Documente Academic

Documente Profesional

Documente Cultură

Sop 01-Turbine Cold Startup

Încărcat de

tpplantDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sop 01-Turbine Cold Startup

Încărcat de

tpplantDrepturi de autor:

Formate disponibile

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

MB POWER (MP) LIMITED

2600 MW Thermal Power Project,

ANUPPUR

Standard Operating Procedure

For

TURBINE COLD START-UP

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

Sl.NO.

1.0

2.0

3.0

4.0

4.1

4.2

5.0

6.0

Index

Purpose

Scope

Responsibility

System Description

Pre Start-up checks

Start-up

References

Records

Page No.

4

4

4

4

6

7

12

12

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

Revision status Record:

Revision Date

No.

Page no.

Details of Changes

Reason for changes

Document Approval sheet:

Prepared by

Signature

Checked by

Signature

Reviewed by

(HOD)

Signature

Approved by

(Head-O&M)

Signature

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

1.0 Purpose:

This Procedure is intended to provide guidance and instructions for carrying out the startup procedures

of turbine.

2.0 Scope:

a) This Procedure is applicable to turbine start-up process during cold start-up, warm start-up, hot

start-up & very hot start-up in plant.

3.0 Responsibility:

a) All the personnel involved in carrying out /supervising the above activities are required to ensure

implementation of this procedure and may consult any other relevant documents indicated under

Reference section below.

b) In the event of any changes required in the procedure such changes may be requested with

operation head, who would take appropriate action with approval from respective departmental

heads.

4.0

System Description:

(Start-up conditions are determined by the First Stage metal temperature of HP turbine)

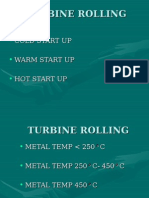

1. Cold start-up: the first stage metal temp 120, (for start-up after long time shutdown)

2. Warm start-up I : the first stage metal temp >120 &260, (for start-up after shutdown of

> 72 hours)

Steps as per Curve:

0-600 rpm @150 r/m (5 minutes)

Soak for 5 minutes at 600 rpm

600 - 2400 rpm @150 r/m (12 minutes)

Soak for 90 minutes at 2400 rpm

2400 - 3000 rpm @300 r/m (2 minutes)

[Change from TV to GV at 2900 rpm and raise speed up to 3000 rpm]

[Total time from 0 to 3000 rpm = 114 minutes]

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

Load Rising Rate:

Synchronisation+5% Load after 120 minutes

5% Load Holding -30 Minutes

Load Raising: 5% to 30% -@3MW/Min,

@12 MW/min

30% to 50%-@6MW/Min, 50% to 100%-

3. Warm start-up II: the first stage metal temp >260 &400 0,

(for start-up after shutdown of 10- 72 hours)

Steps as per Curve:

0-600 rpm @300 r/m (2 minutes)

Soak for 5 minutes at 600 rpm

600 - 3000 rpm @300 r/m (8 minutes)

[Change from TV to GV at 2900 rpm and raise speed up to 3000 rpm]

[Total time from 0 to 3000 rpm = 15 minutes]

Load Rising Rate:

Synchronisation+5% Load after 20 minutes

5% Load Holding -15 Minutes

Load Raising : 5% to 30% -@6MW/Min, 30% to100%-@12MW/Min

4. Hot start-up: the first stage metal temp >400 &450,

(For start-up after shutdown of 1-10 hours.)

Steps as per Curve:

0-3000 rpm @ 300 r/m (10 minutes)

[Total time from 0 to 3000 rpm = 10 minutes)

Load Rising Rate:

Synchronisation+5% Load after 15 minutes

5% Load Holding -1 Minutes

Load Raising: 5% to 30% -@9MW/Min, 30% to100%-@12MW/Min

5

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

5. Very Hot start-up: the first stage metal temp >450, (for start-up after shutdown of less than

1 hour.)

