Documente Academic

Documente Profesional

Documente Cultură

Dfs

Încărcat de

upadhyaysanuTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dfs

Încărcat de

upadhyaysanuDrepturi de autor:

Formate disponibile

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Module 2 - GEARS

Lecture 4: WORKED OUT PROBLEMS ON INVOLUTE SPUR GEARS

Content

4.1 Introduction

4.2 Gear Calculation -Worked example 1

4.3 Gear Calculation -Worked example 2

4.1 INTRODUCTION

In the earlier lectures, the definition of gear, gear terminology, interference, methods of

eliminating interference, standard tooth systems for spur gears, profile shifted gears,

involutometry and design of gear blanks were dealt in detail. With the background of the

above knowledge, solving of simple gear problems will be dealt in this lecture.

4.2 GEAR CALCULATION Worked out example 1

In a drive, a velocity ratio of 2.5 with a centre distance of 70 mm is desired. (a) Determine

the pitch diameter of the gears with 20o full depth involute teeth; (b) Is there any

interference in the system? If so, how will you avoid it? (c) Determine the contact ratio, (d)

Find the dedendum, addendum, root diameters and the tip clearance, (e) If the centre

distance is increased by 1.5%, what will be the new pressure angle?

i = 2.5;

C = 70 mm; = 20o;

Given Data:

It is an involute full depth tooth system ;

To be found:

m = ?;

Z1 = ? ;

d1 = ?;

Interference exists or not ?;

Z2 = ?;

d2 = ?;

CR = ?

We know that,

C = (r1 +r2) = 0.5 m ( Z1 + Z2) = 0.5 m (Z1 + i Z1) = 70 mm

1

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

From the above,

i.e., m x Z1 = 40

Possible solutions for standard modules as can be seen from the table:

Solution I:

m = 2mm, Z1 = 20, Z2 = i. Z1 = 2.5 x 20 = 50

d1 = m Z1 = 2 x 20 = 40 mm

d2 =i d1 = 2.5 x 40 = 100 mm

STANDARD MODULES IN mm:

0.3

0.4

0.5

0.6

0.7

0.8

1.0

1.25 1.5

1.75

2.0

2.25

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

10

11

12

13

14

15

16

18

20

22

24

26

28

30

33

36

39

42

45

50 Further increase is in terms of 5 mm

Minimum number of teeth that can engage with the gear of 50 teeth without

interference is given by,

z12 + 2 z1 z2 =

4k(z2 + k)

sin 2

For full depth gears, k = 1. Substituting the values Z2 = 50, = 20o in the above

equation,

z12 2 z1 x50

4 x 1( 50 1 )

sin 2 20 o

z 2 + 100 z 1744 0

1

1

i.e., Z1min = 15 is the minimum permissible number of teeth without interference.

Since from the above it is seen that, Z1 > Z1min no interference will occur.

2

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

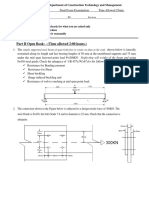

Fig 4.1. Path of Contact

Contact ratio, CR:

Referring to fig. 4.1, the path of contact:

La = ua + ur

L ( r a )2 r 2 cos 2

a

1

1

( r a )2 r 2 cos 2 ( r r ) sin

2

2

1 2

Substituting the values,

L ( 20 2 ) 2 20 2 cos 2 20o ( 50 2 ) 2 50 2 cos 2 20o ( 20 50 ) sin 20o

a

9.798 mm

3

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Now CR can be calculated with the formulae below,

CR

L

L

9.798

9.798

a

a

1.660

p cos m cos x 2 x cos 20o

5.901

For full depth tooth, the various values calculated are as shown below:

Addendum:

a = 1m = 1x2

= 2mm

Dedendum:

b = 1.25m = 1.25x2 = 2.5 mm

Clearance:

c = 0.25 m = 0.25x2

Pinion root circle diameter:

dr1 = d1- 2b = 40 2x2.5 = 35 mm

Pinion addendum diameter:

da1 = d1+ 2a = 40 + 2x2 = 44 mm

Gear root circle diameter:

dr2 = d2- 2b = 100 2x2.5 = 95 mm

Gear addendum diameter:

da2 = d2+ 2a = 100 + 2x2 = 104 mm

= 0.5 mm

Solution II:

The centre distance is given by, C = (r1 +r2) = 0.5 m ( Z1 + Z2) = 0.5 m (Z1 + i Z1)

= 70 mm

Simplifying, m x Z1 = 40

Another possible solution for standard module from the table is,

m = 2.5 mm, Z1 = 16, Z2 = i x Z1 = 40,

d1 = m Z1 = 2.5x16=40 mm,

d2 = m Z2 = 2.5 x 40 =100 mm

Minimum number of teeth that can engage the gear of 40 teeth without interference

is given by,

z12 + 2 z1 z2 =

4 k (z2 + k)

sin 2

4

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

For full depth gears k = 1. Substituting Z2 = 40, = 20o, in the above equation,

4(40 + 1 )

z 2 + 2 z x 40 =

1

1

sin2 20o

z 2 + 80 z 1402 0

1

1

i.e., Z1min = 15 is the minimum permissible without interference.

