fraction

Palmyrah

Paramasivam et al. (1984) conducted a feasible study of

making coir fibre reinforced corrugated slabs for use in

low cost housing particularly for developing countries.

0

They gave recommendations for the production of

coconut fibre reinforced corrugated slabs along with

0

2

4

6

8

39

(c)

casting technique.

Strain (%)

Tests for flexural strength, thermal and acoustic

Figure 3. Correlation of mechanical properties for natural

properties were performed. For producing required slabs

fibres (a)

Paramasivan properties

et al. (1984)for

(b)natural

Munawar

et al. (a) Paramasivam

ig. 3. Correlations

of mechanical

fibres*.

et strength of 22 MPa, a volume fraction of

having a flexural

(2007) (c) Satyanarayana et al. (1990). (Graphs are

3%,

a

fibre

length of 2.5 cm and a casting pressure of

al. (1984)

(b) Munawar et al. (2007) (c) Satyanarayana et al. (1990).

reproduced here for better quality).

0.15 MPa (1.5 atmosphere) were recommended. The

thermal conductivity and sound absorption coefficient for

low frequency were comparable with those of locally

available asbestos boards.

15%) and casting pressure (from 1 to 2 MPa with an

increment of 0.33 MPa). Different properties like bending,

impact, shrinkage, water absorption, permeability and fire

Effect of impact loading

resistance were investigated.

They concluded that the optimum composite was a

Ramakrishna and Sandararajan (2005b) investigated the

200

Coconut

194

J. Civ. Eng. Constr. Technol.

Table 2. Chemical composition of coconut fibres.

Fibre

Coir

a

b

Hemi-cellulose (%)

a

31.1

15 - 28 b

16.8

0.15 0.25

Cellulose (%)

a

33.2

35 - 60 b

43

68.9

36 - 43

Lignin (%)

a

20.5

20 - 48 b

45

32.1

41 - 45

Reference

Ramakrishna and Sundararajan, 2005a

Agopyan et al., 2005

Satyanarayana et al., 1990

Asasutjarit et al., 2007

Corradini et al., 2008

The compositions are % by weight of dry and powdered fibre sample.

Chemical compositions are % by mass and author took other researchers data.

Table 3. Mechanical properties of coconut fibre reinforced cement paste composites (Das Gupta et

al., 1978 as cited by Aziz et al., 1981).

Fibre volume fraction (%)

2

3

4

5

6

Tensile strength (MPa)

1.9

2.5

2.8

2.2

1.5

resistance to impact loading for cement sand mortar (1:3)

slabs. The slab specimens (300 x 300 x 20 mm) were

reinforced with natural fibres (coconut, sisal, jute and

hibiscus cannabinus fibres) having four different fibre

contents (0.5, 1.0, 1.5 and 2.5% by cement weight) and

three fibre lengths (20, 30 and 40 mm).

A fibre content of 2% and a fibre length of 40 mm of

coconut fibres showed best performance by absorbing

253.5 J impact energy among all tested fibres. All fibres,

except coconut fibres, showed fibre fracture, at ultimate

failure where as coconut fibre showed fibre pull out

failure.

Coir mesh reinforcement in slab

Li et al. (2007) studied fibre volume fraction and fibre

surface treatment with a wetting agent for coir mesh

reinforced mortar using nonwoven coir mesh matting.

They performed a four-point bending test on a slab

specimen and concluded that cementitious composites,

reinforced by three layers of coir mesh (with a low fibre

content of 1.8%) resulted in a 40% improvement in the

maximum flexural stress, were 25 times stronger in

flexural toughness, and about 20 times higher in flexural

ductility.

Boards

Asasutjarit et al. (2007) determined the physical,

mechanical and thermal properties of coconut-based light

weight cement board after 28 days of hydration. The

Modulus of rupture (MPa)

3.6

4.9

5.45

5.4

4.6

parameters studied were fibre length, coir pre-treatment

and mixture ratio. Boiled and washed fibres with 6 cm

fibre length gave better results. On the other hand, optimum mixture ratio by weight for cement: fibre: water was

2:1:2. Also, tested board had lower thermal conductivity

than commercial flake board composite.

