Documente Academic

Documente Profesional

Documente Cultură

Kiln Etude Thermel

Încărcat de

Said EL FakkoussiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Kiln Etude Thermel

Încărcat de

Said EL FakkoussiDrepturi de autor:

Formate disponibile

Recent Advances in Finite Differences and Applied & Computational Mathematics

Thermal analysis of the rotary kiln through FEA

SUSANA ARAD

Computer, Informatics and Electrical Engineering Department

University of Petrosani

332006 Petrosani, 20 Universitatii str.

ROMANIA

susanaarad@yahoo.com, http://www.upet.ro

Abstract: - This paper aims at analyzing numerical heat transfer in kiln clinker production in cement factory

Deva, important processing equipment in the cement production. The importance of knowing this process aims

to rationalize the consumption of raw materials and energy but also to get high standard finished products. We

used QuickField software package Version 5.10.1 for analysis of thermal problems in a rotary kiln to obtain an

optimal and efficient sinterization process. In this study, our objectives are to predict the temperatures in the

inner surface/refractory and inner surface of bed before any variations in process parameters, to decrease the

errors arisen from the operators, to increase the efficiency and finally decrease the process cost also the

variation of inside temperature with flame temperature.

Key-Words: - FEA, modelling, heat transfer, rotary kiln, efficient operation, clinker.

impact on the environment which is why a lot of

investment projects headed in this direction.

Process automation and information technology

are industrial areas which offer the biggest and most

satisfying challenges in terms of combining

traditional engineering skills with technological

innovation [4].

The demands on cement industry in relation to

productivity, quality and price, means an ever

increasing need to improve the quality products, to

productivity increase improvement of products

quality, modernization of the technological flow and

environmental quality.

1 Introduction

Today, Portland cement is the most widely used

building material in the world with about 1.56

billion tones (1.72 billion tons) produced each year

(Cement Association of Canada, 2001). Global

economic situation sets more and more challenges

to cement manufacturers both in our country and

globally. Although the cement market in Romania

has reached a high level with annual an increase up

to 30%, the end of 2012 was faced with stagnation

or at most an increase of 1-2% and in 2013 most

likely cement market will record a standstill,

because of demand, but also due to rising prices. It

must be noted that the need to maintain producers

on the market is due to more and more discipline

regarding costs and optimizing them according tp

technological efficiency and rationalization of raw

materials and energy (Carpatcement Holding, 2013)

The main cement producers on the Romanian

market are: Carpatcement (Bicaz factories, Fieni

and Deva), Lafarge (Medgidia Hoghiz and Targu

Jiu) and Holcim (Turda and Alesd). Carpatcement

Holding hope for a rearrangement of the

macroeconomic situation of the country starting this

year and also for a market that depends on several

conditions so that construction work can be started

earlier than in 2012 (Carpatcement Holding, 2013).

The cement industry is actively engaged and

committed

to

sustainable

developmenta

philosophy that focuses on meeting our construction

needs today without depleting future resources.

Cement industry production process has a big

ISBN: 978-1-61804-184-5

2 State of Art

Portland cement clinker is produced from a mixture

of raw materials containing calcium, silicon,

aluminum, and iron as the main elements. The

mixture is heated in kilns that are long rotating steel

cylinders on an incline. The feed of a typical cement

kiln consists of limestone and other, mainly oxide

and silicate based material, which typically contain

calcium, magnesium and iron. The process goes

through the raw material grinding, blending,

precalcining, calcining (clinker formation), cooling

and grinding of final product. In the preheating

system, the raw material goes through preliminary

steps, where the calcination of CaCO 3 and

formation of calcium oxide takes place.

The material is fed from the top of the cyclone

and move downward in counter stream with gas

182

Recent Advances in Finite Differences and Applied & Computational Mathematics

monitoring using integrated systems there are many

objectives which can do the efficiency growth.

