Documente Academic

Documente Profesional

Documente Cultură

Tire & Wheel

Încărcat de

Eko SunaryoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tire & Wheel

Încărcat de

Eko SunaryoDrepturi de autor:

Formate disponibile

SERVICE DATA

SERVICE DATA

SPECIFICATIONS

Item

Vehicle model

Tire

Size

Wheel

Construction

Size

Mounting

CKB-CT

CWB-KT

Series

CKC, CWC

Series

CWA

Series

20 x 7.00T-162

10.00-20-14 PR

10

20 x 7.50V-165

20 x 7.00T-162

10.00-20-16 PR

8, 10

8, 10

8, 10

20 x 7.50V-165

20 x 7.50V-165

11.00-20-14 PR

B

20 x 7.50 (TRILEX)

20 x 7.50V-165

11.00-20-16 PR

B

20 x 7.50 (TRILEX)

20 x 8.50V-180

12.00-20-16 PR

10

10

20 x 8.50 (TRILEX)

12.00-20-18 PR

20 x 8.50V-180

CKA, CKB,

CDA, CGB,

CWB

Series

22.5 x 7.50-162

12R22.5-14 PR

22.5 x 8.25-165

8, 10

12R22.5-16 PR

22.5 x 8.25-165

8, 10

8, 10

8, 10

8, 10

11R22.5-14 PR

11R22.5-16 PR

8, 10

22.5 x 8.25-165

22.5 x 7.50-162

8, 10

22.5 x 8.25-165

20 x 7.00T-162

10.00R-20-14 PR

R

20 x 7.50V-165

20 x 7.00T-162

10.00R-20-16 PR

8, 10

20 x 7.50V-165

20 x 7.50V-165

11.00R-20-14 PR

R

20 x 7.50 (TRILEX)

20 x 7.50V-165

11.00R-20-16 PR

R

20 x 7.50 (TRILEX)

20 x 8.50V-180

12.00R-20-16 PR

10

10

10

20 x 8.50 (TRILEX)

20 x 8.50V-180

12.00R-20-18 PR

R

20 x 8.50 (TRILEX)

12.00R-24-18 PR

24 x 8.50 (TRILEX)

NOTE

+ Tire construction m: Tubeless, B: Bias, R: Radial

+ Wheel mounting 8: 8 Studs, 10: 10 Studs

TW-1-1

SERVICE DATA

Please note that the sizes in the below chart are examples of

typical tire sizes and do not necessarily apply to your vehicle.

DJ-053E

TIRE SIZE DESIGNATION

Truck type radial

10.00

20

G (14PR)

Load range

Rim diameter in inches

Indicates radial construction

Nominal section width in inches

11

22.5

L (16PR)

Load range

Rim diameter in inches

Indicates radial construction

Nominal section width in inches

Truck type bias

7.50 -

20

F (12PR)

Load range

Rim diameter in inches

Nominal section width in inches

WHEEL SIZE DESIGNATION

22.5 x

6.75 -

152

Offset (in mm)

Rim width (in inches)

Rim diameter (in inches)

TW-1-2

SERVICE DATA

SERVICE DATA

TIRE SIZES AND TIRE INFLATION PRESSURES

Standard air pressure

Tire size designation

638

{6.50, 92}

662

{6.75, 96}

687

{7.00, 100}

711

{7.25, 103}

736

{7.50, 107}

760

{7.75, 110}

785

{8.00, 114}

10.00-20-14 PR

10.00-20-16 PR

+

11.00-20-14 PR

11.00-20-16 PR

12.00-20-16 PR

kPa {kgf/cm2, psi}

12.00-20-18 PR

11R22.5-14 PR

+

+

11R22.5-16 PR

+

12R22.5-14 PR

12R22.5-16 PR

+

10.00R-20-14 PR

10.00R-20-16 PR

+

11.00R-20-14 PR

11.00R-20-16 PR

+

12.00R-20-16 PR

12.00R-20-18 PR

+

12.00R-24-18 PR

TW-1-3

SERVICE DATA

WHEEL SERVICE DATA

Unit: mm (in)

Maintenance

standard

Service

limit

Horizontal

2.0 (0.079)

Vertical

1.8 (0.071)

Horizontal

1.8 (0.071)

Vertical

1.8 (0.071)

Horizontal

2.4 (0.094)

Vertical

2.4 (0.094)

Horizontal

2.0 (0.079)

Vertical

1.8 (0.071)

2-7

(0.08 0.28)

Item

20 x 7.50V-165

20 x 7.00T-162

Type I

Disc wheel

runout

ETW001A

20 x 8.50V-180

22.5 x 7.50-162

22.5 x 8.25-165

Side ring end clearance

Type II

NOTE

+ Disc wheel sectional area and measuring points differ

between type 1 and type 2. (Refer to the figure.)

