Documente Academic

Documente Profesional

Documente Cultură

Minimon Manual e 31

Încărcat de

Duy KhaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Minimon Manual e 31

Încărcat de

Duy KhaDrepturi de autor:

Formate disponibile

Manual

miniMon

Simple CAN Monitoring Tool for Windows

Software Version 2.0

The expert for industrial and automotive communication

IXXAT

Headquarter

IXXAT Automation GmbH

Leibnizstr. 15

D-88250 Weingarten

US Sales Office

IXXAT Inc.

120 Bedford Center Road

USA-Bedford, NH 03110

Tel.: +49 (0)7 51 / 5 61 46-0

Fax: +49 (0)7 51 / 5 61 46-29

Internet: www.ixxat.de

e-Mail: info@ixxat.de

Phone: +1-603-471-0800

Fax: +1-603-471-0880

Internet: www.ixxat.com

e-Mail: sales@ixxat.com

Support

In case of unsolvable problems with this product or other IXXAT products

please contact IXXAT in written form by:

Fax: +49 (0)7 51 / 5 61 46-29

e-Mail: support@ixxat.de

Copyright

Duplication (copying, printing, microfilm or other forms) and the electronic

distribution of this document is only allowed with explicit permission of

IXXAT Automation GmbH. IXXAT Automation GmbH reserves the right to

change technical data without prior announcement. The general business

conditions and the regulations of the license agreement do apply. All rights

are reserved.

miniMon-Manual-E-V3.1

Contents

1 OVERVIEW.....................................................................................5

2 FUNCTIONS AND HANDLING .........................................................6

2.1 Starting the program.............................................................6

2.2 Configuration ........................................................................6

2.2.1 Board Type (Hardware Configuration ...................................................6

2.2.2 Baudrate .............................................................................................8

2.2.3 Filtering of received objects (acceptance) .............................................9

2.3

2.4

2.5

2.6

2.7

2.8

Start/Stop.............................................................................10

Transmission of objects (Transmit) ......................................10

Request of objects (Request)...............................................11

Clear all windows ................................................................11

Reception of CAN objects ....................................................12

Status Display ......................................................................13

Copyright IXXAT Automation GmbH

miniMon-Manual-E-V3.1

Overview

1 Overview

The CAN miniMon is a simple and low-cost CAN bus monitor program which

allows the online monitoring of bus traffic on the CAN bus as well as the

transmission of single CAN objects. The CAN miniMon is delivered with VCI V2

and therefore available for Windows 9x//ME/NT/2000/XP.

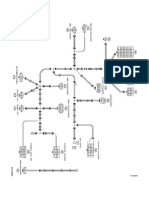

Picture 1-1: CAN miniMon

Copyright IXXAT Automation GmbH

miniMon-Manual-E-V3.1

Functions and Handling

2 Functions and Handling

2.1 Starting the program

The CAN miniMon can be started in the Start menu folder of the VCI or by

directly executing the file MINMON32.EXE.

Upon start the dialog box for selecting the type of CAN interface is opened

automatically. In this dialog box you have to select a PC/CAN interface which is

installed on your PC (see chapter 2.2.1).

2.2 Configuration

By selecting the item Config in the main menu, the sub-menu for the

configuration of the CAN miniMon is opened.

2.2.1 Board Type (Hardware Configuration

Since CAN miniMon is able to run with different types of PC/CAN interfaces, the

user has to specify which CAN interface the CAN miniMon has to use.

Picture 2-2: Board type configuration in CAN miniMon

Copyright IXXAT Automation GmbH

miniMon-Manual-E-V3.1

Functions and Handling

In this dialog the parameter Board shows that CAN interface which was used

in your last session. If you want to select a different CAN interface, press the

button next to the parameter window. After that a window opens which shows

all PC/CAN interfaces which are installed on the PC (corresponding to the applet

IXXAT Interfaces). Here you can select the CAN interface the CAN miniMon

shall work with and confirm your selection by pressing OK. It is not necessary to

specifiy hardware specific parameters like interrupt number or memory address.

Furthermore it is necessary to specify which CAN controller of the PC/CAN

interface (if the interface has two CAN controllers) and which CAN protocol

shall be used.

Chip:

The CAN interface can be provided with one or two CAN

controllers (e.g. one SJA1000 and one 82527). Therefore the

user has to specify which CAN controller should be used.

The CAN controllers are referenced as CAN 1 and CAN 2.

The information about the hardware configuration of the

used interface can be taken

- from the IXXAT Interfaces applet in the Control Panel

by executing the hardware test.

- from the CAN-Type dialog in the CAN miniMon menu

View

- from the manual of the interface.

Protocol:

- from your order.

Selection which CAN protocol shall be used: standard

protocol (11 bit identifier ) or extended protocol (29 bit

identifier).