Steps as per Curve:

0-3000 rpm @ 300 r/m (10 minutes)

[Total time from 0 to 3000 rpm = 10 minutes)

Load Rising Rate:

Synchronisation+5% Load after 15 minutes

5% Load Holding -1 Minutes

Load Raising: 5% to 30% -@18MW/Min, 30% to100%-@30MW/Min

4.1 Pre Start-up Checks:

Fire Fighting System

CW System

ACW System

CCCW System & ensure Expansion tank level normal

Instrument Air Compressor

EH Oil System

Lube Oil System (Maintain Pr at bearings > 0.083MPa & temp at bearing outlet 60-70C)

Seal Oil System

Generator Stator Water System

Hydrogen circulating Blower

Air Pre Heater

Flame Scanner Air Fan

MDBFP with its lube oil system/ running in re-circulation

Boiler drum level /Dearator level /Hot well level is normal

( if required start Boiler fill pump/hot well make up pump)

CEP running in re-circulation

6

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

All heaters charged through water side.

Vacuum pump & its system

Boiler Circulation Pump

ESP hopper heating system

LDO system /HFO System is running & charged up-to boiler in long recirculation.

4.1 Start-up:

Ensure to open all drains of turbine proper and HP&IP system. ( should be opened till 20% load)

Put LP cylinder spray system in auto to maintain temp 70 and keep vacuum normal.

Start Jacking oil pump. Check & sure jacking oil pr at header/ bearing are normal. ( Pr=11.76-14.7

MPa)

Put Turning gear into operation and check no any abrasion sound.

Charge auxiliary steam from another unit, which will be used to heat feed water tank, and put into

shaft gland, when temperature and pressure reach, to create vacuum.

Set inclination of burner to be horizontal position.

Start Induced draft fan & maintained furnace draft -100 Pa.

Start Forced draft fan system & maintained furnace draft -50 Pa.

Adjust air flow (30~40%) & purge the boiler.

Lit-up the boiler.

Start one gland sealing cooling fan and Open gland sealing regulating valve (keep gland sealing pr

7-21 KPa & temp 120-180 C) and establish condenser vacuum.

Get required parameter of drum pressure.

Open HP Bypass valve to maintain MS pr <5.6 MPa and Open IP Bypass valve to maintain HRH pr

to 1.0 MPa.

Check parameters required for Turbine Latch. If OK, latch the turbine from DEH Screen in DCS.

After successful latch, check IP main steam valve (RSV 1&2) opened & Enable Roll is on.

Click control set value button on DEH Screen and set speed rise rate with target speed as per data

given as above in respective start up.

Raise the turbine speed as per warm/hot start up curve.( as mentioned above in each startup)

7

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

Charge LPH 1, 2, 3 &4 from steam side as well as drip system.

At 2900 rpm click TV/GV Change button: GV will close slowly and TV will open slowly.

After TV/GV changeover raise turbine speed up to 3000 rpm.

Carefully watch all critical parameters such as bearing vibration& temp/axial shift/differential

expansion/condenser vacuum.

Ensure MOP suction/discharge pr is ok. Stop AOP ,seal oil standby pump and put them in auto

mode.

Ensure Barring gear motor & JOP stops on auto, otherwise stop them manually.

Close Main steam & RH steam line drain & vents.

Charge the excitation system.

Synchronize the unit.

After the unit synchronizes, it is controlled by control valve and takes on an initial load of 5%.Hold

the 5% load as per warm/hot start up curves. In this process, the temperature rise rate of main

steam temperature shall be controlled at no more than 83/h. When the temperature rise rate of

steam temperature drops to 14/10min, it indicates that main steam temperature has been

stable, and loading up rate can be raised to 1020%.

Put Coal mill in service as per pr/temp requirement.

Close economiser recirculation valve.

Regulate steam temperature and load to reduce the metal temperature

Maintain the initial load until the LP cylinder exhausting outlet has been cooled down below 52.

Close the MSV valve upper seat and lower seat drain valves.

Cylinder transferring : On the turbine control interface, click Increase load, check if the IP

regulating valve opened gradually until fully opened, HP regulating valve begin to open, V.V valve

closed, HP exhausting check valve opened. HP bypass valve turns down automatically and keep

the turbine main pressure at 5MPa. When HP bypass are all closed, check both side LP bypass

valve closed. (When the unit load is higher than 120MW or HP bypass all closed, cylinder

transferring ends.)

