Documente Academic

Documente Profesional

Documente Cultură

Roof Framing Simple

Încărcat de

TuroyDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Roof Framing Simple

Încărcat de

TuroyDrepturi de autor:

Formate disponibile

Roof Framing

References:

NZS 3604: 1999 Timber Framed Buildings

Rafter Lengths and Bevels, Woods, Wilson

House Building: A Practical Guide, R J Wilson

BRANZ House Building Guide

Roof Truss Erection Manual by Able Cooke Ltd

Mitek product catalogue (http://www.mii.com/newzealand )

Introduction

The main framing members of a roof are the rafters, ridges, hips, valleys, underpurlins,

struts, collar ties and associated bracing. The functions of roof framing are:

(i)

To provide support and fixing for the roof covering

(ii)

To transmit the roof load to the walls and thus to the foundations

(iii)

To tie and stiffen the wall frame.

Roofing

August 2009

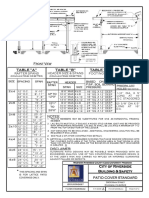

GABLE ROOF

A gable roof is a very popular roof form, being comparatively simple in design and readily adaptable to a

wide variety of different roof pitches. The actual part referred to as the gable is the vertical triangular

section at the end of the roof, from the top plate to the rafters.

Figure 1. Gable roof

RAFTER LENGTHS AND BEVELS

Rafters for gable or lean-to roofs can be calculated by a number of methods including:

1.

Rafter tables, (see Rafter Lengths and Bevels)

Roofing

August 2009

2.

Secants from a calculator,

(Length = run x secant of the pitch)

3.

Pythagoras, a2+ b2 = c2

4.

Roofing square

5.

Scaled or full size drawing,

6.

Pre programmed calculators or computers

Most of the methods mentioned give the length of the rafter from the outside of the plate to

the centre line of the ridge.

Roofing

August 2009

BASIC ROOF TERMS

Span The overall horizontal distance across the building to be roofed, measured from the

outside of the framing on one side to the outside of the framing on the opposite side. (A D)

Run

Rise

Half of the span in a roof of equal pitches. It is measured horizontally from the

outside face of the framing to a vertical cutting the intersection of the inclined

surface. (AB)

The height of the roof measured from the top of the top plate to the apex. (B C)

Pitch or Slope These terms express the inclination of a roof from the horizontal.

The pitch is expressed in degrees, such as 35 pitch or 37 pitch etc

Figure 2. Roof measurement names

Roofing

August 2009

Roof Bevels.

The angle used to form the plumb cut (bevel) is obtained from the triangle formed by the run and rise.

The angle used to form the seat cut (bevel) is also obtained from the same triangle. A seat cut is used

on a birdsmouth and overhang cut for soffit lining.

The birdsmouth - In order to give a rafter seating on the top plate, a triangular piece is cut out leaving

what is called a birdsmouth. The two cuts required to form a birdsmouth are:

(i)

the plumb cut (vertical) and

(ii)

the seat cut (horizontal).

Note:

Always cut one rafter accurately and use this as a pattern to mark the others.

Figure 3. Rafter parts named

Roofing

August 2009

SETTING OUT PLATES AND RIDGES

The ridge board is a horizontal member positioned parallel to the top plates to which the

top end of rafters are fixed.

Where possible, set out the positions of rafters on the top plate before constructing the wall and erecting

the frames.

Lay the ridge board alongside the top plate and transfer the top plate rafter set out onto the ridge. Allow

for overhang of ridge for the verges if required.

Rafter positions can be set out at the maximum spacings or equal spacings (especially for

exposed rafters). (refer to NZS 3604, table 10.2 rafter spacings)

Where flying rafter construction is used, the last common rafters must be placed one spacing from the

end wall to allow for fixing of the outriggers.

Figure 4. Roof frame members

Roofing

August 2009

STRUTTING BEAMS, UNDERPURLINS, STRUTS, COLLAR TIES

Strutting beams

(refer to NZS 3604, 10.2.11)

Carry roof loads from the underpurlins via struts. Strutting beams must be at least 25mm above the

ceiling joists and should have 65 mm bearing at each end. (refer to NZS 3604, fig 10.12 and table 10.7)

Purlins

Purlins are horizontal framing timbers fixed across the tops of rafters to support the roof covering.(refer

to NZS 3604, 10.2.16 and table 10.9)

Underpurlins

Where rafters exceed their safe span, underpurlins are used to support the rafters. To make installation

of struts easier, underpurlins should generally be placed as near as possible to the ridge (refer to NZS

3604,10.2.9, fig 10.10 and fig 10.11)

Refer to NZS 3604, table 10.6 for the sizes and spans of underpurlins.

Struts (refer to NZS 3604, 10.2.10, fig. 10.10, 10.11 and 10.12)

Strut members transmit loads from the rafters or under purlins down to:

(i)

a strutting beam

or

(ii)

a load bearing partition (refer to NZS 3604, fig 10.10)

Struts supporting underpurlins can be placed:

(i)

In pairs, (refer to NZS 3604, fig 10.12)

or

(ii)

Vertical, (refer to NZS 3604, fig 10.12)

or

(iii)

At right angles to the underpurlin and roof,

or

(iv)

Anywhere between (ii) and (iii)

Collar Ties

In standard roof construction (couple close roof) steeper than 100 (1 in 6 slope) pairs of rafters must be

connected together with either collar ties or cleats.

