Documente Academic

Documente Profesional

Documente Cultură

Verify Test Prep and Equipment

Încărcat de

aasattiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Verify Test Prep and Equipment

Încărcat de

aasattiDrepturi de autor:

Formate disponibile

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Verification of Test Preparation and Test Equipment for

Pressure Testing

PROJECT TITLE

SAIC NUMBER

SAIC-A-2009

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

DATE APPROVED

25-May-05

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

Preparation for Testing

A1

Test Pack is available for verification and review.

(Refer to SAIC-L-2001).

Best Practice

A2

Pre-Test Punchlisting complete and Test Pack Flow Chart signed

accordingly. (Refer to SAIC-L-2001).

Best Practice

A3

All pre-test punchlist designated as "A" items are cleared.

(NOTE: "A"-items are pre-test punchlists required to be completed prior

to pressure testing .)

Best Practice

A4

Flanges that will not be disturbed after the pressure test are

marked/identified and tightened WITH the approved SAIC-L-2014 &

SATR-L-2001.

Best Practice

A5

Flushing or internal Cleanliness of system is complete. Test Package

Flow chart signed-off accordingly.

SAES-A-004,

Para. 7.1.2

A6

Components which interfere with filling, venting, draining or flushing shall

not be installed until after line flushing and pressure testing are

completed. These include orifice plates, flow nozzles, sight glasses,

venturies, positive displacement and turbine meters and other in-line

equipment.

SAES-A-004,

Para. 7.1.4

A7

Equipment Excluded from Pressure Test

The following equipment are excluded from the in-situ pressure testing of

the tested system.

a) Rotating machinery, such as pumps, turbines and compressors;

b) Strainers and filter elements;

c) Rupture disks and pressure relief valves;

d) Locally mounted indicating pressure gauges, where the test

pressure will exceed their scale range;

e) Equipment that cannot be drained;

f) Instrument Devices.

SAES-A-004,

Para. 7.2

A8

Temporary supports are installed if they were determined to be required

per SAES-L-150.

SAES-A-004,

Para. 7.5.2

A9

Expansion joints and spring hangers or spring supports are provided with

temporary restraints where needed to prevent excessive travel or

deformation under the test loads.

SAES-L-150,

Para. 6.4

All joints including welded joints are left exposed for visual leak detection

A10 during the strength test.

(NOTE: This excludes joints that will be subject to 24-hr recorded test. )

SAES-L-150,

Para. 7.3

A11

Work permit is obtained for all pressure testing and associated work

within restricted areas as covered in G.I. 2.100, Work Permit System.

G.I.-2.102,

Para. 5.6

A12

Equipment and appurtenances that are not adequate for test pressures

are isolated.

G.I.-2.102,

Para. 5.7

Page 1 of 3

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Verification of Test Preparation and Test Equipment for

Pressure Testing

PROJECT TITLE

SAIC NUMBER

SAIC-A-2009

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

If isolation valves are used in lieu of blinds, provisions are

A13 made to ensure that no overpressuring can occur in equipment that is

not being tested, due to possible valve leak.

G.I.-2.102,

Para. 5.7

Materials Safety Data Sheets or Chemical Hazard Bulletins are reviewed

for all chemicals handled such as corrosion inhibitor, bactericide,

chlorine, and oxygen scavenger, and a written procedure to safely handle

A14 chemicals during testing, and proper disposal of the chemicals after

testing, is approved prior to start of the work. Personal protective

equipment shall be utilized as shown

on these sheets and bulletins.

G.I.-2.102,

Para. 5.9

A15

The test areas are marked and warning signs posted to alert

approaching personnel.

G.I.-2.102,

Para. 5.11

A16

Where a road parallels within 30 m (100 ft.) of an aboveground pipeline

being tested, traffic shall be diverted or stopped during the test. If this is

not practical, the area Loss Prevention offices should be contacted to

confirm that the test can be conducted safely.

G.I.-2.102,

Para. 5.11

If non-Saudi Aramco facilities will be exposed in a pressure test of Saudi

Aramco facilities, the proponent organization of the test shall so inform

A17

the Saudi Aramco Affairs representative prior

to the test.

B

G.I.-2.102,

Para. 5.12

Test Piping and temporary appurtenances:

B1

Test piping, fittings and hoses are designed or have pressure rating that

matched or exceed the system test pressure.

G.I.-2.102,

Sec.4

B2

Paddle blinds or spectacle blinds used to isolate the test sections are of

the same class rating of the system or may be fabricated based on

appropriate calculations.

SAES-A-004

Para. 7.3

Test Manifold

C1

The pressure testing manifold was separately pressure tested to at least

1.2 times the system test pressure.

