Documente Academic

Documente Profesional

Documente Cultură

Lathe Accessories

Încărcat de

Anand BalajiDrepturi de autor

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentLathe Accessories

Încărcat de

Anand BalajiACCESSORIES & ATTACHMENTS

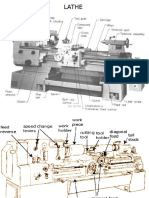

LATHE

THEORY

Accessories and attachments:v Lathe accessories include centers, catch plates and carriers,

chucks, collets, face plates, mandrels and rests.

v They are either used for holding or for supporting work or

for holding tool.

v Lathe attachments are additional equipment used for

specific purposes.

v They include stops; taper turning, milling, crank turning

attachments, etc.

vLathe center:o The most common method of holding the working a lathe

is between two centers - live and dead.

o These two centers take up the thrust due to metalcutting and the entire load of work piece on small

bearing surface.

o They are made up of very hard material to resist

deflection and wear.

ACCESSORIES & ATTACHMENTS

LATHE

THEORY

vCarriers and catch plate:o Carriers or driving dogs are attached to the end of the

work piece by a set-screw and catch-plates are either

screwed or bolted to the nose of head-stock spindle.

o A projecting pin from catch-plate or carrier fits into slot

provided in either of them.

o This imparts a positive drive between lathe-spindle and

work piece.

vChuck:o Work piece of short length and large diameter of

irregular shape which cannot be conveniently mounted

between centers are held quickly and firmly in a chuck.

o In a three-jaw universal chuck, all the jaws may be made

to slide simultaneously by an equal amount within the

slots provided on the body by rotating any one of three

pinions which meshes with the teeth.

ACCESSORIES & ATTACHMENTS

LATHE

THEORY

o In a four-jaw chuck, each and every jaw should be aligned

separately, and should be checked continuously for

wobbling.

o The advantage of a four-jaw chuck is that when the job is

fit perfectly in the chuck, there is no wobbling in it and

the level of finish is high.

vMandrel:o A mandrel is a device for holding and rotating a hollow

piece of work that has been previously drilled or bored.

o The work revolves with mandrel which is mounted

between two centers.

o The mandrel should be free with accurate center holes

for machining outer surface of work piece.

ACCESSORIES & ATTACHMENTS

LATHE

THEORY

vRests:o It is a mechanical device which supports a long slender

work piece when it is turned between centers or by a

chuck, at some intermediate point to prevent bending of

work piece due to its own weight and vibration setup due

to cutting forces that act on it.

o A rest should always be used when the length is 10-12

times the diameter of work piece.

o Following are the types of rests used:-

Steady rest: The main function of steady rest is to provide

support to a long, slender work piece.

The jaws are properly adjusted radially by rotating

individual screws to accommodate work pieces of

different diameters.

They rest on a spot on the work piece which has

been previously turned, to provide true bearing

surface.

ACCESSORIES & ATTACHMENTS

LATHE

THEORY

Follower rest: It consists of a like casting having 2 adjustable jaws

which supports the work piece.

The rest is bolted to back end of carriage and moves

with it.

The tool is fed longitudinally by the carriage, the

jaws always follow the tool, giving continuous

support to work piece.

The follower rest prevents the job from springing

away when the cut is made.

vFace plate:o A face plate consists of a circular disc bored out and

threaded to fit the nose of lathe spindle.

o It has radial, plain and T-slots for holding work by bolts

and clamps.

o It is used for holding work pieces which cannot be

conveniently held between centers.

v Saddle:- It is a H shaped casting that fits over bed and

slider along ways.

ACCESSORIES & ATTACHMENTS

LATHE

THEORY

vCross-slide:o It comprises of a casting machined on lower side for

attachment to saddle.

o It has dove tail way at right angle to center axis of lathe

which serves to guide cross-slide itself.

vAngle plate:o It is a cast-iron plate having 2 faces machined to make

them absolutely at right angles to each other.

o Holes and slots are provided on both faces, so that it may

be clamped on a faceplate and can hold the work piece

on other faces by bolts and nuts.

o Angle plates are used in conjunction with a face plate

when the holding surface of work piece should be kept

horizontal.