Since Z1 > Z1min, no interference will occur.

Contact ratio, CR :

Referring to the fig. 4.1, the path of contact is given by,

La = ua + ur

L ( r a )2 r 2 cos 2

a

1

1

( r a )2 r 2 cos 2 ( r r ) sin

2

2

1 2

Substituting the values,

L ( 20 2.5 )2 20 2 cos 2 20 o

a

11.854 mm

( 50 2.5 )2 50 2 cos 2 20 o ( 20 50 ) sin 20 o

Now CR can be calculated as,

CR

L

L

11.854

11.854

a

a

1.607

p cos m cos

5.901

x 2.5 x cos 20o

For full depth tooth the values are,

Addendum :

a =1m = 1x2.5 =2.5mm

Dedendum :

b =1.25m =1.25x2.5 = 3.125 mm

5

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Clearance:

c = 0.25 m = 0.25x2.5 = 0.625 mm

[Pinion root circle diameter:

dr1= d1- 2b = 40 2x3.125 = 33.75 mm

Pinion addendum diameter:

da1= d1+ 2a = 40+2x2.5 = 45 mm

Gear root circle diameter:

dr2= d2- 2b = 100 2x3.125 = 93.75 mm

Pinion addendum diameter:

da2= d2+ 2a = 100 + 2x2.5 = 105 mm

New Pressure angle when the centre distance C is increased by 1.5% is given by:

= cos-1( r1 cos20o / r1 1.015) = 22.21o

4.3 GEAR CALCULATIONS- Worked out example 2

A 21 teeth gear has 20o full depth involute teeth with a module of 12mm. (a) Calculate the

radii of pitch circle, base circle and addendum circle (b) Determine the tooth thickness at

base circle, pitch circle and addendum circle. Comment on the top land thickness.

rb

cos

inv tan

t

t 2 r ( 1 inv inv )

2r

1

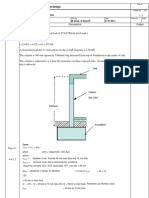

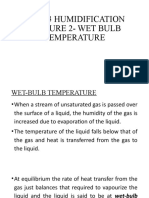

Fig 4.2 Involutometry

The terminologies used in the problem are explained in earlier chapters. Hence the figures

referred are self explanatory.

6

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

Fig. 4.3 Layout for tooth thickness determination at any point on tooth profile

Given Data: Pressure angle, =20o = 0.349 rad., Z1 = 21, m= 12mm.

Solution:

r1 = 0.5.m.Z1 = 0.5 x 12 x 21=126 mm

rb = r1.Cos = 126 x cos 20o = 118.4 mm

a = 1m = 1 x 12 = 12 mm

ra = r1 + a = 126 + 12 = 138 mm

p1 = .m = . 12 = 37.14 mm

t1 = 0.5 p1 = 0.5 x 37.14 = 18.57 mm

inv = tan - = tan 0.349 0.349 = 0.015 rad

7

Indian Institute of Technology Madras

Machine Design II

Prof. K.Gopinath & Prof. M.M.Mayuram

At the base circle b= 0, Hence tooth thickness tb at the base circle is:

t

t 2 r ( 1 inv inv )

b

b 2r

b

1

18.57

2 x 118.4 x(

0.015 0 ) 21.0 mm

2 x126

At the addendum circle the pressure angle is given by,

a=cos-1(rb/ra) =cos-1(118.4 /138) =0.54 rad

inv a = tan 0.54 0.54 = 0.059

Hence tooth thickness ta can be calculated as,

t

t 2 r 1 inv inv

a

a 2r

a

1

Substituting the values,

18.57

t 2 x 138 x

0.015 0.059 8. 20 mm

a

2 x 126

Minimum recommended top land thickness is,

tamin = 0.25 m = 0.25 x 12 = 3 mm

From the above, we know that, ta > tamin, hence the tip thickness is adequate and

permissible.

