Documente Academic

Documente Profesional

Documente Cultură

8.axial Loading CVG2140 - Mechanics of Materials I

Încărcat de

Fadey FaridTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

8.axial Loading CVG2140 - Mechanics of Materials I

Încărcat de

Fadey FaridDrepturi de autor:

Formate disponibile

CVG 2140

Mechanics of Materials I

Winter 2016

Axially Loaded Members

Lecture 8:

Normal Stress and Strain

Structural components subjected only to tension or compression are known as axially loaded members.

Examples include truss members, engine connecting rods, and building columns.

P

A

Uniform or Average Normal Stress = Axial force divided by cross-sectional area

Units: S.I.

F

L2

P

A

N

Pa

m2

1 MPa 1 mm2

Normal Strain = Elongation divided by length

(dimensionless)

Sign Convention

When the load P causes the member to elongate the normal stress is considered

positive and is called a tensile stress. The corresponding normal strain is known as

a tensile strain.

When the load P causes the member to shorten the normal stress is considered

negative and is called a compressive stress. The corresponding normal strain is

known as a compressive strain.

University of Ottawa

Lecture 8 - 1

CVG 2140

Mechanics of Materials I

Winter 2016

Limitations / Assumptions

(1)

(2)

(3)

(4)

Stress is uniformly distributed over the cross-sectional area.

The axial force P acts through the centroid.

The members are prismatic (uniform cross-section) and therefore the deformation is

uniform throughout the volume.

The material is homogeneous

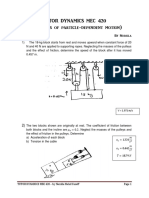

Example 1:

For the hollow metal tube axially loaded in compression the strain gauge indicates a strain of 540

microstrains. In addition, the stress in the member was calculated to be 40 MPa. The outside and inside

diameters of the tube are 60 mm and 50 mm, respectively. Determine (a) the shortening , and (b) the

load P acting on the tube

Strain Gauge

P

out = 60 mm, in = 50 mm

L = 500 mm

Solution

(a) Measured = 540 x 10-6,

(b) Stress = 40 MPa,

P

A

=?

L 540 106 500 mm 0.270 mm

P=?

P A 40 MPa

(602 502 ) 34.5 kN

Changes in Lengths of Axially Loaded Members

P

L

University of Ottawa

Lecture 8 - 2

CVG 2140

Mechanics of Materials I

P

A

Winter 2016

If we assume that the material is linearly elastic, hence it follows Hookes Law, we can combine the

above relations to obtain a relation for the elongation of the bar:

E

A

L

PL

EA

(1)

The denominator EA is called the axial rigidity of the member.

(2)

Rearranging the expression for the elongation as follows

EA

k

L

then the ratio of the axial rigidity to the length EA/L defines the stiffness of the

member and is often denoted by k. Stiffness represents the force required to produce

a unit elongation.

(3)

The reciprocal of stiffness is the flexibility of the member and it represents the

elongation due to a unit load.

L

1

f

EA

k

Example 2:

H

A

L/2

University of Ottawa

L=6m

H = 1.5 m

A = 3000 mm2

E = 200 GPa (Steel)

L/2

Lecture 8 - 3

CVG 2140

Mechanics of Materials I

Winter 2016

For the above steel truss calculate (a) the horizontal displacement of joint C when P = 120 kN, and (b)

the maximum load P if the horizontal displacement of the joint cannot exceed 2.0 mm.

Solution

(a) P = 120 kN, c = ?

B

120 kN (T)

FBC

1.5

FDC

120 kN (T)

120 kN (T)

60 kN

D

120 kN

60 kN

60 kN

Fy 0

60

Fx 0

2

5

FBC 0

FDC 120 kN (T)

120 10 6 10

200 10 3000

3

1.2 mm

Pmax = ?

