Documente Academic

Documente Profesional

Documente Cultură

An Analysis of Factors Affecting Particle-Size Distribution of Hydraulic Cements PDF

Încărcat de

saeedhoseiniDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

An Analysis of Factors Affecting Particle-Size Distribution of Hydraulic Cements PDF

Încărcat de

saeedhoseiniDrepturi de autor:

Formate disponibile

Subhas G. Malghan ~ and Lin-Sien H.

L u m ~

An Analysis of Factors Affecting Particle-Size Distribution of

Hydraulic Cements

REFERENCE: Malghan, S. G. and Lum, L.-S. H., "An Analysis of

Factors Affecting Particle-Size Distribution of Hydraulic Cements,"

Cement, Concrete, and Aggregates, CCAGDP, Vol. 13, No. 2, Winter

1991, pp. 115-120.

ABSTRACT: Particle-size distribution of hydraulic cements plays an

indispensable role in controlling the product quality and maintaining

reliable performance in end applications. Selection of particle-size

measurement methods is becoming increasingly complex due to the

availability of a variety of instruments based on different measurement principles. This paper discusses the primary criteria to be met

by a particle-size distribution analyzer for applications in hydraulic

cement characterization. Among the several methods available for

measuring the particle-size distribution, a light diffraction technique

was utilized to examine the effect of dispersion solvents on the resulting size distribution. Distilled water, distilled water containing a

polyacrylate surfactant, isopropyl alcohol, and a commercially available organic surfactant were used as dispersion solvents. The resulting

data are analyzed with respect to variations due to the dispersion

solvents and factors responsible for the observed variations.

KEY WORDS: particle-size distribution, hydraulic cements, dispersion in solvents, methods of size analysis, light scattering, instrument

selection, sample preparation

More than one property of hydraulic cement is relevant in

defining its characteristics. Many of these properties are related

to some of the more fundamental measurements of particles such

as mean size, size distribution, shape, concentration and form

of impurities, and surface chemical composition. The measurement of particle-size distribution constitutes one of the most

important aspects of hydraulic cement characterization because

particle size affects homogeneity, settling time, and strefigth of

the final product. Therefore, size distribution of the cement particulates can be obtained either for product quality evaluation

or for on-line measurement in process control.

In recent years, the availability of particle-size measurement

systems has increased markedly due to application of different

physical principles. The range of particle-size measurement covered by each instrument has also broadened. Some of the driving

forces for the availability of a large number of systems are: increased recognition of a need for measurement of particle-size

distribution, emphasis on quality control and reliability, and a

need for overall manufacturing cost reduction.

In response to these technical and market-driven forces, numerous particle-size measurement systems have been developed.

This paper discusses steps involved in the particle-size measurement, describes a classification of measurement methods, and

outlines criteria for selection of measurement systems. In addition, results are given for the measurement of particle-size distribution of a typical hydraulic cement in aqueous and nonaqueous liquid environment. A light diffraction technique was

used in these studies since it is not affected by density differences

of the particles.

Steps Involved in Particle-Size Analysis

Some of the requirements of the size analysis are to obtain

data in similar conditions to that existing in the process or to

meet technical specifications of the cement. This necessitates

obtaining a representative sample from a bulk lot. The second

requirement is the dispersion of particles in a chosen solvent so

that true particle size (as determined by scanning electron or

optical microscopy) is determined. Dry techniques do not require

the use of solvents for dispersion. However, as the mean particle

size of the hydraulic cement becomes smaller, dispersion-related

errors increase. For cements of particles sizes in the 1 to 100Ixm range, wet techniques are generally preferred. The third

requirement in the particle-size measurement is the appropriate

use of standard materials and procedures for material and instrument calibration. Each instrument should be checked for

calibration errors using the appropriate standard materials. The

steps involved [1] in the particle-size measurement are shown

schematically in Fig. 1. The overall measurement error is a function of the error associated with the individual steps. For hydraulic cements, errors due to chemical aspects of dispersion and

due to sampling are expected to dominate [].

Selection Criteria and Types of PSD Measurement Techniques

Selection of a particular technique for size distribution measurement is dependent on several criteria [-4]:

1. Accuracy of measurement (systematic error).

2. Reproducibility and repeatability of measurement (random

error).

