Documente Academic

Documente Profesional

Documente Cultură

Standard Inspection and Test Plan For API6D Valves PDF

Încărcat de

Waqas JawaidDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Standard Inspection and Test Plan For API6D Valves PDF

Încărcat de

Waqas JawaidDrepturi de autor:

Formate disponibile

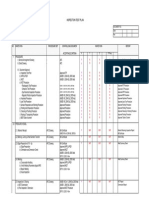

A GSL COMPANY QUALITY ENDORSED

STANDARD INSPECTION AND TEST PLAN FOR API6D VALVES

P.O.Number :

Page 1 of 4

Reference No.: APV160-001

Customer :

Description :

Project :

Location :

ACTION

PROCEDURE No.

ITEM NO.

MANUFACTURING OR INSPECTION DESCRIPTION

SPECIFICATION

REPORT,

RECORD/

WITNESSED

DOCUMENT REF.

API6D

MSS SP55

WPS/PQR

Mill Certificates

ASTM STD

MATERIAL CERTIFICATE

TYPE 3.1

Chemical Composition

ASTM STD

API6D

MATERIAL CERTIFICATE

ASTM STD

NACE MR0175

MATERIAL CERTIFICATE

Impact Test

ASTM STD

API6D

MATERIAL CERTIFICATE

Heat Treatment

ASTM STD

HEAT TREATMENT RECORD

FW

TEST CERTIFICATE

INSPECTION AND TEST PLAN

Casting surface inspection

Material (Body, Body Cap, Ball, Stem, Bonnet, Bolts)

Mechanical Test (Tensile, Bend, Hardness)

Marking Check

ACTIONED BY/

REQUIREMENTS

1

SUPPLIER'S

CERTIFICATE

Key

1. Australian Pipeline Valve

FW : Full witness inspection/test

R : Verify by reviewing documentation

2. Purchaser

SW : Spot witness inspection/test

SP : Specified by the purchaser

3. Other

H : Hold Point

www.australianpipelinevalve.com.au

9-15 Boolcunda Avenue Salisbury Plain, South Australia 5109 Telephone +61 (0)8 8285 0033 Fax +61 (0)8 8285 0044 admin@australianpipelinevalve.com.au

STANDARD INSPECTION AND TEST PLAN FOR API6D VALVES

P.O.Number :

Page 2 of 4

Reference No.: APV160-001

Customer :

Description :

Project :

Location :

ACTION

PROCEDURE No.

ITEM NO.

MANUFACTURING OR INSPECTION DESCRIPTION

SPECIFICATION

REQUIREMENTS

NDE (If specified by client)

RT for pressure retaining casting

SUPPLIER'S

ACTIONED BY/

REPORT,

RECORD/

WITNESSED

DOCUMENT REF.

CERTIFICATE

SP

API6D

SP

TEST CERTIFICATE

SP

TEST CERTIFICATE

ASME B16.34 SEC 8

RT for pressure retaining casting

(Apply to Body, Cap, Bonnet )

API6D

ASME B16.34 ANNEX D

`AFTER ASSEMBLY`

5

Pressure Testing (Ambient)

FW

Req'd

Hydrostatic shell testing

API6D

FW

TEST CERTIFICATE

Hydrostatic seat testing

API6D

FW

TEST CERTIFICATE

Low pressure gas seat

API598

FW

TEST CERTIFICATE

Torque Test (If specified by the client)

API6D

SP

TEST CERTIFICATE

Key

1. Australian Pipeline Valve

FW : Full witness inspection/test

R : Verify by reviewing documentation

2. Purchaser

SW : Spot witness inspection/test

SP : Specified by the purchaser

3. Other

H : Hold Point

www.australianpipelinevalve.com.au

STANDARD INSPECTION AND TEST PLAN FOR API6D VALVES

P.O.Number :

Page 3 of 4

Reference No.: APV160-001

Customer :

Description :

Project :

Location :

ACTION

PROCEDURE No.

ITEM NO.

MANUFACTURING OR INSPECTION DESCRIPTION

Visual Check

Dimensional Check

SPECIFICATION

REQUIREMENTS

MSS-SP-55

FW

SUPPLIER'S

ACTIONED BY/

REPORT,

RECORD/

WITNESSED

DOCUMENT REF.

