Documente Academic

Documente Profesional

Documente Cultură

Tribological Behaviour of Shot Peened Cu-Ni Austempered Ductile Iron

Încărcat de

Raniero FalzonDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tribological Behaviour of Shot Peened Cu-Ni Austempered Ductile Iron

Încărcat de

Raniero FalzonDrepturi de autor:

Formate disponibile

See

discussions, stats, and author profiles for this publication at: http://www.researchgate.net/publication/256913852

Tribological behaviour of shot peened CuNi

austempered ductile iron

ARTICLE in WEAR APRIL 2013

Impact Factor: 1.91 DOI: 10.1016/j.wear.2012.12.027

CITATIONS

READS

75

5 AUTHORS, INCLUDING:

Ann Zammit

Stephen C Abela

University of Malta

University of Malta

2 PUBLICATIONS 7 CITATIONS

12 PUBLICATIONS 14 CITATIONS

SEE PROFILE

SEE PROFILE

Lothar Wagner

Mansour Mhaede

Technische Universitt Clausthal

Technische Universitt Clausthal

130 PUBLICATIONS 961 CITATIONS

58 PUBLICATIONS 128 CITATIONS

SEE PROFILE

SEE PROFILE

Available from: Mansour Mhaede

Retrieved on: 19 December 2015

Wear 302 (2013) 829836

Contents lists available at SciVerse ScienceDirect

Wear

journal homepage: www.elsevier.com/locate/wear

Tribological behaviour of shot peened CuNi austempered ductile iron

A. Zammit a,n, S. Abela a, L. Wagner b, M. Mhaede b, M. Grech a

a

b

Department of Metallurgy and Materials Engineering, Faculty of Engineering, University of Malta, Msida MSD 2080, Malta

Institute of Materials Science and Engineering, Clausthal University of Technology, Agricolastrasse 6, D-38678 Clausthal-Zellerfeld, Germany

a r t i c l e i n f o

abstract

Article history:

Received 6 August 2012

Received in revised form

10 December 2012

Accepted 13 December 2012

Available online 23 December 2012

Wear and fatigue properties of power transmission components are usually improved by various

surface engineering processes. One surface modication process is shot peening which is generally

carried out to improve bending fatigue. However there are contrasting studies meant to investigating

whether shot peening actually increases the sliding wear resistance of austempered ductile iron (ADI).

Unlubricated wear tests were conducted on ground ADI and shot peened ADI pins. Hardness

measurements of the worn ADI surfaces showed a 19% increase in hardness after testing at low loads,

possibly due to strain hardening and frictional heating. Metallography of the worn surfaces showed

a distorted microstructure at the surface, indicative of surface ow. On the other hand, samples tested

at high loads showed a 73% increase in hardness. A white non-etchable layer which was identied

as untempered martensite formed upon cooling of wear test samples. Calculation of the wear factors

and friction coefcients showed that shot peening does not improve the wear resistance. This has been

attributed to the fact that the potential advantages resulting from the higher hardness at the surface,

stress-induced austenite to martensite transformation and the residual compressive stresses of the shot

peened specimens are counteracted by the induced surface roughness.

& 2012 Elsevier B.V. All rights reserved.

Keywords:

Austempered ductile iron

Sliding wear

Shot peening

Phase transformation

1. Introduction

Careful selection of austempering heat treatment parameters

applied to ductile iron results in a variety of microstructures and a

correspondingly wide range of bulk mechanical properties. This

renders austempered ductile iron (ADI) a potential alternative to

steel, having comparable strength and toughness, lower density

and greater damping capacity, combined with excellent castability.

ADI is in fact suitable for automotive components such as crank

shafts, connecting rods and transmission gears [1,2].

It has been reported [36] that the unique wear behaviour of

ADI is affected by the presence of surface graphite nodules as well

as the ability of the retained austenite, which is metastable at

room temperature, to transform to martensite when loaded.

Straffelini et al. [4] show that ADI exhibited a lower coefcient

of friction and wear coefcient than that of nitrided steel during

dry rolling-sliding wear testing. The authors attribute this to the

smearing of graphite on to the surface which in turn served as

a solid lubricant between the two wear surfaces. Straffelini et al. [4]

determined the wear mechanism occurring during sliding of

austempered ductile iron by using the wear-mechanism maps

described by Lim and Ashby [7]. The latter authors gave graphical

Corresponding author. Tel.: 356 2340 2066; fax: 356 21343577.

E-mail address: ann.t.triccas@um.edu.mt (A. Zammit).

0043-1648/$ - see front matter & 2012 Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.wear.2012.12.027

presentations of wear phenomena showing the wear rate and the

wear mechanism dominance in steel/steel tribocontacts over a

wide range of loads and sliding speeds.

Surface engineering techniques are usually applied to improve

the surface properties namely by changing the microstructure or

the composition of the surface. This can be achieved by thermal,

chemical, thermochemical or mechanical treatments. Tan et al. [8]

reported that after laser hardening, the surface hardness and

abrasive wear resistance of nodular cast irons could be considerably improved due to a predominantly martensitic structure

produced in the hardened zone. Lu and Zhang [9] obtained

relatively high sliding wear resistance for both austempered and

laser-hardened CuMo ADI specimens when compared to ductile

iron specimens. This was attributable to the strain-induced

martensite transformation of the retained austenite occurring

during the wear process and the martensite formed during laser

processing. In addition, Xue et al. [10] reported that ADI specimens with and without laser hardening showed a higher contact

fatigue resistance than that of induction hardened steel.