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

When turbine cylinder transferring ends, turbine main control put in auto mode: check if the

turbine main steam pressure is 5MPa, click require remote control on the unit main control

interface, click auto to put in, check if the unit control mode is TF.

When the load is higher than 60MW, check turbine proper HP side drain link closed, when the unit

load is higher than 120MW, check turbine LP side drain link closed, or close it manually.

Put other mill in service.

At 90 MW load ensure turbine exhaust hood spray valve closed.

Close all drains at 20% load.

Changeover power supply from station service to main transformer.

Put TDBFP for steam heating.

When the load is within 160~180MW, parallel the first TDBFP with MDBFP.

Change dearator steam & TDBFP steam source from auxiliary to 4th extraction.

Put #3, #2#1 HP heater in service by sequence.

At 200 MW load put third mill in service.

At 240 MW load withdraw oil support of running mill whose load is >60%.

At 240 Mw load put other TDBFP in heating.

Above 300 MW load put 4th mill in service and take out all guns.

Put other TDBFP in service & stop MDBFP.

At 360 MW load Burner Tilt operation may put in auto to maintain RH temp.

Above 400 MW load put 5th mill in service

Above 500 MW load put 6th mill in service

Raise load up-to 600 MW

Put all control loops/ all master controller in auto mode.

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

Warm start-up I Curve

Warm start-up II Curve

10

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

Hot start-up Curve

Very Hot start-up Curve

11

MB POWER (MP) LIMITED,ANUPPUR

Title:

Document No.

Issue No/Date

Revision No/ Date

MBPMPL/OPN-SOP/TG/01

01/02.02.2015

00/02.02.2015

TURBINE COLD STARTUP

Cold start-up Curve

5.0 References:

1. Operation and Maintenance Manual for Steam Turbine Document No.: LITL-020-MEV-202-W30334,

2. Start Up Curve: LITL-020-MEV-202-T-30251(R1)

6.0 Records:

Turbine desk logbook.

12

S-ar putea să vă placă și

- Unit Start Up Sequence ActivitiesDocument6 paginiUnit Start Up Sequence ActivitiesranjanÎncă nu există evaluări

- Turbine Rolling & Synchronisation Indicative Flow PathDocument11 paginiTurbine Rolling & Synchronisation Indicative Flow Pathlp mishraÎncă nu există evaluări

- Sop of WHRPPDocument21 paginiSop of WHRPPHaider AliÎncă nu există evaluări

- Deh Operation InstructionDocument19 paginiDeh Operation Instructionmuhammad nasimÎncă nu există evaluări

- Write Up On Turbine OperationDocument5 paginiWrite Up On Turbine OperationSarah Frazier100% (2)

- Mjis Operation Order For - # Turbine Hot Status StartingDocument4 paginiMjis Operation Order For - # Turbine Hot Status StartingEduardo GarridoÎncă nu există evaluări

- SOP For Turbine ChecklistDocument11 paginiSOP For Turbine Checklistpradeep.selvarajanÎncă nu există evaluări

- Sop TurbineDocument4 paginiSop TurbinesambhuÎncă nu există evaluări

- Sop of TG & AuxilliariesDocument29 paginiSop of TG & Auxilliarieschcrr67% (3)

- Unit Startup ProcedureDocument148 paginiUnit Startup ProcedureAmit Chauhan100% (9)

- Cep Startup and ShutdownDocument5 paginiCep Startup and ShutdownAnonymous W9VINoTzaÎncă nu există evaluări

- Seal Oil SopDocument18 paginiSeal Oil SopSonrat100% (1)

- 300 MW ThermalPower Plant Cold Start UpDocument4 pagini300 MW ThermalPower Plant Cold Start Upsunil481100% (1)

- Cold Start Up ProcedureDocument18 paginiCold Start Up ProcedurerahulÎncă nu există evaluări

- 660mw Adani - Cold Start Up ProcedureDocument11 pagini660mw Adani - Cold Start Up Procedurekalyanm203515100% (1)

- Turbine StartupDocument16 paginiTurbine StartupSakthi Murugan100% (1)

- Turbine Start Up ProcedureDocument3 paginiTurbine Start Up ProcedureShameer Majeed100% (1)