PL

EA

Pmax

EA

L

University of Ottawa

FBC 134.2 kN (C)

60 5 FDC 0

PL

EA

(b) c 2.0 mm,

2.0 200 103 3000

6 10

3

200 kN

Lecture 8 - 4

CVG 2140

Mechanics of Materials I

Winter 2016

Changes in Lengths of Nonuniform Bars

PA

A

E1

L1

NL

i i

i 1 Ei Ai

PB

B

L2

E2

C

Example 3:

P1 = 400 kN

For the problem at right, given that the deformation cannot exceed

1.0 mm, determine (a) the minimum permissible area A1 when A2 =

A1

3A1, and (b) the area A1 if the compressive stresses in both parts of

P2 = 650 kN

2m

the pedestal are the same?

A2

E = 25 GPa

1.5 m

1.0 mm

Solution

1050 kN

a) A2 = 3A1, Minimum permissible A1

400 10 2000

25 10 A

3

400 kN

1050 10 1.5 10

25 10 3 A

3

24 105 1575 103 75 A1

1050 kN

N

University of Ottawa

A1 53,000 mm2

Lecture 8 - 5

CVG 2140

Mechanics of Materials I

Winter 2016

b) Compressive stresses in both parts are the same, A1 = ?

P1

A1

P2

A2

400 10 2000

25 10 A

1050 10 1.5 10

A

25 10 1050

400

P2

A1 2.625 A1

P1

A2

8 105 600 103 25 A1

A1 56,000 mm2

Bars with Continuously Varying Loads or Dimension

P(x)

P(x)

N(x)

dx

N(x)

dx

L

N( x ) dx

d

EA( x )

N( x ) dx

EA( x )

Note: Satisfactory results are obtainable if angle of taper is small.

Example 4:

A tapered bar AB, of solid circular cross section and length L, is supported at end A and subjected to a

tensile load P at the free end B. The diameters of the bars at ends A and B are A and B, respectively.

Determine the elongation of the bar due to the load P.

University of Ottawa

Lecture 8 - 6

CVG 2140

Mechanics of Materials I

Winter 2016

Solution:

dx

LB

LA

B LB

A LA

A( x )

x

x

A LA

[x ]2

4

N ( x ) dx

EA( x )

4PL2A

EA2

A x

LA

[x ]2 x 2

4L2A

LA

LB

P dx 4L2A

4PL2A

EA2 x 2

EA2

LA

LB

4PL2A

dx

x2

EA2

1

4PL2A LA LB

4PL2A

1

LA

EA2 LALB

EA2

LB

University of Ottawa

4PL

EA2

LA

LB

or

A

1

LB

LALB

4PL

EAB

Lecture 8 - 7

CVG 2140

Mechanics of Materials I

Winter 2016

Statically Indeterminate Structures

RA

A

A1

RA P RB 0

AB 0

(equilibrium equation)

(compatibility equation)

Change in length must be compatible with conditions at the

supports.

C

b

A2

AC

RA a

EA1

CB

RB b

EA2

(displacement relation)

AB AC CB 0

RB

Example 5:

A rigid bar of weight W =80 lb hangs from three equally spaced vertical wires, two of steel and one of

aluminium, as shown in the figure below. The wires also support a load P acting at the midpoint of the

bar. The diameter of the steel wires is 1/8 in., and the diameter of the aluminum wire is 3/16 in.

Determine what load P can be supported if the allowable stress in the steel wires is 20,000 psi and in the

aluminum wires is 12,000 psi? Assume ES = 30 106 psi and EA = 10 106 psi.

Aluminum

wire

Steel

wire

Steel

wire

Rigid

bar

P

Solution:

Steel wire:

s = 1/8

allow = 20,000 psi

ES = 30 106 psi

Aluminum wire:

A = 3/16

allow = 12,000 psi

EA = 30 106 psi

University of Ottawa

Lecture 8 - 8

CVG 2140

Mechanics of Materials I

Winter 2016

P=?

