Documente Academic

Documente Profesional

Documente Cultură

Splines: Side Splines For Soft Holes in Fittings-Sae J499a

Încărcat de

manuTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Splines: Side Splines For Soft Holes in Fittings-Sae J499a

Încărcat de

manuDrepturi de autor:

Formate disponibile

17

Splines

Tllis report has been published separately as ANSI B92.1, available from

~(Hll:tyof Automotive Engineers, Inc., 400 Commonwealth Drive, WarrenPenna. 15096.

_.k,

,PARALLEL

SIDE SPLINES FOR SOFT

,IROACHED HOLES IN FITTINGS-SAE

;'"

~.'IHlrl. of

""Ill Ie

Broaches Division approved January 1914, revised by Shaft Fittings

Splines and Inspection-October

1975.

J499a

Division

March

1920, and reviewed

I 'his Information Report along with SAE J500 and J50 I is generally underjliHldto be technically obsolete for the design of new applications, However, it

1_ listed for those existing applications where it may be required, For the

I!;-,il(nof new applications, consult ANSI B92.1-1970-Involute Splines and

'1"'l'cctions Standard.

IThe dimensions, given in inches, apply only to soft broached holes. The

Ihul'ldimensions depend upon the shape and material of the parts, their heat

jlf'lIlment, and methods of machining to give the required fit. The method

amount of "breaking" sharp corners and edges also depend upon the

"'lilditions and requirements of each application.

The formula for theoretical torque capacity (pressure on sides of spline) in

,~I,'h-pounds per inch of bearing length (L) and at 1000 psi pressure is:

January

1936. Last revised by ANSI B92 Committee-

wider tolerances may be permitted on both the large and small diameters.]

Radii on corners of splines are not to exceed 0.015 in,

Splines shall not be more than 0,006 in per ft out of parallel with respect to

the axis of the shaft.

No allowance is made for radii on corners or for clearance. Dimensions are

intended to apply to only the soft broached hole. Allowance must be made for

machining.

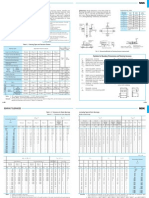

For values of D, W, d, h, and T for four-, six-, ten-, and sixteen-spline

fittings, see Tables 2, 3, 4, and 5, respectively.

f."d

No. of

Splln

The tolerances allowed are for good construction and may be readily

'Illuintained by usual broaching methods. The tolerances selected for the large

, lid small diameters will depend upon whether the fit between the mating

Al'lS, as finally made, is on the large or the small diameter. The other

'Iumeter, being designed for clearance may have a wider manufacturing

ukrance. If the final fit between the parts is on only the sides of the spline,

FIG. I-DIMENSIONS

6

10

16

FOR 4, 6, 10. AND 16 SPLINE

17.01

Permanent

Fit

h

.c

0.241"

0.250

0.156

0.098

B

To Slide when Not

W

For All

Fit.

--0.075

0.050

0.045

0.045

FITTINGS

under

---- --0.850

0.900

0.910

0.910

(SEE TABLE

0.125

0.075

0.070

0.070

J)

C

To Slide under

Lood

Load

--0.750

----

0.850

0.860

0.860

0.100

0.095

0.095

---0.800

0.810

0.810

For All Fib

Nominal

010

4.4, Permanent

For All Fits

49, To Slido whon Not under Load

Fit

,:

T

lOA, Permanont Fit

lOB, To Slide whon

Not under Load

Nominal

010

---

Min

--

3/4

7/8

0.7 49

0.874

0.999

1-1/8

1.1/4

1-3/8

1.124

1.249

1.374

1.1/2

1-5/8

1-3/4

Max

-0.750

Min

--

0.179

0.209

0.239

Max

Max

Min

Min

--- -- -0.181 0.636 0.637 0.055

Max

Mln

--

0.211

0.241

0.743

0.849

0.744

0.850

0.065

0.074

0.056

0.066

0.075

1.125 0.269

1.250 0.299

1.375 0.329

0.271

0.301

0.331

0.955

1.061

1.168

0.956

1.062

1.169

0.083

0.093

0.102

1.499

1.624

1.749

1.500

1.625

1.750

0.359

0.389

0.420

0.361

0.391

0.422

1.274

1.380

1.486

1.275

1.381

1.487

2

2.1/4

2.1/2

1.998

2.248

2.498

2.000

2.250

2.500

0.479

0.539

0.599

0.482

0.542

0.602

1.698

1.910

2.123

2.998

3.000

0.720

0.723

2.548

0.875

1.000

Max

---78 -0.561 0.562

Mln

--

107

139

0.655

0.749

0.656

0.750

0.093

0.108

0.124

0.084

0.094

0.103

175

217

262

0.843

0.936

1.030

0.844

0.937

1.031

0.111

0.121

0.130

0.112

0.122

0.131

311

367

424

1.124

1.218

1.311

1.700

1.912

2.125

0.148

0.167

0.185

0.150

0.169

0.187

555

703

865

2.550

0.223

0.225

1249

Max

--0.094

123

0.109

0.125

167

219

0.140

0.155

0.171

0.141

0.156

0.172

277

341

414

1.125

1.219

1.312

0.186

0.202

0.218

0.187

0.203

0.219

491

577

670

1.498

1.685

1.873

1.500

1.687

1.875

0.248

0.279

0.310

0.250

0.281

0.312

875

1106

1365

2.248

2.250

0.373

0.375

1969

Min

Max

Mln

Max

Mln

Max

7/8

0.874

0.999

0.875

1.000

0.135

0.154

0.137

0.156

0.795

0.909

0.796

0.910

1.1/8

1.1/4

1.3/8

1.124

1.249

1.374

1.125

1.250

1.375

0.174

0.193

0.213

0.176

0.195

0.215

1.023

1.137

1.250

1.1/2

1.5/8

1.3/4

1.499

1.624

1.749

1.500

1.625

1.750

0.232

0.252

0.271

0.234

0.254

0.273

2

2.1/4

2.1/2

1.998

2.248

2.498

2.000

2.250

2.500

0.309

0.348

0.387

3

3-1/2

2.998

3.497

3.997

3.000

3.500

4.000

4.497

4.997

5.497

4.1/2

5

5.1/2

6

6A,

Permanent

6B, To Slide when

No' under ~oad

Fit

---

()