3. Chemical reaction of particles with liquid.

4. Size range of application.

5. Time required for measurement.

6. Skill level of operator.

7. Cost of instrument.

Accurate measurement of particle-size distribution requires

the development of improved techniques of sample preparation

and associated measurement techniques. Systematic errors can

be minimized by enhanced precision (agreement within a set of

observations obtained as directed in a method) and repeatability

~Group leader, Ceramics Division, and chemical engineer, respectively, National Institute of Standards and Technology, Gaithersburg,

MD.

1991 by the American Society for Testing and Materials

115

This standard is for EDUCATIONAL USE ONLY.

116

CEMENT,CONCRETE, AND AGGREGATES

I Homogenization of Cement

I

I Sampllngfrom a LargeLot I

1

Preparationand

Dispersion ]

[ CalibratlonofInstrument]

l

1.-=-= I

I

Interpretationand

Conversion of Data

FIG. 1--Schematicofstepsinvolved m the measurement Qfpanic~size d~tribution.

(comparison of data obtained in a single laboratory and technique). However, reproducibility is totally dependent on precision involving comparison between laboratories and/or between

different techniques. Accuracy of the technique is enhanced when

the degree of agreement between the true and average of many

observed values increases.

Since hydraulic cements react with aqueous environment, other

solvents, especially organic solvents, can be used. However, for

ease of handling and cost effectiveness, the use of water-based

dispersants is desirable. Dispersion of cement particles in aqueous

environment can be carried out in the presence of low-molecularweight (5000 to 10 000) polyacrylates, which provide steric stabilization [5] at high pH. Examples of organic dispersants are

alcohols and commercially available mineral oil-based solvents.

The cost of the instrument, the time requirement for analysis,

and the skill level of the operator, etc, are some of the external

factors which influence the decision on the selection of instruments. The overall cost of analysis should also include those due

to the instruments, dispersion solvents, and cement samples.

When extensive cleaning between the runs is necessary, the overall cost increases. The time requirement for analysis can range

from 5 rain to several hours depending on the particle-size distribution of a specific material, instrument principle, and dispersion preparation. Instruments based on light scattering offer

high speed of operation. The selection of these instruments is

dependent on the skill level of the operator (e.g., production

environment versus research laboratory), In most cases, a reasonably well-trained operator is required.

Therefore, the question of which technique/instrument to select for a given application leads to the analysis of factors affecting particle-size distribution and specific requirements of the

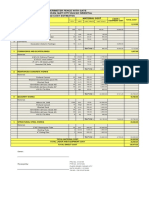

process. The myriad of analysis techniques, measurement parameters, and the nominal range of application of these techniques are broadly grouped in Table 1.

Wet Versus Dry Methods

The potential for determining the particle-size distribution accurately depends on the ease with which the cement particles

can be dispersed. As the particles become smaller their tendency

to adhere to each other increases due to van der Waals and

coulombic attractive (between chemically dissimilar particles)

forces. Hence, in a dry mode of particle-size measurement, agglomeration or the tendency of fine particles to stick to large

ones cannot be easily controlled. Therefore, accurate and reproducible size distribution measurement may not be obtained

by methods based on dry particulates. In addition, accuracy of

quantitative determination of the finest size fraction is diminished

in the case of dry powders.

Though wet techniques are preferred over dry techniques, they

suffer from interactions between the particles and surrounding

solvent. When the hydraulic cement comes in contact with a

solvent, the silicates and aluminates of lime are expected to

undergo surface dissolution and thereby contributes ionic species

to the adjoining bulk solution. The extent of surface dissolution

depends on a number of characteristics of which the chemical

composition of the cement and that of the solvent are the most

important, Water, being a polar solvent, induces higher surface

dissolution than organic solvents. The resulting electrical double

layer properties of a given cement particle are expected to be

different in water than in organic solvents. The electrical double

layer formation and the resulting dispersion properties are described elsewhere [6].