TIGHTENING TORQUE

Unit: Nm {kgfzm, ftzlbf}

Item

Tightening torque

SAE type

412 - 481 {42 - 49, 304 - 354}

ISO type

588 - 637 {60 - 65, 434 - 470}

Wheel nut

TW-1-4

ETW002A

DISASSEMBLY

DISASSEMBLY

REMOVAL

<CONVENTIONAL WHEEL TYPE>

Key point of removal

1. Apply the parking brake and chock all tires except the one to be

removed.

2. Be careful as the wheel nuts differ between the SAE type and

ISO type.

SAE type

The wheel nuts on the right side of the vehicle have right-handed

threading, the left side wheel nuts have left-handed threading.

ETW015A

ETW016A

ISO type

Type I (Outboard type)

The left and right wheel nuts have the same right-hand thread

designs.

ETW017A

ETW018A

TW-2-1

DISASSEMBLY

+ Changing wheel types

WARNING

Use only the same type and style wheels and mounting

hardware to replace original parts. Do not use unauthorized

wheel components. Failure to do so may result in an

assembly which does not fit together properly resulting in

premature wheel or fastener failures.

+ Fasteners like bolts and nuts removed from the vehicle

should be re-used in the same spot whenever possible.

If not possible, new fasteners selected must match those

replaced and obtain good metal-to-metal contact. It is

imperative to identify and use only those fasteners designated for use with the respective vehicle being serviced. Mismatched or incorrect fasteners can result in

vehicle damage or possible personal injury.

+ Do not attempt to mix ball seat wheels or fasteners with

flange nut wheels or fasteners.

+ Do not change from aluminum wheels to steel or vice

versa without changing the mounting hardware. In the

case of some flange nut assemblies, the hub must be

changed also.

NOTE

+ Be careful not to damage the threads of the hub bolts with

the bolt holes in the disc wheel when removing wheel.

DISASSEMBLY

<CONVENTIONAL WHEEL, WITH TUBE TYPE>

Key point of disassembly

1. Carefully remove the tire valve core and release all air pressure

inside the tire. If the valve is obstructed while discharging air

pressure, use a thin wire to remove the foreign matter.

WARNING

+ The valve sometimes freezes because of high air pressure inside the tire. Do not put your face close to the

valve while discharging air pressure. Pieces of ice may

surge out, causing an injury.

NOTE

+ While removing the valve core, hold it with your fingers so

that it does not pop out.

TW-2-4

CTW1-001

DISASSEMBLY

2. Drive a bead hammer between the tire bead and rim flange until

the bead and flange separate completely.

3. Spread lubricant or soapy water on the tire bead and rim flange.

CTW1002A

4. Insert the lever into the end gap of the side ring. Push it down

to the point where the lever groove is visible.

ETW003A

5. Push the other lever into the lever groove. Turn the lever over

toward the wheel center by pivoting the lever so that the side

ring end surface is elevated.

CTW1004A

6. Insert the two levers between the side ring and rim alternately.

Gradually pry up the levers to remove the side ring.

NOTE

+ When the side ring comes off about half of the circumference, hold remaining, yet to be removed portion of the ring

with foot.

7. Install the cap on the valve and press-fit the valve stem into the

valve hole.

CTW1004C

8. Raise the tire and gradually and push the wheel center out

using foot.

NOTE

+ The wheel may suddenly come out from the tire. Be careful

not to allow the wheel to roll out.

CTW1006A

TW-2-5

DISASSEMBLY

9. Insert the lever between the bead and rim near the valve. Push

the rim out and remove the wheel.

NOTE

+ The wheel may suddenly come out from the tire. Be careful

not to allow the wheel to roll out.

10. Remove the flap and then pull the tube out.

CTW1006B

<CONVENTIONAL WHEEL, TUBELESS TYPE>

Key point of disassembly

1. Carefully remove the tire valve core and release all air pressure

inside the tire. If the valve is obstructed while discharging air

pressure, use a thin wire to remove the foreign matter.