S-ar putea să vă placă și

- Lathe WorkDocument186 paginiLathe WorkAjay Sharma100% (1)

- Mother of Machines - Lathe MachineDocument5 paginiMother of Machines - Lathe MachineUsman KhalilÎncă nu există evaluări

- Lathe and Capstan & TurretDocument13 paginiLathe and Capstan & TurretNishit Parmar100% (1)

- Accessories and Attachments of Lathe MachineDocument6 paginiAccessories and Attachments of Lathe MachinejadeÎncă nu există evaluări

- Lathe Accessories and Attachments Lathe Accessories:: 1. Face PlateDocument7 paginiLathe Accessories and Attachments Lathe Accessories:: 1. Face PlateRohan SahaÎncă nu există evaluări

- Chapter 2 - Metal Cutting LatheDocument165 paginiChapter 2 - Metal Cutting LathebmdbmdbmdÎncă nu există evaluări

- Lathe - LVDocument23 paginiLathe - LVakshaygiitmÎncă nu există evaluări

- Use of Dividing HeadDocument20 paginiUse of Dividing Headajs_pto3117Încă nu există evaluări

- The Indexing or Dividing Head For Milling MachineDocument4 paginiThe Indexing or Dividing Head For Milling MachineDion Adi PutraÎncă nu există evaluări

- Production & Special Purpose LathesDocument38 paginiProduction & Special Purpose LathesShubham Shekhar100% (1)

- LatheDocument130 paginiLatheAjay Sharma86% (7)

- 02 Dividing Head 1Document22 pagini02 Dividing Head 1farid said errahmaniÎncă nu există evaluări

- Lathe Miscellaneous FunctionDocument7 paginiLathe Miscellaneous FunctionsuryavenkatramanÎncă nu există evaluări

- Lathe Machine PrinciplesDocument15 paginiLathe Machine Principlesscratch89Încă nu există evaluări

- Milling NotesDocument20 paginiMilling NotesleoandresmessiÎncă nu există evaluări

- Lathe: GS, SctceDocument48 paginiLathe: GS, SctceGouthamPrasad100% (2)

- Construction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill BitsDocument8 paginiConstruction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill Bitsviruz2_09Încă nu există evaluări

- Catalog Strunguri Pentru Lemn - August 2013Document11 paginiCatalog Strunguri Pentru Lemn - August 2013Expert Masini UnelteÎncă nu există evaluări

- Milling Machine (Group 7)Document52 paginiMilling Machine (Group 7)Faisal Maqsood100% (1)

- Drilling Machine & ReamersDocument42 paginiDrilling Machine & ReamersSomenath RahaÎncă nu există evaluări

- 07 Dividing Head of A MillingDocument8 pagini07 Dividing Head of A MillingkabbirhossainÎncă nu există evaluări

- Lathe Part IDocument151 paginiLathe Part Ishiva100% (2)

- Unit - V: Manufacturing TechnologyDocument54 paginiUnit - V: Manufacturing TechnologyIjanSahrudinÎncă nu există evaluări

- Chassis AnalysisDocument11 paginiChassis AnalysisDaani OloraÎncă nu există evaluări

- Machining Processes Used To Produce Various Shapes: MillingDocument28 paginiMachining Processes Used To Produce Various Shapes: MillingSuleiman SaidÎncă nu există evaluări

- Caddy LHN 130, 140, 200, (Caddy) PDFDocument36 paginiCaddy LHN 130, 140, 200, (Caddy) PDFPE TruÎncă nu există evaluări

- Study of Dividing HeadsDocument10 paginiStudy of Dividing HeadsChandan SrivastavaÎncă nu există evaluări

- Manufacturing of Spur Gear: Aim of The ExperimentDocument5 paginiManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaÎncă nu există evaluări

- ShaperDocument20 paginiShaperMilan SainiÎncă nu există evaluări

- Tool & Cutter GrinderDocument64 paginiTool & Cutter GrinderAFIFAHZABIDI ZABIDIÎncă nu există evaluări

- Catalog Universaluri, Bacuri, Flanse BERNARDO - Austria - eMasiniUnelteDocument22 paginiCatalog Universaluri, Bacuri, Flanse BERNARDO - Austria - eMasiniUnelteExpert Masini UnelteÎncă nu există evaluări

- Classification of Machine ToolsDocument7 paginiClassification of Machine ToolsglisoÎncă nu există evaluări

- CNC Lathe Machines PDFDocument7 paginiCNC Lathe Machines PDFMetwally Naser100% (1)

- Making A Spur GearDocument9 paginiMaking A Spur GearHaraprasad DolaiÎncă nu există evaluări

- Lathe DrillingDocument16 paginiLathe DrillingManjunatha EikilaÎncă nu există evaluări

- Drilling Machine and TypesDocument15 paginiDrilling Machine and TypesFaisÎncă nu există evaluări

