Documente Academic

Documente Profesional

Documente Cultură

Inventory List

Încărcat de

Jesus GutiérrezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Inventory List

Încărcat de

Jesus GutiérrezDrepturi de autor:

Formate disponibile

Inventory & quotable material

Scot Forge carries an extensive inventory of raw materials, allowing for shorter lead times and quick reaction to market

changes. Additionally, we offer custom-melt materials uniquely suited to your application, so while the materials listed

below are the more commonly quoted, dont hesitate to call us for any other specification or grade.

Carbon Steel

1006

1008

1010

1018

1020

1021

1022

1026

1029

1040

1045

1050

1053

1055

1060

1065

1070

1080

1117

1141

1146

1215

1552

2317

1030

1035

10B60

1541V

15B22

17CrNiMo6

18CrNiMo7-6

Common carbon steel specification grades include: ABS Grade 2, ABS Grade 2C, ASTM A105, ASTM A181, ASTM A266, ASTM A290, ASTM A291,

ASTM A304, ASTM A350, ASTM A36, ASTM A576, ASTM A668, ASTM A694

Alloys Steel

3310

4125

4130

4137

4140

4142

4145

4150

4170

4220

4320

4325

4340

4350

4360

4532

4620

4715

4820

5080

6150

8620

8622

8625

8740

8822

9310

52100

21CrMoV511

300M

34CrNiMo6

4330V

43B17

8630

D6AC

E4340

EX55

HY-100

HY-130

HY-80

NITRALLOY "N"

NITRALLOY 135

Common Alloy Steel Specification Grades: ASTM A469, ASTM A707, API Spec 6A, ASTM A182F91, ASTM A182F11, ASTM A182F12, ASTM A182F22,

ASTM A182F5, ASTM A182F9, ASTM A288, ASTM A290, ASTM A291, ASTM A304, ASTM A336F1, ASTM A336F11, ASTM A336F22/F22A, ASTM

A350, ASTM A508, ASTM A668, ASTM A723, ASTM A837, ASTM A182FI, ASTM A588, ASTM A694, MIL-S-23284CL1, MIL-S 23284CL2 NACE

MRO175, SAE AMS6257, SAE AMS6419, SAE AMS6431, Shell DEP, T9074-BD-GIB-010/0300 & SA/A 508 Grade 4N

Bearing Quality

4130

4140

4150

4320

4340

4820

Calcium Treated

8620

8822

9310

4130

4140

4150

52100

4340

4330

Aircraft Quality

4340

4140

9310

4320

8822

4150

4130

8620

4820

13-8 Mo

4330 Modified

4330V VAR

AERMET 100 (UNS K92580)

6Al-2Sn-4Zr-2Mo Titanium

N06686

Common Aircraft Quality Specification Grades: SAE AMS2301, SAE AMS2304, SAE AMS4311, SAE AMS5632, SAE AMS6382, SAE AMS6414, SAE

AMS6415, SAE AMS6349, SAE AMS6484, SAE AMS5632, SAE AMS5934, SAE AMS6260, SAE AMS6370, SAE AMS6348, SAE AMS6427, SAE AMS5000,

SAE AMS4975, SAE AMS6484, SAE AMS6758, SAE AMS6359, SAE AMS6274, MIL-S-5626, MIL-S-8690, ASME SB-564, ASTM B564

Aluminum

1100

2014

2024

2050

2195

2219

2618

4032

5083

5086

5456

6013

6061

7039

7050

7075

7085

7175

Copper

C10100

C11000

C18000

C18000 Zr

Modified

C18150

C18200

C18400

C61400

C63000

C63200

C70600

C71500

HIDURON

191

Nickel

N02200

N04400

N05500

N06600

N06617

N06625

N07718

N07725

N07750

Titanium

N08020

N08367

N08800

N08810

N08811

N08825

N09901

N10276

Magnesium

CP Ti GR.1

6-2-4-2 TI

CP Ti GR.2

Ti Beta C

CP Ti GR.3

10-2-4-2

CP Ti Gr. 4

CP Ti 70

6Al-4V Ti

6Al-4V ELI Ti

5-1-1-1 Ti

ZK-60A (UNS M16600)

AZ-31B (UNS M11311)

WE-43 (UNS M18430)