Mln

Max

3/4

7/8

1

0.749

0.874

0.999

1.1/8

1-1/4

1-3/8

1.124

1.249

1.374

1.125

1.250

1.375

1.1/2

1-5/8

1-3/4

1.499

1.624

1.749

1.998

2.248

2.493

Min

Max

Min

Max

0.186

0.217

0.248

0.188

0.219

0.250

0.674

0.787

0.899

0.675

0.788

0.900

0.279

0.311

0.342

0.281

0.313

0.344

1.012

1.124

1.237

1.013

1.125

1.238

1.500

1.625

1.750

0.373

0.404

0.436

2.000

2.250

2.500

0.497

0.560

0.622

0.375

0.406

0.438

1.349

1.462

1.574

0.500

0.563

0.625

1.798

2.023

2.248

1.350

1.463

1.575

1.800

2.025

2.250

~I~

--80

0.637

1.09 0.743

143 0.849

0.638

0.744

0.850

0.955

1.062

1.168

0.956

1.063

1.169

180

223

269

321

376

436

570

721

891

1.274

1.380

1.487

1.275

1.381

1.488

1.698

1.911

2.123

1.700

1.913

2.125

I

0

-117

Max

165

215

0.752

0.859

0.753

0.860

248

326

0.708

0.809

0.709

0.810

329

430

1.024

1.138

1.251

271

336

406

0.967

1.074

1.182

0.968

1.075

1.183

412

508

614

0.910

1.012

1.113

0.911

1.013

1.114

545

672

813

1.364

1.478

1.592

1.365

1.479

1.593

483

566

658

1.289

1.397

1.504

1.290

1.398

1.505

732

860

997

1.214

1.315

1.417

1.215

1.316

1.418

967

1135

1316

-0.312

0.351

0.390

1.818

2.046

2.273

1.820

2.048

2.275

860

1088

1343

1.718

1.933

2.148

1.720

1.935

2.150

1302

1647

2034

1.618

1.821

2.023

1.620

1.823

2.025

1720

2176

2688

0.465

0.543

0.621

0.468

0.546

0.624

2.728

3.182

3.637

2.730

3.185

3.640

1934

2632

3438

2.578

3.007

3.437

2.580

3.010

3.440

2929

3987

5208

2.428

2.832

3.237

2.430

2.835

3.240

3869

5266

6878

4.500

5.000

5.500

0.699

0.777

0.855

0.702

0.780

0.858

4.092

4.547

5.002

4.095

4.550

5.005

4351

5371

6500

3.867

4.297

4,727

3.870

4.300

4.730

6591

8137

9846

3.642

4.047

4.452

3.645

4.050

4.455

8705

10746

13003

5.997

6.000

0.933

0.936

5.457

5.460

7735

5.157

5.160

11718 4.857

4.860

15475

Mln

Max

TABLE5-SIXTEEN SPLINE FITTINGS

under Load

0.750

0.875

1.000

2

21/4

2-1/2

Mln

6C, To Slido when

ominal

010

--- --- --- --- --- -- --- --- -- --- --- -----0.115

0.117

0.750

0.682

120 0.644

0.645

183 0.607 0.608

3/4

0.749

0.683

241

.(

For All Fit>

10C, To Slido whon

undorLoad

16A, Pormanont Fit

For All Fill

~IMax

--

159

208

0.599

0.699

0.799

0.600

0.700

0.800

152

207

270

263

325

393

0.899

0.999

1.099

0.900

1.000

1.100

342

421

510

468

550

637

1.199

1.299

1.399

1.200

1.300

1.400

608

713

827

833

1052

1300

1.598

1.798

1.998

1.600

1.800

2.000

,

1080

1367

1688

16B, To Slide whon

No! under

Nominal

010

--2

2.1/2

Load

16C, To Slido whon

underload

Mln

Max

Mln

Max

Mln

Max

Mln

Max

Mln

Max

-------------------- -------------1.620

1.720

2751

1.817

1.820

2083 1.617

1.997 2.000

1375 1.717

0.193

0.196

2.497

2.500

0.242

0.245

2.273

2.275

2149

2.147

2.150

3255

2.022

2.025

4299

3

3-1/2

2.997

3.497

3.000

3.500

0.291

0.340

0.294

0.343

2.727

3.182

2.730

3.185

3094

4212

2.577

3.007

2.580

3.010

4687

6378

2.427

2.832

2.430

2.835

6190

8426

4

4.1/2

3.997

4.497

4.000

4.500

0.389

0.438

0.392

0.441

3.637

4.092

3.640

4.095

5501

6962

3.437

3.867

3.440

3.870

8333

10546

3.237

3.642

3.240

3.645

11005

13928

5

5.1/2

4.997

5.497

5.000

5.500

0.487

0.536

0.490

0.539

4.547

5.002

4.550

5.005

8595

10395

4.297

4.727

4.300

4.730

13020

15754

4.047

4.452

4-Spline Fittings

4A-Permanent

For All Fits

Nom.