Shot peening (SP) is a conventional mechanical surface treatment that may be used to improve the fatigue strength of

automotive components subjected to fatigue loading. In this

process, the surface of a material is bombarded with a ow of

spherical media, creating a layer of compressive residual stress

and inducing high dislocation densities [11]. The compressive

layer induced by shot peening increases the resistance to crack

830

A. Zammit et al. / Wear 302 (2013) 829836

initiation and propagation which in turn prolongs the lifetime of

components. However, as the spherical shots hit the surface,

dimples are formed which roughen the surface. The surface nish

of mating surfaces affects the wear resistance of components. This

combination of a high friction coefcient at the beginning of the

test and a work hardened surface was also observed by Ohba et al.

[12] when studying rolling contact fatigue properties of ADI.

Similar ndings were also reported by Ho et al. [13] who showed

that shot peening did not improve the sliding wear resistance of

annealed 1018 steel, but it did decrease the wear rate of hardened

4340 steel. On the other hand, work by Vaxevanidis et al. [14]

showed that shot peening had a benecial effect on the tribological behaviour of steel.

A large number of studies have shown that shot peening

improves the bending fatigue strength [1519]. However, very

few works have been conducted on the tribological behaviour

after shot peening, and it is thus not clear whether it actually

improves the wear resistance. This paper compares the sliding

wear behaviour of ground ADI with shot peened ADI specimens

tested under dry conditions.

of standard deviation to the mean) of the measurements was in

all cases below 5%.

Phase analysis before and after shot peening was carried out

using the X-ray diffraction method and a Bruker D8 Advance

X-Ray diffractometer (Mo-Ka radiation). The scanning step was

0.011, the dwell time 0.2 s and 2y values between 15 and 401. The

tube acceleration voltage and current used were 45 kV and

35 mA, respectively. The XRD patterns obtained were subjected

to the SavitzkyGolay smoothing lter which performs a local

polynomial regression to the raw data reducing the signal noise

[21]. A 3rd order regression was found to preserve features of the

pattern including relative maxima and width of peaks. The

retained austenite content (gret) in the ADI was measured with

the X-ray diffractometer using the simplied method described

by Miller [22].

2.4. Test equipment and conditions

After heat treatment of both pins and disks, the surfaces were

ground up to a mean surface roughness Ra of 0.2 mm. After

grinding, half of the pins were shot peened. Shot peening was

carried out using S330 shots, with an Almen intensity of

0.38 mmA up to 100% coverage. The stand-off distance was

90 mm while the angle of impingement was set at 901. The

surface roughness Ra of the shot peened pins was measured to

be 3.7 mm.

Dry sliding wear tests were carried out using a conventional

pin-on-disk tribometer capable of maintaining a constant unidirectional, sliding velocity between the pin and disk. The machine

used was an Italdesign TR-20 which allowed control of the load,

velocity, duration of test and radius at which the pin acts on the

disk. In this study, a cantilever loaded at ended cylindrical ADI

pin was made to slide over a rotating hardened steel disk. The pin

was xed to one end of the cantilever arm, and the other end was

attached to displacement and force transducers. The tribometer

was connected to a computer which monitored and recorded the

displacement of the pin and disk and the frictional force.

Tests followed ASTM G99-05 (Standard test method for wear

testing with a pin-on-disk apparatus) procedures and were carried

out in ambient air held at room temperature. Tests were

performed at two values of pressure acting between the cylindrical surface of the pin and the horizontal rotating disk namely at

2.5 and 10 MPa, while the sliding distance, sliding velocity and

radius at which the pin acted upon the disk were kept constant at

3.6 km, 4 m/s and 26 mm, respectively.

Before and after tribological tests, both the pins and the disks

were cleaned for 10 min in an acetone ultrasonic bath, and then

rinsed in isopropanol and dried in a jet of hot air. For each

experiment, a new pin and new counter body were used. The

mass of both the pins and the disks was measured before and

after each test using a digital balance having an accuracy of

70.1 mg. The mass lost was converted into wear volume W,

taking the density r of the ADI material as 6890 kg/m3. The wear

factor K was then calculated using the relation K W/Fs, where W

represents the wear volume in mm3, F is the applied load in N and

s is the sliding distance in m [23]. Two surface conditions of ADI

were tested namely: ground ADI (G) and shot peened ADI (SP)

(Table 3). At least ve sliding tests were carried out for each

condition and applied load, and the average data is reported.

2.3. Characterisation

Table 2

Chemical composition of the steel reference disks.

2. Experimental procedure

2.1. Material and processing

Test pins of 5 mm diameter used for the pin-on-disk wear

testing were machined from ductile iron keel blocks, having the

composition shown in Table 1. After machining, samples were

austenitised at 900 72 1C, and then rapidly quenched in a salt

bath at 36075 1C and held for 1 h. The samples were then air

cooled to room temperature. These austempering parameters

were optimised in a previous study [20]. Samples were coated

using a dedicated paint (SEMCO Zir H) to prevent decarburisation

during the austempering process.