Stainless Steel

13-8 Mo (XM-13)

15-5 PH (XM-12)

15-5 PH VAR

17-4 PH (630)

17-4 PH VAR

Nitronic 50 (XM-19)

Nitronic 50 ESR (XM-19)

Nitronic 60 (UNS S21800)

Nitronic 40 (XM-11)

Nitronic 40 ESR (XM-11)

304/304L ESR

304/304L

304/304L Low Cobalt

304H

304LN

310H

254 SMO

316/316L

316H

317/317L

UNS S31803 (F51)

321

321 VAR

2205 (F60)

Ferralium 255 (F61)

2507

2507 ESR

347

405

410 (F6a)

403

415 (F6NM)

416

420

422 ESR

UNS S42225

431

440A

Custom 450 (XM-25)

A286 (660)

AL6XN (UNS N08367)

904/904L

Customer Specified Grades

General Electric

Caterpillar

Lufkin

Falk

Howco

8001 Winn Road, Box 8, Spring Grove, IL 60081 847/587-1000 800/435-6621 Fax 847/587-2000 sales@scotforge.com www.scotforge.com

INV 4-14

Commonly Forged Shapes:

With no minimum requirements for stocking grades, you can order single-piece or high-volume quantities ranging

from a few lbs. up to 100,000 lbs. in a wide range of ferrous or non-ferrous materials.

Disks/Blanks

Rings

Disks from ferrous

and non-ferrous

metals up to 144

O.D. with variable

diameter and

thickness ratios or

combinations

Bars

Hubs/Tooled Forgings

Rolled rings to

252 O.D., 49

height, and wts.

to 60,000 lbs.

Open die rings

to 144 O.D.,

90 height.

Semi-Closed Die

Step Shafts/Spindles

Unique process

pioneered by Scot

Forge. Provides costeffective conversion

of cast or fabricated

parts. Powered by a

collaboration of CAD

and simulation

software.

Round, square, or

hex up to 65 cross

section, rectangles

to 120 wide.

Lengths to 700.

Tartan Bars from 6

to 16 O.D.

Hollows

Single, double

or tapered hubs

to 144 O.D.

Torch Cut or Profile Cut

Concentric or

eccentric to 65

O.D. Round,

square, rectangle or polygonal

dimensions.

Upset flangedend. Lengths to

600

Complex Forged Shapes

Infinite shape

possibilities. Torch

cut shapes or contours in carbon and

alloy forged parts up

to 32 thick with

cross sections ranging between 96 x

144 and 88 x 282

Single or multiple

O.D./ I.D. up to 90

O.D.

2 minimum wall

thickness. lengths

to 360

Unique and innovative forged

shapes. Created in

collaboration with

process engineering teams. Powered by simulation

and CAD software.

The above capabilities are only general guidelines. If your needs are a bit more complex, we will take the time to listen.

Please contact us and we will put you in direct communication with a Scot Forge technical sales expert or industry

specialist.

We also offer all downstream value-added processes including saw cutting, heat treating, contour torch cutting,

destructive testing, metallurgical analysis and Level III nondestructive testing.

Certified to

ISO 9001:2008

AS9100C

Heat Treating

Nondestructive Testing

Call us with your specific requirements!

100% Employee Owned

Visit our website at

www.scotforge.com

8001 Winn Road, Box 8, Spring Grove, IL 60081 847/587-1000 800/435-6621 Fax 847/587-2000 sales@scotforge.com www.scotforge.com

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Valve Material EquivalentsDocument3 paginiValve Material EquivalentsAndre Villegas Romero100% (1)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Technical 133 PDFDocument1 paginăTechnical 133 PDFSatheshkumar EagambaramÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Pioneer Ddj-sb2 QSGDocument9 paginiPioneer Ddj-sb2 QSGJesus GutiérrezÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Pioneer Ddj-sb2 QSGDocument9 paginiPioneer Ddj-sb2 QSGJesus GutiérrezÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Twister LE: Code: Color: SizeDocument1 paginăTwister LE: Code: Color: SizeJesus GutiérrezÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Technical 133 PDFDocument1 paginăTechnical 133 PDFSatheshkumar EagambaramÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- D2 08Document36 paginiD2 08Jesus GutiérrezÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Articulo para Traducir 64 HojasDocument64 paginiArticulo para Traducir 64 HojasJesus GutiérrezÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- CRDocument8 paginiCRErfan EffendyÎncă nu există evaluări