Using the PLCs and expert systems has been

brought forward to the board of the company,

managing to deploy an expert system. Thus the

technological process is carried out from the

command room using the visualisation system ECSNtech and the PLCs Allen Bradley (kiln and cooler)

and Siemens [12]. Through this system the attendant

can overlook the performance of the technological

process using the computer network. [1]

Correct measurement of the temperature on a

kiln shell is essential for efficient operation of the

kiln. ECS/CemScanner represents the state-of-theart in kiln shell infrared scanning. The thermal

detailed image and real-time monitoring of the ring

formations in the kiln are set up. If obstacles prevent

the scanner from viewing parts of the kiln shell, up

to 8 infrared pyrometers can be installed to measure

temperatures in these specific areas. [12] To obtain

an optimal and efficient sinterization process both in

terms of economy of materials and to obtain quality

products, besides all the monitoring and control of

rotary kiln temperatures we performed a thermal

analysis using software QuickField.

resulting from the combustion process that flows

through cyclone separator from lower levels to

higher ones. Flow chart of clinker production is

shown in Fig. 1, [12]. In this way the gas are cooling

as raw material preheating and start the process of

calcinations. Raw material in suspension separates

the gas in each gear shift and gas reunited in the

descent step. This process are repeating (separation mixing) every step of unloading mix material

exchanger to ensure good furnace heat transfer.

The calcination (transforming of raw material

into clinker, the intermediate product used to

produce cement) occurs in rotary kiln according to

the four zones: calcination area, transition zone,

clinkering zone and cooling zone. The kiln

temperature needed for this process is about 1450 C

and flame temperature of approximately 2000 C. [5]

The rotary kiln is divided into successive control

volumes or cells [6]. The volume elements of the

bed and the gas in the cells are described as open

thermochemical systems, which transforms heat and

mass with each other.

3. Background

The finite element method FEM is used to solve

complex engineering problem [2]. Engineers who

need to model electromagnetic or thermal fields

frequently turn to finite-element analysis (FEA), a

numerical technique for solving field problems of

all kinds [9]. The first step in finite-element analysis

is to divide the analyzed configuration into small

homogeneous elements. The model contains

information about the device geometry, material

constants, loads and boundary constraints [3]. In

each finite element, a linear variation of the field

quantity is assumed. The corners of the elements are

called nodes. The goal is to determine the field

quantities at the nodes. The Finite-Element Analysis

technique solves the unknown field quantities by

minimizing energy functional. The energy

functional is an expression describing all the energy

associated with the configuration being analyzed.

QickField is a finite element analysis software

package, a slick FEA for solving two or three

dimensional field problems. From studies and

evaluations conducted by a team of developers it is

estimated that QuickField is easy and suitable for

this problem. [11]

Compared to other FEA programs, QuickField

has two main facilities: exceptional user-friendliness

and blinding speed. The program has a typical

Fig. 1. Clinker production flow chart [12]

The clinker leaving the kiln enters the cooler

rack which has two functions: to recover a larger

amount of energy from the hot clinker to be used in

the process and to reduce the clinker temperature to

the right level for its later semi fabricated use for

cement production.

Although there is a quite high level of

automation and the control of installations for each

stage of cement production from Deva Factory and

ISBN: 978-1-61804-184-5

183

Recent Advances in Finite Differences and Applied & Computational Mathematics

Windows interface, drop-down menus, and

extensive help facility, and is equipped with many

sample programs [11]. While the user has to

understand something about the physics of the

problem to successfully carry out a simulation, the

mechanics themselves are straightforward. Even on

a slow PC, users can construct and run models with

tens of thousands of nodes, which make it practical

to solve very complex models on modest platforms.

The program itself is small, a few megabytes with

various required files.

Heat-transfer equation for linear problems in

rotary kiln is represented by the differential

mathematical model of the thermal conduction [11]:

Fig. 2 Heat transfer mechanisms from the kiln

div(gradT ) + q c

T

=0

t

,

T

T T

= q c

+ y

x

t

x x y y

Convection (from gas to bed and inner wall and

outer wall to surroundings)

Conduction (between bed and inner wall and

inner and outer wall)

Radiation (main heat transfer mechanism).

A typical operational case of the kiln is modeled

to show the process inside the kiln and the

capability of the process modeling. The kiln is

fuelled by natural gas, liquid fuel and coal and solid

alternative fuel or fuel combination. The

combustion air is provided, which works out to

about 15% excess air. 80% of the total combustion

air is secondary air, and the rest goes into the kiln

through the gas burner.

The model developed was for a rotary kiln of 5.8

m in diameter on a vertical cross section with 0.58

cm diameter. As mentioned previously the model

takes into account convection, radiation and

conduction from combustion and from the hot gas.