- Standard Operating Instruction: KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For LP HeatersDocument7 paginiStandard Operating Instruction: KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For LP HeatersSonratÎncă nu există evaluări

- Toshiba Power PlantDocument24 paginiToshiba Power PlantMac Gerald Alindong100% (2)

- Boiler Feed PumpDocument11 paginiBoiler Feed PumpSolai100% (2)

- Turbine Shutting Down From Full LoadDocument7 paginiTurbine Shutting Down From Full Loadrohit_0123100% (1)

- Procedure of Turbine Cold Startup?Document3 paginiProcedure of Turbine Cold Startup?sunil601100% (1)

- Sop For Gauge Glass ChargingssDocument2 paginiSop For Gauge Glass ChargingssKUSH SHARMAÎncă nu există evaluări

- 2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Document59 pagini2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Tiara Noir100% (2)

- Turbine Trip LogicDocument2 paginiTurbine Trip Logicdilbagh_scribd50% (2)

- Technical DiaryDocument45 paginiTechnical DiarysambhuÎncă nu există evaluări

- Sop For Vacuum PumpDocument7 paginiSop For Vacuum PumpSonratÎncă nu există evaluări

- LP Bypass SystemDocument7 paginiLP Bypass SystemJackSparrow86Încă nu există evaluări

- EH Oil Pump SOPDocument8 paginiEH Oil Pump SOPSonratÎncă nu există evaluări

- Standard Operating Procedure FOR Oil Gun Light-UpDocument5 paginiStandard Operating Procedure FOR Oil Gun Light-Upsambhu100% (3)

- MDBFP Sop KSKDocument12 paginiMDBFP Sop KSKSonratÎncă nu există evaluări

- Standard Operating Procedure For Boiler Circulation Pump (BCP)Document5 paginiStandard Operating Procedure For Boiler Circulation Pump (BCP)PabitraMandalÎncă nu există evaluări

- HPBPDocument25 paginiHPBPSolaiÎncă nu există evaluări

- Cold Start Up Procedure: - NTPC, SimhadriDocument29 paginiCold Start Up Procedure: - NTPC, SimhadriAhemadÎncă nu există evaluări

- Standard Operating Procedure FOR Vacuum PumpDocument7 paginiStandard Operating Procedure FOR Vacuum Pumpsambhu100% (2)

- AUXILIARY COOLING WATER SystemDocument7 paginiAUXILIARY COOLING WATER Systemsambhu100% (1)

- Turbine Drains SOPDocument6 paginiTurbine Drains SOPSonratÎncă nu există evaluări

- SUPER CRITICAL BOILER (660 MW) at PROJECTDocument53 paginiSUPER CRITICAL BOILER (660 MW) at PROJECTWahedali SayyedÎncă nu există evaluări

- Cep Sop KSKDocument11 paginiCep Sop KSKSonratÎncă nu există evaluări

- Turbine Emergency - Thermal Power Plant A-ZDocument5 paginiTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (1)

- HP-LP Bypass FDocument16 paginiHP-LP Bypass FSolaiÎncă nu există evaluări

- 020-SOP of H2 CYLINDER Room ChargingDocument4 pagini020-SOP of H2 CYLINDER Room ChargingsambhuÎncă nu există evaluări

- 660 MW Harbin Boiler FSSS WriteupDocument40 pagini660 MW Harbin Boiler FSSS Writeupkumar_ranjan_3100% (1)

- Cold Srat UpDocument21 paginiCold Srat Upthiagu1989100% (1)

- 023 CepDocument12 pagini023 Cepjp mishraÎncă nu există evaluări

- DehDocument34 paginiDehAnand Swami100% (1)

- TDBFP Start Up Procedure 600 MWDocument1 paginăTDBFP Start Up Procedure 600 MWmayukh_mitra_2Încă nu există evaluări

- Cold Start Up - CSTPS PDFDocument19 paginiCold Start Up - CSTPS PDFAhemadÎncă nu există evaluări

- Unit Lightup Synchronisation & ShutdownDocument43 paginiUnit Lightup Synchronisation & ShutdownVara BikkinaÎncă nu există evaluări

- 057 - SOP of Boiler Circulating Pump FlushingDocument6 pagini057 - SOP of Boiler Circulating Pump FlushingsambhuÎncă nu există evaluări