WARNING

+ The valve sometimes freezes because of high air pressure inside the tire. Do not put your face close to the

valve while discharging air pressure. Pieces of ice may

surge out, causing an injury.

CTW1-001

NOTE

+ While removing the valve core, hold it with your fingers so

that it does not pop out.

2. Drive a bead hammer between the tire bead and rim flange until

the bead and flange separate completely.

CAUTION

+ In aluminum wheels, the lever should be used carefully so

as not to damage the wheel. Never use a bead hammer.

3. Spread lubricant or soapy water on the tire bead and rim flange.

ETW004A

ETW005A

TW-2-6

DISASSEMBLY

4. Insert the curved end of both levers at point 25 cm (9.8 in) from

the valve on both sides.

Insert both levers, and step on the tire opposite the valve to

direct the first bead into the well.

CTW1-003

5. Hold one lever in position with your foot and lean the second

lever toward the center of the wheel.

Progressively work the first bead off the rim.

WARNING

+ Be careful when pulling the lever toward the center of the

wheel. The tip of the lever may slip out from the tire.

NOTE

+ Take off about 1/2 the circumference. The rest comes off

easily.

CTW1-004

6. Stand the tire assembly up in the vertical position. Insert the

straight end of the lever between the tire bead and back rim

flange. Lean the tire assembly slowly toward the lever.

CTW1-005

7. Push the lever to raise the wheel and insert another lever in

close vicinity to further raise the wheel by providing a rocking or

bouncing action to pry the rim out of the assembly.

NOTE

+ Take off about 1/3 the circumference. The rest comes off

easily.

CTW1-006

TW-2-7

INSPECTION

INSPECTION

TIRE

New tire

There are many types of tire construction, tread patterns and tire

sizes. It is very important to select the best one for the particular

vehicle (including rims) and for the conditions it will be used in.

NOTE

+ Never mix the following tires on one vehicle.

+ Different kinds of tires (bias, radial, etc.)

+ Different sizes

+ Normal tires, snow tire, snow tire with spikes

+ Mount snow tires on all wheels on snowy or icy roads.

Used tire

Check for abnormalities as instructed in section MA. Replace if

faulty.

RIM AND DISC WHEEL

Check for cracks or damage. If any of the following faults are

noticed, replace the rim and disc wheel as a unit.

CTW1-011

TW-3-1

INSPECTION

Cracked bead seat

If left unheeded, the cracked area will increase with operation,

resulting in damage to the tire. This is very dangerous.

Deformed flange

A deformed flange results from heating due to partial movement of

the tire or trapped foreign matter.

Corroded bead seat

Excessive corrosion reduces the thickness of the seat, resulting in

a decrease in strength and safety.

Damaged seating surface of nuts

Fatigue or cracks will result with operation if the nut is not tightened

to the specified torque.

Cracks on designed holes

This is due to overloading. If left unheeded, the cracked area will

enlarge resulting in breakage.

TW-3-2

REASSEMBLY

REASSEMBLY

REASSEMBLY

<CONVENTIONAL WHEEL, WITH TUBE TYPE>

Key point of reassembly

1. To prevent friction between the tire inside and tube, and the

tube and flap, coat each part with talc powder.

ETW006A

2. Blow a small amount of air into the tube and insert the tube into

the tire.

NOTE

+ Be sure to blow air with the valve core installed.

ETW007A

3. Insert the valve stem into the valve hole in the flap. Sequentially

insert the flap uniformly.

NOTE

+ Be careful not to allow the upper and lower ends of the flap

to bend inside the tire.

ETW008A

4. Place the wheel on a level surface and insert the valve stem

into the valve hole.

ETW009A

5. Fit the tire in the wheel by slowly sliding the tire around the

wheel. Then, rotate the wheel so that the valve is located in the

center of the rim hole.

6. Press-fit the side ring into the rim groove.

NOTE

+ Locate the end gap of the side ring 90 from the valve so it

is evenly spaced between the disc ornamental holes.

ETW010A

TW-4-1

REASSEMBLY

INSTALLATION

<CONVENTIONAL WHEEL TYPE>

Key point of installation

+ Procedures for mounting tires differ between the SAE type and

ISO type. When installing tires, be sure to observe precautions

for each tire.

SAE type

1. Clean the wheel mounting surfaces with a wire brush and clean

waste cloth. Dirty mounting surfaces may cause the wheel nuts

to loosen.

