Documente Academic

Documente Profesional

Documente Cultură

Butterfly Valve Maintenance - NEW

Încărcat de

Cowdrey Ilan0 evaluări0% au considerat acest document util (0 voturi)

170 vizualizări1 paginăMAINTENANCE

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentMAINTENANCE

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

170 vizualizări1 paginăButterfly Valve Maintenance - NEW

Încărcat de

Cowdrey IlanMAINTENANCE

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

Weco Butterfly Valve

5.

Maintenance Instructions

Disassembly

1.

2.

3.

4.

5.

6.

Close valve and remove from the line. Turn

the valve to the open position. Handle may

be left on the upper stem or taken off by

removing cap screw and washer.

Remove both the upper and lower roll pins

with a drift pin or pin punch and hammer.

(Use any strong piece of steel rod which

fits the roll pin hole ID)

Pull both the upper and lower stems from

the body. If the stems cannot be removed

readily, grasp the stem in a vise and gently

tap the body with a hammer. A twisting

motion between the body and stems will

allow the stems to be removed easily. A

groove on the lower stem permits prying

the lower stem from the body by using a

screwdriver.

Remove the disc from the seat.

Remove the seat from the body. The seat

may have to be tapped lightly and evenly

around the edge from one end since the

seat fits snugly the body ID. Take care not

to damage the inside of the body.

7.

8.

Maintenance and Repair

1.

2.

3.

9.

Inspect the disc and stems. If worn or

pitted, substitute new ones.

When replacing the seat, new O-rings

should be installed.

It is recommended that all rubber parts

(seats, O-rings) be lightly but thoroughly

lubricated with a grease such as Dow

Corning #111 silicone, to facilitate

assembly. Spread lubricant on the inside

diameter of the seat.

12

13

11

7

6

Assembly (Ref: FMC Specification

3253718 or Q50038)

1.

2.

3.

4.

Place well lubricated O-rings into the top

and bottom holes of the seat.

Place the seat in a vise with the stem holes

parallel to the vise jaws. Use smooth jaws

or otherwise protect the seat OD from

damage. Carefully apply pressure to distort

the seat and only enough pressure to insert

the disc. Excessive pressure can damage the

seat. Slide the disc into the seat and center

the disc by inserting the upper and lower

stems. Remove the seat/disc subassembly

from the vise.

Using the upper stem, rotate the disc to the

partially closed position.

Remove the upper stem (leaving the lower

stem in place).

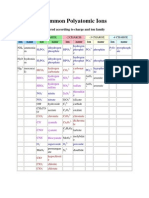

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Body

Disc

Upper Stem

Lower Stem

Seat

Detent Plate

Cap Screw

Lock Washer

Hex Nut

Roll Pin

O-Ring

Cap Screw

Washer

10.

11.

12.

11

13.

10

5

Lubricate the body ID or seat OD with a

silicone spray such as Dow Corning #316.

Using lower stem in the seat/disc assembly

and a lower stem in the body, lay the seat/

disc assembly on top of the body using a

right angle alignment fixture to align the

stems. Insert the seat enough to get started

and then remove the stems from the body

and the seat/disc assembly. Complete

inserting the seat/disc assembly into the

body with uniform pressure.

Install third O-ring in groove of upper stem.

If butterfly valve has a grease fitting, skive

cut third O-ring prior to installation onto

upper stem. Lubricate upper and lower

stems with Climax 422 CM or equivalent

(ref. FMC specification 3259721). Apply

lubricant on smaller surfaces at disc end of

the lower stem. Apply lubricant on large

OD surfaces of upper stem, between the

O-ring groove and the hex end. Do not

apply lubricant in roll pin groove or on

smaller surfaces on hex end.

Install the lower stem into the body. The

lower stem is in correct position when the

roll pin hole in the body is aligned with the

groove on the stem.

Before installing the upper stem, orient the

indicator groove on top of the upper stem

so that it is aligned with the disc. Install

the upper stem into the body by pushing

the stem while slightly turning back and

forth. This will allow the stem to engage

and align with the disc hex. The upper

stem is in the correct position when the

roll pin hole in the body is aligned with the

groove on the stem.

Install roll pins into body with start of

outside of coil 180 away from stem groove.

Make certain roll pins pass through grooves

of stems and are flush with body. Apply a

clear silicone adhesive sealant to the ends

of the roll pins.

Install the cap screw and washer to retain

the handle.

Install the cap screw and washer to retain

the handle.

Install detent plate. Tighten detent plate

mounting bolts until lock washer is

flat. If installing a 180 detent plate, the

plate should be installed so the

valve will have 2 closed positions and 1

open position. Countersunk holes

of the detent plate should be installed on

top.

Hand tighten retaining cap screw and

washer on the upper stem.