- Final KSK Sop Instrument CompressorDocument10 paginiFinal KSK Sop Instrument CompressorSonratÎncă nu există evaluări

- Turbine RollingDocument39 paginiTurbine RollingSarah Frazier100% (2)

- Division - E HP Bypass System Volume - E1 Control Valves, Actuator and Accessories Contents ListDocument150 paginiDivision - E HP Bypass System Volume - E1 Control Valves, Actuator and Accessories Contents ListAnonymous ZnuMEWN1Încă nu există evaluări

- Tripping of Turbine On High Differential PressureDocument3 paginiTripping of Turbine On High Differential Pressureatulbhogare7Încă nu există evaluări

- Coal Mill, Feeder & PULV 1Document7 paginiCoal Mill, Feeder & PULV 1sambhuÎncă nu există evaluări

- Condensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDocument8 paginiCondensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajÎncă nu există evaluări

- Power Plant Start Up ProcedureDocument4 paginiPower Plant Start Up ProcedureFirman Adi Susetyo50% (2)

- Presentation On Steam Turbine Operation by S ChandDocument36 paginiPresentation On Steam Turbine Operation by S Chandsomyaranjan das100% (1)

- CCPP Cold Start ProcedureDocument3 paginiCCPP Cold Start ProcedureSahariar Bin ShafiqueÎncă nu există evaluări

- 3.digital Electric HydraulicDocument35 pagini3.digital Electric HydraulicBui Vanluong100% (1)

- Successful Negotiation Skills Process PDFDocument12 paginiSuccessful Negotiation Skills Process PDFtpplantÎncă nu există evaluări

- TQM Awards: National Quality Award (BNQA) in The United StatesDocument2 paginiTQM Awards: National Quality Award (BNQA) in The United StatestpplantÎncă nu există evaluări

- అతీంద్రియ రహస్యాలు - బ్లావట్స్కీDocument162 paginiఅతీంద్రియ రహస్యాలు - బ్లావట్స్కీtpplant100% (2)

- S.No Name Place of Incorporation: EXHIBIT (21) - List of Company SubsidiariesDocument12 paginiS.No Name Place of Incorporation: EXHIBIT (21) - List of Company SubsidiariestpplantÎncă nu există evaluări

- Presentation On GST: (Goods and Services Tax)Document11 paginiPresentation On GST: (Goods and Services Tax)tpplantÎncă nu există evaluări

- On The Basis of Creation:-: ExampleDocument8 paginiOn The Basis of Creation:-: ExampletpplantÎncă nu există evaluări

- GST Data CollectedDocument11 paginiGST Data CollectedtpplantÎncă nu există evaluări

- Nitrogen Plant Operation Manual With DrawingDocument29 paginiNitrogen Plant Operation Manual With Drawingtpplant100% (3)

- 2014 05 Turbine Generator PKG EreDocument8 pagini2014 05 Turbine Generator PKG EretpplantÎncă nu există evaluări

- Hydrogen Gas Dryer - AspxDocument2 paginiHydrogen Gas Dryer - AspxtpplantÎncă nu există evaluări

- HRSG StartupDocument19 paginiHRSG Startuptpplant100% (1)

- Top Tools For CalligraphersDocument2 paginiTop Tools For CalligrapherstpplantÎncă nu există evaluări

- 2013 02 Working of Gas TurbineDocument3 pagini2013 02 Working of Gas TurbinetpplantÎncă nu există evaluări

- Wiki Wobbe IndexDocument2 paginiWiki Wobbe IndextpplantÎncă nu există evaluări

- TC/TCM Two Stage Liquid Ring Vacuum PumpsDocument4 paginiTC/TCM Two Stage Liquid Ring Vacuum PumpstpplantÎncă nu există evaluări

- Common Names of ChemicalsDocument6 paginiCommon Names of ChemicalstpplantÎncă nu există evaluări

- Wiki Wobbe IndexDocument2 paginiWiki Wobbe IndextpplantÎncă nu există evaluări

- Us 6431550 PDFDocument9 paginiUs 6431550 PDFtpplantÎncă nu există evaluări

- Eje Delantero BMW F10Document94 paginiEje Delantero BMW F10Daniel Muñoz SotomayorÎncă nu există evaluări