(refer to NZS 3604, 10.2.13.2, fig 10.13)

Collar ties must be 150 x 25 mm or 100 x 50 mm fixed to every third pair of rafters or at 1.8m centres

whichever is closer.

Cleats

Use 100 x 25 mm at the same centres as collar ties and tie opposing (pairs) rafters immediately below

the ridge. (refer to NZS 3604, 10.2.13.3, fig 10.14)

Roofing

August 2009

ROOF BRACING

(Gable roof)

Bracing for roofs can be either:

(i)

A roof plane diagonal brace - A length of 100 x 25mm or a pair of diagonally opposed steel strips

placed at 450 to the ridge and fixed at the ridge and top plate). (refer to NZS 3604, fig. 10.25, 10.5.2.3)

and/or

(ii)

A roof space diagonal brace (one or two pieces of 100 x 50mm fixed from the ridge to ceiling joist

level. (refer to fig. 10.26, 10.4., for heavy roofs see fig. 10.24, 10.4.5, 10.5.3)

The number of braces required can be found in NZS 3604, 10.5

Note: Heavy roofs (concrete tile) require more bracing than light roofs (metal)

both roof space and roof plane braces are required.

(refer to NZS 3604, fig. 10.2, 10.4.5.)

and that

SET OUT AND CONSTRUCTION OF GABLE ROOFS

A.

GABLE END FRAMING

(References from NZS 3604)

Gable ends may be framed up in a number of ways: (refer to 10.15, 10.2.15, table 10.9)

(i)

Purlins cantilevered over the end common rafter (refer to fig.10.15) Jack studs are cut between

rafter and end top plate. (refer to 10.2.15.2)

(ii)

Outriggers cantilevered over an end wall raking plate and supporting a flying rafter. Nogs

(blocking) are cut between the outriggers over the raking plate to support the purlins. (refer to fig 10.15)

Jack studs are cut between the raking plate and the end top plate. (refer to 10.2.15.3)

(iii)

The gable end boxed out over the end wall giving a horizontal verge soffit.

In (i) and (ii) a barge board is fixed to the purlins or purlins and flying rafter, so that the verge lining

can fit into the groove in the barge board. Where the gable end is boxed out, the barge board must fit

over the gable end sheathing.

PURLINS AND BATTENS

Always place purlins or battens at centres to suit the roof cladding being used. Check manufacturers

brochures if in doubt. For long run iron sheet roofing, reduce the spacing at the ridge and the gutter (end

spacing) e.g. for corrugated iron sheet roofing use 800 mm crs at the ends, 1.000 crs for the others.

Always butt join purlins and battens over a rafter or other solid support.

For Purlin sizes, spacings and spans see table 10.9

Minimum purlin fixing requires 2/100 x 3.75mm nails skew nailed.

Where purlins are fixed over sarking, extra fastenings may be

required. (refer to 10.2.16, 10.2.17, fig 10.19, fig 10.20, table 10.10 nailing schedule

for purlins or battens)

Roofing

August 2009

SARKING AND UNDERLAY

Underlay must be provided under all metal and fibre cement roofing materials and is

required under other roofing materials where the roof pitch is low.

(see manufacturers information)

Underlay should be breather type building paper laid on netting or other supporting materials.

Sarking may be used over the top of the rafters as a ceiling lining (sheet material, tongue

and groove timber, etc) or over the top of the purlins as permanent support for the underlay. In both

cases the sheet material is often used as a ceiling/roof diaphragm to provide support for the outside

walls (refer to 10.5.4(b), fig 10.27)

Where diagonal hit and missor sheet sarking is used over the rafters, roof plane

diagonal braces are not required.

EAVES AND VERGE FRAMING

Eaves Construction (refer to 10.2.14)

(i)

Boxed Eaves Eaves bearers (sprockets) ribbon boards (soffit plates)

and fascia are used. The bottom end of the rafter may need to be cut, to suit the fascia board used.

(ii)

Raking Eaves The eaves lining is parallel to the roof slope, placed over or under the rafters.

If the lining is over the rafters, fascia board is often not used.

(iii)

Flush Eaves The fascia board is fixed directly to the wall framing

Verge Construction (refer to 10.2.15.2)

(i)

Cantilevered purlins are used

to support the barge board often

with packers underneath (refer to 10.2.15.2, fig10.15)

Outriggers of the same size as the rafters give support to the verge lining

in the same position as the eaves lining (raking eaves) (refer to fig. 10.15).

(iii)

Gable end is often framed out to the barge board with a

horizontal verge lining in line with the eaves lining.

August 2009

Roofing

CEILING JOIST

A horizontal framing timber which supports ceiling linings.

Refer to NSZ 3604 table 10.4 regarding ceiling joist sizes and maximum spans.

Ceiling joists must:

Have a minimum landing on their support of 32 mm.

Not support roof framing members other than ceiling runners.

Join over supports and shall either:

be lapped not less than 300 mm, or

butted and flitched with timber of the same dimension as the joist and

extending not less than 225 mm on each side of the joint.

(refer to NZS 3604, fig 10.8)

CEILING RUNNER

A timber beam supporting ceiling joists that exceed the permissible span in standard

roof construction.