-----------------------

8

Indian Institute of Technology Madras

S-ar putea să vă placă și

- ATI TEAS Calculation Workbook: 300 Questions to Prepare for the TEAS (2023 Edition)De la EverandATI TEAS Calculation Workbook: 300 Questions to Prepare for the TEAS (2023 Edition)Încă nu există evaluări

- Vehicle Test Plan Apollo Mission A-004 Spacecraft 002Document160 paginiVehicle Test Plan Apollo Mission A-004 Spacecraft 002Bob AndrepontÎncă nu există evaluări

- 12b Example - Composite Slab PDFDocument7 pagini12b Example - Composite Slab PDFjonathanbido100% (4)

- Lecture 3 - Chapter 3 (Modeling in The Time Domain)Document57 paginiLecture 3 - Chapter 3 (Modeling in The Time Domain)Jessiedee Mark GingoÎncă nu există evaluări

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument26 paginiWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraÎncă nu există evaluări

- Fourth Quarter ExaminationDocument10 paginiFourth Quarter ExaminationJay Ronnie PranadaÎncă nu există evaluări

- Ch09 TestbankDocument61 paginiCh09 Testbanklimpaj35Încă nu există evaluări

- Helical Gears ProblemsDocument29 paginiHelical Gears Problemsa17e100% (1)

- Design of Slender Columns According To EC2Document5 paginiDesign of Slender Columns According To EC2selinaÎncă nu există evaluări

- Column and Foundation DesignDocument12 paginiColumn and Foundation DesignMohafisto SofistoÎncă nu există evaluări

- RCCe11 Element DesignDocument8 paginiRCCe11 Element DesignZayyan RomjonÎncă nu există evaluări

- Lecture 16 - Worm Gears Worked Out ProblemsDocument19 paginiLecture 16 - Worm Gears Worked Out ProblemsApurba haldar50% (2)

- Analytic Geometry: Graphic Solutions Using Matlab LanguageDe la EverandAnalytic Geometry: Graphic Solutions Using Matlab LanguageÎncă nu există evaluări

- Bevel Gear ProblemDocument16 paginiBevel Gear ProblemJaymin80% (5)

- Research PaperDocument18 paginiResearch PaperRommel Dave Tejano100% (1)

- Tutorial For Topic 2 - SolutionDocument4 paginiTutorial For Topic 2 - Solutionmurwanashyaka augustin100% (1)

- Design of Hydraulic GateDocument20 paginiDesign of Hydraulic GateTarunPatra100% (1)

- Bamboo StructureDocument37 paginiBamboo Structureniravhirpara67% (3)

- Alchemical LexiconDocument8 paginiAlchemical Lexicondeus_primusÎncă nu există evaluări

- CraneDocument36 paginiCraneGautam Paul100% (2)

- Solved Example On Design of Slender Columns According To EC2Document7 paginiSolved Example On Design of Slender Columns According To EC2Mouhamad Wehbe100% (1)

- 6 Design of Constant Dia RCC Chimney and Foundation 23052014Document16 pagini6 Design of Constant Dia RCC Chimney and Foundation 23052014Ahmad Badsha Quadri0% (1)

- Hw3 Chap4 SolutionDocument13 paginiHw3 Chap4 Solutioncoasterfan13100% (1)

- Π HistoryDocument5 paginiΠ Historydbest12Încă nu există evaluări

- BITS Pilani: Instructor in Charge-Dr. Kalyana Rama J SDocument23 paginiBITS Pilani: Instructor in Charge-Dr. Kalyana Rama J SSaiteja SistlaÎncă nu există evaluări

- ME 3031 Design of Machine Elements: Sample Questions & AnswersDocument27 paginiME 3031 Design of Machine Elements: Sample Questions & AnswersbalajimeieÎncă nu există evaluări

- Finite Element Method PDFDocument43 paginiFinite Element Method PDFAdetiyo Burhanudin HakimÎncă nu există evaluări

- Proiect An, CricDocument27 paginiProiect An, CricŞtefania ApostolÎncă nu există evaluări

- Module 2 - GEARS Lecture - 4: Worked Out Problems On Involute Spur GearsDocument8 paginiModule 2 - GEARS Lecture - 4: Worked Out Problems On Involute Spur GearsMuhammad WaqasÎncă nu există evaluări

- Involute Spur Gear ProblemsDocument6 paginiInvolute Spur Gear ProblemsChiragJansari100% (1)

- Steel Structure - Solutions - Batch AbDocument7 paginiSteel Structure - Solutions - Batch AbAvinash ChoudharyÎncă nu există evaluări