CERTIFICATE

Req'd

3

TEST CERTIFICATE

Req'd

API6D

Approved Drawings

FW

TEST CERTIFICATE

End Flange Dimension

ASME B16.5

FW

TEST CERTIFICATE

Marking/Tagging Check

API6D

FW

TEST CERTIFICATE

10

Painting Inspection

FW

TEST CERTIFICATE

Face to Face Dimension

Key

1. Australian Pipeline Valve

FW : Full witness inspection/test

R : Verify by reviewing documentation

2. Purchaser

SW : Spot witness inspection/test

SP : Specified by the purchaser

3. Other

H : Hold Point

www.australianpipelinevalve.com.au

STANDARD INSPECTION AND TEST PLAN FOR API6D VALVES

P.O.Number :

Page 4 of 4

Reference No.: APV160-001

Customer :

Description :

Project :

Location :

ACTION

PROCEDURE No.

ITEM NO.

11

12

MANUFACTURING OR INSPECTION DESCRIPTION

SPECIFICATION

3

SUPPLIER'S

ACTIONED BY/

REPORT,

RECORD/

WITNESSED

DOCUMENT REF.

REQUIREMENTS

CERTIFICATE

Prototype Fugitive Emission Leak Test

SPE 77/312-2002

FW

FW

Req'd

TEST CERTIFICATE

Production Fugitive Emission Leak Test

SPE 77/312-2002

SW 3%

SW 3%

Req'd

TEST CERTIFICATE

MESC77/306

SW 10%

SW

Req'd

TEST CERTIFICATE

FW

SW

Req'd

TEST CERTIFICATE

Fugitive Emission Leak Test (if specified)

Low Temp./Cryogenic Test (Acceptance Test)

(if specified)

13

Positive Alloy Material Identification

(Apply to the valve of alloy body, Body, Body Cap, Bonnet,

Stem: 100%, Bolt & Nut: 5% )

(if specified)

Key

1. Australian Pipeline Valve

FW : Full witness inspection/test

R : Verify by reviewing documentation

2. Purchaser

SW : Spot witness inspection/test

SP : Specified by the purchaser

3. Other

H : Hold Point

Copyright Australian Pipeline Valve 2013

API6D Valves Inspection Test Plan R2 - AS

www.australianpipelinevalve.com.au

S-ar putea să vă placă și

- Supplier ITP Inspection PlanDocument4 paginiSupplier ITP Inspection PlanHassan SajidÎncă nu există evaluări

- Hydrotest ProcedureDocument6 paginiHydrotest Procedurebagusu_6Încă nu există evaluări

- Inspection Test PlanDocument3 paginiInspection Test PlanMohd Shafuaaz Kassim100% (2)

- Field inspection plan for structural steel erectionDocument1 paginăField inspection plan for structural steel erectionDelta akathehusky100% (1)

- ITP For Flow MeterDocument4 paginiITP For Flow MeterSayee KrishnanÎncă nu există evaluări

- Internal Painting Works ITPDocument2 paginiInternal Painting Works ITPPrasanna Kumar100% (1)

- Inspection and Test PlantDocument121 paginiInspection and Test PlantMajid Dixon89% (9)

- I&C Inspection and Test Plan - NWC Dhurma Pump Station, Pp11, Pp12, Pp13Document16 paginiI&C Inspection and Test Plan - NWC Dhurma Pump Station, Pp11, Pp12, Pp13Mohd Sami UddinÎncă nu există evaluări

- Scaffold ChecklistDocument5 paginiScaffold ChecklistMohamed GhariebÎncă nu există evaluări

- A05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFDocument14 paginiA05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFfdfazfzÎncă nu există evaluări

- Inspection and Test Plan For Pipe Rack and Piping Painting WorksDocument2 paginiInspection and Test Plan For Pipe Rack and Piping Painting WorksRanjan KumarÎncă nu există evaluări

- Equipment Inspection and Testing ProcessesDocument13 paginiEquipment Inspection and Testing ProcessesDevid Peri Sonefel100% (1)

- Inspection & Test Plan for Chilled Water Expansion TanksDocument1 paginăInspection & Test Plan for Chilled Water Expansion TanksvictorÎncă nu există evaluări

- Quality Assurance PlanDocument6 paginiQuality Assurance Planvkrishnamoorthy100% (2)