Test disks of 90 mm diameter were made out of D2 tool steel

of chemical composition shown in Table 2 and heat treated to a

hardness of 61 HRC. The heat treatment cycle consisted of preheating, followed by austenitising at a temperature of 1025 1C

and then quenching using nitrogen at a pressure of 5 bar. After

that, the disks were tempered at a temperature of 190 1C for 3 h.

2.2. Surface treatment

The microhardness measurements were taken using a

Mitutoyo MVK-H12 microhardness tester. Three measurements

for the hardness were taken. The coefcient of variation (the ratio

Element

Cr

Mo

Mn

Si

Fe

Composition (wt%)

11.8

1.55

0.8

0.8

0.4

0.3

Bal

Table 1

Chemical composition of the keel blocks.

Element

Si

Cu

Ni

Mn

Mg

Al

Fe

Composition (wt%)

3.26

2.36

1.63

1.58

0.24

0.011

0.057

0.024

0.006

Bal

A. Zammit et al. / Wear 302 (2013) 829836

831

Table 3

Tribological test conditions.

Specimen

identication

Surface

condition

Nominal applied

pressure (MPa)

G2.5

SP2.5

G10

SP10

Ground ADI

Shot peened ADI

Ground ADI

Shot peened ADI

2.5

10

Fig. 2. SP microstructure.

Fig. 1. Austempered ductile iron microstructure.

The tests were carried out at an ambient temperature of 1873 1C

and relative humidity of 4275%.

2.5. Post-wear characterisation

The worn surfaces of the pins were examined using optical

microscopy and scanning electron microscopy. Changes in the

subsurface region were also investigated by using metallographic

techniques and by taking microhardness measurements on the

cross-section wear test samples.

After the tests, the debris was collected in order to investigate

the products generated during sliding of the specimens. SEM and

EDX were used to obtain information regarding the morphology

and chemical composition of the wear debris.

3. Results and discussion

3.1. ADI microstructure

The microstructure of the austempered material (Fig. 1) contains 200 graphite nodules per mm2 with graphite nodularity

greater than 95% in a matrix consisting of acicular ferrite and

carbon enriched austenite. The macrohardness of the ADI structure is 336715 HV, while the microhardness of the ausferritic

structure is 370710 HV.

3.2. Characterisation of shot peened specimens

Shot peening of austempered ductile iron results in a straininduced phase transformation. In fact, the face centred cubic (FCC)

retained austenite present in the ausferrite matrix transforms to body

centred tetragonal (BCT) martensite by cold-working caused by shots

impinging on the surface of the component. It is evident from the

micrograph in Fig. 2 that the microstructure at the surface is distinct

from that of the base matrix.

Fig. 3. X-ray diffraction patterns of as-treated and shot peened ADI.

Optical micrograph observations are supported by the X-ray

diffraction patterns shown in Fig. 3. The amount of retained austenite

in as-austempered polished specimens was calculated to be about

44%. In comparison, none of the austenite peaks (g111, g200, g220, g311)

were observed in the shot peened ADI specimen, but only ferrite and

martensite peaks. This indicates that the austenite has transformed to

martensite as a result of shot peening.

The work hardening induced by shot peening and the phase

transformation to martensite results in an increase of the surface

hardness from 370 to 535 HV. The microhardness depth-prole

shown in Fig. 4 also indicates that the hardness falls continuously

as the distance from the surface increases.

The residual compressive stress of shot peened specimens was

measured in a previous study [15]. The maximum occurred at the

surface and was about 975 MPa, 67% higher than the yield point of

the material.

3.3. Study of the surfaces of wear test samples

In tribological tests, the wear process changes as the properties of the surface alter. At a low applied pressure of 2.5 MPa, the

microhardness of the worn surface is about 19% higher than that

832

A. Zammit et al. / Wear 302 (2013) 829836

Fig. 4. Microhardness prole of specimens before wear tests.

Fig. 5. Microhardness proles of a cross section of the worn surface.

of the bulk; 440 and 370 HV, respectively (Fig. 5) for tested G

specimens. The thickness of this hardened layer is around

100 mm. This was also observed by Refaey et al. and Islam et al.

[24,25] who state that this increase in hardness is due to strain

hardening of the ausferritic matrix at the surface region which

predominates over any frictional heating effect. As a result of this

plastic deformation, the material is stronger and causes surface

ow and the microstructure to distort. Fig. 6 shows the distorted

microstructure of a section taken across the worn surface after

testing with the lower load.

It is noted that the hardness of SP specimens decreases after

wear testing, from 535 to 450 HV. This is probably due to the

removal of part of the shot peened layer during the wear test, or

tempering of the martensite which was formed during the shot

peening process (Fig. 3).

On the other hand, the microhardness at the surface of specimens tested at the higher load is over 600 HV (Fig. 5). This

indicates a phase transformation to a high hardness phase.

Micrographs show that a white non-etchable phase is present at

the surface of the specimens tested with the higher load (Fig. 7).

When the two surfaces slide over each other, most of the work

done against friction is converted into heat, causing a general rise

Fig. 6. Microstructure just below the worn surface shows distortion and surface

ow.