A combustion profile is incorporated into the model

to simulate the non instantaneous combustion

process. The parameters of rotary kiln from Deva

Factory are: diameter of 5.8 m, length of 97 m,

production capacities Q = 3000 t/ day, the main

driving power, P = 500 kW with rotation speed, n =

750 rot/ min, second driving P = 500 kW with n =

750 rot/ min and an angle from horizontal position

of 3 %.

(1)

(2)

where: T scalar temperature T; t - time; x (y,r,z) components of heat conductivity tensor; (T) - heat

conductivity as a function of temperature

approximated by cubic spline (anisotropy is not

supported in nonlinear case); q (T) - volume power

of heat sources, in linear case - constant, in

nonlinear case - function of temperature

approximated by cubic spline; c (T) - specific heat,

in nonlinear case - function of temperature

approximated by cubic spline and - density of the

substance.

4. Modelling of heat transfer with FEA

The clinker production process involves heat and

mass transfer between the kiln, fuel, primary and

secondary air, drying of raw material mix call flour,

and calcining of CaCO 3 [6]. It is important to have a

comprehensive understanding of these processes in

order to: diagnose operational problems, improve

energy consumption, increase production, reduce

emissions, increase refractory life, improve the

product quality and optimize kiln operations.

The given computer model of thermal processes,

allows to calculate temperatures pattern both at a

surface and inside a body [10]. The model allows to

perform calculation heat transfer of a multy-layer

ring structure of a body with a granular mixture clinker, roasted inside it (Fig. 2). [7] The kiln body

is coated with refractory brick and is analysing like

a multy-layer body: shell, chamotte, air inside and

clinker. There are three different heat transfer

mechanisms in the rotary kiln, Fig. 2 [7].

ISBN: 978-1-61804-184-5

4.1. Model formulation

The first stage of Finite Element Analysis is

problem description that includes: edit problem

description options, as well as material properties,

field sources and boundary conditions. Our problem

is a steady-state heat transfer, linear with

axisymmetric model class. In our linear problem all

the parameters are constant within each block of the

model.

184

Recent Advances in Finite Differences and Applied & Computational Mathematics

source is concentrated and defined by a block unlike

the second option with four blocks in which the heat

source is defined by a labeled vertex with boundary

condition and source specified through temperature

value T = 2000K.

Edge label with boundary condition specified for

two scenarious are shown in Table 2.

The model is described through a multi layered

with different properties model, that is the outside

layer is formed of 2 layers and the inside of the kiln

contains the gas, clinker and heat source. The

geometric model is composed of blocks with

different properties, in this case, it was assigned 4

blocks with material properties specified (air,

chamotte, clinker, steel shell), Table 1. In each

block the material properties was specified (thermal

conductivity and volume power of Heat souces Q).

The model geometry was described by create

vertex label with source specified (burner flame Q)

and edge label with boundary condition specified

that form boundaries of all subregions having

different physical properties. We created two

geometrical models.

Table 1. Material properties in each blocks

Block Label

Thermal conductivity

1 (W/K.m)

2 (W/K.m)

air

11

11

chamotte

0.165

0.165

clinker

1.2

0.1225

steel shell

22

22

Fig. 3 Geometrical model and the mesh

Table 2. Boundary conditions applied

Edge Labels

Temperature

Temperature

T 1 (K)

T 2 (K)

Outer

293

293

Inner

0

0

Bed surface

1450

1000

Applied mesh is shown in Figure 3 and the field

values at the nodes have been calculated.

Finite Element analysis is based on discretization

of the area into the number of simple shapes, in case

of QuickField triangles. Accuracy of the results

highly depends upon the finite element mesh density

and quality. Moreover, in complicated cases

problem solution on the non-adequate meshes may

not converge. Thats why the mesh generation is

one of the most important operations in all practical

FEA applications. QuickField Model Editor is

equipped with very efficient mesh generators. But

sometimes, then the geometry was really complex,

smooth mesh generation required many manual

adjustments. Improved mesh building algorithms of

this version 5.10 assure automatic generation of the

smooth meshes even in the most complicated cases,

which allows good results of the model.

We have built the mesh in all blocks

participating in field calculation. Flame positioning

for example can be predicted in multi-dimensional

models rather than used as an input. In one of the

models the flame position is concentrated in the

center of the section and in a point of the upper half

of the section in other model, Fig. 3. Each model

was individually tested and where appropriate, was

compared to experimental results.

