Documente Academic

Documente Profesional

Documente Cultură

10 70 PDF

Încărcat de

KopTer JacopDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

10 70 PDF

Încărcat de

KopTer JacopDrepturi de autor:

Formate disponibile

THIRTY-SEVENTH CONFERENCE

THE PERFORMANCE OF A HEAVY DUTY

SHREDDER

By C. D. CLARKE and R. J. McCULLOCH

Farleigh Co-operative Sugar Milling Association Ltd., Farleigh, Mackay

Summary

In this paper comments and observations on the first year's performance of a new shredder at Farleigh have been set down, together

with an assessment of its operating characteristics.

The shredder is of recent, heavy duty design having an anvil bar and

breaker section covering an arc of 85" and is driven by two motors having

a combined rating of 1400 horse-power.

The results of test runs taken during the 1969 crushing operations

were analysed and a relationship established between cell breakage in

prepared cane, fibre rate and power consumption.

Introduction

With increasing factory throughputs in recent years a satisfactory

level of extraction has become increasingly difficult to attain. A decrease

in the fineness of prepared cane was recognized as one of the contributing

factors.

A series of modifications was made to the Searby shredder previously in operation, including the use of hammers of increased effective

weight and length, modification of the breaker section, and the provision

of prime movers of greater horse-power. Some improvement in results

was obtained, but cell breakage in the shredded cane was still estimated

at below seventy per cent: and no noticeable improvement in milling

extraction was evident.

In considering possible solutions to this problem, due attention was

given to shredder developments reported from overseas, particularly

from Hawaii. From these reports, and a comparison of our experiences

with shredder operation, it was felt that a shredder of much more robust

construction than that of current local designs, with power input considerably upgraded, would be required.

However, during 1968 season the opportunity was afforded the

authors of observing a new heavy duty shredder in operation at C.S.R.

Co. mills in the Ingham area. This machine had been designed to run at

a maximum speed of 1100 revlmin, and was originally provided with one

anvil bar and hammers up to 42 lb in weight. A breaker section covering

60"-70, and of saw tooth design had been added. This shredder was

claimed to be giving cell breakage figures of 85 per cent and over at a

crushing rate of 250 tons of cane per hour with cane of 13 per cent fibre

content. The prime mover was a turbine of 1,000 hp.

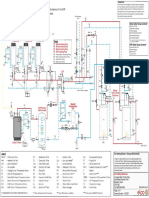

Description of the Shredder

A machine developed from this design was installed at Farleigh for

1969 season. The shredder is shown in cross-section in Figure l .

182

THIRTY-SEVENTH CONFERENCE

1970

An anvil bar and six breaker bars cover a breaker section of approximately 85" of the arc swept by the hammers. The anvil bar is adjustable

externally and breaker bars are detachable. By using bars of different

thickness, setting variations can be made with each breaker. The shredder

is driven by two 700 hp motors at 960 revlmin. This power requirement

was based on a figure of 32 hp per ton of fibre per hour. Eighty-seven

hammers having a double cutting edge, as shown in Figure 2, were used,

each hammer being approximately 36 lb weight. A further setting variation was possible by having pivot rods and through rods interchangeable

but on different pitch circles.

Feeding of the Shredder

The shredder is mounted with the anvil bar under the vertical casing

of the top knife box as shown on Figure 1. Cane discharged under the

top knives, which are at the head of the carrier, strikes the casing and

falls into the shredder.

Fig. I-Cross

section of the shredder.

1970

THIRTY-SEVENTH CONFERENCE

Fig. 2-Double

183

cutting edge of hammer.

Shredder Settings

Initial settings were 3 in over the anvil bar, 4 in over the first two

breakers, 3 in over the riext two and t in over the final two. These

settings have been progressively reduced to 3 in over the anvil bar, in

over the first breaker and 1in over the remainder.

Operation of the Shredder

No serious operating problems have been encountered, apart from

a very bad choke when hammer wear was extremely heavy because of

high levels of mud in cane.

When crushing whole-stick cane, quite heavy surges of power

demand of short duration were experienced. This was apparently caused

by the tendency of the top knives to drag material through unevenly into

the feed shute of the shredder, and was accentuated with excessive wear

on the top knives.

Loss of preparation was noticeable when this occurred, due partly,

it is assumed, to reduced knifing preparation, and partly to the higher

throughput of short durationato be handled by the shredder. The effect

always occurred following a heavy surge in top knife amperage.

The load so induced in the shredder tended to be a limiting factor

when considering close settings. Although the average hourly loading on

the shredder motors at no time exceeded 75 per cent of full load, surges

of short duration in excess of full load were quite frequent when crushing

whole-stick cane.