Size Distribution Measurement in Wet Dispersions

The primary goal of the measurement of particle-size distribution is to determine the absolute size distribution of the particles in the cement sample. Therefore, the formation of agglomerates should be prevented. The major steps involved in the

preparation of highly deagglomerated dispersions in aqueous and

nonaqueous solvents are shown in Fig. 2.

In the case of hydraulic cement, obtaining a representative

sample for size distribution measurement involves the use of a

spinning riffler [2]. Since cement is a highly heterogeneous maTABLE 1--Techniques of particle-size analysis and a typical

measurement parameter 1~-41

Techniques

Measurement

Diameter

Nominal Range,

Ixm

Image

Optical

Electron

Image

Mechanical sieving

Dry

Wet

Sieve/mechnical

Sedimentation

Elutriation

Gravity

Centrifugal

Dynamic/

Stoke's

1-100

0.1-130

0.05-100

Zone sensing

Optical

Resistivity

Geometric

0.01 - 500

0,05-500

Hydrodynamic

chromatography

Geometric

0.0t-1.0

Brownian motion

Geometric

Equivalent

spherical

0.01-I

Other

Gas adsorption

Gas permeability

Mercury intrusion

This standard is for EDUCATIONAL USE ONLY.

0,5-1000

0.01 - 10

>10

>2

0.05-50

O.1-40

O.1- 200

MALGHAN AND LUM ON HYDRAULIC CEMENTS

Dry Sample Preparation ]

[ Wetting and Mixingwlth a Surfaetant ]

!

-r.=-.-oo

I Measurementof Slze Distributlon 1

I

[ ,,Presentationof Data [

FIG. 2--Sequence of steps involved in the measurement of particlesize distribution by wetting the cement.

terial consisting of chemical components of various sizes and

densities, segregation is a serious issue. Therefore, care should

be exercised in the division of a bulk lot of cement sample into

subsamples. Each type of instrument requires a different weight

of the sample. Errors in sampling can be minimized by using the

largest possible subsample for analysis consistent with the sample

requirement. For fine-size cements, wet samples of higher than

the required particle concentration can be prepared, and the final

sample for size determination can be taken from this parent

sample. When dilution of the parent sample is involved, the

surfactant concentration in the final dispersion should be maintained at the same level as in the parent sample.

Wetting and mixing of the powder requires the selection of a

proper combination of the solvent and a surfactant. Organic or

inorganic surfactants [6] can be used; however, organic dispersants provide higher flexibility and more definite dispersion in

complex chemical systems. Water is a preferred solvent, though

it has certain disadvantages, such as surface dissolution, swelling,

and setting. In dilute suspensions (less than 1% by weight), the

effects of these interactions are considered to be minimum.

The selection of an appropriate dispersant requires the knowledge of surface charge and isoelectric point, pH~ep (the pH at

which the particles carry a net zero charge) of the cement particles in a given solvent. Since cement has a highly complex

chemical composition, accurate determination of pHie p by traditional electrokinetic techniques is somewhat tedious and difficult. However, based on relative weight ratios of silicates, aluminates, and other components, the pHiep can be estimated.

Also, experimental determination of the pH~ep is possible by the

application of a relatively new technique in which electrokinetic

sonic amplitude is measured [7] as a function of pH.

Ultrasonication of the slurry containing the cement particles

is an essential step in the preparation of well-dispersed suspensions. During ultrasonication, the particles are subjected to cavitation which dislodges loosely held particles [8]. Two primary

devices of ultrasonication are baths and probes. The probe is a

preferred device because it allows the application of a specific

quantity of ultrasonic power localized to the sample. Ultrasonication by the probe is completed in just a few minutes since the

power intensity is high.

The size distribution of a well-dispersed slurry is determined

by following the recommended procedure of a particular equipment. If the suspension has to be diluted, the solvent chemistry

117

should be the same as that used in the preparation of the parent

suspension. Care should be exercised to avoid settling of coarse

particles during sampling of the parent suspension.

Presentation of the data is dependent on the equipment. Most

often, the data are provided in the form of number or weight/

volume fraction. Direct conversion of data from the number to

weight/volume fraction is not possible without taking into account densities of different chemical components of the hydraulic

cement. Similarly, the size distribution data from gravitational

and centrifugal sedimentation devices is affected by different

densities of the constituting chemical components of the cement.