The first option has been created with a

digitization network of 5 blocks in which the heat

ISBN: 978-1-61804-184-5

Because thermal conductivity function of

temperature in nonliner case, we have carried out

two scenarios considering the conductivity

variation, = (T) of clinker and results are shown

in Fig. 4 for 1 and in Fig. 5 for 2.

Fig 4 Temperature distribution for 1

The energy to raise the temperature and drive

endothermic reactions is from the combustion of a

range of fuels such as natural gas, coal and more

and more alternative fuels.

185

Recent Advances in Finite Differences and Applied & Computational Mathematics

kiln. The temperature profile at inside the kiln

follows a parabolic function [7].

Fig. 5. Temperature distribution for 2

Fig. 7. Temperature distribution for 2, T2=1000

4.2 Temperature distribution inside

The feasibility of simulating heat transfer 2D using

a common, finite element modeling package

QuickField was tested. The aim was to recreate well

known, but difficult to simulate, interactions

between thermal transfers in multy layer structure.

For the test application, QuickField was chosen

for the following reasons: the Heat Transfer module

is used to analyze the temperature distribution in

static and transient heat transfer processes; nonlinear

or anisotropic properties; boundary temperature and

heat fluxes and boundary conditions with

convective/radiative terms.

Temperature distribution T, in vertical section

and vectors of Heat flux F are presented in Fig.5

when it was chosen a temperature inside about

1450C for surface of bed.

The contour definite for calculus of quantities

value is shown in Fig 6 and also isotherms.

4.3 Results

To analyze the results obtained on the contour

defined in Fig. 6 and Fig. 7 at temperatures T1 and

T2 we have performed parametric analyzer with

LabelMover. We have specified the values which

we want to optimize and start optimization process

for some physical quantities.

We have calculated with Harmonics Browse the

plot for temperature values and amplitudes for the

two boundary conditions, T1 and T2. Harmonic and

linear approximation of the temperature variation

(K) on contour inside the kiln (m) that corresponds

at the whole period, are shown in Fig. 8. The plot of

temperatures approximation for the value of 1

without conditions imposed for the temperature of

clinker bed surface, only temperature source, like

T= 2000K, has been raised.

1732.7

T e m pe ra tu re

1688.5

1644.4

L in e a r a ppro x im a tio n

H a rm o n ic a ppro x im a tio n

Fig. 8.Plot for temperature approximation

This add-in allows us to calculate and view

harmonics (that is, phases and amplitudes for

Fourier series) for any displayed quantity related to

the currently selected contour.

The graph of temperature variation, obtained

from model described has been presented in Fig. 9.

We stopped at the results that are comparable with

the results achieved from measurements. The

following results are retrieved: temperature, heat

flow, thermal gradients, and total heat loss on any

Fig. 6. Temperature distribution for 2, T1 =1450

The same contour was chosen for temperature of T

= 1000K and quantities value has been collated, Fig

7. We have applied two values on the boundary

conditions for the temperature inside the kiln on the

clinker surface T1 and T2. The combustion to the

fuel is assumed to occur at a point two meters into

the kiln and is complete at a point 32 m into the

ISBN: 978-1-61804-184-5

186

Recent Advances in Finite Differences and Applied & Computational Mathematics

given part and other whole inner surface of

quantities for clinker bed.

source can be changed to accommodate longer less

intense flames. To maximize refractory life, it is

essential to avoid flame impingement on the

refractory lining. Therefore it is recommended to

positioning burner system in order to avoid possible

refractory failure in that region. Engineers can use

the software to diagnose equipment problems.

References:

[1] Arad, S, Arad, V., Heat transfer in rotary kiln

from Deva cement factory. Papers SGEM2012/

Proceedings, ISSN 1314-2704, Vol. 2, 2012, pp

373 380;

[2] Bargallo, R., Finite Elements for Electrical

Engineering, EUETIB-UPC, 2006;

[3] Kenneth R. Foster, Quick and easy field

analysis, IEEE Spectrum, Vol. 36, Number 12;

[4] Marcu, M., Uu, I., Popescu, F., Pana, L.

Simulation Software for Static Switch

Controllers. Annals of University of Petrosani,

Electrical Engineering, Vol 9, pp 153-159,

Petrosani, 2007.

[5] Penttil, K. A Simulation Model of TiO2calcination Kiln. M.Sc. thesis, Helsinki

University of Technology, Faculty of Process

Engineering and Materials Science, 1996.