Description of Test Procedure

All results were obtained under normal milling conditions, and no

special alterations were made to any equipment. As a consequence it was

expected that some unaccountable variations must occur in data collected

through faulty sampling and analysis, unsteady conditions etc., regardless of precautions taken. It was decided therefore to perform a large

number of measurements of all the variables in order to obtain some

significant results. In all 35 tests were performed on bin cane and none

have been deleted from the analysis.

The measurement of operating variables was carried out as follows:

1. Crushing rate was measured by obtaining the weights of all trucks

tipped in a measured time of about twenty minutes. Care was taken to

ensure that the stock of cane between the tip and top knives was approximately the same before and after the test.

2. Power consumed was measured using the Golds relay, which indicated the moving average current, as a percentage of full load current,

over 14-minute intervals. With voltage constant and power factor varying

slightly with load, the value so obtained, expressed as a percentage of

184

THIRTY-SEVENTH CONFERENCE

1970

nominal maximum horse-power, can be regarded as a measure of

horse-power. Appendix 1 explains this further.

3. A sample of prepared cane was taken through the fibre sampling

door, mixed on a table by hand for about one minute, and about f removed as a subsample into a covered container. The subsample included

every particle of cane down to the table in the section taken. This sample

was then removed and a further sample taken, and so on until the time

for the run had elapsed. About four to six subsamples were taken on each

test. After collecting the subsamples the table was cleared and all cane

tipped back and mixed again by hand. A final subsample was taken and

removed for analysis for p01 per cent open cells (Henderson, 1970) and

fibre (Blake, 1964).

4. Samples of No. 1 mill first expressed juice were taken from the

sampling trough about six times per test period and mixed in a container.

Samples of last expressed juice from this mill were taken from under the

delivery roll using a long handled dipper.

5. A sample of first mill bagasse was taken and the p01 per cent

bagasse found using disintegrater analysis.

6. The nominal shredder setting was known for each run.

Dimensional Analysis of the Operation of Shredding

Before undertaking the investigation, the classical methods of

dimensional analysis were applied to the situation to help in organizing

the data and to reduce the number of variables to be correlated.

The criterion by which shredder performance will be judged is P, the

percentage of broken cells in the prepared cane. The physical nature of

the situation demands that the following variables be taken into account.

(a) fibre rate, ton/h, f

(b) power consumed, ft lbf/h, p

(c) a shredder setting, ft, 1

(d) cane density, lbm/ft3, d

(e) cane strength, lbf/ft2, k

(f) a hammer wear factor, dimensionless, W

(g) conversion factor, 1.862 X 10' ft ton/lbf h', g

The derivation of the dimensionless groups is gven in Appendix 3.

These groups are:

1.

(g)

3. P

4. W

A relationship should exist whereby:

P = KA"BbWW

where K, a, b and W are all constants.

At this point we now have four variables to handle, P, A, B and W,

whereas there were eight before grouping.

In practice it was not possible to measure all these variables and the

dimensionless groups used were modified as follows:

A was modified to

1970

THIRTY-SEVENTH CONFERENCE

185

where hp is horse-power consumed and X is fibre % cane.

HP is related to p by a constant factor.

The cane density d could not be measured in the time available so it

was assumed to be constant, and was neglected.

The value k is a measure of the toughness of the cane, or its resistance

to cell breakage, and has been given the dimensions of pressure, and

presumably k is some ultimate tensile or compressive strength of the

cane. This value could noto be measured but it seems reasonable to

approximate it by the fibre /o of cane X.

2. The group B has been modified to

pi4

gx

The d and k factors were treated as in A.

The difficulty of expressing the shredder setting as a length when

there is an anvil bar and six breaker bars each with a separate setting, was

overcome in a very arbitrary manner. The influence of each bar was

assumed to extend over a sector of a circle of 12.5". This value was

divided by the nominal clearance in ft. between the hammers and the

appropriate

bar.

- Thus 1 is defined as C

for each bar.

The dimensions of 1 have been defined as ft-l and hence 1 now

appears in the numerator of B.

3. P was not modified.

4. The wear factor W was defined using the following assumptions :

(a) the observed effects of hammer wear on cell rupture would be

proportional to the per cent loss in weight of the hammers.

(b) the weight loss is a linear function of elapsed time. Measurements gave an average weight loss of 1.25 per cent over 130

hours operation.

hours x 1.25 x 10 = 0.0962 x elapsed hours

:. W =

130

Thus W is really a measure of elapsed time.