- Product Management Self-Learning ManualDocument261 paginiProduct Management Self-Learning ManualAbhishek Arekar100% (1)

- Gordon NovelDocument50 paginiGordon NovelNic Hotep100% (2)

- Ultrasonic Mixer: Project 99.11Document11 paginiUltrasonic Mixer: Project 99.11Febri SandiÎncă nu există evaluări

- Alloys DensityDocument4 paginiAlloys DensityArnold Melissa CollettÎncă nu există evaluări

- Chapter 19A ConcreteDocument10 paginiChapter 19A ConcreteMofasa EÎncă nu există evaluări

- HiraDocument30 paginiHiravijay kumar singhÎncă nu există evaluări

- Stay CablesDocument22 paginiStay Cablesalex_g00dyÎncă nu există evaluări

- 701.ssvseat 1.04Document2 pagini701.ssvseat 1.04Cosmin MuscaluÎncă nu există evaluări

- Materials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilDocument5 paginiMaterials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilBart MaxÎncă nu există evaluări

- 27C ChainDocument19 pagini27C ChainyanaziÎncă nu există evaluări

- EM230 BR BM3 Fitting InstructionsDocument2 paginiEM230 BR BM3 Fitting InstructionsRoman BabaevÎncă nu există evaluări

- AI in RobotsDocument75 paginiAI in RobotsIslam SehsahÎncă nu există evaluări

- Concept of Circulation in A Free Vortex FlowDocument55 paginiConcept of Circulation in A Free Vortex FlowAnil KumarÎncă nu există evaluări

- Capstone Documentation RevisedDocument5 paginiCapstone Documentation RevisedMary Joy BolinaÎncă nu există evaluări

- Kinematics-03-Subjective SolvedDocument11 paginiKinematics-03-Subjective SolvedRaju SinghÎncă nu există evaluări

- Portal Info StubDocument11 paginiPortal Info Stubzamanqomaru8Încă nu există evaluări

- Rigaku Progeny Spec Sheet LTR 3.14Document2 paginiRigaku Progeny Spec Sheet LTR 3.14DATA24Încă nu există evaluări

- Ude My For Business Course ListDocument51 paginiUde My For Business Course ListShehroz BhuttaÎncă nu există evaluări

- Unit-II Some PPT NetDocument2 paginiUnit-II Some PPT NetbandisaidaiahÎncă nu există evaluări

- Portland CementDocument46 paginiPortland Cementni putu diah untariningsihÎncă nu există evaluări

- Sluice Gates ExportDocument20 paginiSluice Gates ExportsaishankarlÎncă nu există evaluări

- Shell Hazardous Area Classification FundamentalsDocument30 paginiShell Hazardous Area Classification Fundamentalsthekevindesai100% (17)

- 1998-10 The Computer Paper - Ontario EditionDocument156 pagini1998-10 The Computer Paper - Ontario Editionthecomputerpaper100% (1)

- Ammonia Production From Natural Gas-Haldor Topsoe ProcessDocument22 paginiAmmonia Production From Natural Gas-Haldor Topsoe ProcessYash BhimaniÎncă nu există evaluări

- CoreJava Ratan CompleteMarerial PDFDocument398 paginiCoreJava Ratan CompleteMarerial PDFSivaShankar100% (7)

- Diet Coke & Mentos Geyser Lab 2011-2012Document4 paginiDiet Coke & Mentos Geyser Lab 2011-2012Frederick LoganÎncă nu există evaluări

- Oracle Jrockit Mission Control Lab GuideDocument17 paginiOracle Jrockit Mission Control Lab GuideashuhegdeÎncă nu există evaluări

- Web 2.0: Dynamic Web PagesDocument12 paginiWeb 2.0: Dynamic Web PagesAra PantaleonÎncă nu există evaluări

- Meai Mar 2010Document36 paginiMeai Mar 2010Daneshwer VermaÎncă nu există evaluări