- Liquid Phase SinteringDocument242 paginiLiquid Phase SinteringAbir Roy100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Precipitation-Hardening Stainless Steels: Properties and Types (Martensitic, Austenitic, SemiausteniticDocument3 paginiPrecipitation-Hardening Stainless Steels: Properties and Types (Martensitic, Austenitic, SemiausteniticClaudia MmsÎncă nu există evaluări

- Advanced High Temperature AlloysDocument123 paginiAdvanced High Temperature Alloysalvaedison00100% (1)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Dental CeramicsDocument161 paginiDental CeramicsANUBHA77% (13)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- KORLOYDocument22 paginiKORLOYJuan Jose Ruiz FreyreÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Igcse Chemistry SolutionsDocument6 paginiIgcse Chemistry Solutionspreeti.2405Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- LateriteDocument2 paginiLateriteadinbenzÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Advanced High Strength Sheet SteelsDocument415 paginiAdvanced High Strength Sheet SteelsYair Salinas Escutia100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- Clinoptilolite Zeolite - Technical Data SheetDocument3 paginiClinoptilolite Zeolite - Technical Data SheetrafaeldiserioÎncă nu există evaluări

- Weld RepireDocument91 paginiWeld RepireKapil ManloiÎncă nu există evaluări

- Fundamental Research On Underwater Welding: Effects of Water Environment On Metallurgical Structures of WeldsDocument11 paginiFundamental Research On Underwater Welding: Effects of Water Environment On Metallurgical Structures of WeldsJeesonAntonyÎncă nu există evaluări

- Gold Purity Guide - Difference Between 24k, 22k and 18k GoldDocument7 paginiGold Purity Guide - Difference Between 24k, 22k and 18k GoldSergio FloresÎncă nu există evaluări

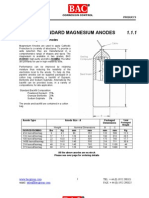

- 1.1.1 ISOLINE MG Anode StandardDocument2 pagini1.1.1 ISOLINE MG Anode StandardJaka SembungÎncă nu există evaluări

- Exhibitor List 2015Document5 paginiExhibitor List 2015Ravishankar BKÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Astm IndexDocument30 paginiAstm IndexAnshul JainÎncă nu există evaluări

- Brazilian Gemstones: Earth-Science ReviewsDocument13 paginiBrazilian Gemstones: Earth-Science ReviewsDaniela TeixeiraÎncă nu există evaluări

- 441 AK Steel Write-UpDocument6 pagini441 AK Steel Write-UpJason AnnesÎncă nu există evaluări

- Mineral WollastoniteDocument2 paginiMineral WollastoniteFaiza Rahman HakimÎncă nu există evaluări

- The Role of Shielding GasDocument13 paginiThe Role of Shielding Gasdev-nullÎncă nu există evaluări

- Phone: 1300 365 110 Stocking Locations included:Trade Centres (pick up or deliveryDocument41 paginiPhone: 1300 365 110 Stocking Locations included:Trade Centres (pick up or deliveryKevin YewÎncă nu există evaluări

- Flowforming or Metal Spinning (Spin Forming)Document2 paginiFlowforming or Metal Spinning (Spin Forming)ShivajiÎncă nu există evaluări

- Color Code Chart - ASME B16.20: Canflex™ Style RWDocument1 paginăColor Code Chart - ASME B16.20: Canflex™ Style RWnunosobralÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Buehler Technotes - Indentation Testing MappingDocument3 paginiBuehler Technotes - Indentation Testing Mappingdev-nullÎncă nu există evaluări

- Zircon Mineral DataDocument4 paginiZircon Mineral DataeriksarumpaetÎncă nu există evaluări

- Theories of Ore GenesisDocument10 paginiTheories of Ore GenesisIrwan EPÎncă nu există evaluări

- Material Hand BookDocument47 paginiMaterial Hand BookHARIMETLYÎncă nu există evaluări

- 304 VS 316Document2 pagini304 VS 316Sheikh ZakirÎncă nu există evaluări

- UR35NDocument4 paginiUR35NricardodelatorreÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)