Runners are used in roof truss construction to provide lateral support to the bottom

chord and support the intermediate ceiling joists.

Ceiling runner are laid in straight lines and on edge. Refer to NZS 3604 table 10.5

regarding ceiling runner sizes and maximum spans.

Ceiling runners must have a minimum landing of 65 mm on a packer, which is

directly supported by the top plate of a loading bearing wall, provided that either:

The ceiling runner lands directly over a stud, or

The packer spans between the studs on each side of the ceiling runner.

Ends of ceiling runners may be chamfered, but the depth of the ceiling runner at its

support shall remain at least 50%.

Ceiling runners are fixed to the ceiling joists by:

Purpose made steel hangers which alternate on opposite sides of the

ceiling runner, or

50 x 50 mm timber hangers. (refer to NZS 3604, fig 10.9)

TRIMMING OF RAFTERS AND OPENINGS IN CEILINGS

(refer to NZS 3604 section 13 Ceilings)

Where possible, position rafters to avoid any cutting i.e. planning for rafters on each side of a chimney is

better than cutting rafters later.

(ii)

Trusses must not in any circumstances be cut. A truss must be

placed on each side of the opening and ordinary rafters used in between if required.

10

Roofing

August 2009

(iii)

Ensure the trimmer/s and the rafters supporting the trimmer/s are strong enough to support the

increased loading. It may be necessary to double the rafters, used as the trimming joist ,i.e. each side of

a dormer window.

(iv)

Access to the ceiling space shall be provided through a clear opening not less

600 mm x 500 mm, giving easy unobstructed access of at least 600 mm in height between the

top of the ceiling joists and other roof members.

(refer to 13.3.1)

(v)

Openings in ceilings shall be bounded by trimmers and trimming joists.

(refer to fig 13.2, fig 13.3)

Trimmers shall be the same depth as the curtailed ceiling joists.

(refer to 13.3.3, 13.3.4)

CEILING BRACES

Any ceiling area exceeding the maximum spacing lines will require:

A ceiling diaphragm, or (refer to NZS 3604 section 13.5, fig 13.4)

Ceiling lining materials for diaphragm refer to NZS 3604, 13.5.2)

A dragon tie

Consist of a continuous length of 100 x 50 mm timber, or a steel angle of

equivalent compression strength.Fixed at 450 to both external walls and not more than 2.5m from the

corner. Fixed directly to the top plates or fixed to blocking pieces which are not deeper than 100 mm and

are at least 75 mm wide. At the external wall being considered, the dragon ties shall also be fixed to a

joist, truss or rafter located within 100 mm of the top plate.

CEILING BATTEN

A horizontal timber or metal member fixed below ceiling joists or truss bottomchords to which the ceiling

linings or ceiling tiles are fixed.Refer to NZS 3604 table 13.1 Ceiling battens

11

Roofing

August 2009

3.

HIP AND VALLEY ROOF CONSTRUCTION

The hip roof is one of the most popular roof forms in use in residential house building. The roof is

pitched on all sides of the building and if the pitch is the same on all sides, it is termed equal pitched.

Setting out top plates

Mark the positions of all rafters on the top plate before wall frame is erected.

Mark the rafter positions on to the ridge board at the same time.

JR

run

CR

CR

CR

CR

Top plate

JR

TR

centre line

ridge board

run

JR

JR

CR

CR

CR

CR

CR

CR

CR

CR

Top plate

run

12

Roofing

August 2009

Setting out and cutting common rafters (CR) (50mm thick)

(i)

Determine rafter run (half the span)

(ii)

Calculate the length of the common rafter (refer to rafter tables or secants)

(iii)

Set out a pattern common rafter using bevels from rafter tables, roofing square or

means.

Common rafter

- deduct 13mm (half thickness of ridge ( 25mm thick)

(square off the plumb cut)

Thrust rafter -

deduct 25mm (half thickness of

square off the plumb cut.

other

common rafter

(iv)

Cut out pattern common rafter. Take special care when cutting the birdsmouth.

(v)

Use the pattern common rafter to set out all other rafters.

deduct

half thickness of ridge

square off plumb cut

PATTERN COMMON RAFTER-

calculated rafter length

overhang length

D

3/4 D or65 mm min.

x

overhang

run

seat cut

32 mm minimum bearing

100 mm maximum

rafter run

13

Roofing

August 2009

Setting out and cutting hip rafter (HR) (25mm thick)

(i)

Calculate the length of the hip rafter

Deduct 36 mm (square off plumb cut) (refer to Hip roof intersection pp. 20)

(ii)

Rafters may be lengthened by butting and flitching each side of the joint with timber

thick and 450 mm long minimum.

25 mm

(iii)

Hip rafters that project 600mm or more beyond the corner of the building must be

either 50 mm thick or be flitched on both sides at the birdsmouth with 25 mm thick

and 900 mm long timber.

(iv)

Cut out pattern hip rafter.

(v)

Use the pattern hip rafter to set out the other hip rafters.

Note

An on site measure can be used to check accuracy of set out and squareness of building

PATTERN HIP RAFTER

calculated hip rafter length

overhang length

edge cut

50 x 75 purlin

36 mm

x + 50

plumb cut

measurement ?