- Portacabin Inspection ChecklistDocument2 paginiPortacabin Inspection ChecklistApm FoumilÎncă nu există evaluări

- Madina Group W.L.L. Procedure Qualification Record 152Document38 paginiMadina Group W.L.L. Procedure Qualification Record 152MAT-LIONÎncă nu există evaluări

- Hydraulic crash barriers ITPDocument4 paginiHydraulic crash barriers ITPmoytabura96Încă nu există evaluări

- Contractor Quality Control Plan For Rotary Equipment InstallationDocument4 paginiContractor Quality Control Plan For Rotary Equipment InstallationJoel SnowÎncă nu există evaluări

- (A358) Inspection Test Plan - Rev.d - 130514Document5 pagini(A358) Inspection Test Plan - Rev.d - 130514Ronny AjaÎncă nu există evaluări

- Site Inspection Test PlanDocument24 paginiSite Inspection Test Planprabu palaniswamyÎncă nu există evaluări

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DDocument6 paginiFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoÎncă nu există evaluări

- 30a100dbqb23010 - Exde06 - 77 Project Quality PlanDocument81 pagini30a100dbqb23010 - Exde06 - 77 Project Quality Plansamuel madisonÎncă nu există evaluări

- Inspection & Test Plan for Civil and Structural SteelDocument33 paginiInspection & Test Plan for Civil and Structural SteelAhmed Mohsin100% (1)

- Welding Report For PipingDocument1 paginăWelding Report For PipingRifki HasyaÎncă nu există evaluări

- Surface Preparation and PaintingDocument4 paginiSurface Preparation and PaintingSimbu ArasanÎncă nu există evaluări

- Main Inspection Test Plan SampleDocument2 paginiMain Inspection Test Plan SampleMuhd AfiqÎncă nu există evaluări

- Quality Control SpecificationDocument31 paginiQuality Control Specificationم.ذكى فضل ذكى100% (2)

- Itp For InsulationDocument14 paginiItp For InsulationHytham El-NoubyÎncă nu există evaluări

- Joint Coating Application & Pipe Coating Procedure-009-RappDocument8 paginiJoint Coating Application & Pipe Coating Procedure-009-Rappgst ajahÎncă nu există evaluări

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDocument12 paginiAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaÎncă nu există evaluări

- G. Std. ITP For Pipeline Job PDFDocument4 paginiG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGWÎncă nu există evaluări

- Mfjo694 MRB 0001 IndexDocument2 paginiMfjo694 MRB 0001 IndexAkhtar Ansari100% (1)

- ITP Inspection and Test Plan 6MODocument2 paginiITP Inspection and Test Plan 6MOAS DevÎncă nu există evaluări

- Itp Installation of Fiber Optic CablesDocument4 paginiItp Installation of Fiber Optic Cablesqasim078100% (2)

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormDocument1 paginăStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaÎncă nu există evaluări

- Rotating Itp 1Document4 paginiRotating Itp 1abdul aziz100% (1)

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 paginăFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- Inspection Test PlanDocument3 paginiInspection Test PlanMathivanan Anbazhagan100% (2)

- ITP - Control PanelDocument2 paginiITP - Control PanelHoras Canman Sianipar100% (1)

- Dimensional Inspection ReportDocument2 paginiDimensional Inspection Reportshabbir626Încă nu există evaluări

- Inspection Test PlanDocument2 paginiInspection Test PlanBalaji Guru90% (10)

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Document37 paginiIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedÎncă nu există evaluări

- (Painting Works) : Inspection and Test PlanDocument2 pagini(Painting Works) : Inspection and Test Planrize1159Încă nu există evaluări

- Hydrotest Check ListDocument1 paginăHydrotest Check ListSaut Maruli Tua SamosirÎncă nu există evaluări

- Visual Inspection Checklist For Piping Systems: Connected Mechanical Equipment, Instrumentation, and Pipe Support SystemsDocument1 paginăVisual Inspection Checklist For Piping Systems: Connected Mechanical Equipment, Instrumentation, and Pipe Support Systemsikan100% (1)

- Structural Steel and Pipe Work ProcedureDocument5 paginiStructural Steel and Pipe Work ProcedureMohamed100% (2)

- Material Inspection Report Steel FormDocument1 paginăMaterial Inspection Report Steel FormMohamedGhanemÎncă nu există evaluări