Diam

Fit

TL

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

3/

0.749

0.750

0.179

0.181

0.636

0.637

0.055

0.056

78

7/

0.874

0.875

0.209

0.211

0.743

0.744

0.065

0.066

107

0.999

1.124

1.000

0.239

0.241

0.849

0.850

0.074

0.075

139

11/S

1.125

0.269

0.271

0.955

0.956

0.083

0.084

175

1.249

1.250

0.299

0.301

1.061

1.062

0.093

0.094

217

0.331

1.168

1.169

0.102

0.103

262

0.361

1.274

1.275

0.111

0.112

311

0.121

0.122

367

0.131

424

11/4

13/

1.374

1.375

11/

1.499

1.500

15/

1.624

1.625

0.389

0.391

1.380

1.381

1\

1.749

1.750

0.420

0.422

1.486

1.487

0.130

1.998

2.000

0.479

0.482

1.698

1.700

0.148

0.150

555

2\

2.248

2.250

0.539

0.542

1.910

1.912

0.167

0.169

703

21/

2.498

2.500

0.599

0.602

2.123

2.125

0.185

0.187

865

2.998

3.000

0.720

0.723

2.548

2.550

0.223

0.225

1249

2

S

0.329

0.359

4-Spline Fittings

4B--To Slide-No

Nom.

Diam.

6-Spline Fittings

Load

For All Fits

D

Max.

Min.

Max.

Min.

Max.

Min.

3/

Min.

0.561

TL

0.562

0.093

0.094

123

0.749

0.750

0.186

0.188

7/

0.655

0.656

0.108

0.109

167

0.874

0.875

0.217

0.219

0.749

0.750

0.124

0.125

219

0.248

0.250

0.843

0.844

0.140

0.141

277

0.999

1.124

1.000

11/S

1.125

0.279

0.281

1\

0.936

0.937

0.155

0.156

341

1.249

1.250

0.311

0.313

13/

1.030

1.031

0.171

0.172

414

1.374

1.375

0.342

0.344

11/

1.124

1.125

0.186

0.187

491

1.499

1.500

0.373

0.375

15/S

1.218

1.219

0.202

0.203

577

1.624

1.625

0.404

0.406

13/4

1.311

1.312

0.218

0.219

670

1.749

1.750

0.436

0.438

1.498

1.500

0.248

0.250

875

1.998

2.000

0.497

0.500

2\

1.685

1.687

0.279

0.281

1106

2.248

2.250

0.560

0.563

Max.

21/2

1.873

1.875

0.310

0.312

1365

2.498

2.500

0.622

0.625

2.248

2.250

0.373

0.375

1969

2.998

3.000

0.747

0.750

S-ar putea să vă placă și

- Table 10.2-Type 6B Flanges For 2000 Psi Rated Working Pressure (See Appendix B For Metric Data)Document27 paginiTable 10.2-Type 6B Flanges For 2000 Psi Rated Working Pressure (See Appendix B For Metric Data)Jors SanzÎncă nu există evaluări

- Threads and Thread CuttingDocument56 paginiThreads and Thread CuttingkoshkadaÎncă nu există evaluări

- TR 45 150 Roof Wall Sandwich Panel Data SheetDocument4 paginiTR 45 150 Roof Wall Sandwich Panel Data SheetanwarÎncă nu există evaluări

- Pipe DesignDocument6 paginiPipe DesignmaneeshmsanjagiriÎncă nu există evaluări

- Module IV: Gears and Gear TrainsDocument38 paginiModule IV: Gears and Gear TrainsSuraj VinayÎncă nu există evaluări

- Product Catalogue-300M Series Modular Planetary Gearboxes IE2-IE3 - ENG - R02 - 0Document598 paginiProduct Catalogue-300M Series Modular Planetary Gearboxes IE2-IE3 - ENG - R02 - 0Dispatch TranstechgearsÎncă nu există evaluări

- Gear CorrectionDocument17 paginiGear CorrectionMurugesanÎncă nu există evaluări

- FITSDocument11 paginiFITSArun51092Încă nu există evaluări

- Dowel Pins BasicsDocument3 paginiDowel Pins Basicsjr_satish100% (1)

- Bearing FitsDocument9 paginiBearing Fitsm2110Încă nu există evaluări

- Kisssoft Tut 008 E Cylindrical GearpairDocument23 paginiKisssoft Tut 008 E Cylindrical GearpairLuis TestaÎncă nu există evaluări