(50 mm approx. deeper than C/R)

overhang

run

(diagonal of C/R

over hang)

hip run (diagonal of C/R run)

14

Roofing

August 2009

Setting out and cutting valley rafters

(VR) (50mm thick)

(i)

Although the valley rafter has the same calculated length on the centre line as the

rafter, it has a different birdsmouth and deduction.

hip

Deduct 18mm (half diagonal thickness of the ridge)

(ii)

Use cut valley rafter as a pattern for others if required.

VALLEY RAFTER

calculated valley rafter length

( same as hip rafter )

overhang length

deduction 18 mm

to centre of edge cut

50 mm thick

valley rafter

add on 25 mm

overhang

run

over hang

valley run

15

Roofing

August 2009

Setting out and cutting jack rafters

(JR)

(i)

Calculate lengths individually (run x secant pitch) or

use shortening (spacing of rafters x secant pitch).

(ii)

Plumb and seat cuts are the same as the common rafter

(iii)

Deduct 18mm (half diagonal of hip rafter) or

take the calculated length to the long point (not exactly right but close enough!)

JACK RAFTERS

jack rafter edge cut

calculated length 2

calculated length 1

Jack rafters can be set out

on the pattern common rafter

Note:

Jack rafters must be cut in pairs.

Valley jack and cripple jack rafters are set out in a similar way.

16

Roofing

August 2009

ROOF INTERSECTIONS

common rafter

50 mm thick

hip rafter (25 mm)

major ridge (25 mm)

thrust rafter (50 mm)

centre line

36 mm

hip shortening

broken hip rafter (25 mm)

valley jack rafter or

common rafter (50 mm)

common rafter (50 mm)

valley rafter (50 mm)

18 mm VR shortening

minor ridge board (25 mm)

Setting out and cutting purlins

(i)

Fixed approx. 100 mm away from the ridge and all hip rafters,

alongside the valley boards, at the fascia board and at regular spacing to

suit the roofing being used.

(ii)

Set out, cut, and fix the bottom purlin first which must cut tight to the hip

rafters.

(iii)

Set out cut and fix hip purlins, then cut and fix all intermediate

purlins. (See sketch in Rafter Lengths and Bevels).

Scotch valley

For additions to an existing roof, a scotch valley using lay boards may be used.

(See sketch in Rafter Lengths and Bevels.)

Underpurlins

17

Roofing

August 2009

Where the span of the rafter exceeds the maximum allowed for that size either:

(i)

Increase the depth of the rafters until they can span from the top plate to

the ridge unsupported. (refer to 10.2.9, table 10.6)

or

(ii)

Set out, cut, and fix underpurlins as required with support from isolated

struts or paired struts. (refer to 10.2.10, fig 10.10)

SELECTION AND FIXING OF ROOF BRACING

1

(i)

Determine the number and type of braces required from table 10.1

(ii)

Cut and fix braces as shown in fig.10.22, 10.23, 10.24, 10.25, and 10.26.

(refer to 10.5.2)

(i)

Where underpurlins are used, cut and fix collar ties as shown in fig. 10.13

(ii)

Where underpurlins are not used, cut and fix cleats as shown in fig. 10.14

ROOFING SQUARE

Before the roofing square can be used to set out rafters, the rise per metre of run (rise/m.run)

must be found.

1

Pitch of the roof can be expressed as:

(i)

ratio of rise to span, (rise span) (See Stanley metric square booklet).

(ii)

slope of roof in degrees

(iii)

rise (mm) to metre of run(rise run).

Example

(i)

Roof rise 2.400, roof span 8.000

pitch = 2.4 8 = 0.3 pitch

(ii)

310 slope = 600mm rise per metre run (tangent)

(iii)

600mm rise/metre run (equals 0.3 pitch)

18

Roofing

August 2009

Setting out rafters using the steel square

(1)

Common rafter

Total length of CR

equals run times

length of common rafter

per metre run.

cut

(see roofing square table)

plumb 600 mm rise/metre run

(120 mm) Common rafter length

(Rise)

seat cut

C.R. set point

(200)

(Run)

(2)

Hip & valley rafters

Total length of HR (&VR)

equals run times length

of hip or valley per metre

run (see roofing square).

600 mm rise/metre run (120 mm)

Hip rafter length

plumb

cut

(Rise)

seat cut

(Run)

(3)

H.R. set point (283)

Side (edge cut) cuts

(i)

Jack rafters

edge cut

jack rafter

233 from table

(side cut of jack use)

(Rafter length)

(Run)

(ii)

200 mm

Hip or valley rafters

edge cut

hip rafter

217 from table (side cut of hip or

valleys use)

(Hip length)

(Run)

200 mm

19

Roofing

August 2009

ROOF TRUSSES

Roof trusses shall be specially designed in accordance with NZS 3603 and shall be fabricated

in controlled factory conditions, however the Engineer may approve the assembling of

trusses on site.

Drawing and Specifications shall be provided for all trusses. These shall contain all

information necessary to fabricate and erect the truss. (refer to NZS 3604, section 10.3)

PRINCIPLES OF TRUSS DESIGN

All truss construction is based on a system of triangles which when connected together can be

supported at two points only, refer to Terms illustration on page 23.

Advantages of using trusses

1

No central supports are needed. All partitions can be non load bearing.

Roof structure is stronger than standard rafter construction.

Long spans are possible.