For the selection of the CAN controller to be used the following has to be

considered:

-

The extended CAN protocol (29 bit identifier) and the detection of error

frames is not supported by the 82C200 CAN controller.

The reception of remote frames in the receive window is only possible using

the SJA1000 CAN controller.

When the 82527 CAN controller is used an exact display of the actual bus

load is not possible.

Copyright IXXAT Automation GmbH

miniMon-Manual-E-V3.1

Functions and Handling

2.2.2 Baudrate

The baud rate can either be selected from a list which provides a number of

standard baud rates for selection (acc. to CiA) or can be set directly by entering

the values for the bus timing registers.

Baudrate (list of values)

The baud rate is selected and confirmed by pressing OK.

Picture 2-1: Baudrate configuration with a list of values

Baudrate (manual)

The values for the bit timing registers of the CAN controller are entered directly

and confirmed by pressing OK. The values are stored when the CAN miniMon

program is terminated and reloaded when the program is restarted.

-

BTR0: CAN baudrate register 0

BTR1: CAN baudrate register 1

Picture 2-2: Manual baudrate configuration

The values have to be calculated for a CAN controller SJA1000 or 82527,

clocked with 16 MHz

Copyright IXXAT Automation GmbH

miniMon-Manual-E-V3.1

Functions and Handling

2.2.3 Filtering of received objects (acceptance)

By selecting the item Config|Acceptance in the main menu a filter for the

reception of CAN objects can be configured.

Picture 2-3: Acceptance mask

In the dialog box Acceptance the values for the acceptance code and

acceptance mask are set. The input is hexadecimal. The acceptance mask

specifies the bits in the identifier that are relevant for the filter (1 = relevant; 0

= not relevant). The acceptance code specifies the value which the relevant bits

must have to be allowed to pass the filter. The acceptance filter works

independent of the used type of CAN controller. The input is hexadecimal. For

standard CAN identifiers (11 bit identifier) only the last three hexadecimal digits

are used.

Example:

You are only interested in CAN objects with value 5 in the lower 4 identifier bits.

Therefore only the lower 4 identifier bits are relevant for filtering:

MASK = 000 0000 1111 = 0x00F

These relevant bits must have the value 5:

CODE = 000 0000 1001 = 0x005

With these settings CAN miniMon will only receive CAN objects with value 5 in

the relevant identifier bits:

0x005, 0x015, 0x025, 0x035, 0x045 ...

Copyright IXXAT Automation GmbH

miniMon-Manual-E-V3.1

Functions and Handling

Filter algorithm:

A bitwise AND operation is performed between the identifier of a received CAN

object and the adjusted acceptance mask. The result of the AND operation is

compared with the adjusted acceptance code. Only CAN objects for which the

result of the AND operation is equal to the acceptance code are allowed to pass

the acceptance filter. All other CAN objects are not received.

If 0 is set for the acceptance mask there are no relevant bits and therefore the

filter is completly open. All CAN objects will be received.

2.3 Start/Stop

The item Start/Stop in the main menu is a switch for starting and stopping all

functions. The actual status is displayed in the status window in the window

CAN status (RUN or RESET, see chapter 0).

When the operation is stopped, all queues , buffers and status information are

deleted. The receive window contents are kept and the CAN controller is in

reset.

2.4 Transmission of objects (Transmit)

By selecting the item Transmit a dialog box is opened which allows the input

of a CAN object. The CAN object is specified by the identifier and the data

which have to be transmitted. The input of the identifier and data is

hexadecimal with spaces between identifier and each data byte. By pressing

OK the object is transmitted.

The following dialog show a CAN object with 11-bit identifier 0x123 and the

data bytes 0x0A, 0x0B, 0x0C, 0x0D, 0x0E, 0x0F, 0xEE, 0xFF.

Picture 2-4: Message input by using 11 bit identifier

Copyright IXXAT Automation GmbH

10

miniMon-Manual-E-V3.1

Functions and Handling

The following dialog show a CAN object with 29-bit identifier 0x12345678 and

the data bytes 0x0A, 0x0B, 0x0C, 0x0D, 0x0E, 0x0F, 0x01, 0x02.

Picture 2-5: Message input by using 29 bit identifier

2.5 Request of objects (Request)

By selecting the item Request a dialog box is opened which allows the input

of remote frame. A remote frame requests a CAN object with the same

identifier from another bus node. The input of the identifier which shall be

requested is hexadecimal. By pressing OK the object is requested by the

transmission of the remote frame.

2.6 Clear all windows

The item Clear deletes all contents of the receive queue and all contents of

the receive window. The error frame counter are reset.

Copyright IXXAT Automation GmbH

11

miniMon-Manual-E-V3.1

Functions and Handling

2.7 Reception of CAN objects

Received CAN objects are displayed in the receive window. Each object is

displayed with time stamp (decimal, resolution 1 millisecond), identifier and

data (hexadecimal).