Fig. 7. Martensite formed on worn surfaces, tested at an applied pressure of

10 MPa.

in temperature, as well as localised temperature spikes where an

asperity makes contact with the mating surface. The resulting rise

in temperature may modify the mechanical and metallurgical

properties of the sliding surfaces, causing them to oxidise, or

possibly melt. This high temperature transforms the ausferrite to

austenite and can result in carbon diffusion into the austenite,

making it stable and hence increasing the hardenability of the pin.

As a consequence, the critical cooling rate is lowered, resulting in

the formation of untempered martensite at a slow cooling rate

upon cooling of the pin and disk after the test is stopped. Another

plausible reason of martensite formation is that the austenite

being produced due to the high temperatures being formed at the

asperities is rapidly cooled due to heat being conducted into the

underlying bulk material.

This was also observed by Fordyce et al. [26] who reported a

white non-etching layer formed during the unlubricated sliding

wear of austempered spheroidal cast iron. However, these white

layers were not found on the worn surfaces of the as-cast

spheroidal iron. Straffelini et al. [4] explained how the wear rate

of ADI at high sliding speeds (1.52.6 m/s) was dominated by the

formation and cracking of this white layer formed on the sliding

surface. Sharma [27] has also shown that high loads applied

A. Zammit et al. / Wear 302 (2013) 829836

during wear testing may transform the metastable austenite to

martensite.

3.4. Wear rates

In all tests, the disk wear was negligible. This can be explained

by the higher hardness of the steel disks compared to that of the

ADI pins, and the contact area on the disk which is several times

greater than that of the area of the pin.

The wear displacement, which is the progressive movement of

the pin and disk [28], can be seen in Fig. 8. The graphs for the

higher load are divided in two regions, a short running-in stage

(about 300 m) and the longer steady-state region. The displacement is much larger during the running-in stage, while during the

steady-state region, the wear rate increases more or less linearly

with the sliding distance. The graphs showing wear displacement

for tribological tests carried out at the lower load show a constant

wear rate throughout the entire test, without a running-in region.

Fig. 9 shows the wear factor, K, of ground and shot peened

specimens as a function of sliding distance. Even though there is a

large scatter of wear factor values, it is noted that the ground

surfaces show a lower wear rate than the shot peened surfaces.

These results may suggest that a higher original hardness does

not necessarily result in better wear resistance. It may be argued

833

however that the potential improvement resulting from an

increase in hardness is being counterbalanced by the increased

surface roughness caused by shot peening.

The wear factor was higher for specimens which were tested

at the higher load. The austenite to martensite transformation

increases the strength at the surface, rendering it able to withstand the high contact loads. However, martensite is known to be

brittle and is susceptible to cracking. Analysis of the worn

surfaces showed cracks at the surface of specimens (Fig. 10).

Cracks could also be a result of micro-adhesive interactions

between the pin and disk. Propagation of these cracks led to

pitting of the surface (Figs. 10 and 11), resulting in loss of material

and increased wear rate.

The coefcients of variation (COV) which is the standard

deviation divided by the mean were calculated in order to give

an indication of the data dispersion and therefore reliability of the

results. The dispersion of the wear data was between 29 and 79%.

The possible causes for the disparity in wear test results include

the variation of the applied load caused by vibrations generated

during testing, the difference in composition and microstructure

due to the multiple phases of the materials being tested, and the

accuracy of material loss measurements.

The presence of graphite nodules has a major inuence on the

wear rate of ADI as supercial graphite is smeared over the

surface and aids in lubricating the surfaces in sliding contact. Also,

as can be seen in Fig. 12, cracks have a tendency of passing

through the graphitematrix interface, this being the path of least

resistance. On the other hand, a nodule may arrest crack propagation, Fig. 13. Whether or not a crack is arrested or assisted to

propagate as it reaches a graphite nodule would depend on the

angle of approach. It follows that graphite nodules inuence the

propagation path.

3.5. Coefcient of friction (CoF)

Fig. 8. Wear displacement as a function of sliding distance for G and SP specimens.

Fig. 9. Wear factors of G and SP samples.

Frictional heat is generated when the pin slides on the disk.

It can be seen from CoF data shown in Fig. 14 that there is only

a minimal difference in the values pertaining to ground and shot

peened specimens. This is despite the initial rougher SP surface

(Ra 3.7 mm) as compared to the initial surface roughness of the

ground specimens (Ra 0.2 mm). Results suggest that the higher

wear rate of the SP specimens shown in Fig. 9, cannot be

attributed to localised heating caused by the increase in roughness of the dimpled surface resulting from the shot peening

treatment. On the contrary, Mokhtar claimed that heat treatment,

Fig. 10. Pitting of worn G surfaces tested at an applied pressure of 10 MPa.

834

A. Zammit et al. / Wear 302 (2013) 829836

Fig. 11. Pitting of worn SP surfaces tested at an applied pressure of 10 MPa.

Fig. 14. Friction coefcient evolution.

Fig. 12. Crack propagation through graphite nodules (G10).

hence lowers the frictional resistance [30]. This contrasts with the

results shown in the present work. One may argue that the

negative impact of the rougher surface, was in this study more

dominant than the benecial inuence of any phase transformation (Figs. 2 and 3), and compressive residual stresses present at

the surface of SP specimens [15]. Analysis of the surface roughness of the shot peened wear test samples used in the two studies

may throw more light on this apparent inconsistency.