Roof structure can be erected very quickly.

Trusses can be spaced up to 1200 mm centres for light weight roofing and

900 mm centres for heavy weight roofing, or can be spaced further apart if

required.

Trusses can be designed and built to cantilever over porches etc.

20

Roofing

August 2009

Nail plates

Plate sizes are expressed in centimetres . e.g. A 3 x 10 connector is 30 mm

wide by l00 mm long.

(ii)

Short plate teeths are all high density

(iii)

Longer plates incorporate medium and low density teeth near the centre.

FIXING ROOF TRUSSES

Set out

(i)

out.

Check truss set out drawing supplied by the fabricator before doing any setting

Mark out the truss locations on top of the top plate referring to the truss layout

plan (roof truss layout plan is provided by the truss fabricator)for reference.

(iii)

Trusses are always designed to be spaced at regular intervals. For light roofs,

the truss spacing shall not exceed 1200 mm and for heavy roof 900 mm.

Girder and truncated girder trusses should be set out first as other truss

positions are usually measured from them. Dual purpose girders i.e. truncated

girder/girders, need special attention as they may appear similar in profile to

others. It is important they are located accurately. Standard trusses should

then be set out, taking care not to exceed the design spacing.

21

August 2009

Roofing

22

Roofing

August 2009

Handling of trusses

(i)

Trusses must always be lifted in a manner that minimises lateral bending. It is

usually recommended to keep them strapped in bundles until they are erected

as this reduces the likelihood of damage.

Trusses may be lifted either by crane, hiab hoist or manually, depending on

the span and wall height. Trusses should always be kept vertically when

handled individually.

(iii)

Trusses lifted by crane requires sling or spreader bars.

Note: Never hoist a truss into position on its flat.

SLING

(iv)

SPREADER BAR

When erected by hand, slide the truss over the side walls on skids, spread at

3 m intervals. Rotate into position and supported at apex and panel points

or web points to ensure they do not distort or sag between supports.

(v)

Provided internal partitions are in place, trusses can be laid on their flat

temporarily before standing into correct position.

23

Roofing

August 2009

Erection of trusses

Take care when standing up steep trusses. Where possible tie ropes to the

panel points and hold or tie temporarily until temporary bracing can be fixed.

(ii)

Set trusses to a line, or mark the top plate position on each truss.

(Top plate must be straightened first!)

(iii)

Have temporary ties ready to fix truss at its correct position at the apex and at

least the half way point on each side. (Preferably at the panel points).

Purlins or roofing battens will hold trusses in permanent position.

(iv)

Put one or two ties onto the bottom chord of each truss. Ceiling battens

generally supply permanent tying of bottom chords. (refer to NZS 3604,

24

S-ar putea să vă placă și

- Everything you need to know about skillion roofsDocument2 paginiEverything you need to know about skillion roofsTeodoro Miguel Carlos IsraelÎncă nu există evaluări

- Engineered Wood Construction Guide PDFDocument72 paginiEngineered Wood Construction Guide PDFneo_may_sing100% (1)

- Continuously Reinforced Concrete PavementDocument36 paginiContinuously Reinforced Concrete Pavementzultrsb689Încă nu există evaluări

- Timber Frame Design 1Document6 paginiTimber Frame Design 1Avery SanbornÎncă nu există evaluări

- Structural Masonry KsnseminarDocument85 paginiStructural Masonry KsnseminarArvind DhimanÎncă nu există evaluări

- Beam Truss AnalogyDocument4 paginiBeam Truss AnalogyspamÎncă nu există evaluări

- Wind Loading (ASCE7-10)Document9 paginiWind Loading (ASCE7-10)Min KhantÎncă nu există evaluări

- Seismic Response of Wood-Frame Construction: Part B: The Role of Wood-Framed DiaphragmsDocument4 paginiSeismic Response of Wood-Frame Construction: Part B: The Role of Wood-Framed Diaphragmsrmm99rmm99Încă nu există evaluări

- Long Span StructuresDocument20 paginiLong Span StructuresShrishank Rudra100% (11)

- Hip and VallyDocument40 paginiHip and VallyKiran Kumar KondapalliÎncă nu există evaluări

- Domo 20ft Floor PlansDocument13 paginiDomo 20ft Floor PlansxfirealxÎncă nu există evaluări

- Raft Technical ManualDocument24 paginiRaft Technical ManualTuroy100% (1)

- Wood ConnectionsDocument29 paginiWood ConnectionsgullipalliÎncă nu există evaluări

- GD&T Selft Evaluation Test - Level 4Document25 paginiGD&T Selft Evaluation Test - Level 4pops10067% (6)

- International Truss SYSTEMS (Pty) LTD: Product CatalogueDocument34 paginiInternational Truss SYSTEMS (Pty) LTD: Product Catalogueansara89Încă nu există evaluări

- III. Sill Floor JointsDocument8 paginiIII. Sill Floor JointsCristian Morar-BolbaÎncă nu există evaluări

- Weep Hole Part Elevation Section: Drawn: Checked: Approved: Date: CAW 5/9/2011Document1 paginăWeep Hole Part Elevation Section: Drawn: Checked: Approved: Date: CAW 5/9/2011Peter Jean-jacquesÎncă nu există evaluări

- Masonry Reinforcement Product SelectorDocument8 paginiMasonry Reinforcement Product Selectorkakarock79Încă nu există evaluări