Installation with Flanges

1

9

Valves should be in the closed position during

installation to prevent damage to the disc. Check

indicator groove on top of upper stem for proper

disc alignment. After tightening flanges against

the valve, valve may be opened, but caution

should be taken to ensure opening of disc does

not contact ID of flange or pipe. Striking of disc

can result in possible leak paths.

10

11

4

FMC Technologies Inc.

1803 Gears Road

Houston, TX 77067

281 260 2121

Manufacturing

2825 West Washington

Stephenville, TX 76401

800 772 8582

S-ar putea să vă placă și

- Gate ServiceDocument28 paginiGate ServiceCowdrey IlanÎncă nu există evaluări

- Boiler Stop ValveDocument1 paginăBoiler Stop ValveCowdrey IlanÎncă nu există evaluări

- GEH 6700bDocument478 paginiGEH 6700baurel_c12-1100% (3)

- 17.4 PH Material SpecificationDocument2 pagini17.4 PH Material SpecificationDevendra BangarÎncă nu există evaluări

- Internship Forms From Campus2careersDocument7 paginiInternship Forms From Campus2careersஅகிலன் சோமசுந்தரம்Încă nu există evaluări

- Cat SFV 04 15Document36 paginiCat SFV 04 15el_apache10Încă nu există evaluări

- Acid DewpointDocument4 paginiAcid DewpointCowdrey IlanÎncă nu există evaluări

- Daily Racing Program for Summerside Raceway on September 21, 2014Document16 paginiDaily Racing Program for Summerside Raceway on September 21, 2014Cowdrey IlanÎncă nu există evaluări

- 17.4 PH Material SpecificationDocument2 pagini17.4 PH Material SpecificationDevendra BangarÎncă nu există evaluări

- Boiler Stop ValveDocument1 paginăBoiler Stop ValveCowdrey IlanÎncă nu există evaluări

- WeldingofStainlesssSteelandotherJoiningMethods 9002Document0 paginiWeldingofStainlesssSteelandotherJoiningMethods 9002jvs11021102Încă nu există evaluări

- Supersedes: Construction/Material DataDocument1 paginăSupersedes: Construction/Material DataCowdrey IlanÎncă nu există evaluări

- CRUISER2 WebManual EN NA 2Document17 paginiCRUISER2 WebManual EN NA 2Darrell EnnisÎncă nu există evaluări

- Brochure 29Document3 paginiBrochure 29Cowdrey IlanÎncă nu există evaluări

- Article Optical PyrometryDocument8 paginiArticle Optical PyrometryCowdrey IlanÎncă nu există evaluări

- Pressure ReliefDocument207 paginiPressure ReliefAH100% (1)

- Differential PH and Orp SensorsDocument4 paginiDifferential PH and Orp SensorsCowdrey IlanÎncă nu există evaluări

- Understanding Heat ExchangersDocument4 paginiUnderstanding Heat ExchangersCowdrey IlanÎncă nu există evaluări

- 1st year study plan for General Medicine 2012/2013Document1 pagină1st year study plan for General Medicine 2012/2013Cowdrey IlanÎncă nu există evaluări

- Chapter 8Document14 paginiChapter 8Nghi NguyenÎncă nu există evaluări

- GE Fanuc Automation: CIMPLICITY HMI Plant Edition Trend and XY ChartDocument228 paginiGE Fanuc Automation: CIMPLICITY HMI Plant Edition Trend and XY ChartCowdrey IlanÎncă nu există evaluări

- 3/4-Inch Combination PH and ORP Sensor KitsDocument8 pagini3/4-Inch Combination PH and ORP Sensor KitsCowdrey IlanÎncă nu există evaluări

- 2011-04-20 DC Battery TestDocument2 pagini2011-04-20 DC Battery TestCowdrey IlanÎncă nu există evaluări

- Take-Out & Delivery: Appetizers & Starters Famous Rotisserie Chicken Dinners Sandwiches & WrapsDocument1 paginăTake-Out & Delivery: Appetizers & Starters Famous Rotisserie Chicken Dinners Sandwiches & WrapsCowdrey IlanÎncă nu există evaluări

- The Laws of Motion: Multiple ChoiceDocument42 paginiThe Laws of Motion: Multiple ChoiceCowdrey IlanÎncă nu există evaluări

- 2 DMotionDocument88 pagini2 DMotionCowdrey IlanÎncă nu există evaluări

- RBC Visa Infinite Avion statement breakdownDocument2 paginiRBC Visa Infinite Avion statement breakdownCowdrey IlanÎncă nu există evaluări

- Common Polyatomic Ions ChartDocument3 paginiCommon Polyatomic Ions ChartCowdrey IlanÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Valve Abbreviations (MSS) (2017-05-17)Document1 paginăValve Abbreviations (MSS) (2017-05-17)Maarten Valves100% (1)