Free-body Diagram:

FS

FA

FS

P+W

2FS FA P W

FA 2FS P W

S A

FS L

ES AS

FA

2FS

E A AA

FS

ES AS

E A AA

FS

ES AS

E AA

FS 2 A

ES AS

FA L

E A AA

P W

W 2 P W

FS

ES AS

E A AA 2ES AS

ES AS

W

E A AA 2ES AS

ES AS

P W

E A AA 2ES AS

FA

FS

AS

ES

W

E A AA 2ES AS

20,000 psi

P 596 lbs ( governs ! )

FA

AA

EA

W

E A AA 2ES AS

12,000 psi

P 1136.8 lbs

where,

AA

A2

4

(32 )

4 16

0.0276 in

AS

S2

4

(12 )

4 8

0.0123 in2

E A AA 2ES AS 1,014,000 lbs

University of Ottawa

Lecture 8 - 9

S-ar putea să vă placă și

- Bombay Scottish 2013 ICSE Maths Prelim Paper Answer KeyDocument5 paginiBombay Scottish 2013 ICSE Maths Prelim Paper Answer KeyPavan KumarÎncă nu există evaluări

- J.B PetitDocument28 paginiJ.B PetitBmt KingÎncă nu există evaluări

- ResPaper Arya Vidya Mandir 2015 Mathematics Prelim Paper ICSEDocument6 paginiResPaper Arya Vidya Mandir 2015 Mathematics Prelim Paper ICSEPavan KumarÎncă nu există evaluări

- Mechanics of Materials I formula sheetDocument4 paginiMechanics of Materials I formula sheetFadey FaridÎncă nu există evaluări

- Campion School 2015 Maths Prelim Paper ICSE Answer KeyDocument5 paginiCampion School 2015 Maths Prelim Paper ICSE Answer KeyPavan KumarÎncă nu există evaluări

- ICSE 10 HISTORY/CIVICS FREE SAMPLE PAPERDocument5 paginiICSE 10 HISTORY/CIVICS FREE SAMPLE PAPERPandit Katti NarahariÎncă nu există evaluări

- Rillej: Portlan'D Cement AssociationDocument328 paginiRillej: Portlan'D Cement AssociationCarlos PEREZ NEYRAÎncă nu există evaluări

- PDF 4 1 PDFDocument139 paginiPDF 4 1 PDFMohammed Mohsen Tadulan Tawfiq100% (1)

- 07 Axisymmetric Finite Element ModelingDocument14 pagini07 Axisymmetric Finite Element ModelingSchubertDeierlein100% (1)

- Shear Centre Location and Effects in Non-Symmetric BeamsDocument2 paginiShear Centre Location and Effects in Non-Symmetric BeamsPaulSmile100% (1)

- Thick Plate On Elastic FoundationDocument21 paginiThick Plate On Elastic FoundationHasanain Almusawi100% (1)

- Test Mos FinalDocument12 paginiTest Mos FinalAbhishek Tiwari100% (1)

- On The Evaluation of Critical Lateral Torsional Buckling Loads of Monosymmetric Beam ColumnsDocument8 paginiOn The Evaluation of Critical Lateral Torsional Buckling Loads of Monosymmetric Beam ColumnsPauloAndresSepulvedaÎncă nu există evaluări

- CAC Handbook Chapter 11 Seismic DesignDocument27 paginiCAC Handbook Chapter 11 Seismic DesignthailecanadaÎncă nu există evaluări

- Plastic Buckling of Mindlin PlatesDocument280 paginiPlastic Buckling of Mindlin Platesडॉ. कनिष्क शर्माÎncă nu există evaluări

- BC C Punmia BeamDocument14 paginiBC C Punmia BeamvikrantgoudaÎncă nu există evaluări

- Tutor 4 Dependent MotionDocument4 paginiTutor 4 Dependent MotionEden HazardÎncă nu există evaluări

- Shear Force and Bending Moment Diagrams ZP 14Document17 paginiShear Force and Bending Moment Diagrams ZP 14ZdenkoÎncă nu există evaluări

- Assignment 2 Series Parallel and Star Delta 1Document5 paginiAssignment 2 Series Parallel and Star Delta 1Sajan MaharjanÎncă nu există evaluări

- Strain Energy MethodDocument16 paginiStrain Energy MethodpengniumÎncă nu există evaluări