- Shaktiman Tech. Tools (India) - Patiala Data SheetDocument1 paginăShaktiman Tech. Tools (India) - Patiala Data Sheetਗਗਨ ਜੋਤÎncă nu există evaluări

- Calculation of Gear Dimensions - KHK Gears PDFDocument25 paginiCalculation of Gear Dimensions - KHK Gears PDFlawlawÎncă nu există evaluări

- Design II MDE 221 Mott CH 8 and CH 9 Spur GearsDocument42 paginiDesign II MDE 221 Mott CH 8 and CH 9 Spur GearsThieroy PelendaÎncă nu există evaluări

- Creo Manufacturing 4 0 PDFDocument26 paginiCreo Manufacturing 4 0 PDFtwo-1Încă nu există evaluări

- Straight Sided Serrations SpecificationsDocument2 paginiStraight Sided Serrations SpecificationsMarcel Dandaro100% (1)

- The Shape of The Cone of The Twist Drills Unit-2Document5 paginiThe Shape of The Cone of The Twist Drills Unit-2Akesh KakarlaÎncă nu există evaluări

- STI 463 ModelDocument1 paginăSTI 463 Modelਗਗਨ ਜੋਤÎncă nu există evaluări

- Astm D 91 - 02Document3 paginiAstm D 91 - 02Edwin RamirezÎncă nu există evaluări

- Gear DesignDocument83 paginiGear DesignmuhammadaminjamalmutÎncă nu există evaluări

- ADD-00058819 Six Sigma Learning Guide PDFDocument65 paginiADD-00058819 Six Sigma Learning Guide PDFHéctor NorthmanÎncă nu există evaluări

- Cutting With BroachDocument5 paginiCutting With BroachJori Kristian RidayatÎncă nu există evaluări

- Service Factor RatingsDocument4 paginiService Factor Ratingschu42Încă nu există evaluări

- 6.4 Measuring Clearance and Wear of Pivoted Shoe Journal BearingsDocument3 pagini6.4 Measuring Clearance and Wear of Pivoted Shoe Journal BearingszulmodangguÎncă nu există evaluări

- Vibration Specs FFT Analyzer SetupDocument40 paginiVibration Specs FFT Analyzer SetupHemanth Kumar83% (6)

- UNIT-2 Design of Spur GearDocument56 paginiUNIT-2 Design of Spur GearMarthandeÎncă nu există evaluări

- Steering Universal JointsDocument11 paginiSteering Universal JointsAman JainÎncă nu există evaluări

- TUBE To HEADER JOINTS PDFDocument4 paginiTUBE To HEADER JOINTS PDFRiza KhanÎncă nu există evaluări

- Semi-Topping Shaper CuttersDocument4 paginiSemi-Topping Shaper CuttersalemarlonstosÎncă nu există evaluări

- Key Characteristics Designation System: KCDS Pyramid KCDS PyramidDocument33 paginiKey Characteristics Designation System: KCDS Pyramid KCDS PyramidmichaelÎncă nu există evaluări

- Is 1786 2008Document19 paginiIs 1786 2008Anonymous YHcvra8Xw6Încă nu există evaluări

- Spiral bevel gear pairs formulaDocument4 paginiSpiral bevel gear pairs formulaer_winwibowo100% (2)

- Rubric For Pipe BendingDocument4 paginiRubric For Pipe BendingleogarybonÎncă nu există evaluări

- Din 8570-1987Document8 paginiDin 8570-1987Kike Silva100% (2)

- Circlip Design PDFDocument6 paginiCirclip Design PDFSandeep KumarÎncă nu există evaluări

- Bonfiglioli Geared MotorDocument584 paginiBonfiglioli Geared MotorProdip SarkarÎncă nu există evaluări

- Gearsand GearingDocument57 paginiGearsand Gearingcamohunter71Încă nu există evaluări

