Documente Academic

Documente Profesional

Documente Cultură

Square Coils With High Dimensional Accuracy by 4-Roll Mill: New Products & Technologies

Încărcat de

ikramDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Square Coils With High Dimensional Accuracy by 4-Roll Mill: New Products & Technologies

Încărcat de

ikramDrepturi de autor:

Formate disponibile

New Products & Technologies

JFE TECHNICAL REPORT

No. 15 (May 2010)

Square Coils with High Dimensional Accuracy

by 4-Roll Mill

Some steel parts used in the electrical, automobile

or machine industry are made of steel bars with square

closed section, which are usually supplied by bright

steelmakers. The process ow is very complicated; it

consists of some drawing and annealing processes.

JFE Steel has developed a 4-roll mill in cooperation

with Sumitomo Heavy Industries, Ltd. since 1994. With

this roll, JFE Steel can produce a square coil with high

dimensional accuracy compared with the traditional

2-roll mill. Our customers, using our square coil, can

produce steel bars with square closed section by onetime drawing without annealing.

2. Square Coil with

High Dimensional Accuracy

2.1 Rolling Method

Square coils are produced by the 4-roll mill as

bar-in coils. The available sizes are from 12.7 to 27 mm

square.

The round bars are rolled by a 4-at-roll to form a

square coil as shown in Fig. 1.

The most difcult part of this process is how to con-

5.5

Radius on corner (mm)

1. Introduction

4.5

3.5

2.5

1.5

0.5

10

5

Fig. 2

15

20

25

30

Reduction of 4-roll flat pass (%)

35

Relation between reduction and radius on corner

trol the radius of the corners. As shown in Fig. 2, this

is related to the reduction ratio of the 4-roll mill. We

control the radius of the corners by selecting the most

suitable reduction ratio. Commercially, we can supply

square coils of 2.0-mm corner radius.

2.2 Actual Dimensions

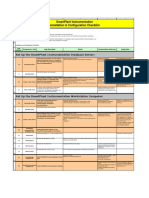

Table 1 compares the actual dimensions of square

coils produced by the traditional 2-roll mill and our

4-roll mill. The 4-roll mill shows better results than the

traditional method. Table 2 shows the range of regular

sizes of square section bars, and we can produce other

special sizes if required by customers. We can also produce coils with rectangular closed section as shown in

Table 1

Comparison of rolling results for square section coils

S: 0.1 mm

4 Roll

D: 0.2 mm

90

D1

2 Roll

Fig. 1

D2

R2*

R1*

Rolling method of square coils by 4 roll mill

Originally published in JFE GIHO No. 23 (Mar. 2009), p. 5354

36

D1: 0.2 mm

D2: 0.5 mm

R1R2

S1: 0.2 mm

*R: Radius on corner

90

Square Coils with High Dimensional Accuracy by 4-Roll Mill

Table 2

Size range of square section bars

(mm)

Size repertory

Square section bars

12.7

14

15.5

16

T

TW

Method of rolling rectangular section

Conventional

New Process

Round section bar

Square section bar

Shot blasting

19

19.3

20

21

22

24

25

27

3. Development of Customer Process

Fig. 3

18

Shot blasting

Figure 4 shows the process flow of one of our customers. They used to draw the conventional round coils

twice (rough and finish) then apply the annealing process. With our square coils, they can achieve the final

product by drawing only once.

4. Summary

JFE Steels West Japan Works produces wire rods

and bars, and has developed an original 4-roll mill

which can produce square coils with high dimensional

accuracy. With these coils, our customers can improve

their process flow and reduce production cost.

JFE Steel will continue to develop new products to

meet customers needs.

Drawing (rough)

Reference

Annealing

1) Sakurai, Tomoyasu; Sakamoto, Toshio; Takeda, Ryo. Development of High Dimensional Accuracy Smaller Diameter

Wire Rods and Square Coils Manufactured by 4-Roll Mill.

Kawasaki Steel Technical Report. 2002, no. 47, p. 4247.

Pickling

Finish drawing

Finish drawing

Fig. 4

Process comparison of square section bars

Fig. 3. In this case, the radius of corners is bigger than

that of coils with square section.