- Ceramic Stone and Waterproofing Systems and Work Method StatementsDocument65 paginiCeramic Stone and Waterproofing Systems and Work Method StatementsumitÎncă nu există evaluări

- Intro To Foundation EngineeringDocument35 paginiIntro To Foundation EngineeringNimra KhanÎncă nu există evaluări

- Diaphragms For Timber Framed Buildings Vol 17 No1 2004Document8 paginiDiaphragms For Timber Framed Buildings Vol 17 No1 2004Tiago Lamy SilvaÎncă nu există evaluări

- Structural Diagrams: Framing: Jeff Graybill & Johanna MikitkaDocument33 paginiStructural Diagrams: Framing: Jeff Graybill & Johanna MikitkaYashika Bhathiya JayasingheÎncă nu există evaluări

- Diaphragm Action and Design - SpringerDocument3 paginiDiaphragm Action and Design - SpringerGuillermo Agustín Yáñez QuezadaÎncă nu există evaluări

- Types of Long Span TrussesDocument3 paginiTypes of Long Span TrussesPeter WhiteÎncă nu există evaluări

- Architects DictumDocument3 paginiArchitects DictumChristian James TuazonÎncă nu există evaluări

- Sustainable Masonry: Stability and Behavior of StructuresDe la EverandSustainable Masonry: Stability and Behavior of StructuresÎncă nu există evaluări

- Hip & Valley Roofs - Doc - 2010Document10 paginiHip & Valley Roofs - Doc - 2010kjdaraÎncă nu există evaluări

- 38f-Ply Web Box Beam Type 03.PngDocument5 pagini38f-Ply Web Box Beam Type 03.PngParthiban ArivazhaganÎncă nu există evaluări

- Ventilated Facade Design in Hot and Humid ClimateDocument50 paginiVentilated Facade Design in Hot and Humid ClimateFernando Arantes BarbosaÎncă nu există evaluări

- Process Selection and Facility LayoutDocument32 paginiProcess Selection and Facility LayoutPher MorsÎncă nu există evaluări

- Engineered WoodDocument12 paginiEngineered WoodAlfredo Romero100% (1)

- Load Design ChartDocument12 paginiLoad Design ChartLuis Ugalde MirandaÎncă nu există evaluări

- Strip, Pad & Raft Foundations ExplainedDocument8 paginiStrip, Pad & Raft Foundations ExplainedkannanÎncă nu există evaluări

- Fig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyDocument3 paginiFig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyAmer GonzalesÎncă nu există evaluări

- Complex Roof Framing HandoutDocument23 paginiComplex Roof Framing HandoutMaria ComanÎncă nu există evaluări

- Safe Load TablesDocument12 paginiSafe Load TablesdeviationzÎncă nu există evaluări

- Masonry Design PDFDocument28 paginiMasonry Design PDFnanaamoakoÎncă nu există evaluări

- DL021 FloorDeck CatalogDocument160 paginiDL021 FloorDeck CatalogYeisonÎncă nu există evaluări

- Concrete Mix Design As Per Is 10262 - 2019Document14 paginiConcrete Mix Design As Per Is 10262 - 2019Rajendra BadjatyaÎncă nu există evaluări

- Shear Walls - An OverviewDocument6 paginiShear Walls - An OverviewTabish IslamÎncă nu există evaluări

- Door and Window Standard Sizes WANZ Test Size Configurations - July 2007Document1 paginăDoor and Window Standard Sizes WANZ Test Size Configurations - July 2007TuroyÎncă nu există evaluări

- Construction Technique L01Document26 paginiConstruction Technique L01khushbu naqviÎncă nu există evaluări

- Foundation Design Using Standard Penetration Test (SPT) N-ValueDocument39 paginiFoundation Design Using Standard Penetration Test (SPT) N-Valueneilmark undagÎncă nu există evaluări

- Reinforced Concrete BeamsDocument28 paginiReinforced Concrete BeamsEdriane Jude MalemÎncă nu există evaluări

- SDP - BBR1 - 14B2 - 008R - Recomendation For Extension of Time No PDFDocument2 paginiSDP - BBR1 - 14B2 - 008R - Recomendation For Extension of Time No PDFAiman ZhafriÎncă nu există evaluări

- Kokas CollectionDocument24 paginiKokas CollectionRossÎncă nu există evaluări

- Hambro Joist Typical DetailsDocument27 paginiHambro Joist Typical DetailsjgjgÎncă nu există evaluări

- APA Force Transfer Around OpeningsDocument12 paginiAPA Force Transfer Around Openingsmike wilson100% (1)

- Principles of ConstructionDocument78 paginiPrinciples of ConstructionY SAHITHÎncă nu există evaluări

- Chattral-Kadi Industrywise Data FileDocument25 paginiChattral-Kadi Industrywise Data FileKaran TrivediÎncă nu există evaluări

- CBB1443 How To Timber DeckDocument2 paginiCBB1443 How To Timber DeckTuroyÎncă nu există evaluări

- Staircase Terminology: Home. Stairs. Reviews. ContactDocument3 paginiStaircase Terminology: Home. Stairs. Reviews. ContactmarusvÎncă nu există evaluări