Wall paneling system

Mohammad (2005) tested wall panels made of gypsum

and cement as binder and coconut fiber as the reinforcement. Bending strength, compressive strength, moisture

content, density, and absorption were investigated.

Coconut fibres did not contribute to bending strength of

the tested wall panels. Compressive strength increased

with the addition of coconut fibres, but the compressive

strength decreased with an increase in water content and

density was increased. There was no significant change

of moisture content with coconut fibres. However,

moisture content increased with time. There was also no

significant effect to water absorption on increasing

coconut fibre content.

House construction

Some researchers (Luisito et al., 2005) of PCAZamboanga Research Center, San Ramon, Zamboanga

city invented coconut fibre boards (CFB) for different

applications as shown in Figure 4. According to them,

CFB can replace construction materials such as tiles,

bricks, plywood, and asbestos and cement hollow blocks.

Ali

195

Table 4. Properties of coconut fibre reinforced concrete (CFRC) (Baruah and Talukdar, 2007).

Fibre volume

fraction (%)

0.5

1.0

1.5

2.0

Compressive

strength (MPa)

21.42

21.70

22.74

25.10

24.35

Split tensile

strength (MPa)

2.88

3.02

3.18

3.37

3.54

Modulus of

rupture (MPa)

3.25

3.38

3.68

4.07

4.16

Shear strength

(MPa)

6.18

6.47

6.81

8.18

8.21

Toughness

index, I5

1.934

2.165

2.109

2.706

2.345

Toughness

index , I10

1.934

2.270

2.773

4.274

3.452

Figure 4. Applications of coconut fibre boards in house construction and other utilities (Luisito et al., 2005).

It is used for internal and exterior walls, partitions and

ceiling. It can also be used as a component in the

fabrication of furniture, cabinets, boxes and vases,

among others.

pavements, land reclamation and filtration in road drains,

containment of soil and concrete as temporary seeding

etc, highway cut and fill slopes, control of gully erosion

and shallow mass waste.

Slope stabilization

APPLICATIONS

TECHNOLOGIES

Coir erosion fabrics provide firm support on slopes and

unlike other natural fibre alternatives like cotton or jute,

do not degrade until 5 years. They have the necessary

strength and come in a number of forms such as matting,

rolls and logs and are used for soil stabilization.

Coconut fiber finds applications in slope stabilization in

railway cutting and embankments, protection of water

courses, reinforcement of temporary walls and rural

unpaved roads, providing a sub base layer in road

IN

OTHER

ENGINEERING

Bullet proof vest

Yuhazri and Dan (2008) developed a unique bullet proof

vest made of coconut fibre, which provides all the

protection that can be found in a regular vest. It is not

only economical but also lighter. A normal bullet-proof

vest costs about RM 16, 000/- and weighs 9 kg, but this

vest is only 3 kg and cost RM 2, 000/-. The test proved

that the vest was capable of stopping 9 mm caliber

196

J. Civ. Eng. Constr. Technol.

bullets at a 5 m range. They also tested high impact

hybrid composite material with coconut fibres as

reinforcement for ballistic armor, and satisfactory results

were reported.

Motorcycle helmet

Yuhazri and Dan (2007) utilized coconut fibres in the

manufacturing of motor cycle helmet. They used epoxy

resins from thermo set polymer as the matrix materials

and coconut fibres as the reinforcement. After the development of helmet shells fabrication method, mechanical

testing (dynamic penetration) was performed on this

composite material to determine its performance. The

result in the mechanical performance showed that

coconut fibres performed well as a suitable reinforcement

to the epoxy resin matrix.