[6] Tscheng, S. and Watkinson, A. Convective Heat

Transfer in a Rotary Kiln. Can. J. Chem. Eng.,

57, pp. 433443, 1979

[7] Palmer, G., Howes, T. Heat transfer in rotary

kilns, Cement Industry Federation Technical

Conference 1998,

[8] Petrilean, D.C., Mathematical Model for the

Determination of the Non-Stationary Coefficient

of Heat Transfer in Mine Works, RECENT

ADVANCES IN MATHEMATICS (ASM '13),

Published by WSEAS Press, pp 124-130, 2013

[9] Powell, S., Finite element modelling of

magnetostatics for magnetron sputter sources.

"CAD for Electromagnetic Devices", seminar, 2

November 2006, Rolls Royce plc, UK

[10] Zerafat Angiz, F., Amanifard, N., Haghi, A. K

A Numerical Study on Thermal Drying of Moist

Porous Solid, Proceedings of the 5th

IASME/WSEAS INT. CONFERENCE ON

HEAT

TRANSFER,

THERMAL

ENGINEERING AND ENVIRONMENT,

Athens, Greece, 2007

[11] QuickField 5.10 User's Guide Tera Analysis

Ltd.

[12] CARPATCEMENT

HOLDINGDEVA

Factory, Dispatcher Report on ECSNTech software, 2012

Fig. 9. Temperature variation on bed surface

Data achieved from a full-scale cement kiln at

Deva factory are comparable to results achieved

with the software used. The best approximation is

achieved on the clinker surface when the

temperature of the heat source is taken from the

pyrometer inside the rotary kiln like in Fig. 10.

Fig. 10 Data from pyrometer measurements

inside the kiln

5. Conclusions

The validation of any model is extremely

importance for the effective use of the model as a

design tool. Validation to heat transfer has been

done using full scale kilns at Deva cement factory.

In further development of the model the aim is to

incorporate not only thermal profiles for the rotary

section of dry process kilns but the effect of chain

systems in long wet kilns including dust entrainment

through the chains.

We see significant temperature increase close to

flame of burner (e.g. T = 1810K). However, the heat

ISBN: 978-1-61804-184-5

187

S-ar putea să vă placă și

- Article 4 ConferenceDocument6 paginiArticle 4 ConferenceSaid EL FakkoussiÎncă nu există evaluări

- Comm 5Document10 paginiComm 5Said EL FakkoussiÎncă nu există evaluări

- 2023 Abaqus For Engineers Fe Safe Research Gate PreviewDocument105 pagini2023 Abaqus For Engineers Fe Safe Research Gate PreviewSaid EL FakkoussiÎncă nu există evaluări

- Catia Support ExercicesDocument99 paginiCatia Support Exerciceshixwin100% (1)

- Support BaseV5 Exercice 03 04Document65 paginiSupport BaseV5 Exercice 03 04Said EL FakkoussiÎncă nu există evaluări

- Extended Finite Element Method (XFEM) overviewDocument24 paginiExtended Finite Element Method (XFEM) overviewjangdiniÎncă nu există evaluări

- Kiln Mechanics 222222Document59 paginiKiln Mechanics 222222Said EL FakkoussiÎncă nu există evaluări

- Feeco Rotary Kiln Design Paper PDFDocument16 paginiFeeco Rotary Kiln Design Paper PDFRoshan AgrawalÎncă nu există evaluări

- Abaqus Tutorial 01Document18 paginiAbaqus Tutorial 01api-3869476100% (1)

- Feeco Rotary Kiln Design Paper PDFDocument16 paginiFeeco Rotary Kiln Design Paper PDFRoshan AgrawalÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 11P Trusses ProblemsDocument39 pagini11P Trusses ProblemsHoward Johann Gomez VÎncă nu există evaluări

- Huygens' Principle, Maxwell's Displacement CurrentDocument7 paginiHuygens' Principle, Maxwell's Displacement CurrentGalleta Galleta MetralletaÎncă nu există evaluări

- Stress Distribution Around HolesDocument1.008 paginiStress Distribution Around HolesffontanaÎncă nu există evaluări

- Storage and Flow of Powder: Mass Flow Funnel FlowDocument9 paginiStorage and Flow of Powder: Mass Flow Funnel FlowDuc HuynhÎncă nu există evaluări