- Pryda Truss Systems For Floors Rafters 2015 WDocument6 paginiPryda Truss Systems For Floors Rafters 2015 WStructural EngineerÎncă nu există evaluări

- All CladdingDocument44 paginiAll CladdingalloytarungÎncă nu există evaluări

- T12 - 03 Special Hybrid Moment Frames Composed of Discretely Jointed Precast and Post - Tensioned Concrete MembersDocument15 paginiT12 - 03 Special Hybrid Moment Frames Composed of Discretely Jointed Precast and Post - Tensioned Concrete MembersAndrew BlackÎncă nu există evaluări

- Cavity Wall Construction Guide: Insulation Methods, Advantages & DetailsDocument30 paginiCavity Wall Construction Guide: Insulation Methods, Advantages & DetailsTejas JoshiÎncă nu există evaluări

- Product Technical Guide For Kwik Bolt-TZ Expansion Anchor Technical Information ASSET DOC LOC 1543424Document21 paginiProduct Technical Guide For Kwik Bolt-TZ Expansion Anchor Technical Information ASSET DOC LOC 1543424corrokokoÎncă nu există evaluări

- Floor Systems in Multistory BuildingsDocument25 paginiFloor Systems in Multistory Buildingsمحمد. إخوانÎncă nu există evaluări

- Simson Joist HangerDocument5 paginiSimson Joist HangerdamindaÎncă nu există evaluări

- Lateral Frame FormulasDocument16 paginiLateral Frame FormulasTariq MahmoodÎncă nu există evaluări

- Design A Deck Planning PDFDocument18 paginiDesign A Deck Planning PDFdvsÎncă nu există evaluări

- Modelling High Rise Structures Using MicrostranDocument10 paginiModelling High Rise Structures Using Microstranlerouge09Încă nu există evaluări

- A Mechanics Based Approach For Determining Deflections of Stacked Multistorey Woodbased ShearwallsDocument10 paginiA Mechanics Based Approach For Determining Deflections of Stacked Multistorey Woodbased ShearwallsEtienneLampronÎncă nu există evaluări

- TFEC 4 2020 Design Guide For Timber Roof TrussesDocument72 paginiTFEC 4 2020 Design Guide For Timber Roof TrussesEinÎncă nu există evaluări

- Flat Slab Design - Engineering DissertationsDocument34 paginiFlat Slab Design - Engineering DissertationsBobby LupangoÎncă nu există evaluări

- L9b - Timber StructuresDocument12 paginiL9b - Timber StructuresalexrodriguezabcÎncă nu există evaluări

- Retaining Structures ManualDocument197 paginiRetaining Structures ManualCarlos Rivera PerezÎncă nu există evaluări

- Engineered TimberDocument14 paginiEngineered TimberNaar Muhendislik100% (1)

- ct3 Steel Space Frame RoofDocument19 paginict3 Steel Space Frame Roofapi-339788639Încă nu există evaluări

- Soil Liquefaction - Presentation June 2009Document27 paginiSoil Liquefaction - Presentation June 2009TuroyÎncă nu există evaluări

- Common Problems With Coordinate System Configurations - Trimble GeospatialDocument12 paginiCommon Problems With Coordinate System Configurations - Trimble GeospatialTuroyÎncă nu există evaluări

- 038Document8 pagini038Divya Dev C MÎncă nu există evaluări

- Bioremediated Ground ImprovementDocument26 paginiBioremediated Ground ImprovementTuroyÎncă nu există evaluări

- Biochemical Oxygen DemandDocument4 paginiBiochemical Oxygen DemandHutapeaReynoldHamonanganChristoffelÎncă nu există evaluări

- Triggering of Liquefaction Recurring Questions 10-BoulangerDocument30 paginiTriggering of Liquefaction Recurring Questions 10-BoulangerTuroyÎncă nu există evaluări

- BBSC 433 Jessica Bennett Wind Design GuideDocument34 paginiBBSC 433 Jessica Bennett Wind Design GuideTuroyÎncă nu există evaluări

- Reproducing The REal Pressure CoefficientsDocument8 paginiReproducing The REal Pressure CoefficientsTuroyÎncă nu există evaluări

- Mitek 6kN Pile FixingDocument2 paginiMitek 6kN Pile FixingTuroyÎncă nu există evaluări

- Wind Design of Timber Panelised Roof Structures de-Panelized-Roof-WindDocument40 paginiWind Design of Timber Panelised Roof Structures de-Panelized-Roof-WindTuroyÎncă nu există evaluări

- Design of Chinese steel TV towers: Analysis of wind and seismic loadsDocument6 paginiDesign of Chinese steel TV towers: Analysis of wind and seismic loadsTuroyÎncă nu există evaluări

- Mitek 12kN Pile FixingDocument2 paginiMitek 12kN Pile FixingTuroyÎncă nu există evaluări

- Considerations in Wind Design of Wood StructuresDocument9 paginiConsiderations in Wind Design of Wood StructuresTuroyÎncă nu există evaluări

- SLIDE Water ModellingDocument10 paginiSLIDE Water ModellingTuroyÎncă nu există evaluări

- Grout Epcon c6Document8 paginiGrout Epcon c6TuroyÎncă nu există evaluări

- Options For A WInd Loading CodeDocument10 paginiOptions For A WInd Loading CodeTuroyÎncă nu există evaluări