Fig. 14 also shows that a lower CoF was recorded when testing

specimens at a higher applied load. High applied pressure

promotes the phase transformation of retained austenite to

martensite, a harder and load bearing phase. It is known that

friction properties are generally improved when the hardness of

the surface is increased. As explained by Mokhtar et al. [31], cold

weld junctions formed when hard phases like martensite are

present are relatively easy to break, hence lowering the adhesion

of the surfaces and the frictional resistance. Also, martensite has

better thermal properties, providing better heat dissipation leading to a reduction in the CoF [32,33].

On the other hand, under the action of low applied loads, no

martensite formation is observed. The asperities of the harder

disk indent into the softer ausferritic structure of the pin causing

plastic deformation and strong cold-welded junctions are formed.

Frictional sliding resistance to motion is thus higher due to the

larger force required to shear these welded junctions [31].

3.6. Wear mechanism

Fig. 13. Crack arrested by the graphite nodule.

alloying or shot peening, increased surface hardness resulting in

lower frictional resistance [29]. He attributed this to the fact that

hardening and shot peening introduce residual stresses and phase

transformations which lower the strength of the cold-welded

junctions. This, he maintains, lowers adhesion of the surfaces and

Different wear mechanisms are believed to have occurred

during the tests. As observed by Straffelini et al. [4], the wear

factors shown in Fig. 9 are typical of mild oxidational wear [7,34].

During dry sliding, the surfaces interact with the atmosphere

resulting in a mild form of corrosive wear, known as oxidational

wear, which primarily occurs during unlubricated conditions of

sliding [23]. Due to the high frictional heating during sliding, fast

oxidation occurs. The oxide layers formed usually appear as

islands on the sliding surfaces (Fig. 15). The separation of the

surfaces due to these layers results in mild wear [35].

Debris is formed due to the fatigue of the oxide lm produced

and the generation of frictional heat which raises the temperature

of the sliding surfaces. This weakens the bonding strength

between the oxide lm and the substrate, resulting in delamination of the oxide layer. The worn surfaces and the wear debris

collected after wear tests had a redbrown tinge and EDX analysis

A. Zammit et al. / Wear 302 (2013) 829836

identied large amounts of oxygen (Fig. 16). This conrms the

oxidational wear as the main wear mechanism which occurred

during the tests. The other identied peaks in Fig. 16 shows the

presence of iron, carbon, silicon and copper, all of which are

elements present in the material being studied.

SEM observation of wear debris generated by sliding showed

that small particles were agglomerated to combine into larger

wear particles (Fig. 17). This was also observed by Stachowiak

where the wear particles were seen to agglomerate into clusters

during the unlubricated sliding wear of steels and cast iron [36].

835

Fig. 18 shows the wear scar of a pin where sliding marks

parallel to the direction of sliding were observed. The ne grooves

show that several plateaus are formed at the beginning of the

wear process when the contacting surfaces achieved conformity

[23]. During sliding, these plateaus become unstable, they break

up to form debris, and other wear grooves tracks are formed. The

generation of wear particles can change the wear mechanism to

three-body abrasive wear, which leads to microploughing of the

surface. The dimpled surface of the SP specimens can trap these

wear particles, thus increasing the wear rate [37].

4. Conclusions

In this study, unlubricated sliding wear tests were carried out

to determine the effect of shot peening (SP) on the tribological

behaviour of CuNi alloyed austempered ductile iron. Pin-on-disk

tests were conducted on ground ADI, and shot peened ADI

specimens using two nominal applied loads. The results of the

present work are summarised as follows:

Fig. 15. Oxide layer on worn surface of G2.5 pin.

(1) Shot peening of ADI results in an increase in surface roughness and hardness, together with austenite to martensite

transformation.

(2) Specimens tested at the lower load showed a distorted

microstructure just below the wear scar indicative of surface

ow. An increase in surface hardness of 19% was noted on

these surfaces after wear tests. On the other hand, untempered martensite was observed on the surface of specimens

Fig. 16. EDX analysis of the wear debris.

Fig. 18. Ploughing marks on the pin surface.

Fig. 17. SEM micrographs of debris collected from wear tests; (a) ADI 10 MPa, (b) SP 10 MPa.

836

A. Zammit et al. / Wear 302 (2013) 829836

tested at the higher load. This was attributed either to the

high ash temperatures and/or to the high stresses reached

during sliding.

(3) The main wear mechanism was mild oxidative wear where

a reddish-brown layer was seen on the worn surfaces. In

addition, material loss was due to the result of three-body

abrasive wear.

(4) No improvement was noticed on the wear factor after shot

peening, despite the increase in surface microhardness, the

introduction of residual compressive stresses, work hardening

of the surface and stress-induced austenite to martensite

transformation. The roughened surface induced by shot peening,

and possibly the entrapment of wear particles between the

dimpled surface of the SP specimens and the disk may have had

an inuence on the wear rate. In addition, no differences were

noticed on the microstructures just below the worn surfaces,

debris analysis and friction coefcients of ground and shot

peened samples.