C2

Pressure rating or design of test manifold components, ie: isolation

valves, pipe nipples, are not less than 20% above the system test

pressure.

G.I.-2.102,

Para. 5.5

C3

A blow down valve of adequate pressure rating is installed to

depressurize the system.

G.I.-2.102,

Para. 5.5

C4

An isolation valve of adequate pressure rating is installed to isolate the

test piping manifold from the system under test.

G.I.-2.102,

Para. 5.5

Test Relief Valve(s)

D1

Relief valve(s) of adequate capacity are set to relieve at 5% above the

hydrotest pressure.

SAES-A-004

Para 5.5.1

D2

The relief valve(s) are tested, dated, and tagged within one week prior to

the pressure testing.

SAES-A-004

Para 5.5.1

D3

Isolation valves installed on the inlet and outlet of the relief valve are

sealed open during the test.

G.I.-2.102,

Para. 5.5

D4

The relief valve is located in the system under test and near the test

pump.

G.I.-2.102,

Para. 5.5

Page 2 of 3

SAES-A-004

Para 5.5.4

DATE APPROVED

25-May-05

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Verification of Test Preparation and Test Equipment for

Pressure Testing

DATE APPROVED

SAIC-A-2009

PROJECT TITLE

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

Pressure Gages and Recorders

E1

A minimum of two pressure gages are required for the test system.

Their accuracy shall be within 5% of one another.

(NOTE: When large systems are tested, Inspection personnel will

determine the need for additional gages. )

SAES-A-004

Para 7.1.5

E2

Pressure gages and pressure recorders are calibrated within one (1)

month prior to the test. Stickers shall be applied indicating the latest

calibration date.

SAES-A-004

Para 7.1.5

E3

A Test gauge is located at the bottom of the equipment to inable the

reading of the test pressure, including the head of test water.

G.I.-2.102,

Sec.4

E4

All gages have a range such that the test pressure is within 30% to 80%

of the full range.

Temperature Gages (when required, ie: 24-hr recorded test)

F1

Thermocouples are installed to obtain accurate pipe metal temperature

measurements and to determine the acceptance of the pressure test

where pressure variations due to test water temperature changes occur,

such as in cross-country pipelines.

QR NUMBER

25-May-05

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAES-A-004

Para 7.1.5

SAES-L-150,

Para. 11.3

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-A-004, General Requirements for Pressure Testing, (30 April, 2002)

2. GI-2.102, Saudi Aramco General Instruction-Pressure Testing Safely , (22 July, 2001)

3. SAES-L-150, Pressure Testing of Plant Piping and Pipelines, (30 September, 2003)

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

T&I Witnessed

QC Record Reviewed

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Work Verified

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 3 of 3

Work Verified

N = NO F = FAILED

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- API 570 Mock Exam Closed BookDocument17 paginiAPI 570 Mock Exam Closed Bookaasatti100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Certification Program: Aws - CwiDocument5 paginiCertification Program: Aws - CwiaasattiÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Important - Accept Because Progression in SMAW Is Non-Essential Variable. - 300 S/sDocument1 paginăImportant - Accept Because Progression in SMAW Is Non-Essential Variable. - 300 S/saasattiÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Api Exam-Part 2Document2 paginiApi Exam-Part 2aasattiÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- API 570 Exam Publications Effectivity SheetDocument1 paginăAPI 570 Exam Publications Effectivity SheetaasattiÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- API Standards For RefiningDocument3 paginiAPI Standards For Refiningaasatti100% (2)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Saudi Aramco NDT Methods Application On Heat ExchangersDocument30 paginiSaudi Aramco NDT Methods Application On Heat Exchangersaasatti100% (1)

- Example of Pipe Wall Thickness CalcDocument1 paginăExample of Pipe Wall Thickness CalcaasattiÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Chapter 4 Transport PhenomenaDocument89 paginiChapter 4 Transport PhenomenaaasattiÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Transport Phenomena in Porous Media-2&3-2Document125 paginiTransport Phenomena in Porous Media-2&3-2aasatti100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Dimensional & Material Standards For Piping ComponentsDocument3 paginiDimensional & Material Standards For Piping ComponentsaasattiÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Caesar II Applications GuideDocument308 paginiCaesar II Applications Guidebanjinolimit8299100% (5)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Answer All The Questions: Padge 101 (Eq.3.20)Document4 paginiAnswer All The Questions: Padge 101 (Eq.3.20)aasattiÎncă nu există evaluări