- Generative AI: The Insights You Need from Harvard Business ReviewDe la EverandGenerative AI: The Insights You Need from Harvard Business ReviewEvaluare: 4.5 din 5 stele4.5/5 (2)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyDe la EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyEvaluare: 4 din 5 stele4/5 (51)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumDe la EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumEvaluare: 3 din 5 stele3/5 (12)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceDe la EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceEvaluare: 5 din 5 stele5/5 (5)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldDe la EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldEvaluare: 4.5 din 5 stele4.5/5 (55)

- The Bitcoin Standard: The Decentralized Alternative to Central BankingDe la EverandThe Bitcoin Standard: The Decentralized Alternative to Central BankingEvaluare: 4.5 din 5 stele4.5/5 (41)

- System Error: Where Big Tech Went Wrong and How We Can RebootDe la EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootÎncă nu există evaluări

- The E-Myth Revisited: Why Most Small Businesses Don't Work andDe la EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andEvaluare: 4.5 din 5 stele4.5/5 (709)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldDe la EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldEvaluare: 4.5 din 5 stele4.5/5 (107)

- AI Superpowers: China, Silicon Valley, and the New World OrderDe la EverandAI Superpowers: China, Silicon Valley, and the New World OrderEvaluare: 4.5 din 5 stele4.5/5 (398)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyDe la EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyÎncă nu există evaluări

- Artificial Intelligence & Generative AI for Beginners: The Complete GuideDe la EverandArtificial Intelligence & Generative AI for Beginners: The Complete GuideEvaluare: 5 din 5 stele5/5 (1)

- YouTube Secrets: The Ultimate Guide on How to Start and Grow Your Own YouTube Channel, Learn the Tricks To Make a Successful and Profitable YouTube ChannelDe la EverandYouTube Secrets: The Ultimate Guide on How to Start and Grow Your Own YouTube Channel, Learn the Tricks To Make a Successful and Profitable YouTube ChannelEvaluare: 4.5 din 5 stele4.5/5 (48)

- The $100 Startup by Chris Guillebeau: Summary and AnalysisDe la EverandThe $100 Startup by Chris Guillebeau: Summary and AnalysisEvaluare: 4 din 5 stele4/5 (8)

- The World's Most Dangerous Geek: And More True Hacking StoriesDe la EverandThe World's Most Dangerous Geek: And More True Hacking StoriesEvaluare: 4 din 5 stele4/5 (49)

- 2019 Business Credit with no Personal Guarantee: Get over 200K in Business Credit without using your SSNDe la Everand2019 Business Credit with no Personal Guarantee: Get over 200K in Business Credit without using your SSNEvaluare: 4.5 din 5 stele4.5/5 (3)

- Your AI Survival Guide: Scraped Knees, Bruised Elbows, and Lessons Learned from Real-World AI DeploymentsDe la EverandYour AI Survival Guide: Scraped Knees, Bruised Elbows, and Lessons Learned from Real-World AI DeploymentsÎncă nu există evaluări

- The AI Advantage: How to Put the Artificial Intelligence Revolution to WorkDe la EverandThe AI Advantage: How to Put the Artificial Intelligence Revolution to WorkEvaluare: 4 din 5 stele4/5 (7)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseDe la EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseEvaluare: 3.5 din 5 stele3.5/5 (12)

- Artificial Intelligence: A Guide for Thinking HumansDe la EverandArtificial Intelligence: A Guide for Thinking HumansEvaluare: 4.5 din 5 stele4.5/5 (30)

- Who's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesDe la EverandWho's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesEvaluare: 4.5 din 5 stele4.5/5 (13)

- HBR's 10 Must Reads on AI, Analytics, and the New Machine AgeDe la EverandHBR's 10 Must Reads on AI, Analytics, and the New Machine AgeEvaluare: 4.5 din 5 stele4.5/5 (69)

- 100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziDe la Everand100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziÎncă nu există evaluări

- T-Minus AI: Humanity's Countdown to Artificial Intelligence and the New Pursuit of Global PowerDe la EverandT-Minus AI: Humanity's Countdown to Artificial Intelligence and the New Pursuit of Global PowerEvaluare: 4 din 5 stele4/5 (4)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewDe la EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewEvaluare: 4.5 din 5 stele4.5/5 (104)