- The Centre LatheDocument5 paginiThe Centre LatheShuvoVattÎncă nu există evaluări

- Tail Stock of LatheDocument7 paginiTail Stock of LatheKIÊN HOÀNG TRUNG100% (1)

- 01 ASME Thrufeed CenterlessDocument6 pagini01 ASME Thrufeed CenterlessSachin AherÎncă nu există evaluări

- Generalized Kinematics of Five-Axis Serial Machines WithDocument47 paginiGeneralized Kinematics of Five-Axis Serial Machines WithJoss Joss100% (1)

- Suzuki Samourai Repair Guides - Electronic Engine Controls - Idle Speed Control Solenoid (Iscs) ValveDocument1 paginăSuzuki Samourai Repair Guides - Electronic Engine Controls - Idle Speed Control Solenoid (Iscs) ValveAymzÎncă nu există evaluări

- JJ 104 Workshop Technology 1 MillingDocument44 paginiJJ 104 Workshop Technology 1 MillingHusaini Zamzury0% (1)

- Gearmanufacturing MethodsDocument9 paginiGearmanufacturing Methodskumar pÎncă nu există evaluări

- En At125 01Document14 paginiEn At125 01Pablo SalinasÎncă nu există evaluări

- LatheDocument16 paginiLathepokalÎncă nu există evaluări

- Non Chip FormingDocument33 paginiNon Chip FormingNur AmirahÎncă nu există evaluări

- MILL PPS006 Full Dividing Heads and Rotary Tables PDFDocument32 paginiMILL PPS006 Full Dividing Heads and Rotary Tables PDFChandran Pandiyan100% (1)

- PPTs On Milling Cutters and Twist DrillDocument30 paginiPPTs On Milling Cutters and Twist DrillTulsi ChouhanÎncă nu există evaluări

- Geometry of Twist DrillDocument15 paginiGeometry of Twist Drillbest4reverÎncă nu există evaluări

- WheelhorseTractor 1978 B C D SeriesServiceManual 810063RlDocument70 paginiWheelhorseTractor 1978 B C D SeriesServiceManual 810063RlJamesÎncă nu există evaluări

- Introduction To The Lathe Machine-M3 - ADocument17 paginiIntroduction To The Lathe Machine-M3 - ASagar JaatÎncă nu există evaluări

- WErbsen CourseworkDocument562 paginiWErbsen CourseworkRoberto Alexis Rodríguez TorresÎncă nu există evaluări

- Production Technology (IV Sem)Document24 paginiProduction Technology (IV Sem)Shubham AgrawalÎncă nu există evaluări

- Ball Traction Drive - FinalDocument46 paginiBall Traction Drive - FinalTejas Shete0% (1)

- LeBlond's Dual Drive Lathe SmallDocument28 paginiLeBlond's Dual Drive Lathe Small4U6ogj8b9snylkslkn3nÎncă nu există evaluări

- Lathe Machine: Description and Function of Lathe PartsDocument16 paginiLathe Machine: Description and Function of Lathe PartsRenjith Rajendraprasad100% (1)

- Lathe Accessories: Work Holding Tool HoldingDocument33 paginiLathe Accessories: Work Holding Tool HoldingSuhasÎncă nu există evaluări

- FixingDocument13 paginiFixingPR projectÎncă nu există evaluări

- Workshop AssignmentDocument23 paginiWorkshop AssignmentMr. NasrullahÎncă nu există evaluări

- Machine Tools Lab Manual (13-14)Document39 paginiMachine Tools Lab Manual (13-14)Krishna Murthy100% (1)

- GrindingDocument6 paginiGrindingAnand BalajiÎncă nu există evaluări

- Milling MachineDocument6 paginiMilling MachineAnand BalajiÎncă nu există evaluări

- Drilling MachineDocument6 paginiDrilling MachineAnand BalajiÎncă nu există evaluări

- Lathe OperationsDocument7 paginiLathe OperationsAnand Balaji0% (1)

- Lathe IntroductionDocument6 paginiLathe IntroductionAnand BalajiÎncă nu există evaluări

- Pp1 Module1 FundamentalsDocument15 paginiPp1 Module1 FundamentalsAnand BalajiÎncă nu există evaluări

- Friction T2 TestDocument5 paginiFriction T2 TestAnand BalajiÎncă nu există evaluări

- Weiss ITC Manual 13 Web Engl 201307Document123 paginiWeiss ITC Manual 13 Web Engl 201307Ciprian BalcanÎncă nu există evaluări