(5) This work shows that shot peening does not result in an

improvement in the sliding wear resistance. This indicates

that shot peening can be applied to components which

require a higher bending fatigue resistance, without lowering

signicantly the wear resistance.

Acknowledgements

The authors would like to thank Mr. Mark Joseph Zerafa

(B.Eng.(Hons.)) for his contribution in machining and testing of

specimens.

In addition, the authors would like to acknowledge the

positive impact of ERDF funding and the purchase of the testing

equipment through the project: Developing an Interdisciplinary

Material Testing and Rapid Prototyping R&D Facility (Ref. no. 012).

References

[1] R.C. Voigt, C.R. Loper, Austempered ductile ironprocess control and quality

assurance, Journal of Heat Treating 3 (1984) 291309.

[2] J. Race, L. Stott, Practical experience in the austempering of ductile iron, Heat

Treatment of Metals 4 (1991) 105109.

[3] U.R. Kamari, R.P. Rao, Study of wear behaviour of austempered ductile iron,

Journal of Materials Science 44 (2009) 10821093.

[4] G. Straffelini, M. Pellizzari, L. Maines, Effect of sliding speed and contact

pressure on the oxidative wear of austempered ductile iron, Wear 270 (2011)

714719.

[5] T. Nasir, D.O. Northwood, J. Han, Q. Zou, G. Barber, X. Sun, P. Seaton, Heat

treatment-microstructure-mechanical/tribological property relationships in

austempered ductile iron, in: Surface Effects and Contacts Mechanics X, 2011.

[6] B. Bosnjak, B. Verlinden, B. Radulovic, Dry sliding wear of low alloyed

austempered ductile iron, Materials Science and Technology 19 (7) (2003)

650656.

[7] S.C. Lim, M.F. Ashby, Wear-mechanism maps, Acta Metallurgica 35 (1987)

124.

[8] Y.H. Tan, S.I. Yu, J.L. Doong, J.R. Wang, Abrasive wear property of bainitic

nodular cast iron in laser processing, Journal of Materials Science 25 (1990)

41334139.

[9] G.X. Lu, H. Zhang, The structure and sliding-contact wear resistance of a

laser-hardened austempered ductile iron, Wear 138 (1990) 112.

[10] L. Xue, M.U. Islam, G. McGregor, Dot matrix hardening of steels using a ber

optic coupled pulsed Nd:YAG laser, Materials and Manufacturing Processes

14 (1999) 5365 1999.

[11] V. Schulze, Proceedings of the Eighth International Conference on Shot

Peening, Garmisch-Partenkirchen, Wiley, Germany, 2002.

[12] H. Ohba, S. Matsuyama, T. Yamamoto, Effect of shot peening treatment on

rolling contact fatigue properties of austempered ductile iron, Tribology

Transactions 45 (2012) 576582.

[13] J.W. Ho, C. Noyan, J.B. Cohen, V.D. Khanna, Z. Eliezer, Residual stresses and

sliding wear, Wear 84 (1983) 183202.

[14] N.M. Vaxevanidis, D.E. Manolakos, A. Koutsomichalis, G. Petropoulos,

A. Panagotas, I. Sideris, A. Mourlas, S.S. Antoniou, The effect of shot peening

on surface integrity and tribological behaviour of tool steels in AITC-AIT,

Parma, Italy, 2006.

[15] A. Zammit, M. Mhaede, M. Grech, S. Abela, L. Wagner, Inuence of shot

peening on the fatigue life of CuNi austempered ductile iron, Materials

Science and Engineering A 545, pp. 7885.

[16] V. Schulze, Modern Mechanical Surface Treatment, WILEY-VCH, 2006.

[17] Y. Ochi, K. Masaki, T. Matsumura, T. Sekino, Effect of shot-peening treatment

on high cycle fatigue property of ductile cast iron, International Journal of

Fatigue 23 (2001) 441448.

[18] A. Ebenau, D. Lohe, O. Vohringer, E. Macherauch, Inuence of Shot Peening on

the Microstructure and the Bending Fatigue Strength of Bainitic-Austenitic

Nodular Cast Iron in ICSP-4, 1990, pp. 389398.

[19] M.H. Mhaede, K.M. Ibrahim, M. Wollmann, L. Wagner, Enhancing Fatigue

Performance of Ductile Iron by Austempering and Mechanical Surface

Treatments, in: Arabcast 2008, 2008.

[20] A. Zammit, L. Hopkins, J.C. Betts, M. Grech, Austenite transformation in

austempered ductile iron, in: Materials Science and Engineering (MSE 2008),

Nuremberg, Germany, 2008.

[21] A. Savitzky, M.J.E. Golay, Smoothing and differentiation of data by simplied

least squares procedures, Analytical Chemistry 36 (1964) 16271639.

[22] R.L. Miller, A rapid X-ray measurement for the determination of retained

austenite, ASM Transactions 57 (1964) 892899.

[23] A. International, Friction, Lubrication and Wear Technology Vol. 18, 1992.

[24] A. Refaey, N. Fatahalla, Effect of microstructure on properties of ADI and low

alloyed ductile iron, Journal of Materials Science 38 (2003) 351362.