This is probably one of the main reasons for using the light

diffraction-based device in this study for the size measurement

of cement. Irrespective of the method of size measurement, the

resulting data can be analyzed by using a number of mathematical

models. The parameters of these models can serve the purpose

of comparing the characteristics of various cements.

Application of the Light-Scattering Method

The particle-size distribution of Portland Cement Proficiency

Sample 95 [9], distributed by the Cement and Concrete Reference Laboratory (CCRL), was determined using a light diffraction-based particle-size measurement system (Horiba LA-500)

[10]. CCRL is a research associate program at NIST sponsored

by ASTM [11]. The primary focus of this study was to examine

the influence of solvents in which the cement is dispersed. The

solvents examined were distilled water, distilled water containing

500 ppm polyacrylate (Darvan C-Vanderbilt Chemical Company) as a dispersant, isopropyl alcohol, and Sedisperse A-12 (a

surfactant manufactured by Micromeritics Corporation). 2

Dispersions of the cement were prepared by mixing cement

and the solvent in the weight ratio of 1 to 20, followed by ultrasonication (ultrasonic probe of 19 mm diameter, 30 W, total of

3 rain). The dispersion was ultrasonicated stepwise by applying

power for 1 min followed by 1 rain of cooling. This process was

repeated to give a total uttrasonication time of 3 rain. The dispersed powders were size analyzed using a procedure developed

for ceramic powders. Each measurement is an average of 25

scans, and triplicate data were obtained using three separate

subsamples from the primary dispersion. The data presented are

an average of the three measurements.

The size distribution data of the cement sample are presented

in Fig. 3. In general, all four dispersions show a bimodal size

distribution in which there is a small quantity of submicrometre

fraction and a large quantity of fraction whose ds,, is in the range

of 10 to 20 p.m. The dso is the size in micrometres through which

50% of the particles pass. The following general guideline was

used in the evaluation of the effectiveness of solvents and dispersants: the most suitable solvent-dispersant combination is one

that gives the finest size distribution. Based on this criterion,

isopropyl alcohol (IPA) appears to be the most suitable solvent.

On the other hand, Sedisperse A-12 is the least effective dispersant. Both water and water containing 500 ppm Darvan C

give similar size distributions in the fine-size range and a slightly

2Certain commercial equipment, vendors, instruments, or materials

are identified in this report in order to describe adequately experimental

requirements. In no case does such identification imply recommendation

or endorsement by the National Institute of Standards and Technology,

nor does it imply that the vendor, material, or equipment identified is

necessarily the best available for the purpose.

This standard is for EDUCATIONAL USE ONLY.

118

CEMENT,CONCRETE, AND AGGREGATES

11

10

Cement in H20

- - - Cement in H20 w / 5 0 0 ppm Darvan

9

rItc(3n

,m

0)

>

-)

c

Cement in IPA

-.-

Cement in A - 1 2

6

5

2

1

.'

.,;s"

0 ,-

1.0

0.1

10.0

100.0

Particle Diameter, microns

FIG. 3--Size distribution data of CCRL portland cement proficiency sample by using Horiba LA-500

device. The effect of four solvents is shown: (1) water; (2) water plus 500 ppm Darvan C; (3) 1PA; and

(4) Sedisperse A-12.

Another important feature of these data is that 90% of the

weight is finer than 19 ~m in the case of IPA. When using other

solvents, a coarser size distribution is observed. In addition, in

the case of IPA, more fines are observed at the finer end of size

distribution. A possible reason for IPA's superiority in this particular case is its inertness to surface reactivity with cement particles.

different dgo. The overall differences in the entire size range are

presented in Fig. 4. These data, in terms of cumulative size

fraction, show that IPA is by far a superior solvent. The dg0, ds0,

and d25 data summarized in Table 2 show specific differences in

the size distributions. The size distribution data are presented in

terms of weight fraction by assuming that density variation between the particles is negligible.

tO0

Cement in H20

90

-

Q)

.E

ta_

.Cn

, m

Q)

80

70

"'"

Cement in H20 w / 5 0 0 ppm Darvan

Cement in IPA

." t/~/t

b,'

---- Cement in A - 1 2

." t~,/

60

." .i/1P

50

:;7

>

-.a,.,a

/ ~

/ Y

..' / /

20

- f~

jQ

1"

10

O,

0.1

1

1

1.0

10.0

Porticle Diometer, microns

I

100.0

FIG. 4--Size distribution data of Fig. 3 presented in the form of cumulative weight fraction to highlight

differences in the entire size distribution,

This standard is for EDUCATIONAL USE ONLY.