2. Apply a coat of engine or gear oil to the threaded portions of the

hub bolts and wheel nuts only. Do not use molybdenum grease

for this purpose.

3. The wheel nuts on the right side of the vehicle have righthanded threading; the left side wheel nuts have left-handed

threading.

4. Tighten the wheel nuts in the sequence shown in the figure little

by little to the specified torque.

: 412 - 481 Nm {42 - 49 kgfzm, 304 - 354 ftzlbf}

NOTE

+ Do not tighten the wheel nuts excessively.

+ After removing only the rear outer wheel, retighten the

inner wheel nuts to the specified torque setting.

ETW020A

ETW031A

ISO type

1. The left and right wheel nuts have the same right-hand thread

designs.

2. Clean the wheel mounting surfaces with a wire brush and a

clean waste cloth. Dirty mounting surfaces may cause the

wheel nuts to loosen.

3. Remove any foreign material from the tapered portion between

the wheel nuts and washers using compressed air so that the

wheel nuts and washers rotate smoothly. If they do not rotate

smoothly, replace them with new ones.

DK-105E

TW-4-5

S-ar putea să vă placă și

- 8 DigitalDocument15 pagini8 DigitalEko SunaryoÎncă nu există evaluări

- 3.3 E-OLSS Control ValveDocument12 pagini3.3 E-OLSS Control ValveEko Sunaryo92% (13)

- Bosch CRI Book PDFDocument61 paginiBosch CRI Book PDFEko Sunaryo100% (1)

- Bosch CRI BookDocument61 paginiBosch CRI BookEko Sunaryo100% (1)

- 3.2 E-OLSS PumpDocument19 pagini3.2 E-OLSS PumpEko Sunaryo92% (13)

- 3.4 E-OLSS Electronic ControlDocument12 pagini3.4 E-OLSS Electronic ControlEko Sunaryo67% (3)

- 170 EngineDocument37 pagini170 EngineWayz Cah LunggupzÎncă nu există evaluări

- Teori 7 C56 Sensor SharingDocument3 paginiTeori 7 C56 Sensor SharingEko SunaryoÎncă nu există evaluări

- Materi Air Conditioning (AC)Document56 paginiMateri Air Conditioning (AC)AbdullahkhadiqÎncă nu există evaluări

- HoseDocument55 paginiHoseEko SunaryoÎncă nu există evaluări

- Hydraulic CicuitDocument88 paginiHydraulic CicuitEko Sunaryo100% (2)

- 14MDocument6 pagini14MMinaSaeed100% (4)

- Electrical Circuit Diagram: CAB Specification D65EX-12 63403 and Up D65PX-12 63304 and UpDocument2 paginiElectrical Circuit Diagram: CAB Specification D65EX-12 63403 and Up D65PX-12 63304 and UpEko SunaryoÎncă nu există evaluări

- IeDocument42 paginiIeEko SunaryoÎncă nu există evaluări

- Diag BaranDocument37 paginiDiag Baranuser100% (6)

- Auxiliary Equipment: Service DataDocument5 paginiAuxiliary Equipment: Service DataEko SunaryoÎncă nu există evaluări

- 7MBDocument2 pagini7MBEko SunaryoÎncă nu există evaluări

- 14MDocument6 pagini14MMinaSaeed100% (4)

- Flip-Flop 1 (2156x1487x24b Jpeg)Document1 paginăFlip-Flop 1 (2156x1487x24b Jpeg)Eko SunaryoÎncă nu există evaluări

- DC GeneratorDocument16 paginiDC GeneratorEko SunaryoÎncă nu există evaluări

- Lubrication System: Service DataDocument11 paginiLubrication System: Service DataEko SunaryoÎncă nu există evaluări

- Maintenance Nissan CWBDocument13 paginiMaintenance Nissan CWBEko Sunaryo100% (1)

- Regulator For AltDocument14 paginiRegulator For AltEko SunaryoÎncă nu există evaluări

- Electrical System Nissan cwb45Document195 paginiElectrical System Nissan cwb45Eko Sunaryo97% (32)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Specification Jumbo Drill Sandvik DD311D-40Document4 paginiSpecification Jumbo Drill Sandvik DD311D-40Nathania Boas E SÎncă nu există evaluări

- SML Isuzu LimitedDocument20 paginiSML Isuzu LimitedASHA KAINDALÎncă nu există evaluări