- Calculation of A Helical Gear Pair: 1. Tooth Geometry and MaterialDocument14 paginiCalculation of A Helical Gear Pair: 1. Tooth Geometry and Materialsumeetsaini88Încă nu există evaluări

- Rolling Contact Bearings - DMEDocument28 paginiRolling Contact Bearings - DMESumitÎncă nu există evaluări

- Long Addendum Gears 1946Document15 paginiLong Addendum Gears 1946Marco ViniciusÎncă nu există evaluări

- Assy Gear Box AgitatorDocument1 paginăAssy Gear Box Agitatorer_winwibowoÎncă nu există evaluări

- Basics Gear TheoryDocument7 paginiBasics Gear TheorydineshkshirsagarÎncă nu există evaluări

- Gear MotorDocument45 paginiGear Motorb3ltaÎncă nu există evaluări

- ISO Gear Standards GuideDocument6 paginiISO Gear Standards GuideEslam YehiaÎncă nu există evaluări

- Design Calculation PinDocument4 paginiDesign Calculation PinUdhasu NayakÎncă nu există evaluări

- Design of Clamps Chapter SummaryDocument54 paginiDesign of Clamps Chapter SummaryKhaled HamdyÎncă nu există evaluări

- Problems s8Document4 paginiProblems s8zangue billy jamesÎncă nu există evaluări

- BEARING TOLERANCES TABLEDocument12 paginiBEARING TOLERANCES TABLESandeep MatetiÎncă nu există evaluări

- A Crowning Achievement For Automotive ApplicationsDocument10 paginiA Crowning Achievement For Automotive ApplicationsCan CemreÎncă nu există evaluări

- Design Guide - O-Ring, Quad-Ring, ERIKSDocument13 paginiDesign Guide - O-Ring, Quad-Ring, ERIKSDerekÎncă nu există evaluări

- Guide to O-rings and back-up rings for hydraulic cylinder sealingDocument55 paginiGuide to O-rings and back-up rings for hydraulic cylinder sealingkamal167Încă nu există evaluări

- ISO Standardisation of Bevel Gears: Overview and Ideas On Method A"Document28 paginiISO Standardisation of Bevel Gears: Overview and Ideas On Method A"vincemugnaioÎncă nu există evaluări

- Bevel Gear Transmission AnglesDocument6 paginiBevel Gear Transmission AnglesNabende UmarÎncă nu există evaluări

- Gleason LTCA ExampleDocument8 paginiGleason LTCA ExamplereddykvsÎncă nu există evaluări

- Section Q: Splined Hubs, Drive KitsDocument8 paginiSection Q: Splined Hubs, Drive KitshaggÎncă nu există evaluări

- Machine Design Lec3Document75 paginiMachine Design Lec3sam0415Încă nu există evaluări

- 5.1 Chordal Tooth Thickness MeasurementDocument20 pagini5.1 Chordal Tooth Thickness Measurementsharma RISHIÎncă nu există evaluări

- Bearing NomenclatureDocument4 paginiBearing NomenclatureVaibhav Vithoba Naik100% (1)

- Bearing PDFDocument64 paginiBearing PDFRajvardhan JaidevaÎncă nu există evaluări

- 1570 (Part II)Document20 pagini1570 (Part II)Kaushik SenguptaÎncă nu există evaluări

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987De la EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonÎncă nu există evaluări

- Is 13095 1991Document15 paginiIs 13095 1991Surendra MalasaneÎncă nu există evaluări

- Butterfly Valves For General Purposes (: Indian StandardDocument12 paginiButterfly Valves For General Purposes (: Indian Standardrahul caddÎncă nu există evaluări

- Tube To Header JointsDocument4 paginiTube To Header Jointsshabbir626Încă nu există evaluări

- Limits and FitsDocument5 paginiLimits and FitsNAEEMÎncă nu există evaluări

- Gear Cutters 01 PDFDocument4 paginiGear Cutters 01 PDFFabio Gilii100% (1)