MALGHAN AND LUM ON HYDRAULIC CEMENTS

TABLE 2--Effect of solvent on the dispersion of a cement sample

(CCRL Portland Cement Proficiency Sample 95) during particle-size

determination by Horiba LA-500.

Size in Micrometres Through

Which the Specific Weight

Percent Passes

IPA

d9o

dso

dz5

19.0

9.0

3.6

Water

26.0

12.0

7.5

Water + Darvan C

30.0

13.0

7.5

A-12

30.0

it.0

5.0

Bimodal distribution obtained for this sample could be the

result of the application of both ultrasonication energy and solvents for dispersion. Fine, submicrometre particles loosely adhered to coarse particles tend to dislodge by the application of

a combination of mechanical (ultrasonication promoting cavitation) and surface chemical (steric in the case of IPA and A12) dispersive forces. During ultrasonication, the particles are

subjected to cavitation which separates loosely held particles.

Once the particles are separated, they are kept dispersed by the

steric forces imparted by the adsorbed hydrocarbon molecules

of IPA. If the size distribution is carried out by dry sieving, the

bimodal distribution may not be observed in such detail.

Repeatability of the size distribution data is shown in Figs. 5

and 6 for IPA and Sedisperse A-12, respectively. These data

show that, irrespective of the solvent used, the repeatability is

excellent in the case of fine-size fraction (<1.0 ~m). However,

there is a slightly larger variation at the coarse-size fraction when

using IPA; whereas, for Sedisperse A-12, the variation is neg-

ligible. Since the final selection of a solvent-dispersant should

include the evaluation of both accuracy and repeatability, a thorough evaluation of those factors is required in a round-robin

characterization program.

Summary and Conclusions

Major steps involved in the measurement of particle-size distribution are sampling and sample preparation (including dispersion). Errors in these steps are often responsible for lack of

repeatability and reproducibility. A large number of systems are

available that provide data over a wide range of size distributions.

The selection of instruments for a given application depends on

a number of criteria. In recent years, systems based on lightscattering principles are widely used for particulate systems.

Dispersion of hydraulic cement particles in a suitable solvent

is an excellent way to ensure the determination of accurate size

distribution. Selection of an appropriate level and type of ultrasonication and dispersion parameters is the key factor in obtaining near-true size distribution data. The selection of solvents and

dispersants for hydraulic cements can be systematized if surface

charge and pHi~p data are available. In the absence of such data,

four solvents were evaluated by using the CCRL portland cement

proficiency sample. The size distribution data from a light-scattering device indicated that the cement sample has a bimodal

size distribution irrespective of the sotvent-dispersant composition. However, the data from isopropyl alcohol showed that the

overall size distribution was finer. Independent verification of

these size distribution data with those from scanning electron

microscopy is required to test their validity. A slight variation

was observed at the peak of the coarse end of the PSD in the

replicate tests using IPA. In the case of Sedisperse A-12, this

type of variation was negligible.

CEMENT IN IPA

1

0

Sample I

9

C

cD

I,

cljn

{D

Sample

--'- S a m p l e 3

6

,5

.//

>

-

0

O.

1.0

119

'ii,

10.0

100.0

Particle Diameter, microns

FIG. 5--Repeatability of size distribution data by using Horiba LA-500 for cement in 1PA.

This standard is for EDUCATIONAL USE ONLY.

120

CEMENT, CONCRETE, AND AGGREGATES

CEMENT IN A - 1 2

11

10

Sample

- Sample

c-

- - . - S a m p l e .3

b..

o~

,!

f.