- Company Profile: BIS CML No.: 7200050893 An Iso 9001:2015 Certified CompanyDocument4 paginiCompany Profile: BIS CML No.: 7200050893 An Iso 9001:2015 Certified CompanyPowerliteÎncă nu există evaluări

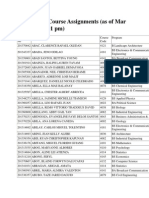

- UP Diliman Course AssignmentsDocument82 paginiUP Diliman Course Assignmentsgamingonly_accountÎncă nu există evaluări

- Blade Profile Optimization of Kaplan Turbine Using CFD AnalysisDocument16 paginiBlade Profile Optimization of Kaplan Turbine Using CFD Analysiscbaraj100% (1)

- Egyptian FractionsDocument80 paginiEgyptian Fractionsmyasweet22Încă nu există evaluări

- Physical Computing NotesDocument2 paginiPhysical Computing NotesAnonymous W9MgRBVtYCÎncă nu există evaluări

- Rock Sizing For Culvert Outlets PDFDocument0 paginiRock Sizing For Culvert Outlets PDFwrobinsonf2scomÎncă nu există evaluări

- Optimising Design and Power Management in Energy Efficient Marine Vessel Power SystemsDocument11 paginiOptimising Design and Power Management in Energy Efficient Marine Vessel Power SystemshamadiÎncă nu există evaluări

- Determine G by Using Simple PendulumDocument3 paginiDetermine G by Using Simple PendulumMohammad Sahedul MarufÎncă nu există evaluări

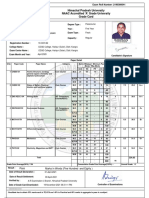

- Serial Number:1920110212668 Exam Roll Number Grade CardDocument2 paginiSerial Number:1920110212668 Exam Roll Number Grade Cardsimran vaidÎncă nu există evaluări

- SM PDFDocument607 paginiSM PDFGladwin SimendyÎncă nu există evaluări

- Mendocino Motor Control ApproachesDocument6 paginiMendocino Motor Control ApproachesAngélica María CastrillónÎncă nu există evaluări

- J.F.M. Wiggenraad and D.G. Zimcik: NLR-TP-2001-064Document20 paginiJ.F.M. Wiggenraad and D.G. Zimcik: NLR-TP-2001-064rtplemat lematÎncă nu există evaluări

- 2 Stage GearboxDocument47 pagini2 Stage GearboxSanad Shajahan0% (1)

- KGT ManualDocument25 paginiKGT ManualLeo MoltoÎncă nu există evaluări

- WinspireDocument44 paginiWinspireBhanu PrakashÎncă nu există evaluări

- Backdraft Response StrategiesDocument6 paginiBackdraft Response StrategiesShan RaffelÎncă nu există evaluări

- Ernest Allen's CVDocument6 paginiErnest Allen's CVernestrallenÎncă nu există evaluări

- CUP IBChemistry c06 It Rates of ReactionsDocument33 paginiCUP IBChemistry c06 It Rates of ReactionsAdnan ChowdhuryÎncă nu există evaluări

- Engineering Calculation Sheet Consulting EngineersDocument17 paginiEngineering Calculation Sheet Consulting EngineersParthiban ArivazhaganÎncă nu există evaluări

- Fire Security NGOAFRDocument5 paginiFire Security NGOAFRseeker05Încă nu există evaluări

- Roxtec Product Catalogue GB FI RU SE IT 2011 2012Document252 paginiRoxtec Product Catalogue GB FI RU SE IT 2011 2012mmaleniÎncă nu există evaluări

- Fluids HandlingDocument234 paginiFluids HandlingVenkatesh GangadharÎncă nu există evaluări

- Induction MotorDocument27 paginiInduction MotorNandhini SaranathanÎncă nu există evaluări

- Quincy Qrds Series Single-Stage, Oil-Less Reciprocating Air Compressors 2-30 HPDocument8 paginiQuincy Qrds Series Single-Stage, Oil-Less Reciprocating Air Compressors 2-30 HPCoral IcmÎncă nu există evaluări

- ParadoxesDocument528 paginiParadoxesMihaela CovrigÎncă nu există evaluări

- Experiment 1 (Equilibrium of Turning Forces)Document5 paginiExperiment 1 (Equilibrium of Turning Forces)shark eye100% (1)