- Tugas Elemen Mesin Pemindah DayaDocument28 paginiTugas Elemen Mesin Pemindah DayaYudha RamadhaniÎncă nu există evaluări

- Meng 149 - Machine Design Learning Task No.2 Shear Stress Collano, Noel Rogie M. Class Schedule: Monday (8:00am - 10:00) AmDocument2 paginiMeng 149 - Machine Design Learning Task No.2 Shear Stress Collano, Noel Rogie M. Class Schedule: Monday (8:00am - 10:00) AmCollano M. Noel RogieÎncă nu există evaluări

- Dme II Test 1 Set 3Document7 paginiDme II Test 1 Set 3Vamshi ReddyÎncă nu există evaluări

- HW 5 - Me 406-152 Plus SolutionDocument3 paginiHW 5 - Me 406-152 Plus SolutiontrishÎncă nu există evaluări

- Mathcad - CONICOS - 2Document15 paginiMathcad - CONICOS - 2Entrerriano de CorzonÎncă nu există evaluări

- Tutorial For Topic 2 - SolutionDocument4 paginiTutorial For Topic 2 - SolutionmarceÎncă nu există evaluări

- Mm216 Eigenvalue EigenvalueDocument4 paginiMm216 Eigenvalue EigenvalueFurkan ŞahinÎncă nu există evaluări

- MECH 360 Homework 2 W14Document5 paginiMECH 360 Homework 2 W14Samuel JiménezÎncă nu există evaluări

- Student Notes For Parametric Modeling of GearsDocument6 paginiStudent Notes For Parametric Modeling of GearsKnvpavankalyan SunnyÎncă nu există evaluări

- Gear DesignDocument37 paginiGear DesignAayush ShahÎncă nu există evaluări

- Punching of Flat Slabs: Design Example: Fib Model Code 2010Document13 paginiPunching of Flat Slabs: Design Example: Fib Model Code 2010Bhagirath JoshiÎncă nu există evaluări

- Lec 41Document16 paginiLec 41Mayuresh AtramÎncă nu există evaluări

- Republika Srbija Visoka Škola Primenjenih Strukovnih Studija VranjeDocument8 paginiRepublika Srbija Visoka Škola Primenjenih Strukovnih Studija VranjeMilan Zabac StanojkovicÎncă nu există evaluări

- In A Spur Gear Drive For A Stone CrusherDocument7 paginiIn A Spur Gear Drive For A Stone Crusherselva_raj2154140% (1)

- Wollega University: School of Graduate StudiesDocument6 paginiWollega University: School of Graduate StudiesAlemu MergaÎncă nu există evaluări

- HW 3 AnswersDocument11 paginiHW 3 AnswersCoryna Wan Chun WahÎncă nu există evaluări

- Answer For Question 4 Structural DesignDocument16 paginiAnswer For Question 4 Structural DesignFaizalhizam NoordinÎncă nu există evaluări

- Input Power (P) 22 KW Input RPM 1400 RPM Reduction Ratio 31.5:1Document6 paginiInput Power (P) 22 KW Input RPM 1400 RPM Reduction Ratio 31.5:1Shree JadhavÎncă nu există evaluări

- Design of Non Slender Column To Eurocode 2Document4 paginiDesign of Non Slender Column To Eurocode 2psconsultantsÎncă nu există evaluări

- Test-9 - ME - Production & MSDocument11 paginiTest-9 - ME - Production & MSJatin prasad TandanÎncă nu există evaluări

- How To Draw Spiral Bevel GearsDocument3 paginiHow To Draw Spiral Bevel GearsprogramiranjecncÎncă nu există evaluări

- Part 5. Designing ShaftDocument14 paginiPart 5. Designing Shaftkhang.trieuk13t6u3002Încă nu există evaluări

- RCCe11 Element DesignDocument8 paginiRCCe11 Element DesignLam TranÎncă nu există evaluări

- Example 9.1Document17 paginiExample 9.1Sarah HaiderÎncă nu există evaluări

- Vehicle Dynamics Project: University "Transilvania" of BraşovDocument11 paginiVehicle Dynamics Project: University "Transilvania" of BraşovAlexa StrumfÎncă nu există evaluări

- Tugas Elemen Mesin II: Nama: Muhammad Nor Khairi NPM: 14.62.0030 Fakultas: Teknik Mesin 5Document4 paginiTugas Elemen Mesin II: Nama: Muhammad Nor Khairi NPM: 14.62.0030 Fakultas: Teknik Mesin 5Anonymous qIihaN5u3FÎncă nu există evaluări