- EE105 Module 3 Lesson 1Document14 paginiEE105 Module 3 Lesson 1Kent Andojar MarianitoÎncă nu există evaluări

- Fabrication of Air Conditioner Integrated With Water Cooler and Water HeaterDocument7 paginiFabrication of Air Conditioner Integrated With Water Cooler and Water HeaterEditor IjasreÎncă nu există evaluări

- User's Guide: Adash 4900 - Vibrio IIIDocument40 paginiUser's Guide: Adash 4900 - Vibrio IIIVladimir KojicÎncă nu există evaluări

- ERIKS - Techniki UszczelnienDocument28 paginiERIKS - Techniki UszczelnienAdrian BożykÎncă nu există evaluări

- Assignment 2 MECH3610 2014Document2 paginiAssignment 2 MECH3610 2014Ashen ThilakaratnaÎncă nu există evaluări

- Side-By-Side Refrigerator: Model No. Plhs69EeDocument21 paginiSide-By-Side Refrigerator: Model No. Plhs69EeEdison EspinalÎncă nu există evaluări

- Itp For Plumbing Amp Drainage SystemDocument98 paginiItp For Plumbing Amp Drainage Systemtristan guarinoÎncă nu există evaluări

- Laterally Loaded Pile With Plaxis 3dDocument5 paginiLaterally Loaded Pile With Plaxis 3dteomalancuÎncă nu există evaluări

- Spare Parts List: Model No. Lf1000Document7 paginiSpare Parts List: Model No. Lf1000Elmir CastroÎncă nu există evaluări

- Inspection and Test Plan Rotating Equipment:: LPG PumpDocument4 paginiInspection and Test Plan Rotating Equipment:: LPG PumpErico Haryanto LumbanrajaÎncă nu există evaluări

- Large Roofs and Sports Stadiums: Wind Loading and Structural Response Lecture 20 Dr. J.D. HolmesDocument22 paginiLarge Roofs and Sports Stadiums: Wind Loading and Structural Response Lecture 20 Dr. J.D. HolmesFreddy Aparicio QuispeÎncă nu există evaluări

- Module 3: Mass Transfer Coefficients: Lecture No. 5Document3 paginiModule 3: Mass Transfer Coefficients: Lecture No. 5Anonymous Clbs7UkÎncă nu există evaluări

- Volvo Penta MD 2020Document2 paginiVolvo Penta MD 2020Tullio Opatti100% (1)

- Wheel Specifications: Line Comp 40 Boost Rear TLR Disc 27.5Document4 paginiWheel Specifications: Line Comp 40 Boost Rear TLR Disc 27.5diegoÎncă nu există evaluări

- Citroen 2CVDocument100 paginiCitroen 2CVmihajloviczoranÎncă nu există evaluări

- CF250 CF250 A: Owner S ManualDocument119 paginiCF250 CF250 A: Owner S Manualjoan sebastianÎncă nu există evaluări

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 paginăSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxÎncă nu există evaluări

- Sea Saw Gen FinalDocument27 paginiSea Saw Gen FinalSanjay Jadhav67% (3)

- Merc Service Manual 30Document355 paginiMerc Service Manual 30Hayduke them100% (6)

- Method Statement Mechanical SystemDocument181 paginiMethod Statement Mechanical SystemOsama Ali100% (1)

- MF5400 Workshop Manual 03-EngineDocument42 paginiMF5400 Workshop Manual 03-EngineFerran Alfonso100% (3)

- Week 4Document4 paginiWeek 4Waqar AhmadÎncă nu există evaluări

- Doosan Worldwide FactoriesDocument8 paginiDoosan Worldwide FactoriesAkhmad SebehÎncă nu există evaluări

- Sy 129 201920Document9 paginiSy 129 201920anirudh patelÎncă nu există evaluări

- Old School Maintenance ScheduleDocument29 paginiOld School Maintenance ScheduleEdi NicolauÎncă nu există evaluări

- 2009-2010 APRILIA RSV4 FactoryDocument81 pagini2009-2010 APRILIA RSV4 FactoryMade ChristianÎncă nu există evaluări

- Universal Machining CentersDocument4 paginiUniversal Machining CentersAdhiraj SinghÎncă nu există evaluări

- Cat c32 - Manual de Partes PDFDocument374 paginiCat c32 - Manual de Partes PDFGALAXY FORCES100% (16)

- Accessories: Fields of Application Professional Ground ScrewsDocument18 paginiAccessories: Fields of Application Professional Ground ScrewsMarta GameiroÎncă nu există evaluări