JFE TECHNICAL REPORT No. 15 (May 2010)

For Further Information, Please Contact:

Wire Rod & Bar Sec., Products Design & Quality Control for

Steel Products Dept.,

JFE Steel

Phone: (81)86-447-2721

Fax: (81)86-447-2723

URL: http://www.jfe-steel.co.jp/

37

S-ar putea să vă placă și

- Bulk Metalworking ProcessesDocument90 paginiBulk Metalworking ProcessesMuhammad Asif Khan0% (1)

- Rolling and The RingDocument35 paginiRolling and The RingzetseatÎncă nu există evaluări

- Cold FormingDocument6 paginiCold FormingMOHAMMED AMEEN MOHAMMED QAIDÎncă nu există evaluări

- Chapter 19-Bulk Deformation Processes IDocument67 paginiChapter 19-Bulk Deformation Processes IMuhammad Qasim QureshiÎncă nu există evaluări

- 4 Roll RollingDocument6 pagini4 Roll Rollingsatish_trivediÎncă nu există evaluări

- Casting, Forming, and ForgingDocument10 paginiCasting, Forming, and ForgingShe DilÎncă nu există evaluări

- Chapter 19-Bulk Deformation Processes IDocument67 paginiChapter 19-Bulk Deformation Processes IMohsin AliÎncă nu există evaluări

- Manufacturing Processes Lecture Four Bulk Deformation ProcessesDocument90 paginiManufacturing Processes Lecture Four Bulk Deformation ProcessesAws AbbasÎncă nu există evaluări

- Iswp Project Internship: Mentor: Mr. Vijayant Kumar Guide: Mr. Vinod KumarDocument34 paginiIswp Project Internship: Mentor: Mr. Vijayant Kumar Guide: Mr. Vinod KumarKunal VaidyaÎncă nu există evaluări

- European Patent ApplicationDocument18 paginiEuropean Patent ApplicationJared ReigleÎncă nu există evaluări

- ME 2252 MANUFACTURING TECHNOLOGY – II: Abrasive Processes and Gear CuttingDocument87 paginiME 2252 MANUFACTURING TECHNOLOGY – II: Abrasive Processes and Gear CuttingTariq Aziz100% (2)

- MEE 332 05 RollingDocument27 paginiMEE 332 05 RollingAhmed AbdulrhmanÎncă nu există evaluări

- Unit-3 (1-40)Document38 paginiUnit-3 (1-40)jasvinder singhÎncă nu există evaluări

- Catalogue NPPLDocument20 paginiCatalogue NPPLamey21rautÎncă nu există evaluări

- Introducing Cold Pilger Mill Technology - Tube and Pipe ProductionDocument4 paginiIntroducing Cold Pilger Mill Technology - Tube and Pipe Productionribeiro30Încă nu există evaluări

- L8 - Bulk Deformation ProcessingDocument70 paginiL8 - Bulk Deformation ProcessingAstha PantÎncă nu există evaluări

- Effect of Pass Schedule on Cross-Sectional Shapes of Circular Seamless Pipes Reshaped into Square ShapesDocument6 paginiEffect of Pass Schedule on Cross-Sectional Shapes of Circular Seamless Pipes Reshaped into Square ShapesAndiniPermanaÎncă nu există evaluări

- PrefaceDocument10 paginiPrefaceVũ Đức ThắngÎncă nu există evaluări

- Rolling and ExtrusionDocument55 paginiRolling and ExtrusionTefea Yemedye LijÎncă nu există evaluări

- Extrusión-Rolling and Forming ProcessDocument50 paginiExtrusión-Rolling and Forming Processquiron2010Încă nu există evaluări

- DryijftjvDocument35 paginiDryijftjv047 Karunakaran MÎncă nu există evaluări

- Theory of Metal MachiningDocument47 paginiTheory of Metal MachiningAragaw MuluÎncă nu există evaluări

- Drawing Process: Bulk Deformation Processes in MetalworkingDocument42 paginiDrawing Process: Bulk Deformation Processes in Metalworkingmarah nimerÎncă nu există evaluări

- Introduction To Manufacturing Systems Design and Analysis: Spring 2019 Isye 415Document41 paginiIntroduction To Manufacturing Systems Design and Analysis: Spring 2019 Isye 415VaikunthtendulkarÎncă nu există evaluări

- Chapter 4-Bulk Deformation Processes in Metal WorkingDocument81 paginiChapter 4-Bulk Deformation Processes in Metal WorkingSeab PisethÎncă nu există evaluări

- Ovality of Bearnings Rings PDFDocument14 paginiOvality of Bearnings Rings PDFДарко БожићÎncă nu există evaluări

- Investment Casting DataDocument28 paginiInvestment Casting DataN.Palaniappan100% (1)