[25] M.A. Islam, A.S.M.A. Haseeb, A.S.W. Kurny, Study of wear of as-cast and heattreated spheroidal graphite cast iron under dry sliding conditions, Wear 188

(1995) 6165.

[26] E.P. Fordyce, The dry sliding wear behaviour of an austempered spheroidal

cast iron, Wear 135 (1990) 265278.

[27] V.K. Sharma, Roller Contact Fatigue Study of Austempered Ductile Iron, vol. 3,

ASM, 1984 326334.

[28] M.J. Neale, M. Gee, Wear Problems and Testing for Industry, William Andrew

Publishing, 2001.

[29] M.O.A. Mokhtar, The effect of hardness on the frictional behaviour of metals,

Wear 79 (1982) 297304.

[30] M.A. Mokhtar, M.A.E. Radwan, The inuence of quenching techniques on

frictional behaviour of carbon steels, in: Semin on Heat and Mass Transfer,

Dubrovnik, 1979.

[31] M.O.A. Mokhtar, M. Zaki, G.S.A. Shawki, Effect of mechanical properties on

frictional behaviour of metals, Tribology International (1979) 165267.

[32] A. Gural, Inuence of martensite particle size on dry sliding wear behaviour

of low carbon dual phase powder metallurgy steel, Metallic Materials 48

(2010) 2531.

[33] S. Sendooran, P. Raja, Metallurgical investigation on cryogenic treated HSS

tool, International Journal of Engineering Science and Technology 3 (2011)

39923996.

[34] F.H. Stott, The role of oxidation in the wear of alloys, Tribology International

31 (1998) 6171.

[35] S.C. Lim, The relevance of wear-mechanism maps to mild-oxidational wear,

Tribology International 35 (2002) 717723.

[36] G.W. Stachowiak, G.B. Stachowiak, Unlubricated friction and wear behaviour

of toughened zirconia ceramics, Wear 132 (1989) 151171.

[37] G.W. Stachowiak, WearMaterials, Mechanisms, and Practice, John, Wiley &

Sons, Ltd, 2005.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Mollier Chart WaterDocument1 paginăMollier Chart Waterchouchou575% (8)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Seakeeping: Complex numbers and Euler's formulaDocument26 paginiSeakeeping: Complex numbers and Euler's formulaRaniero FalzonÎncă nu există evaluări

- MS101 Egypt AssignmentDocument16 paginiMS101 Egypt Assignmentrofaman100% (5)

- International Chemistry Olympiad Problems Volume 03 (2009-2013)Document291 paginiInternational Chemistry Olympiad Problems Volume 03 (2009-2013)Science Olympiad Blog75% (4)

- Notes Wind EnergyDocument22 paginiNotes Wind EnergyRaniero FalzonÎncă nu există evaluări

- RSG Harmonised StandardsDocument11 paginiRSG Harmonised StandardsRaniero FalzonÎncă nu există evaluări

- Electric Water Heaters InstructionsDocument88 paginiElectric Water Heaters InstructionsRaniero FalzonÎncă nu există evaluări

- FBA A Concealed R32 GasDocument2 paginiFBA A Concealed R32 GasRaniero FalzonÎncă nu există evaluări

- Lab Report Bl2Document25 paginiLab Report Bl2Raniero Falzon0% (1)

- What Is The Best Method For Preheating 4130Document5 paginiWhat Is The Best Method For Preheating 4130Raniero FalzonÎncă nu există evaluări

- 81 14 DesignDocument9 pagini81 14 DesignRaniero FalzonÎncă nu există evaluări

- SAE - Design, Manufacturing, and Verification of A Steel Tube Space FrameDocument54 paginiSAE - Design, Manufacturing, and Verification of A Steel Tube Space FrameRaniero FalzonÎncă nu există evaluări

- What Is The Best Method For Preheating 4130 PDFDocument5 paginiWhat Is The Best Method For Preheating 4130 PDFRaniero FalzonÎncă nu există evaluări

- Curved BeamDocument2 paginiCurved BeamRaniero Falzon0% (1)

- Chassis Design1Document5 paginiChassis Design1Ashutosh JadhavÎncă nu există evaluări

- 8 Chemical PresentationDocument18 pagini8 Chemical PresentationRaniero FalzonÎncă nu există evaluări

- Stress Analysis of Truck Chassis Joints Using FEMDocument16 paginiStress Analysis of Truck Chassis Joints Using FEMwaqasjeralÎncă nu există evaluări

- Thin CylinderDocument16 paginiThin CylinderPranksterz StarzÎncă nu există evaluări

- BS EN 00003-3-1996 ScanDocument16 paginiBS EN 00003-3-1996 ScanRinu RavikumarÎncă nu există evaluări

- Future Ship Powering Options ReportDocument51 paginiFuture Ship Powering Options ReportRaniero FalzonÎncă nu există evaluări

- SPSSDocument31 paginiSPSSRaniero FalzonÎncă nu există evaluări

- Answers to End-of-Chapter Problems for Principles of Heat and Mass Transfer (7th EditionDocument32 paginiAnswers to End-of-Chapter Problems for Principles of Heat and Mass Transfer (7th EditionAzam RoslanÎncă nu există evaluări