- TTT DiagramDocument1 paginăTTT DiagramaasattiÎncă nu există evaluări

- Regulators 63egDocument20 paginiRegulators 63egAlberto CastellanosÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Kunkle Safety and Relief Products: Technical ReferenceDocument32 paginiKunkle Safety and Relief Products: Technical Referencetuanhiena10Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Design Requirements For Pressure Safety Relief ValvesDocument5 paginiDesign Requirements For Pressure Safety Relief Valvesvela vanÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Blackmer TX TXD - ManualDocument12 paginiBlackmer TX TXD - ManualFelipe Ignacio PaillavilÎncă nu există evaluări

- 4416 Product Status Report 19 02 2020Document11 pagini4416 Product Status Report 19 02 2020Maimun maimunÎncă nu există evaluări

- Guideline - document-to-ISO-5149 - Version-1Document12 paginiGuideline - document-to-ISO-5149 - Version-1Dott. Giuseppe MaruzzellaÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- CatalogDocument319 paginiCatalogEki NosaÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- Fuel SystemDocument24 paginiFuel SystemHammad Uddin JamilyÎncă nu există evaluări

- Valves PDFDocument12 paginiValves PDFAnonymous HFIQgANMQÎncă nu există evaluări

- Relief Device Inlet Piping Beyond The 3 Percent Rule - HP - Nov 2011 PDFDocument7 paginiRelief Device Inlet Piping Beyond The 3 Percent Rule - HP - Nov 2011 PDFonizuka-t2263Încă nu există evaluări

- 0004 Lesson API RP-576Document65 pagini0004 Lesson API RP-576tayyab aliÎncă nu există evaluări

- 510 Recert. QuizDocument8 pagini510 Recert. QuizAkmal ShauqyÎncă nu există evaluări

- Relief Valve (Line) - Test and Adjust: Shutdown SIS Previous ScreenDocument5 paginiRelief Valve (Line) - Test and Adjust: Shutdown SIS Previous Screenchanlin0% (1)

- Annexure 1 - Technical Bid Analysis For Emergency Relief ValveDocument1 paginăAnnexure 1 - Technical Bid Analysis For Emergency Relief ValveNikhil KarkeraÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Neptune 500-E-Series-Product-BulletinDocument4 paginiNeptune 500-E-Series-Product-BulletinMemory CrushÎncă nu există evaluări

- Module 7Document25 paginiModule 7ajmalÎncă nu există evaluări

- Pressure-Relief ValvesDocument11 paginiPressure-Relief ValvesbalaÎncă nu există evaluări

- Assignment 2 Q2Document2 paginiAssignment 2 Q2Johan Aliff0% (1)

- NRC Generic Fundamentals Examination Question Bank - PWR February 2016Document65 paginiNRC Generic Fundamentals Examination Question Bank - PWR February 2016Iqbal HayatkhanÎncă nu există evaluări

- Relief Valve PDFDocument34 paginiRelief Valve PDFThái Mai ĐìnhÎncă nu există evaluări

- SNP2 SpecDocument3 paginiSNP2 Specmanuales100% (1)

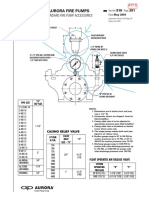

- ATT-3 - Standard Fire Pump AccessoriesDocument1 paginăATT-3 - Standard Fire Pump AccessoriesTolgahan KaradagÎncă nu există evaluări

- Fundaments of Chemical Engineering Process Equipment DesignDocument7 paginiFundaments of Chemical Engineering Process Equipment DesignAgung Priambodho100% (1)

- Bosch Aquastar 125b - LPDocument16 paginiBosch Aquastar 125b - LPSteve RussellÎncă nu există evaluări

- 627 Series Pressure Reducing Regulators BulletinDocument32 pagini627 Series Pressure Reducing Regulators BulletinJonatan Ferney Valenzuela ForeroÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- N-G-HE - 200 - EN Pressure Safety ReliefDocument77 paginiN-G-HE - 200 - EN Pressure Safety ReliefMEGAN ASBROCK100% (1)

- Series 1500/2500 Safety Relief ValvesDocument12 paginiSeries 1500/2500 Safety Relief ValvesSandro ChiliquingaÎncă nu există evaluări

- Selection and Sizing of Pressure Relief ValvesDocument21 paginiSelection and Sizing of Pressure Relief ValvesFaizi RadziÎncă nu există evaluări

- Thermal Relief Valves: From The Automation List Department..Document1 paginăThermal Relief Valves: From The Automation List Department..Sofyan HadiÎncă nu există evaluări

- API 576 Practice Exam QuestionsDocument10 paginiAPI 576 Practice Exam QuestionsMahmoud El Nakeeb100% (1)