- Din 1480 2005Document6 paginiDin 1480 2005PacoÎncă nu există evaluări

- ch20, 21, 24Document63 paginich20, 21, 24Anonymous JwnSUSÎncă nu există evaluări

- Uni LiftersDocument3 paginiUni LiftersgaliskribdÎncă nu există evaluări

- Milling MCDocument27 paginiMilling MCapi-19775783100% (1)

- MEE-332 - 05 RollingDocument27 paginiMEE-332 - 05 RollingAhmed AbdulrhmanÎncă nu există evaluări

- Wire Drawing: A Guide to the ProcessDocument7 paginiWire Drawing: A Guide to the ProcessUtkarsh0% (1)

- FormingDocument70 paginiFormingarya ladhaniÎncă nu există evaluări

- Introducing Cold Pilger Mill TechnologyDocument7 paginiIntroducing Cold Pilger Mill TechnologyTomás BonelloÎncă nu există evaluări

- Jaw In-Shear Type Jaw In-Shear TypeDocument6 paginiJaw In-Shear Type Jaw In-Shear TypeNayo Bravo SáezÎncă nu există evaluări

- Sheet Metal WorkingDocument10 paginiSheet Metal WorkingBhupendhar HarshawardanÎncă nu există evaluări

- Design of Fit Between Die and InsertDocument4 paginiDesign of Fit Between Die and InsertInnovative Research PublicationsÎncă nu există evaluări

- Machining Aluminum: Feeds, Speeds, Tooling TipsDocument12 paginiMachining Aluminum: Feeds, Speeds, Tooling Tipswardendavid5591100% (1)

- Steel Production Process at SMS-IIDocument22 paginiSteel Production Process at SMS-IIRahul PandeyÎncă nu există evaluări

- Production Process Divisions in a Steel PlantDocument11 paginiProduction Process Divisions in a Steel PlantNirmit GandhiÎncă nu există evaluări

- Ch09-2008.Abrasive N Finishing - Kalpakjian-. InaDocument35 paginiCh09-2008.Abrasive N Finishing - Kalpakjian-. InaGilang HermawanÎncă nu există evaluări

- Manufacturing Week 2a - Rolling of MetalsDocument30 paginiManufacturing Week 2a - Rolling of MetalsKeefwat TawfeekÎncă nu există evaluări

- Rolling of Metals Process and Principles (With Diagram)Document11 paginiRolling of Metals Process and Principles (With Diagram)SUDIPTA BHATTACHARJEEÎncă nu există evaluări

- Iswp Project Internship: Mentor: Mr. Vijayant Kumar Guide: Mr. Vinod KumarDocument34 paginiIswp Project Internship: Mentor: Mr. Vijayant Kumar Guide: Mr. Vinod KumarKunal VaidyaÎncă nu există evaluări

- Manufacturing of Dish End PDFDocument48 paginiManufacturing of Dish End PDFYogi YuganÎncă nu există evaluări

- Manufacturing Process of Steam Turbine BladesDocument34 paginiManufacturing Process of Steam Turbine BladesThinesh Rau KrishnamurtyÎncă nu există evaluări

- MFG Pro 1 (1) - 2Document25 paginiMFG Pro 1 (1) - 2Uzair AzziÎncă nu există evaluări

- NTK General MillingDocument14 paginiNTK General Millingswathi_ipeÎncă nu există evaluări

- Die CastingDocument11 paginiDie CastingJimmy Clavel100% (1)

- Abrasive Machining and Finishing OperationsDocument53 paginiAbrasive Machining and Finishing OperationssengcanÎncă nu există evaluări

- Magnetic Chuck AllDocument32 paginiMagnetic Chuck AllAmit SardaÎncă nu există evaluări

- Sheet Cutting PDFDocument10 paginiSheet Cutting PDFkolla satishÎncă nu există evaluări

- Practical Casting - A Studio ReferenceDocument3 paginiPractical Casting - A Studio ReferencebobakerÎncă nu există evaluări

- Aritco Home Lifts 2014 DEC en LDocument52 paginiAritco Home Lifts 2014 DEC en LBuzaareÎncă nu există evaluări

- Culata JD 6466Document4 paginiCulata JD 6466TECNOTRAC AldanaÎncă nu există evaluări

- Temporary Revision 12 053: Aircraft Maintenance ManualDocument26 paginiTemporary Revision 12 053: Aircraft Maintenance ManualKentÎncă nu există evaluări