Car parts

A team of Baylor University researchers is trying develop

a technology to use coconut fiber as a replacement for

synthetic polyester fibers in compression molded

composites. Their aim is to use the coconut fibers to

make trunk liners, floorboards and interior door covers on

car.

General use

Apart from applications in engineering, coconut fibres are

also used in yarn, ropes, mats, mattresses, brushes,

sacking, caulking boats, rugs, geo-textiles, insulation

panels and packaging.

CONCLUSIONS

The versatility and applications of coconut fibres in

different fields is discussed in detail. Coconut fibres are

reported as most ductile and energy absorbent material.

It is concluded that coconut fibres have the potential to be

used in composites for different purposes. Various

aspects of many coconut fibres reinforced composites

have already been investigated; and the economical and

better results are achieved as reported by many

researchers.

Since the use of coconut fibres has given some

marvellous products, there is still possibility of the

invention of new products containing coconut fibres with

improved results. In civil engineering, coconut fibres have

been used as reinforcement in composites for nonstructural components. There is a need of investigating

the behaviour of coconut fibre reinforced concrete to be

used in main structural components like beams, columns

and walls.

REFERENCES

Abiola AAWBO (2008). Mechanical Property Evaluation of Coconut

Fibre. Thesis Masters Degree (ISRN: BTH-AMT-EX-2008/D05-SE),

Dept of Mechanical Engineering, Blekinge Institute of Technology,

Kariskrone, Sweden.

Aggarwal L (1992). Studies on cement bonded coir fibre boards.

Cement Conc. Comp., 14(1): 63-69.

Agopyan V, Savastano JH, John VM, Cincotto MA (2005).

Developments on vegetable fibre-cement based materials in Paulo,

Brazil: An overview. Cement Conc. Comp., 27(5): 527-536.

Asasutjarit C, Hirrunlabh J, Khedari J, Paguenet M, Quenard D (2005).

th

Coconut Coir Cement Board. 10 International Conference on the

Durability of Building Materials and Components. Lyon, France. TT3103.

Asasutjarit C, Hirunlabh J, Khedari J, Charoenvai S, Zeghmati B, Shin

UC (2007). Development of coir-based light weight cement board.

Constr. Build. Mater. 21(2): 277-288.

Aziz MA, Paramasivam P, Lee SL (1981). Prospects for natural fibre

reinforced concretes in construction. Int. J. Cement Comp.

Lightweight Conc., 3(2): 123-132.

Aziz MA, Paramasivam P, Lee SL (1984). Concrete reinforced with

natural fibres. New Reinforced Concrete; pp. 106-140.

Baruah P, Talukdar SA (2007). Comparative study of compressive,

flexural, tensile and shear strength of concrete with fibres of different

origins. Indian Conc. J., 81(7): 17-24.

Cook DJ, Pama RP, Weerasingle HLSD (1978). Coir fibre reinforced

cement as a low cost roofing material. Building Environ., 13(3): 193198.

Corradini E, De Morais LC, De Rosa MF, Mazzetto SE, Mattoso LH,

Agnelli JA (2008). A preliminary study for the use of natural fibers as

reinforcement in starch-gluten-glycerol matrix. Macromolecular

Symposia; pp. 245-246: 558-564.

Das Gupta NC, Paramsivam P, Lee SL (1978). Coir reinforced cement

pastes composites. Conference Proceedings of Our World in

Concrete and Structures, pp. 111-116.

Das Gupta NC, Paramsivam P, Lee SL (1979). Mechanical properties of

coir reinforced cement pastes composites. Housing Science,

Pergamon Press Inc. London, 2(5): 391-406.

Fernandez JE (2002). Flax fiber reinforced concrete - A natural fiber

biocomposite for sustainable building materials. High Performance

Structures and Materials, CA. Brebbia and WP. Wilde, eds., Seville;

pp. 193-207.

Flower PA, Hughes JM, Melias R (2006). Review bio composites:

technology, environmental credentials and market forces. J. Sci.

Food Agric., 86: 1781-1789.