- Inspected by QCP Approval 1-APC 1-Employer (APC) 2 - DAR 2 - Engineer (DAR) 3 - Contractor (NEGEMCO) 4 - Vendor 5 - Third PartyDocument6 paginiInspected by QCP Approval 1-APC 1-Employer (APC) 2 - DAR 2 - Engineer (DAR) 3 - Contractor (NEGEMCO) 4 - Vendor 5 - Third PartyAhmad DagamsehÎncă nu există evaluări

- Inspection Checklist For: Control ValvesDocument2 paginiInspection Checklist For: Control Valvesabdelkader benabdallahÎncă nu există evaluări

- ITP Fencing Rev - 00 PDFDocument3 paginiITP Fencing Rev - 00 PDFanon_987276020Încă nu există evaluări

- Saudi Aramco Pre-Commissioning Form: Sf-6 Pad-Mounted SwitchgearDocument2 paginiSaudi Aramco Pre-Commissioning Form: Sf-6 Pad-Mounted SwitchgearHaleem Ur Rashid BangashÎncă nu există evaluări

- SSM Su 5003 BDocument84 paginiSSM Su 5003 Bresp-ectÎncă nu există evaluări

- Inspection Report For Installation of JB, Juncation BoxDocument1 paginăInspection Report For Installation of JB, Juncation BoxnayumÎncă nu există evaluări

- Installation ITP for Instrumentation SystemDocument8 paginiInstallation ITP for Instrumentation SystemSreerag NageriÎncă nu există evaluări

- ITP's and ITR's A Necessary - Monster - PDFDocument5 paginiITP's and ITR's A Necessary - Monster - PDFshastri85Încă nu există evaluări

- APV STD Insp & Test Plan API6D ValvesDocument4 paginiAPV STD Insp & Test Plan API6D ValvesdbmingoÎncă nu există evaluări

- ITP Format For New PVDocument8 paginiITP Format For New PVDavid LambertÎncă nu există evaluări

- Visual Check List For Control Valve: Rock Payvand Sanat ArvandDocument1 paginăVisual Check List For Control Valve: Rock Payvand Sanat Arvandarmin heidariÎncă nu există evaluări

- Tank Erection Itp & Org ChartDocument34 paginiTank Erection Itp & Org Charthasan_676489616100% (2)

- Inspection Test Plan Equipment - AFC Header Plug Seal Weld 1Document4 paginiInspection Test Plan Equipment - AFC Header Plug Seal Weld 1Mohd Shafuaaz KassimÎncă nu există evaluări

- Catalog of Vortex (Tianjin China.)Document23 paginiCatalog of Vortex (Tianjin China.)Waqas JawaidÎncă nu există evaluări

- UTAS - Basic Medical Terms GuideDocument11 paginiUTAS - Basic Medical Terms GuideDunas SvetlanaÎncă nu există evaluări

- Herbs & Herbal MedicinesDocument21 paginiHerbs & Herbal MedicinesWaqas JawaidÎncă nu există evaluări

- Book PPEDocument35 paginiBook PPEWaqas JawaidÎncă nu există evaluări

- Visa AppDocument2 paginiVisa AppWaqas JawaidÎncă nu există evaluări

- Final Business Plan of Pso in SMDocument30 paginiFinal Business Plan of Pso in SMfraziqurianÎncă nu există evaluări

- PPE GuidelinesDocument44 paginiPPE GuidelinesWaqas JawaidÎncă nu există evaluări

- Excel2003 TutorialPart1Document19 paginiExcel2003 TutorialPart1Waqas JawaidÎncă nu există evaluări

- Herbs & Herbal MedicinesDocument21 paginiHerbs & Herbal MedicinesWaqas JawaidÎncă nu există evaluări

- List of Solvent Plants in PakistanDocument6 paginiList of Solvent Plants in PakistanWaqas Jawaid100% (2)

- Corporate ProfileDocument12 paginiCorporate ProfileWaqas JawaidÎncă nu există evaluări

- Dissertation Christian Schembri FINALDocument188 paginiDissertation Christian Schembri FINALkrixinÎncă nu există evaluări

- Design of anchor bolts for steel pole foundationDocument3 paginiDesign of anchor bolts for steel pole foundationJayÎncă nu există evaluări