- RP Lecture6and7Document41 paginiRP Lecture6and7Tarek MohamedÎncă nu există evaluări

- Calculus: Techniques of IntegrationDocument26 paginiCalculus: Techniques of IntegrationSamuel PascuaÎncă nu există evaluări

- Producing A Thesis Using WordDocument59 paginiProducing A Thesis Using WordRaniero FalzonÎncă nu există evaluări

- FluidsDocument101 paginiFluidsRaniero FalzonÎncă nu există evaluări

- FluidsDocument101 paginiFluidsRaniero FalzonÎncă nu există evaluări

- Producing A Thesis Using WordDocument59 paginiProducing A Thesis Using WordRaniero FalzonÎncă nu există evaluări

- LIGA and Its ApplicationsDocument484 paginiLIGA and Its ApplicationsRaniero FalzonÎncă nu există evaluări

- Catalog Whatman 2018.compressedDocument214 paginiCatalog Whatman 2018.compressedRakha Milan BachtiarÎncă nu există evaluări

- Vacita Integrated ServicesDocument21 paginiVacita Integrated ServicesNwosu AugustineÎncă nu există evaluări

- Radiation Heat Transfer in Combustion Systems - Viskanta and Menguc PDFDocument64 paginiRadiation Heat Transfer in Combustion Systems - Viskanta and Menguc PDFXamir Suarez Alejandro100% (1)

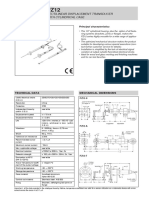

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 paginiRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926Încă nu există evaluări

- ROCKYDocument4 paginiROCKYNelson Alexander Aponte SimbronÎncă nu există evaluări

- PMI Procedure for Verifying Alloy Elements in Metals by XRFDocument2 paginiPMI Procedure for Verifying Alloy Elements in Metals by XRFMohamed NabilÎncă nu există evaluări

- Direct Determination of The Flow Curves of NoDocument4 paginiDirect Determination of The Flow Curves of NoZaid HadiÎncă nu există evaluări

- Gyro Notes For 2ND MateDocument18 paginiGyro Notes For 2ND MateArchit Bhardwaj100% (1)

- Image ProcessingDocument49 paginiImage ProcessingJyoti SinghÎncă nu există evaluări

- Electrical Engineering BA (B), Analog Electronics, ET065G 6 Credits ET064G 7.5 CreditsDocument43 paginiElectrical Engineering BA (B), Analog Electronics, ET065G 6 Credits ET064G 7.5 Creditsdev-nullÎncă nu există evaluări

- Chapter 4Document36 paginiChapter 4Sumedh KakdeÎncă nu există evaluări

- Measuring Planck's Constant with LEDsDocument7 paginiMeasuring Planck's Constant with LEDsAngy100% (1)

- Effect of Speration in Modified BitumenDocument12 paginiEffect of Speration in Modified BitumenyadavameÎncă nu există evaluări

- Hiad 2Document15 paginiHiad 2Hrishikesh JoshiÎncă nu există evaluări

- Long Term Deflection in Concrete BeamsDocument6 paginiLong Term Deflection in Concrete BeamsRenganayagi BalajiÎncă nu există evaluări

- Airborne Wind Energy SystemDocument27 paginiAirborne Wind Energy SystemAbin BabyÎncă nu există evaluări

- Particle Size Analysis Using a HydrometerDocument13 paginiParticle Size Analysis Using a HydrometerShubhrajit MaitraÎncă nu există evaluări

- Design of A Digital Control System and Path Planning Module For The ED-7220C Robot ArmDocument66 paginiDesign of A Digital Control System and Path Planning Module For The ED-7220C Robot ArmTarek Bmr100% (3)

- Offshore Pipeline Hydraulic and Mechanical AnalysesDocument25 paginiOffshore Pipeline Hydraulic and Mechanical AnalysesEslam RedaÎncă nu există evaluări

- Engineering Structures: SciencedirectDocument12 paginiEngineering Structures: Sciencedirectyasemin bürüngüzÎncă nu există evaluări

- 1 s2.0 0304885395011137 MainDocument2 pagini1 s2.0 0304885395011137 MainAyush VermaÎncă nu există evaluări

- Virtual Work 3rd Year Structural EngineeringDocument129 paginiVirtual Work 3rd Year Structural EngineeringStefano Martin PorciunculaÎncă nu există evaluări

- LNG SamplingSystemDocument2 paginiLNG SamplingSystemGuillermo Lopez-FloresÎncă nu există evaluări

- Mapua Institute of Technology: Field Work 1 Pacing On Level GroundDocument7 paginiMapua Institute of Technology: Field Work 1 Pacing On Level GroundIan Ag-aDoctorÎncă nu există evaluări

- Samuel Glasstone - Thermodynamics For Chemists PDFDocument532 paginiSamuel Glasstone - Thermodynamics For Chemists PDFRimmon Singh100% (2)

- A2 Nuclear Models LiqDrop FermiGasDocument19 paginiA2 Nuclear Models LiqDrop FermiGasAbdul RehmanÎncă nu există evaluări

- Ricapito-1 PbLi-T DatabaseDocument16 paginiRicapito-1 PbLi-T DatabaseSasa DjordjevicÎncă nu există evaluări