John VM, Cincotto MA, Sjostrom C, Agopyan V, Oliveira C (2005).

Durability of slag mortar reinforced with coconut fibre. Cement Conc.

Comp., 27(5): 565-574.

Li Z, Wang L, Wang X (2006). Flexural characteristics of coir fiber

reinforced cementitious composites. Fibers Polym., 7(3): 286-294.

Li Z, Wang L, Wang X (2007). Cement composites reinforced with

surface modified coir fibers. J. Comp. Mat., 41(12): 1445-1457.

Luisito JP, Neil JM, Rolendio N (2005). Coconut fibre boards.

http://www.ecocoboard.net/dwnloads/Presentations%20workshop/Pe

namora_Coconut%20fibre%20cement%20boards.pdf

Mohammad HBMH (2005). Coconut fiber reinforced wall panelling

system. Thesis Master of Engineering (Civil-Structure), Faculty of

Civil Engineering, Universiti Teknologi, Malaysia.

Munawar SS, Umemura K, Kawai S (2007). Characterization of the

morphological, physical, and mechanical properties of seven nonwood plant fibre bundles. J. Wood Sci., 53(2): 108-113.

Paramasivam P, Nathan GK, Das Gupta NC (1984). Coconut fibre

reinforced corrugated slabs. Int. J. Cement Comp. Lightweight Conc.,

6(1): 19-27.

Ramakrishna G, Sundararajan T (2005a). Studies on the durability of

natural fibres and the effect of corroded fibres on the strength of

mortar. Cement Conc. Comp., 27(5): 575-582.

Ramakrishna G, Sundararajan T (2005b). Impact strength of a few

natural fibre reinforced cement mortar slabs: A comparative study.

Cement Conc. Comp., 27(5): 547-553.

Rao KMM, Rao KM (2007). Extraction and tensile properties of natural

Ali

fibers: Vakka, date and bamboo. Composite Struct., 77(3): 288-295.

Reis JML (2006). Fracture and flexural characterization of natural fiberreinforced polymer concrete. Constr. Build Mater., 20(9): 673-678.

Satyanarayana KG, Sukumaran K, Mukherjee PS, Pavithran C, Pillai

SGK (1990). Natural fibre-polymer composites. Cement Conc.

Comp., 12(2): 117-136.

Slate FO (1976). Coconut fibers in concrete. Eng. J. Singapore; 3(1):

51-54.

Toledo FRD, Ghavami K, England GL (2005). Free, restrained and

drying shrinkage of cement mortar composites reinforced with

vegetable fibres. Cement Conc. Comp., 27(5): 537-546.

197

Yuhazri MY, Dan MMP (2007). Helmet shell using coconut fibre (DecoHelmet). J. Adv. Manuf. Technolo., 1(1): 23-30. ISSN 1985-3157.

Yuhazri MY, Dan MMP (2008). High impact hybrid composite material

for ballistic armor. J. Adv. Manuf. Technol., 2(1): 1-10. ISSN 19853157.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Lecture 3Document58 paginiLecture 3madhujayarajÎncă nu există evaluări

- F To G: 5 To 6: Spreadsheets To BS 8110 & EC2Document5 paginiF To G: 5 To 6: Spreadsheets To BS 8110 & EC2Kem RaiÎncă nu există evaluări

- Ffinvironrrental Impact Assessment: Ee 7 E Changes.:: Project. ' R // I A' .57$t, S E F, AssessmentDocument1 paginăFfinvironrrental Impact Assessment: Ee 7 E Changes.:: Project. ' R // I A' .57$t, S E F, AssessmentKem RaiÎncă nu există evaluări

- WW 236C Executive Summary CHA IVDocument4 paginiWW 236C Executive Summary CHA IVKem RaiÎncă nu există evaluări