/Z

3~

"

>

-{3

c"

~

~

O.1

1.0

10.0

100.0

Porticle Diometer, microns

FIG. 6--Repeatability of size distribution data by using Horiba LA-500 for cement in Sedisperse A-12.

References

[1] Allen, T. and Davies, R., "Modern Aspects of Particle Size Analysis," Advances in Ceramics, Vol. 21: Ceramic Powder Science,

G. L. Messing et at., Eds., American Ceramic Society, pp. 721746.

[2] Allen, T., Particle Size Measurement, 3rd ed., Chapman and Hall,

New York, 1981.

[3] Modern Methods of Particle Size Analysis, H. G. Barth, Ed., Wiley

Interscience, New York, 1984.

[4] Pohl, M., "Selecting a Particle Size Analyzer: Factors to Consider,"

Powder and Bulk Engineering, Vol. 4, No. 2, February 1990, pp.

26-29.

[5] Napper, D. H., Polymeric Stabilization of Colloidal Dispersions,

Academic Press, Inc., London, 1983, pp. 18-30.

[6] Parfitt, G. D., Dispersion of Powders in Liquids, Chapters 1 and

2, Applied Science Publishers, 198t.

[7] Malghan, S. G. and Lum, L.-S., "'Factors Affecting Interface Properties of Silicon Nitride Powders in Aqueous Environment," in

Ceramic Powder Science, G. L. Messing, et al., Eds., American

Ceramic Society, September 1990.

[8] Anonymous, "Branson Sonifer," Bulletin 200-214-082, Branson Ultrasonics Corp., Danbury, CT, 1989.

[9] Samples obtained from Pielert, J. H., Cement and Concrete Reference Laboratory, Building Materials Division, NIST, July 1990.

[10] Anonymous, "Horiba LA-500 Laser Diffraction Particle Size Analyzer," Bulletin HRE-3610B, Kyoto, Japan, January 1990.

[11] Pielert, J. H., "Construction Materials Reference Laboratories at

NIST," ASTM Standardization News, December 1989, pp. 40-44.

This standard is for EDUCATIONAL USE ONLY.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Application of Variography To The Control of Species in Material Process Streams: in An Iron Ore ProductDocument14 paginiApplication of Variography To The Control of Species in Material Process Streams: in An Iron Ore ProductsaeedhoseiniÎncă nu există evaluări

- Non-Portland Cement Activation of Blast Furnace SlagDocument69 paginiNon-Portland Cement Activation of Blast Furnace SlagsaeedhoseiniÎncă nu există evaluări

- Application of Variography To The Control of Species in Material Process Streams: in An Iron Ore ProductDocument14 paginiApplication of Variography To The Control of Species in Material Process Streams: in An Iron Ore ProductsaeedhoseiniÎncă nu există evaluări

- (Mathematics and Its Applications 38) L. Keviczky, M. Hilger, J. Kolostori (Auth.) - Mathematics and Control Engineering of Grinding Technology - Ball Mill Grinding-Springer Netherlands (1989) PDFDocument185 pagini(Mathematics and Its Applications 38) L. Keviczky, M. Hilger, J. Kolostori (Auth.) - Mathematics and Control Engineering of Grinding Technology - Ball Mill Grinding-Springer Netherlands (1989) PDFsaeedhoseiniÎncă nu există evaluări

- PHD Thesis Michal Hlobil 2016Document227 paginiPHD Thesis Michal Hlobil 2016saeedhoseiniÎncă nu există evaluări

- Early-Age Hydration Studies of Portland Cement PDFDocument172 paginiEarly-Age Hydration Studies of Portland Cement PDFsaeedhoseiniÎncă nu există evaluări

- Cirsys 19Document11 paginiCirsys 19saeedhoseiniÎncă nu există evaluări

- Reid, Henry - The Science and Art of The Manufacture of Portland Cement - With Observations On Some of Its Constructive applications-ICE Publishing (2011) PDFDocument448 paginiReid, Henry - The Science and Art of The Manufacture of Portland Cement - With Observations On Some of Its Constructive applications-ICE Publishing (2011) PDFsaeedhoseiniÎncă nu există evaluări

- Blast Furnace Slag As CementDocument5 paginiBlast Furnace Slag As CementsaeedhoseiniÎncă nu există evaluări