- Aerial Ropeways: Transport via Overhead CablesDocument43 paginiAerial Ropeways: Transport via Overhead CablesAnshul yadavÎncă nu există evaluări

- Form 10 - Program of WorkDocument1 paginăForm 10 - Program of WorkGEYSIL COQUILLAÎncă nu există evaluări

- Protecting Ductile Iron Water Mains from External CorrosionDocument45 paginiProtecting Ductile Iron Water Mains from External CorrosionmuraliÎncă nu există evaluări

- RCC Cantilever Slab DesignDocument1 paginăRCC Cantilever Slab DesigndaxeshÎncă nu există evaluări

- Fcee 2005-06-203-216 Logistics of ConstructionDocument14 paginiFcee 2005-06-203-216 Logistics of ConstructionphilipyapÎncă nu există evaluări

- HOMEVAC PresentationDocument19 paginiHOMEVAC PresentationTMVR's TVÎncă nu există evaluări

- Duo Check Valve MaintenanceDocument2 paginiDuo Check Valve Maintenanceddoyle1351100% (1)

- Duct Construction Standardssflb-Editing PDFDocument20 paginiDuct Construction Standardssflb-Editing PDFClaudia Alvarenga de PaulaÎncă nu există evaluări

- List of I S Codes - CED 36Document2 paginiList of I S Codes - CED 36Rajesh MohananÎncă nu există evaluări

- CVS-English Brief-2018925024Document6 paginiCVS-English Brief-2018925024mohamed ahmedÎncă nu există evaluări

- Near-fault adjustment factors for additional active faults in TaiwanDocument117 paginiNear-fault adjustment factors for additional active faults in TaiwanLEEÎncă nu există evaluări

- Cantilever Poles - 2003 - : Section/Article DescriptionDocument12 paginiCantilever Poles - 2003 - : Section/Article DescriptionMike2322Încă nu există evaluări

- Calculation and Selection ResultDocument18 paginiCalculation and Selection ResultNery TorresÎncă nu există evaluări

- Basco Price List FinalDocument24 paginiBasco Price List FinalBernie Quep100% (1)

- Effect of Alloying Elements On Metal PropertiesDocument5 paginiEffect of Alloying Elements On Metal PropertiesJim GrayÎncă nu există evaluări

- Hub Reduction Gear RH 835Document60 paginiHub Reduction Gear RH 835Syarifuddin Rahman100% (1)

- ARAMCO DrawingDocument1 paginăARAMCO DrawingLainhatanhÎncă nu există evaluări

- Material Takeoff For Clear ASH MezzanineDocument31 paginiMaterial Takeoff For Clear ASH MezzanineMoe Oo Htun - Pebsteel MyanamarÎncă nu există evaluări

- Hetenyi Estimation of Fatigure Life of Jointed Railway BarsDocument10 paginiHetenyi Estimation of Fatigure Life of Jointed Railway BarsphilipyapÎncă nu există evaluări

- Geotechnical SpecificationsDocument14 paginiGeotechnical SpecificationswagwahkiabatheÎncă nu există evaluări

- Pow 17J00056Document3 paginiPow 17J00056GigiÎncă nu există evaluări

- SCentre Infra - The Leading Steel Construction Company in IndiaDocument54 paginiSCentre Infra - The Leading Steel Construction Company in Indiaseo2.artistonkÎncă nu există evaluări

- Harvey Goltz 615 Ellingham Drive, Katy, TXDocument2 paginiHarvey Goltz 615 Ellingham Drive, Katy, TXhgoltz615Încă nu există evaluări

- 14) Presentation by Ching-Ping Wang - 18SEAGC YPSDocument14 pagini14) Presentation by Ching-Ping Wang - 18SEAGC YPSfreezefreezeÎncă nu există evaluări

- Four Bolt Unstiffened End PlateDocument7 paginiFour Bolt Unstiffened End PlateRnD2013Încă nu există evaluări

- Report On The ConcreteDocument203 paginiReport On The ConcreteMohamed Bachir TouirÎncă nu există evaluări

- PMMADocument3 paginiPMMANancy DanielÎncă nu există evaluări

- Swa Cable - Bs6724Document6 paginiSwa Cable - Bs6724adventure11111Încă nu există evaluări