This window shows a received data frame with identifier 0x100 and the data

bytes 0xFF, 0x05, 0x03, 0x08. It was received 33730 msec after opening the

board.

Bild 2-6: A received data frame

This window shows a received remote frame with identifier 0x32F and data

length code (DLC) 1. Remote frames do not contain any data bytes, just a data

length code. It was received 177962 msec after opening the board.

Bild 2-7: A received remote frame

Copyright IXXAT Automation GmbH

12

miniMon-Manual-E-V3.1

Functions and Handling

2.8 Status Display

The windows on the right side displays the actual settings of the CAN controller

and the most important information about the interface

Picture 2-8: Status display

Board:

Information about the current hardware settings

CPU Ld:

Current load of the CPU on the PC/CAN interface board

Bus Ld:

Current bus load in % and as a graphic beam

Section Config:

Prot:

Selected protocol type: standard or extended

Baudr:

Selected baudrate

BTR:

Current values of Bus Time Registers 0 und 1

ACCM:

Current value of acceptance mask

ACCC:

Current value of acceptance code

Copyright IXXAT Automation GmbH

13

miniMon-Manual-E-V3.1

Functions and Handling

Section Status:

CAN Status:

Information about the status bits in the CAN controller (red

= set, green = reset):

- BusOFF:

- Error:

- Overrun:

- Tx-Pend:

- RUN / RESET:

VCI Sts:

Queueload:

Copyright IXXAT Automation GmbH

bus off status

error status

receive overrun

transmit pending

CAN is in initialization mode (RESET) or

active (RUN)

Current status of the software interface and the CAN

interface.

Information about the current load of the receive queue.

14

miniMon-Manual-E-V3.1

S-ar putea să vă placă și

- Comap SupportDocument254 paginiComap Supportmanuel segoviaÎncă nu există evaluări

- TSWG0073EDocument1 paginăTSWG0073EDuy KhaÎncă nu există evaluări

- GDocument1 paginăGDuy KhaÎncă nu există evaluări

- Tswg0077e PDFDocument1 paginăTswg0077e PDFDuy KhaÎncă nu există evaluări

- TSWG0177EDocument1 paginăTSWG0177EDuy KhaÎncă nu există evaluări

- UseMaintanceManual VECTORseries L31900015E Apr06Document43 paginiUseMaintanceManual VECTORseries L31900015E Apr06manuel segoviaÎncă nu există evaluări

- Digest A3Document16 paginiDigest A3Duy KhaÎncă nu există evaluări

- TSHK0025Document1 paginăTSHK0025Duy KhaÎncă nu există evaluări

- TSWG0035EDocument1 paginăTSWG0035EDuy KhaÎncă nu există evaluări

- Tsjj0181e PDFDocument1 paginăTsjj0181e PDFDuy KhaÎncă nu există evaluări

- Tsjj0181e PDFDocument1 paginăTsjj0181e PDFDuy KhaÎncă nu există evaluări

- TSJJ0019EDocument1 paginăTSJJ0019EDuy KhaÎncă nu există evaluări

- TSUZ0083Document1 paginăTSUZ0083Duy KhaÎncă nu există evaluări

- TSJJ0167EDocument1 paginăTSJJ0167EDuy KhaÎncă nu există evaluări

- StarterDocument1 paginăStarterDuy KhaÎncă nu există evaluări

- TSHK0025Document1 paginăTSHK0025Duy KhaÎncă nu există evaluări

- TSUZ0008EDocument1 paginăTSUZ0008EDuy KhaÎncă nu există evaluări

- Tsjj0181e PDFDocument1 paginăTsjj0181e PDFDuy KhaÎncă nu există evaluări

- Tswg0316e PDFDocument1 paginăTswg0316e PDFDuy KhaÎncă nu există evaluări

- TSHK0207EDocument1 paginăTSHK0207EDuy KhaÎncă nu există evaluări

- Tsjj0032e PDFDocument1 paginăTsjj0032e PDFDuy KhaÎncă nu există evaluări

- Tshk0014e PDFDocument1 paginăTshk0014e PDFDuy KhaÎncă nu există evaluări

- TSHK0019EDocument1 paginăTSHK0019EDuy KhaÎncă nu există evaluări

- TSHK0017EDocument1 paginăTSHK0017EThong ChanÎncă nu există evaluări

- TSHK0025Document1 paginăTSHK0025Duy KhaÎncă nu există evaluări

- Tswg0237e PDFDocument1 paginăTswg0237e PDFDuy KhaÎncă nu există evaluări

- GDocument1 paginăGDuy KhaÎncă nu există evaluări

- TSHK0033EDocument1 paginăTSHK0033EDuy KhaÎncă nu există evaluări

- StarterDocument1 paginăStarterDuy KhaÎncă nu există evaluări

- Tswg0243e PDFDocument1 paginăTswg0243e PDFDuy KhaÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)