- Performance and Mechanism of A Multi-Functional Superplasticizer For ConcreteDocument6 paginiPerformance and Mechanism of A Multi-Functional Superplasticizer For ConcretesaeedhoseiniÎncă nu există evaluări

- Zhang ThesisDocument43 paginiZhang ThesissaeedhoseiniÎncă nu există evaluări

- Early-Age Hydration Studies of Portland Cement PDFDocument172 paginiEarly-Age Hydration Studies of Portland Cement PDFsaeedhoseiniÎncă nu există evaluări

- ASTM C-1356, Quantitative Determination of Phases in Portland Cement PDFDocument5 paginiASTM C-1356, Quantitative Determination of Phases in Portland Cement PDFsaeedhoseini100% (1)

- Compare Sizing Methods PDFDocument14 paginiCompare Sizing Methods PDFAnonymous NxpnI6jCÎncă nu există evaluări

- Cao Inv Low CemDocument79 paginiCao Inv Low CemTarek ChikerÎncă nu există evaluări

- Optimal Fluorite/gypsum Mineralizer Ratio in Portland Cement ClinkeringDocument12 paginiOptimal Fluorite/gypsum Mineralizer Ratio in Portland Cement ClinkeringsaeedhoseiniÎncă nu există evaluări

- Rebelo Jonathan 201406 MASc Thesis PDFDocument149 paginiRebelo Jonathan 201406 MASc Thesis PDFBartoFreitasÎncă nu există evaluări

- FineGrindingasEnablingTechnology TheIsaMillDocument21 paginiFineGrindingasEnablingTechnology TheIsaMillPVENARDÎncă nu există evaluări

- Optimal Fluorite/gypsum Mineralizer Ratio in Portland Cement ClinkeringDocument12 paginiOptimal Fluorite/gypsum Mineralizer Ratio in Portland Cement ClinkeringsaeedhoseiniÎncă nu există evaluări

- Rebelo Jonathan 201406 MASc Thesis PDFDocument149 paginiRebelo Jonathan 201406 MASc Thesis PDFBartoFreitasÎncă nu există evaluări

- 90 003Document8 pagini90 003saeedhoseiniÎncă nu există evaluări

- Index 12Document103 paginiIndex 12saeedhoseiniÎncă nu există evaluări

- Sayesh Nahaee PDFDocument4 paginiSayesh Nahaee PDFsaeedhoseiniÎncă nu există evaluări

- Optimization of The Preheater Cyclone Separators Used in The Cement IndustryDocument16 paginiOptimization of The Preheater Cyclone Separators Used in The Cement IndustrysaeedhoseiniÎncă nu există evaluări

- 5.ISCA-RJRS-2012-078 DoneDocument14 pagini5.ISCA-RJRS-2012-078 DonesaeedhoseiniÎncă nu există evaluări

- Concrete Strength DevelopmentDocument14 paginiConcrete Strength DevelopmentGabriel LimÎncă nu există evaluări

- Jeas 1017 6416Document8 paginiJeas 1017 6416saeedhoseiniÎncă nu există evaluări

- 908667Document7 pagini908667saeedhoseiniÎncă nu există evaluări

- Jumate Jaes Issue2 2011Document8 paginiJumate Jaes Issue2 2011saeedhoseiniÎncă nu există evaluări

- Circulation Phenomena in The Clinkerization ProcessDocument101 paginiCirculation Phenomena in The Clinkerization ProcessRaden Ayu Wilda AnggrainiÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Weft MasterDocument20 paginiWeft MasterZulfikar Ari PrkzÎncă nu există evaluări

- DD Folio p01170 CC TuxpanDocument102 paginiDD Folio p01170 CC TuxpanErnesto VazquezÎncă nu există evaluări

- Instruction: Check The Circle That Corresponds To Your AnswerDocument2 paginiInstruction: Check The Circle That Corresponds To Your AnswerXyrile InguilloÎncă nu există evaluări

- Msi 50003931-02 Web EPaper LowresPdf DownloadDocument36 paginiMsi 50003931-02 Web EPaper LowresPdf DownloadceljkoÎncă nu există evaluări