- Techsec 4Document5 paginiTechsec 4Azrul Azis JwÎncă nu există evaluări

- Example1.1.: I. Uncracked Section PropertiesDocument13 paginiExample1.1.: I. Uncracked Section PropertiesOlesea NesterencoÎncă nu există evaluări

- Combined Footing W ExampleDocument29 paginiCombined Footing W ExampleascendancyyfirisaÎncă nu există evaluări

- Strap FootingDocument6 paginiStrap Footingrukesh104Încă nu există evaluări

- Final Exam SolutionDocument5 paginiFinal Exam SolutionMesfinÎncă nu există evaluări

- Cc19 Group 1 Lab Report 9Document12 paginiCc19 Group 1 Lab Report 9PHƯỚC DƯƠNG THANHÎncă nu există evaluări

- Girder Bridge Design ExampleDocument16 paginiGirder Bridge Design ExampleIyœ MøsisæÎncă nu există evaluări

- Tugas Uas Beton Lanjut: Di Susun OlehDocument8 paginiTugas Uas Beton Lanjut: Di Susun OlehRial Hadi RahmawanÎncă nu există evaluări

- RollingDocument4 paginiRollingمؤيد الحطابÎncă nu există evaluări

- Ref. Calculations Output Specification: 25 N/MM 500 N/MMDocument4 paginiRef. Calculations Output Specification: 25 N/MM 500 N/MMadib jamilÎncă nu există evaluări

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationDe la EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationÎncă nu există evaluări

- 10th CBSE Science-Compressed PDFDocument337 pagini10th CBSE Science-Compressed PDFAbhishekÎncă nu există evaluări

- Final Exam 2010 SolnDocument7 paginiFinal Exam 2010 SolnSimon AlmeidaÎncă nu există evaluări

- Approximate Calculation of "Ground Reaction" When A Ship Is Aground Over Quite A Distance of Its Flat-Bottom and Is Not Heavily TrimmedDocument2 paginiApproximate Calculation of "Ground Reaction" When A Ship Is Aground Over Quite A Distance of Its Flat-Bottom and Is Not Heavily Trimmedmyusuf_engineerÎncă nu există evaluări

- Anna UniversityDocument131 paginiAnna UniversityDilipKumarAkkaladeviÎncă nu există evaluări

- 2.secado Papel Tissue - ACOTEPACDocument62 pagini2.secado Papel Tissue - ACOTEPACJorge ForeroÎncă nu există evaluări

- Marksheet PDFDocument1 paginăMarksheet PDFDurjoy DasÎncă nu există evaluări

- DS - en 1993-1-3 DK Na - 2007 eDocument6 paginiDS - en 1993-1-3 DK Na - 2007 ep_meulendijks108Încă nu există evaluări

- SXXa XSDocument5 paginiSXXa XSraviteja tankalaÎncă nu există evaluări

- Fast Numerical Methods For Mixed-Integer Nonlinear Model-Predictive ControlDocument380 paginiFast Numerical Methods For Mixed-Integer Nonlinear Model-Predictive ControlDaniel Suarez ReyesÎncă nu există evaluări

- Lpile Description SheetDocument2 paginiLpile Description SheetMed El Hadi AbidiÎncă nu există evaluări

- Aryabhata Biography: Major WorksDocument2 paginiAryabhata Biography: Major WorksrajeshÎncă nu există evaluări

- Che323 Lecture 2 Humidification Wet BulbDocument19 paginiChe323 Lecture 2 Humidification Wet Bulbifiok100% (1)

- Lecture On Vehicle Dynamics 1 PDFDocument10 paginiLecture On Vehicle Dynamics 1 PDFSuryo mubarokÎncă nu există evaluări

- Session 11 Physical Vapour DepositionDocument26 paginiSession 11 Physical Vapour DepositionMurali DontuÎncă nu există evaluări

- HartfordDocument7 paginiHartfordapi-443631703Încă nu există evaluări

- Chapter3 PDFDocument62 paginiChapter3 PDFKensleyTsangÎncă nu există evaluări

- Module 3: Mass Transfer Coefficients: Lecture No. 5Document3 paginiModule 3: Mass Transfer Coefficients: Lecture No. 5walisyhÎncă nu există evaluări

- 3D ExerciseDocument1 pagină3D ExerciseRashiqah RazlanÎncă nu există evaluări

- 10ME82 16-17 (Control Engg.)Document30 pagini10ME82 16-17 (Control Engg.)Sharanabasappa SajjanÎncă nu există evaluări