- MASONEILAN - Manual de Operacion, Mantenimiento y Lista de Partes PDFDocument43 paginiMASONEILAN - Manual de Operacion, Mantenimiento y Lista de Partes PDFJosé María Rodríguez RiveraÎncă nu există evaluări

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document18 paginiHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcÎncă nu există evaluări

- FM Butterfly ValvesDocument3 paginiFM Butterfly ValvesahsanÎncă nu există evaluări

- Khandala - Pipe - Line - Work - Phase 1 PDFDocument23 paginiKhandala - Pipe - Line - Work - Phase 1 PDFborkarsd007Încă nu există evaluări

- L&T - Triple OffsetDocument16 paginiL&T - Triple OffsetTasneemÎncă nu există evaluări

- Plastics Processing: VFS Butterfly ValvesDocument2 paginiPlastics Processing: VFS Butterfly ValvesLucas Meirelles SiqueiraÎncă nu există evaluări

- Valve Selection & Specification Guide For Building Services: Ahead of The FlowDocument20 paginiValve Selection & Specification Guide For Building Services: Ahead of The FlowGreg FarzettaÎncă nu există evaluări

- Single PPM QUALITY INNOVATION Butterfly ValvesDocument23 paginiSingle PPM QUALITY INNOVATION Butterfly Valveshuutan12345Încă nu există evaluări

- HPW Data SheetDocument2 paginiHPW Data SheetChochomastersÎncă nu există evaluări

- Keystone f990 920 CatalogoDocument4 paginiKeystone f990 920 CatalogoGino Chavez ValenciaÎncă nu există evaluări

- Description: - Butterfly Valve DN 32 - 900Document8 paginiDescription: - Butterfly Valve DN 32 - 900neo dayÎncă nu există evaluări

- Butterfly Valve Technical SpecificationDocument14 paginiButterfly Valve Technical SpecificationLeonardoDeGiovanniÎncă nu există evaluări

- 1 BUTTERFLY Valve InstallationDocument1 pagină1 BUTTERFLY Valve InstallationDachyiÎncă nu există evaluări

- DelVal Flow Controls - 4-Page - Binder-Brochure - PRINT - 04-23-2018 (PC - GEN.002.00)Document4 paginiDelVal Flow Controls - 4-Page - Binder-Brochure - PRINT - 04-23-2018 (PC - GEN.002.00)Prathamesh Pradeep MashilkarÎncă nu există evaluări

- Ivc Valves PDFDocument4 paginiIvc Valves PDFNaveen ReddyÎncă nu există evaluări

- Vanessa Butterfly ValvesDocument12 paginiVanessa Butterfly Valvesdragon2065Încă nu există evaluări

- Catalogo Comercial Apollo PDFDocument296 paginiCatalogo Comercial Apollo PDFjhonny sanchezÎncă nu există evaluări

- Be Butterfly Valves PB VFB PDFDocument14 paginiBe Butterfly Valves PB VFB PDFYogieÎncă nu există evaluări

- Butterfly Valves Installation GuideDocument4 paginiButterfly Valves Installation GuideRobi KeiÎncă nu există evaluări

- Series 50 52 Delval Butterfly ValvesDocument4 paginiSeries 50 52 Delval Butterfly Valvesajo2402Încă nu există evaluări

- Delta SV SVS 8001 01 08 2008 UsDocument4 paginiDelta SV SVS 8001 01 08 2008 Usterrazas.daniel@gmail.comÎncă nu există evaluări

- Air Vent Valmatic CertificatesDocument4 paginiAir Vent Valmatic CertificatesInternational companyÎncă nu există evaluări

- Valve and Pipe ListDocument22 paginiValve and Pipe ListZakky Rohman0% (1)

- Double Block Bleed Twin Plug Ball Valve Single Body ANSI ASMEDocument4 paginiDouble Block Bleed Twin Plug Ball Valve Single Body ANSI ASMEBharuk MechÎncă nu există evaluări

- Gfps Us 1334 Datasheet Type 244 Data Sheet enDocument6 paginiGfps Us 1334 Datasheet Type 244 Data Sheet enOmar GuillenÎncă nu există evaluări

- Technical Manual: Resilient Seated Butterfly ValvesDocument26 paginiTechnical Manual: Resilient Seated Butterfly ValvesIgnacio FranÎncă nu există evaluări

- Butterfly Valves Purushotham: Pro R&D PVT LTDDocument7 paginiButterfly Valves Purushotham: Pro R&D PVT LTDPurushothamÎncă nu există evaluări

- Basic Type of ValvesDocument2 paginiBasic Type of ValvesElton Situmeang100% (3)