- RC Frame Building With Masonry Infill Walls Designed For Gravity LoadsDocument16 paginiRC Frame Building With Masonry Infill Walls Designed For Gravity LoadsFeras TemimiÎncă nu există evaluări

- Structural Analysis IIDocument77 paginiStructural Analysis IIArpan SahaCE1120Încă nu există evaluări

- Mechanics of Materials: Transformations of Stress and StrainDocument22 paginiMechanics of Materials: Transformations of Stress and StrainMohammad Asif KabirÎncă nu există evaluări

- ME Structures Theory Elasticity PlasticityDocument3 paginiME Structures Theory Elasticity PlasticityameykatdareÎncă nu există evaluări

- Stability of Tapered and Stepped Steel Columns With Initial ImperfectionsDocument10 paginiStability of Tapered and Stepped Steel Columns With Initial ImperfectionskarpagajothimuruganÎncă nu există evaluări

- Beam-Columns AISC SummaryDocument46 paginiBeam-Columns AISC SummaryYusuf100% (1)

- Dynamic Analysis of Plane Frame Structure Using Response Spectrum MethodDocument12 paginiDynamic Analysis of Plane Frame Structure Using Response Spectrum Methodarunavaball100% (1)

- Buckling ExamplesDocument5 paginiBuckling ExamplesSrivatsan SampathÎncă nu există evaluări

- Strength of Materials - Torsion of Non Circular Section - Hani Aziz AmeenDocument8 paginiStrength of Materials - Torsion of Non Circular Section - Hani Aziz AmeenHani Aziz Ameen100% (2)

- NUS - MA1505 (2012) - Chapter 6Document27 paginiNUS - MA1505 (2012) - Chapter 6Gilbert SebastianoÎncă nu există evaluări

- Hibbeler Engineering Mechanics Dynamics 12th SolucionarioDocument1.048 paginiHibbeler Engineering Mechanics Dynamics 12th SolucionarioJeisonÎncă nu există evaluări

- 1 D Structures Basic ConceptsDocument42 pagini1 D Structures Basic ConceptsDev MitraÎncă nu există evaluări

- Syllabus of Advanced Structural Analysis CourseDocument2 paginiSyllabus of Advanced Structural Analysis Courseahamedtouhid8990% (1)

- Nonlinear Spring Element (Combin 39)Document19 paginiNonlinear Spring Element (Combin 39)mansoor_yakhchalian2Încă nu există evaluări

- Tension Member LRFDDocument9 paginiTension Member LRFDgullipalliÎncă nu există evaluări

- Chetan N. Benkar (2014) - Finite Element Stress Analysis of Crane HookDocument5 paginiChetan N. Benkar (2014) - Finite Element Stress Analysis of Crane HookGogyÎncă nu există evaluări

- FEM NotesDocument28 paginiFEM NotesBrian Freeman0% (1)

- Structural Design Short FormulaDocument5 paginiStructural Design Short FormulaMIslamMonirÎncă nu există evaluări

- List of Moments of Inertia PDFDocument3 paginiList of Moments of Inertia PDFALÎncă nu există evaluări

- MA1506Document70 paginiMA1506ernie123219405Încă nu există evaluări

- NSTSE 2012 Question Paper For Class 10Document20 paginiNSTSE 2012 Question Paper For Class 10Neepur Garg100% (2)

- STRESS-STRAINDocument14 paginiSTRESS-STRAINcikmonÎncă nu există evaluări

- Fea QBDocument11 paginiFea QBPradeepÎncă nu există evaluări

- Matrix Derivation of Spring FormulaDocument7 paginiMatrix Derivation of Spring FormulanoormqÎncă nu există evaluări

- Tutorial SheetDocument4 paginiTutorial SheetjaiÎncă nu există evaluări

- Moment of Inertia PDFDocument18 paginiMoment of Inertia PDFBernalyn ManaogÎncă nu există evaluări

- Reinforced Concrete Design Course OutlineDocument59 paginiReinforced Concrete Design Course OutlineBobby AguilarÎncă nu există evaluări