- EIA June 2014Document1 paginăEIA June 2014Kem RaiÎncă nu există evaluări

- Spreadsheets To BS 8110: Advisory Group Level - 1 Base B1 RMW 113 CHG - R68Document24 paginiSpreadsheets To BS 8110: Advisory Group Level - 1 Base B1 RMW 113 CHG - R68Suhail AhamedÎncă nu există evaluări

- CRPE Flowchart June 2012Document1 paginăCRPE Flowchart June 2012jaya1816Încă nu există evaluări

- Mso Example Setup File ADocument1 paginăMso Example Setup File ASueño InalcanzableÎncă nu există evaluări

- Footing Staad Test 1Document10 paginiFooting Staad Test 1Kem RaiÎncă nu există evaluări

- Structural Analysis and Design of Multi-Storeyed Building: Project MembersDocument29 paginiStructural Analysis and Design of Multi-Storeyed Building: Project MembersKem Rai100% (1)

- Concrete Mix CalculatorDocument2 paginiConcrete Mix CalculatorSujithÎncă nu există evaluări

- Footing Staad Test 1Document10 paginiFooting Staad Test 1Kem RaiÎncă nu există evaluări

- Speed CameraDocument1 paginăSpeed CameraKem RaiÎncă nu există evaluări

- Preparation of Bar Bending Schedule PDFDocument8 paginiPreparation of Bar Bending Schedule PDFPranjeet Chakravarty25% (4)

- Typical Hotel Planning Circa PDFDocument81 paginiTypical Hotel Planning Circa PDFKem RaiÎncă nu există evaluări

- Shear Force and Bending Moment in Beams and FramesDocument25 paginiShear Force and Bending Moment in Beams and Framesnaveenpnaidu1Încă nu există evaluări

- Dormitory Phase 2 at LTK For RT Knits: Labour, Plant Return and Weather StatusDocument2 paginiDormitory Phase 2 at LTK For RT Knits: Labour, Plant Return and Weather StatusKem RaiÎncă nu există evaluări

- Balance SheetDocument1 paginăBalance SheetmohdsevenÎncă nu există evaluări

- Balance SheetDocument1 paginăBalance SheetmohdsevenÎncă nu există evaluări

- Balance SheetDocument1 paginăBalance SheetmohdsevenÎncă nu există evaluări

- Wall Around Staircase Calc CheckDocument7 paginiWall Around Staircase Calc CheckKem RaiÎncă nu există evaluări

- Methods of Concrete Column Repair For Damages and CracksDocument6 paginiMethods of Concrete Column Repair For Damages and CracksKem RaiÎncă nu există evaluări

- Job Information: Whole Structure Loads 0.1kN:1m 1 ALL (Input Data Was Modified After Picture Taken)Document13 paginiJob Information: Whole Structure Loads 0.1kN:1m 1 ALL (Input Data Was Modified After Picture Taken)Kem RaiÎncă nu există evaluări

- Employee Confidentiality AgreementDocument2 paginiEmployee Confidentiality AgreementFeteneÎncă nu există evaluări

- F. F. F. F. O. Okafor O. Okafor O. Okafor O. Okafor and and and and D. D. D. D. E. Ewa E. Ewa E. Ewa E. EwaDocument7 paginiF. F. F. F. O. Okafor O. Okafor O. Okafor O. Okafor and and and and D. D. D. D. E. Ewa E. Ewa E. Ewa E. EwaYashika Bhathiya JayasingheÎncă nu există evaluări

- Footing Staad Test 1Document10 paginiFooting Staad Test 1Kem RaiÎncă nu există evaluări

- Prokon FinalDocument6 paginiProkon FinalKem RaiÎncă nu există evaluări

- EvacoDocument4 paginiEvacoKem RaiÎncă nu există evaluări

- Salim AutoDocument1 paginăSalim AutoKem RaiÎncă nu există evaluări

- StockDocument1 paginăStockKem RaiÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- BECED S4 Motivational Techniques PDFDocument11 paginiBECED S4 Motivational Techniques PDFAmeil OrindayÎncă nu există evaluări