- SteelwiseDocument5 paginiSteelwiseΈνκινουαν Κόγκ ΑδάμουÎncă nu există evaluări

- RTJ Type Orifice Plates: General DescriptionDocument2 paginiRTJ Type Orifice Plates: General Descriptionxaaabbb_550464353Încă nu există evaluări

- KHD G120 Brochure (12-10)Document6 paginiKHD G120 Brochure (12-10)Rigoberto HerreraÎncă nu există evaluări

- Ti SPC Ohe Fasteners 0120Document31 paginiTi SPC Ohe Fasteners 0120guri317Încă nu există evaluări

- Designed To Perform... Built To Last: Diesel and LPG Counterbalance 4 Wheel Pneumatic TyresDocument5 paginiDesigned To Perform... Built To Last: Diesel and LPG Counterbalance 4 Wheel Pneumatic TyresEdwin NgÎncă nu există evaluări

- Astm B315 (1999)Document9 paginiAstm B315 (1999)Deepak JÎncă nu există evaluări

- Orientation Tolerance GDTDocument30 paginiOrientation Tolerance GDTGanesanGovindarjÎncă nu există evaluări

- EMG 2402 Metrology - Notes 2022 LECTURE 5Document15 paginiEMG 2402 Metrology - Notes 2022 LECTURE 5Harry DaviesÎncă nu există evaluări

- Plan View Isometric View: RPK-SE-942Document1 paginăPlan View Isometric View: RPK-SE-942ajÎncă nu există evaluări

- Guidelines For Work AcceptanceDocument9 paginiGuidelines For Work AcceptanceEr Sanjay MahatoÎncă nu există evaluări

- Mall Pipe ThreadsDocument14 paginiMall Pipe Threadsanac_mathÎncă nu există evaluări

- PCI Standard For Thin BrickDocument2 paginiPCI Standard For Thin BrickJohn CarpenterÎncă nu există evaluări

- Is 10724 1990 PDFDocument11 paginiIs 10724 1990 PDFpramod kumar100% (1)

- Structural Steel Fabrication Process ControlDocument1 paginăStructural Steel Fabrication Process ControlMrk KhanÎncă nu există evaluări

- Evaluating, Selecting, and Specifying Balances and Standard Masses For Use in Soil, Rock, and Construction Materials TestingDocument6 paginiEvaluating, Selecting, and Specifying Balances and Standard Masses For Use in Soil, Rock, and Construction Materials TestingAhmedJardakÎncă nu există evaluări

- Iso 384 1978Document11 paginiIso 384 1978Jhon David VillanuevaÎncă nu există evaluări

- App A, Pls HDBK PDFDocument186 paginiApp A, Pls HDBK PDFpadmanabanÎncă nu există evaluări

- ASTM-A500 Steel Tubing GuideDocument1 paginăASTM-A500 Steel Tubing GuideServando LozanoÎncă nu există evaluări

- C612Document5 paginiC612dinhtung2210100% (1)

- Circulation of Draft Specification Central Road Lab PDFDocument688 paginiCirculation of Draft Specification Central Road Lab PDFsuman subediÎncă nu există evaluări

- JIS G 3193-1990 Dims., Mass & Permissable Variations o Hot Rolled ST Plates, Sheets & StripsDocument10 paginiJIS G 3193-1990 Dims., Mass & Permissable Variations o Hot Rolled ST Plates, Sheets & Stripspu2r.v6Încă nu există evaluări

- Lowcarbongalvanizedsteelwires, Formedwiresandtapesfor Armouringofcables - SpecificationDocument8 paginiLowcarbongalvanizedsteelwires, Formedwiresandtapesfor Armouringofcables - SpecificationShrikant KajaleÎncă nu există evaluări

- Astm A106 1999Document13 paginiAstm A106 1999Rolando CastilloÎncă nu există evaluări

- Is 13159Document65 paginiIs 13159Hari Krishna AaryanÎncă nu există evaluări