- Finite Element MethodsDocument12 paginiFinite Element Methodspraneeth4a100% (1)

- Engineering Tools & Design CalculationsDocument15 paginiEngineering Tools & Design CalculationswerxcvfdsÎncă nu există evaluări

- Structural Analysis of Cantilever Beam in ANSYSDocument55 paginiStructural Analysis of Cantilever Beam in ANSYSkrishna8808100% (2)

- Strength of Materials Courseware by A.A JimohDocument37 paginiStrength of Materials Courseware by A.A JimohSamuelShinaAyodele100% (2)

- A9R206FDocument45 paginiA9R206FAlejandro AguirreÎncă nu există evaluări

- Introduction To Seismic Essentials in GroningenDocument14 paginiIntroduction To Seismic Essentials in GroningenKay Chan SothearaÎncă nu există evaluări

- Shear Center TheoryDocument15 paginiShear Center TheoryRadha Krishnan RÎncă nu există evaluări

- Axially Loaded MembersDocument13 paginiAxially Loaded MembersUnknownÎncă nu există evaluări

- Strain and stress measurement conceptsDocument17 paginiStrain and stress measurement conceptsRasheed AhmedÎncă nu există evaluări

- Of The Bar by Equating The Strain: Problem 2.7-9Document16 paginiOf The Bar by Equating The Strain: Problem 2.7-9EDiane LlanosÎncă nu există evaluări

- Simple StrainDocument36 paginiSimple StrainMartina CelsoÎncă nu există evaluări

- Worked Exp Mechanics 2 PDFDocument144 paginiWorked Exp Mechanics 2 PDFamit1234Încă nu există evaluări

- Cvg2140 - Tutorial 2 (SFDBMD)Document2 paginiCvg2140 - Tutorial 2 (SFDBMD)Fadey FaridÎncă nu există evaluări

- CVG2140 - Tutorial 3 (Centroids Moments of Inertia)Document2 paginiCVG2140 - Tutorial 3 (Centroids Moments of Inertia)Fadey FaridÎncă nu există evaluări

- Beam Bending LabDocument8 paginiBeam Bending LabFadey FaridÎncă nu există evaluări

- CVG2140 - Tutorial 4 (Axial Members)Document2 paginiCVG2140 - Tutorial 4 (Axial Members)Fadey FaridÎncă nu există evaluări

- CVG2140 - Assignment 2 (2016) - SolutionDocument2 paginiCVG2140 - Assignment 2 (2016) - SolutionFadey FaridÎncă nu există evaluări

- CVG2140 - Assignment 2 (2016) - SolutionDocument2 paginiCVG2140 - Assignment 2 (2016) - SolutionFadey FaridÎncă nu există evaluări

- CVG2140 - Assignment 3 (2016) - SolutionDocument6 paginiCVG2140 - Assignment 3 (2016) - SolutionFadey FaridÎncă nu există evaluări

- CVG2140 - Assignment 1 (2016) .SolutionDocument2 paginiCVG2140 - Assignment 1 (2016) .SolutionFadey FaridÎncă nu există evaluări

- William Tell LiteracyDocument29 paginiWilliam Tell LiteracyAndrés Romero SeguraÎncă nu există evaluări

- 2D Compressible Viscous-Flow Solver On Unstructured Meshes With Linear and Quadratic Reconstruction of Convective FluxesDocument77 pagini2D Compressible Viscous-Flow Solver On Unstructured Meshes With Linear and Quadratic Reconstruction of Convective FluxeshityouÎncă nu există evaluări

- Astm E837-08Document17 paginiAstm E837-08jodakiÎncă nu există evaluări

- NY Regents Chemistry Exam Scoring KeyDocument12 paginiNY Regents Chemistry Exam Scoring KeyAAVANIÎncă nu există evaluări

- Forensic Engineering of Fire-Damaged StructuresDocument6 paginiForensic Engineering of Fire-Damaged StructuresMartinÎncă nu există evaluări