- Hard DiskDocument9 paginiHard DiskAmarnath SahÎncă nu există evaluări

- I. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)Document5 paginiI. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)thmeiz.17sÎncă nu există evaluări

- Press Statement - Book Launching Shariah Forensic 27 Oct 2023Document4 paginiPress Statement - Book Launching Shariah Forensic 27 Oct 2023aÎncă nu există evaluări

- MLX90614Document44 paginiMLX90614ehsan1985Încă nu există evaluări

- Chakir Sara 2019Document25 paginiChakir Sara 2019hiba toubaliÎncă nu există evaluări

- IJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyDocument12 paginiIJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyImpact JournalsÎncă nu există evaluări

- Installation Instructions INI Luma Gen2Document21 paginiInstallation Instructions INI Luma Gen2John Kim CarandangÎncă nu există evaluări

- The Bio-Based Economy in The NetherlandsDocument12 paginiThe Bio-Based Economy in The NetherlandsIrving Toloache FloresÎncă nu există evaluări

- Board of Technical Education (Student Marksheet)Document2 paginiBoard of Technical Education (Student Marksheet)Manoj SainiÎncă nu există evaluări

- Abilash - Subramanian CV - 003 PDFDocument4 paginiAbilash - Subramanian CV - 003 PDFAbilash SubramanianÎncă nu există evaluări

- Expression of Interest (Eoi)Document1 paginăExpression of Interest (Eoi)Mozaffar HussainÎncă nu există evaluări

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDocument4 paginiDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaÎncă nu există evaluări

- BSS Troubleshooting Manual PDFDocument220 paginiBSS Troubleshooting Manual PDFleonardomarinÎncă nu există evaluări

- Pam8610 PDFDocument15 paginiPam8610 PDFRaka Satria PradanaÎncă nu există evaluări

- Sony x300 ManualDocument8 paginiSony x300 ManualMarcosCanforaÎncă nu există evaluări

- Transfert de Chaleur AngDocument10 paginiTransfert de Chaleur Angsouhir gritliÎncă nu există evaluări

- Rankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothDocument111 paginiRankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothphysicsÎncă nu există evaluări

- Determinant of Nurses' Response Time in Emergency Department When Taking Care of A PatientDocument9 paginiDeterminant of Nurses' Response Time in Emergency Department When Taking Care of A PatientRuly AryaÎncă nu există evaluări

- VOTOL EMController Manual V2.0Document18 paginiVOTOL EMController Manual V2.0Nandi F. ReyhanÎncă nu există evaluări

- Poster-Shading PaperDocument1 paginăPoster-Shading PaperOsama AljenabiÎncă nu există evaluări

- 5.0008786 Aluminum GrapheneDocument11 pagini5.0008786 Aluminum GrapheneBensinghdhasÎncă nu există evaluări

- Analisis Kebutuhan Bahan Ajar Berbasis EDocument9 paginiAnalisis Kebutuhan Bahan Ajar Berbasis ENur Hanisah AiniÎncă nu există evaluări

- Calculating Free Energies Using Adaptive Biasing Force MethodDocument14 paginiCalculating Free Energies Using Adaptive Biasing Force MethodAmin SagarÎncă nu există evaluări

- RH-A Catalog PDFDocument1 paginăRH-A Catalog PDFAchmad KÎncă nu există evaluări

- TPDocument10 paginiTPfaisal gaziÎncă nu există evaluări

- Meta100 AP Brochure WebDocument15 paginiMeta100 AP Brochure WebFirman RamdhaniÎncă nu există evaluări

- Daftar ObatDocument18 paginiDaftar Obatyuyun hanakoÎncă nu există evaluări

- 2007 ATRA Seminar ManualDocument272 pagini2007 ATRA Seminar Manualtroublezaur100% (3)

- A Short Survey On Memory Based RLDocument18 paginiA Short Survey On Memory Based RLcnt dvsÎncă nu există evaluări