- Testeo Alivio Levante.Document2 paginiTesteo Alivio Levante.PromochileÎncă nu există evaluări

- Resume UpdatedDocument1 paginăResume UpdatedJaneesh Pal SinghÎncă nu există evaluări

- Team-BHP PDI ChecklistDocument8 paginiTeam-BHP PDI Checklistsrini_brÎncă nu există evaluări

- SANY SAC 6000 600 TonsDocument25 paginiSANY SAC 6000 600 TonsLucio Camargo VicenteÎncă nu există evaluări

- Shimano Disk BrakeDocument1 paginăShimano Disk Brakehayleymorris24Încă nu există evaluări

- SSP 823603 3.2 - 3.6-FsiDocument72 paginiSSP 823603 3.2 - 3.6-Fsiaulin64_845645735Încă nu există evaluări

- Mack Euro4 GU Final ETM 2-13-11TOCDocument11 paginiMack Euro4 GU Final ETM 2-13-11TOCfabioÎncă nu există evaluări

- P Johnstone: Jackaroo TipsDocument5 paginiP Johnstone: Jackaroo TipsJimmy Brian KaifitiÎncă nu există evaluări

- MTU Friedrichshafen: MTU Project No. - Engine DataDocument12 paginiMTU Friedrichshafen: MTU Project No. - Engine DataJercy SanchezÎncă nu există evaluări

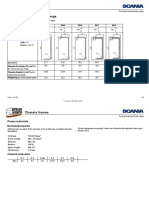

- Scania Chassis FramesDocument6 paginiScania Chassis Framesaamirmub100% (1)

- Stanadyne de Pump Timing InstructionsDocument1 paginăStanadyne de Pump Timing Instructionskonstantin chekan100% (1)

- Unit: Propeller Shaft and Types of JointsDocument7 paginiUnit: Propeller Shaft and Types of JointsMayur PanchalÎncă nu există evaluări

- Sebp6856 00 00 All PDFDocument538 paginiSebp6856 00 00 All PDFMiguel Angel Santos Pintado100% (1)

- VW DiagnosticsDocument23 paginiVW DiagnosticsVers Chalvers M100% (1)

- Apache 160 4V Special EditionDocument2 paginiApache 160 4V Special EditionYASHÎncă nu există evaluări

- Engine Series DEUTZ 2012: Service TrainingDocument72 paginiEngine Series DEUTZ 2012: Service TrainingRensuChawella100% (1)

- Scania Sops RedaktorDocument7 paginiScania Sops Redaktorscania100% (2)

- 12 MARINE Air CompressorDocument13 pagini12 MARINE Air CompressorTuhin HandaÎncă nu există evaluări

- Esquema Electrico Cargador Caterpillar 938g II PDFDocument32 paginiEsquema Electrico Cargador Caterpillar 938g II PDFDarwing A. RodriguesÎncă nu există evaluări

- Office of The Building OfficialDocument2 paginiOffice of The Building OfficialJanico Lanz BernalÎncă nu există evaluări

- Cable Caterpillar PDFDocument2 paginiCable Caterpillar PDFLhoussain Bourda100% (1)

- Parts List 350Document2 paginiParts List 350Johnary RicoÎncă nu există evaluări

- Volvo L180E Wheel Loader: Print SpecificationDocument2 paginiVolvo L180E Wheel Loader: Print Specificationامین پارساÎncă nu există evaluări

- 2020 Creta F 1.6 Mpi-M-TDocument1 pagină2020 Creta F 1.6 Mpi-M-TingenieriaelectronicÎncă nu există evaluări

- Renault Airbag PinoutsDocument11 paginiRenault Airbag PinoutsATMMOBILIS100% (3)

- Certification Report Ford EcoSport MH03BS6753 2412177Document7 paginiCertification Report Ford EcoSport MH03BS6753 2412177scsÎncă nu există evaluări

- Instruction Manual For Diesel Generator DOOSAN MAN DIESEL 5L23 30H 720RPMDocument1.058 paginiInstruction Manual For Diesel Generator DOOSAN MAN DIESEL 5L23 30H 720RPMdionpanag94% (16)

- P020E-Fuel Injector 5 Performance: Theory of OperationDocument2 paginiP020E-Fuel Injector 5 Performance: Theory of OperationWillie AustineÎncă nu există evaluări