Results

Abbreviated primary data and the resultant dimensionless groups

are shown in Table I.

The fitting of the data to an equation was done using multiple

regression techniques, recourse being made to the S.R.I. computer

because of the complexity and volume of the calculations involved. The

mass of data produced by the computer is too large to present here, but

the equations of best fit, with their standard deviations and multiple

correlation coefficients, are given in Table 11.

In Table I11 the values of P found by measurement are compared

with the values of P predicted by equation (3) in Table 11. This relationship has the lowest standard deviation.

In Figure 3 the relationship between P and first mill extraction is

shown graphically.

Discussion

Some comments on the various aspects of shredder operation and

results of the tests carried out are set out below.

186

THIRTY-SEVENTH CONFERENCE

1970

Effects of Fine Preparation on Factory Operations: Figures for crushing

rate appeared to indicate that with a reasonably effective feeding device

on the crusher feeder at the first mill, throughput varied as the bulk

density of the feed material.

Mill feeding was not affected by the more finely prepared bagasse,

although increased loading in the drive for the feeding device on No. 1

mill was noted.

The finer nature of final bagasse did result in some minor problems

TABLE I-Primary

data

No.

TABLE Il-Correlation

equations

THIRTY-SEVENTH CONFERENCE

Fig. 3-Relationship

between degree of preparation and first mill extraction.

TABLE Ill--Predicted

P values

* Rounded to nearest whole number.

188

THIRTY-SEVENTH CONFERENCE

1970

in the furnaces of a hard pressed boiler station. The levels of fuel beds

on t h e flat grates had to be more closely controlled, and the draft

pressure difference between furnace and combustion chambers of the

sloping grate furnaces had to be reduced to prevent bagasse carryover.

The finer bagasse tended to compact into the juice grooves of the

final mill rollers and difficulties were experienced with worn juice

grooves in delivery rollers not being cleaned by new apron plates. The

apron plate teeth wore heavily on the tips in these mills which have

3 in pitch grooving on the delivery rollers.

Actual Worse-power Usage: The figures given in Table 1 for hp, have not

been corrected for power factor. As shown in Appendix 1 the power

factor is expected to be about 0.83 and so the power input is about 22

hp per ton of fibre per hour. As explained in Appendix 2, the fibre

figures taken are likely to be low so a more realistic value would be

about 20. This compares with the value of 17 given by Nicklin (1967).

The Influence of Extraction: The overall extraction for 1969 showed an

increase of 0.3 units over that of the previous year. A number of influences

come in here, and it is difficult to say how much of an increase in extraction was due to cane preparation. Certainly 1969 will not be remembered

as a vintage year for cane quality and low fibre. For a meaningful

comparison we would have to know what extraction would have resulted

if the preparation this year had been the same as last year's.

The data in Figure 3 show that considerable scatter has clouded

any relationship which may exist. Work done under controlled conditions

by the Sugar Research Institute (1958) has shown that first mill extraction

should increase with degree of preparation because the onset of reabsorption is delayed.

There is a tendency towards this relationship in Figure 3, but the

scatter makes a formal regression analysis seem not worthwhile.

Variations in Crushing Rates: The crushing rates measured over the

relatively short duration of the tests showed surprising variations. A

high value of 294 tons per hour, with average hourly rates from 250 to

260, was regarded with suspicion, but it fits into the correlation quite

well. This was test number 20.

Over all the tests, which refer to bin cane only, the average rate was

246 tons per hour, with a standard deviation of 23 tons per hour.

Interpretation of Dimensionless Groups Used: (a) The group A, which is

kf

pi

could be written as p/, and could be interpreted as the potential

kf

d

for breaking cells, i.e. the energy input divided by the capacity per

volume for absorbing this energy, i.e. the resistwee to breakage. The

value of this group should be highly significant in determining cell

P

breakage.

(b) The group B, which is 1 4 kd'

~

is a little more obscure, and a

little licence has been used to try t; interpret its physical significance.

B can be written as

(A},($),('

constant.

, disregarding

which is only a dimensional

1970

THIRTY-SEVENTH CONFERENCE

l89

The term

can be regarded as a measure of the volume rate

passing throughthe area between hammers and bars, or a velocity of

cane through the shredder opening. At a given rotor speed, this term is

inversely proportional to the number of hammer blows a given piece of

material would receive in its passage through the shredder.

The term I is the mass flux per unit area through the shredder.