- Dashcam Number of HrsDocument9 paginiDashcam Number of HrsTuroyÎncă nu există evaluări

- Australia:: What Makes A Home Relocatable?Document2 paginiAustralia:: What Makes A Home Relocatable?TuroyÎncă nu există evaluări

- Differences Between Autocad and Autocad LTDocument2 paginiDifferences Between Autocad and Autocad LTTuroyÎncă nu există evaluări

- Foundations On Expansive Soils Sudan Experience - XXDocument13 paginiFoundations On Expansive Soils Sudan Experience - XXTuroyÎncă nu există evaluări

- Engineers Briefing Invitation 20 May 2016Document2 paginiEngineers Briefing Invitation 20 May 2016TuroyÎncă nu există evaluări

- Foundations On Expansive Clays and RocksDocument6 paginiFoundations On Expansive Clays and RocksTuroyÎncă nu există evaluări

- Discussion On Swelling SoilDocument4 paginiDiscussion On Swelling SoilTuroyÎncă nu există evaluări

- Engineers Briefing Invitation 20 May 2016Document2 paginiEngineers Briefing Invitation 20 May 2016TuroyÎncă nu există evaluări

- Computer Program For Simulation of Wall Construction SequenceDocument90 paginiComputer Program For Simulation of Wall Construction SequenceTuroyÎncă nu există evaluări

- Driven Piles in Central Texas Expansive SoilsDocument10 paginiDriven Piles in Central Texas Expansive SoilsTuroyÎncă nu există evaluări

- Patio Cover Standard DrawingDocument2 paginiPatio Cover Standard DrawingTuroyÎncă nu există evaluări

- Hafele Furniture Fittings PDFDocument20 paginiHafele Furniture Fittings PDFKissa DolautaÎncă nu există evaluări

- Plate No. 02Document4 paginiPlate No. 02Khurt Rizzgil HonradoÎncă nu există evaluări

- General notes staircase dimensions referencesDocument1 paginăGeneral notes staircase dimensions referencesinno musiimeÎncă nu există evaluări

- BS 1881-104 Concrete Vebe TimeDocument11 paginiBS 1881-104 Concrete Vebe TimePD AWSSIESPÎncă nu există evaluări

- High Rise Buildings (Editing)Document37 paginiHigh Rise Buildings (Editing)MohamedÎncă nu există evaluări

- Fdocuments - in The Formwork Experts Timber Formwork Beams 4 999791002 022020 User InformationDocument20 paginiFdocuments - in The Formwork Experts Timber Formwork Beams 4 999791002 022020 User InformationNitish BansalÎncă nu există evaluări

- Speeds & Feeds: Drilling & Reaming Surface Feet Per Minute (SFM)Document6 paginiSpeeds & Feeds: Drilling & Reaming Surface Feet Per Minute (SFM)naninoÎncă nu există evaluări

- (Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualDocument69 pagini(Annexure - I) Lump Sum Tender Market Rate Analysis As Per Table 'H' of Contract ManualPankaj BansalÎncă nu există evaluări

- Case Study Arch BridgeDocument4 paginiCase Study Arch Bridgekunal humaneÎncă nu există evaluări

- Candles & PivotsDocument9 paginiCandles & PivotsbcÎncă nu există evaluări

- SER - Tower Related Price RevisiedDocument270 paginiSER - Tower Related Price RevisiedTasew AberaÎncă nu există evaluări

- Sugar Cane ThesisDocument5 paginiSugar Cane ThesisTajoe MarudoÎncă nu există evaluări

- Vetoset CA547: Polymer Modified Water Resistant Adhesive For Fixing Pool, Fountain & Water Tank TilesDocument2 paginiVetoset CA547: Polymer Modified Water Resistant Adhesive For Fixing Pool, Fountain & Water Tank Tilesmus3b1985Încă nu există evaluări

- Sdo Wapda Basha DamDocument5 paginiSdo Wapda Basha Damsaifal hameedÎncă nu există evaluări

- BS 594.1-92 - Hot Rolled Asphalt For Roads and Other Paved Areas (Spec For Constituent Materials and Asphalt Mixtures)Document21 paginiBS 594.1-92 - Hot Rolled Asphalt For Roads and Other Paved Areas (Spec For Constituent Materials and Asphalt Mixtures)Michael VeneerÎncă nu există evaluări

- Raines Court 2010 - LR-compressedDocument37 paginiRaines Court 2010 - LR-compressedPATEL MIHIKAÎncă nu există evaluări

- Kaizen: An Essential Tool For Inclusion in Industrial Technology CurriculaDocument7 paginiKaizen: An Essential Tool For Inclusion in Industrial Technology Curriculadarff45Încă nu există evaluări

- ASF Katalog 2018 - GBDocument108 paginiASF Katalog 2018 - GBKemo TufoÎncă nu există evaluări

- Mbizm Value Stream Mapping For Manufacturing (VSM) Public TrainingDocument1 paginăMbizm Value Stream Mapping For Manufacturing (VSM) Public TrainingRicky MarkÎncă nu există evaluări

- JIS Pipe CatalogueDocument3 paginiJIS Pipe CatalogueAries BatamÎncă nu există evaluări

- Kresge Auditorium Case StudyDocument23 paginiKresge Auditorium Case StudySindhura Valluri90% (10)