- CBSE Class 9 Work and Energy PDFDocument5 paginiCBSE Class 9 Work and Energy PDFRitesh PandeyÎncă nu există evaluări

- Chemistry Project XIIDocument13 paginiChemistry Project XIIKanav MalhotraÎncă nu există evaluări

- IR sensor operation theory explainedDocument4 paginiIR sensor operation theory explainedSebastin Ashok100% (1)

- Wave OpticsDocument1 paginăWave OpticsBhupeshÎncă nu există evaluări

- Lightning Protection System Analysis of High Voltage 70 KV Transmission Line in Area With High Lightning Density, Study Case Sutt 70 KV MalangDocument8 paginiLightning Protection System Analysis of High Voltage 70 KV Transmission Line in Area With High Lightning Density, Study Case Sutt 70 KV MalangGdeKomangFmoÎncă nu există evaluări

- Hydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1Document1 paginăHydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1rakeshsundaramurthyÎncă nu există evaluări

- Performance Evaluation of Elevated Storage Reservoir With Hybrid StagingDocument11 paginiPerformance Evaluation of Elevated Storage Reservoir With Hybrid StagingVelumani sÎncă nu există evaluări

- Micro Diaphragm Gas Sampling Pumps: Operating and Installation InstructionsDocument12 paginiMicro Diaphragm Gas Sampling Pumps: Operating and Installation Instructionssunilsheelavant100% (1)

- TM-16 Well Test and Completion DetailsDocument32 paginiTM-16 Well Test and Completion DetailsKiki AmrullahÎncă nu există evaluări

- Nioec SP 00 89 (R0) (Ed1)Document8 paginiNioec SP 00 89 (R0) (Ed1)aminÎncă nu există evaluări

- Monninghoff 546 - DatasheetDocument11 paginiMonninghoff 546 - DatasheetirfannadineÎncă nu există evaluări

- Asymptotic Orthogonality Analysis of Sparse Massive MIMO ChannelsDocument5 paginiAsymptotic Orthogonality Analysis of Sparse Massive MIMO Channelshendra lamÎncă nu există evaluări

- Bachelor of Science in Agricultural and Biosystems EngineeringDocument4 paginiBachelor of Science in Agricultural and Biosystems Engineeringsheil.cogayÎncă nu există evaluări

- ME304 HOMEWORK 3Document3 paginiME304 HOMEWORK 3Steve KrodaÎncă nu există evaluări

- Gases Tutorial 2Document4 paginiGases Tutorial 2Idil WarsameÎncă nu există evaluări

- Design and Analysis of Single Plate Friction ClutchDocument29 paginiDesign and Analysis of Single Plate Friction ClutchSagar BhoiteÎncă nu există evaluări

- HW5Document2 paginiHW5Mohammad Iqbal Mahamad Amir100% (1)

- Manual Fundamental Hydraulic SystmsDocument131 paginiManual Fundamental Hydraulic Systmssawmag123100% (3)

- Exploration Archaeology (John M. Stanley)Document4 paginiExploration Archaeology (John M. Stanley)henarroÎncă nu există evaluări

- Titrimetry (anEm'pnmQwQy)Document102 paginiTitrimetry (anEm'pnmQwQy)AchindA FernandoÎncă nu există evaluări

- Measuring Elastic Potential EnergyDocument2 paginiMeasuring Elastic Potential EnergyKerem TuranÎncă nu există evaluări

- Pump Centrifugal Pre Commissioning ITPDocument10 paginiPump Centrifugal Pre Commissioning ITPMohamad IbrahimÎncă nu există evaluări

- 13thPMO Area Ver5Document3 pagini13thPMO Area Ver5Yinkci Heart Entertainment StudioÎncă nu există evaluări

- Bored Socket in BasaltDocument8 paginiBored Socket in BasaltGULF PILING LLCÎncă nu există evaluări

- Matrices and Linear Systems: Matrix AlgebraDocument11 paginiMatrices and Linear Systems: Matrix AlgebraPavirlene Escaño NorteÎncă nu există evaluări