- Science Fair - ECOBRICKSDocument17 paginiScience Fair - ECOBRICKSBrian Voyd RebitoÎncă nu există evaluări

- Gear Data 20-6Document3 paginiGear Data 20-6Kallol MahalanabisÎncă nu există evaluări

- LS-DYNA Analysis For Structural Mechanics-Partial Note SetDocument30 paginiLS-DYNA Analysis For Structural Mechanics-Partial Note Setdr_kh_ahmedÎncă nu există evaluări

- Textile Finishing IntroductionDocument14 paginiTextile Finishing IntroductionSENTHIL KUMAR100% (6)

- Linear Drying Shrinkage of Concrete Masonry Units: Standard Test Method ForDocument6 paginiLinear Drying Shrinkage of Concrete Masonry Units: Standard Test Method ForSalim ChahidÎncă nu există evaluări

- TL - 52337 (2015)Document8 paginiTL - 52337 (2015)Chloe ReyesÎncă nu există evaluări

- DES-WA50 Manual V04VNAI0531Document24 paginiDES-WA50 Manual V04VNAI0531Distrimar LimitadaÎncă nu există evaluări

- Mitsubishi FV DrivelineDocument10 paginiMitsubishi FV Drivelinejs1290Încă nu există evaluări

- Tesa 60150 Adhesion Promoter Data SheetDocument1 paginăTesa 60150 Adhesion Promoter Data SheetBalagopal U RÎncă nu există evaluări

- Trusses II Queenpost TrussesDocument11 paginiTrusses II Queenpost TrussesCristian Morar-BolbaÎncă nu există evaluări

- HeaterDocument12 paginiHeaterErwin Paulian SihombingÎncă nu există evaluări

- Hitachi Eh4000acii EngelskDocument7 paginiHitachi Eh4000acii EngelskmohanÎncă nu există evaluări

- Plant Design of Acetone ProductionDocument20 paginiPlant Design of Acetone ProductionMary Grace VelitarioÎncă nu există evaluări

- Gerb Formulas PDFDocument4 paginiGerb Formulas PDFMuthu KumarÎncă nu există evaluări

- Laser Tattoo Paper ENG PDFDocument1 paginăLaser Tattoo Paper ENG PDFIgor Cece GigoÎncă nu există evaluări

- Chevron Lummus Global Ebullated Bed Bottom-Of-The-Barrel Hydroconversion (Lc-Fining) ProcessDocument18 paginiChevron Lummus Global Ebullated Bed Bottom-Of-The-Barrel Hydroconversion (Lc-Fining) ProcessBharavi K SÎncă nu există evaluări

- Accelerating Admixtures For ShotcreteDocument7 paginiAccelerating Admixtures For Shotcreteneen61Încă nu există evaluări

- Annex A Psi-Guidelines-For-Structural-Engineers-2Document4 paginiAnnex A Psi-Guidelines-For-Structural-Engineers-2dianfeng.envistaÎncă nu există evaluări

- Wire Mesh JISG3551 PDFDocument1 paginăWire Mesh JISG3551 PDFSelphi CristianiÎncă nu există evaluări

- 6421 FulltextDocument97 pagini6421 FulltextDaniel Camilo CanoÎncă nu există evaluări

- ASTM D4048 - 2002 - Detection of Copper Corrosion From Lubricating GreaseDocument4 paginiASTM D4048 - 2002 - Detection of Copper Corrosion From Lubricating GreaseConstantinos Christodoulou100% (1)

- EstimateDocument1 paginăEstimateAlemar Soriano MalintadÎncă nu există evaluări

- 1x50 RM 2xHSYRaY (CTS)Document2 pagini1x50 RM 2xHSYRaY (CTS)Rakib HasanÎncă nu există evaluări

- Tinosorb S Aqua OPPDocument1 paginăTinosorb S Aqua OPPPRINCESS ALYSSA PASAJOLÎncă nu există evaluări

- Farrat Plate BrochureDocument12 paginiFarrat Plate BrochureShaneLinehanÎncă nu există evaluări

- MTM 46 - CM - enDocument5 paginiMTM 46 - CM - enMiguel SeguraÎncă nu există evaluări