- C Programming: Charudatt KadolkarDocument34 paginiC Programming: Charudatt KadolkarDhiliban SwaminathanÎncă nu există evaluări

- Clarion Technologies: at A GlanceDocument7 paginiClarion Technologies: at A GlanceChetan PrasadÎncă nu există evaluări

- SmartPlant Instrumentation installation checklistDocument2 paginiSmartPlant Instrumentation installation checklistmnoormohamed82Încă nu există evaluări

- Workman GTX: Utility VehicleDocument36 paginiWorkman GTX: Utility VehicleDaniel Carrillo BarriosÎncă nu există evaluări

- Manual em Portugues DGX230Document120 paginiManual em Portugues DGX230Agosthis0% (1)

- 218477these Stufy of An in Vehicule Infotainement SystemDocument79 pagini218477these Stufy of An in Vehicule Infotainement SystemKhaled GharbiÎncă nu există evaluări

- PDF Ebook Pickle Things by Marc Brown Download BookDocument5 paginiPDF Ebook Pickle Things by Marc Brown Download BookCorissÎncă nu există evaluări

- Certification Authorities Software Team (CAST) Cast 10Document8 paginiCertification Authorities Software Team (CAST) Cast 10Anastasia SuckallahÎncă nu există evaluări

- Floor ManualDocument35 paginiFloor ManualGihan ChathurangaÎncă nu există evaluări

- DYNAenergetics 2.875 PA Auto-Vent Firing Head Field Assembly ProcedureDocument7 paginiDYNAenergetics 2.875 PA Auto-Vent Firing Head Field Assembly ProceduremahsaÎncă nu există evaluări

- FREE UX Books @UXlinksDocument4 paginiFREE UX Books @UXlinksSyaifudin MashuriÎncă nu există evaluări

- Abrasive Cleaning SystemDocument4 paginiAbrasive Cleaning SystemSulfikar SalimÎncă nu există evaluări

- Cyclopedia of Architecture Carpentry & Building Vol VIIIDocument422 paginiCyclopedia of Architecture Carpentry & Building Vol VIIIbootsola100% (2)

- Aircraft Maintanence Engg Book 9A TypeDocument139 paginiAircraft Maintanence Engg Book 9A TypeimmortalforeverÎncă nu există evaluări

- Installation Guide: For Packetfence Version 8.3.0Document270 paginiInstallation Guide: For Packetfence Version 8.3.0Ferjani TarekÎncă nu există evaluări

- Week 6: Practice Challenge 1 - Charts: InstructionsDocument7 paginiWeek 6: Practice Challenge 1 - Charts: InstructionskiranÎncă nu există evaluări

- Restaurant Pub VIP Lounge Camp Pune SaleDocument4 paginiRestaurant Pub VIP Lounge Camp Pune SaleChandrashekhar Naikare0% (1)

- CTLS Interface Developers GuideDocument242 paginiCTLS Interface Developers GuideLucas Pires SimãoÎncă nu există evaluări

- Formalin MsdsDocument10 paginiFormalin MsdsMank WidhieÎncă nu există evaluări

- J) Method Statement For Discharge of Stormwater and Rain WaterDocument4 paginiJ) Method Statement For Discharge of Stormwater and Rain WaterLee Tin YanÎncă nu există evaluări

- Computed TomographyDocument94 paginiComputed TomographyBMT100% (3)

- L .. Eee - .: Distribution Voltage RegulatorsDocument11 paginiL .. Eee - .: Distribution Voltage RegulatorsSirajulÎncă nu există evaluări

- 6.unit I 2 MarksDocument3 pagini6.unit I 2 MarksprasanthprpÎncă nu există evaluări

- Fluid Mechanics-I: by Dr. Fayaz A Khan Assistant Professor, UET Bannu CampusDocument22 paginiFluid Mechanics-I: by Dr. Fayaz A Khan Assistant Professor, UET Bannu CampusAsim WazirÎncă nu există evaluări

- Manual, contact info and schematic for GSM moduleDocument10 paginiManual, contact info and schematic for GSM modulethaiÎncă nu există evaluări

- Feature Setup Description: Software Basic Data Mcs - TCBCDocument77 paginiFeature Setup Description: Software Basic Data Mcs - TCBCAlexis MauricioÎncă nu există evaluări

- 3.B Coating Maintenance CHEMCODocument51 pagini3.B Coating Maintenance CHEMCOMeleti Meleti MeletiouÎncă nu există evaluări