(h)1;)

is prooprtional to quantity of materialjnumber of

Thus

hammer blows, and it would be expected that degree of preparation

would be inversely proportional to this. Thus B is made up of two

1

opposing influences, the other being -, where degree of preparation

1

k

would be proportional to ., The coeflicient or exponent in the equations

K

will depend on which effect is the greater.

(c) The interpretation of W is obvious, but it should be pointed out

that any influence due to top knife wear with time will also be included

here.

Comments on the Derivd Equations: In interpreting the equations, the

contribution of each term to the final value of P is important. If we take

some typical values of the variables as

A =

2.0

B = 1000

W =

8

hp = 800

f = 30

the contribution of each term can be calculated.

With equation (1) in Table 11, A increases the value of P by 7 units,

B by 7 units and W decreases P by one unit.

With equation (3), A increases P by 13 units, B by 3.5 units and W

decreases P by 4 units.

Equation (3), the linear combination of dimensionless groups, gave

the best set of predicted values of P, Table 111, so could perhaps be

regarded as a better equation.

On the basis of these two equations, it could be concluded that A has

the most effect on P, with an appreciable contribution from B and W.

There is a tendency for the preparation to drop off towards the end of

the week, perhaps helped by deterioration in knife condition.

Equation (4) shows that a reasonable estimate can be made based

just on hp although commonsense indicates that horse-power per unit

of fibre rate would be more logical. This is done in equation (7) and a

better correlation results. Equations (5) and (6) give further correlations

with hp and f, together with the setting number. The hp terms contribute

about three times as much to the value of P as do the f terms. The setting

number has negligible effect.

The equations in Table 11 can be compared using the standard

deviation, which is a measure of the difference .between the observed

value of P and the predicted value using the equation.

The standard deviation i

The best estimate, equation 3, indicates that at the 95 per cent

confidence limit, a range of 1 5 units will include the true value of P,

190

1970

THIRTY-SEVENTH CONFERENCE

when calculated from the measured variables.

The multiple correlation coefficient shown in Table I1 is a measure

of the degree of excellence of fit of the observed data to the derived

equation. A value of 1.0 indicates a perfect fit and a value over 0.7

indicates a fairly strong dependence.

The fact that a good correlation can be found using only hp/f as the

independent variable means that the dimensionless groups are not

independent. If a value is given for fibre rate, the shredder setting

really determines the horse-power input. It could therefore be agreed

that only group A is pertinent. The justification for using all the dimensionless groups is that they can have some interpretation relating to the

mechanism of shredding, and this can be instructive.

The interpretation of group B as depending on the number of hammer blows per unit of material suggests that preparation could be

improved with a higher rotor speed.

The Influence of Fibre per cent Cane: If the crushing rate, per cent fibre

in cane, time of the week and cane properties were constant, the value

of A would depend on the shredder setting. Therefore values of A and

B cannot be chosen independently. From Table I, the average value of

A for each value of setting number was found, and a graph was drawn

up. A linear relationship seemed justified and the line of best fit was

found to be A = 0.993 + 0.463 1. Details are set out in Appendix 4.

Using this relationship as a basis, values of 1 and hence A were

assumed, and at a constant cane crushing rate the value of B was found

for different values of the per cent fibre in cane, x.

Then,

hp = A.f.x.

p = 62.6 ~ 0 . 1 6 3~ 0 . 0 1 3

and

A graph of P against hp for various values of X is shown in Figure 4.

Note that the horse-power figures here are not corrected for power

factor, and fibre figures are low. These inaccuracies do not affect the

conclusion that the fibre content has a very big effect on cell breakage.

It was noticed a number of times that a high degree of preparation at an

average hp value was associated with a fibre of about 11 per cent when

crushing well grown plant cane.

Using Figure 4 and assuming the fibre curves are one unit too low

,e

*g F,-

"LZ +m

_/.-

5%.' L e

I

'

,/.-

,

-

__r"

/'

L"

K,sri

Fig. 4--Effect of cane fibre on degree of

gbo

,A

re aration using the relationship

6 2 . 6 AO.lgJ$0".

1970

THIRTY-SEVENTH CONFERENCE

191

and that power factor is about 0.83, and engaging in a bit of doubtful

extrapolation of the curves, a target of 90 per cent open a l l s would be

reached on the average with this shredder and fibre of about 14 per cent

if the horse-power was about 1400 average.

However, if the fibre percentage were to drop to 12, i.e. the curve

actually shown as 11 per cent, 90 per cent open cells could be reached

with about 1000 hp input.

A paper submitted to this Society's 1964 Conference (Mackay

Institute of Sugar Milling Engineers, 1964) indicated that a 20 per cent

increase in power input occurred, with shredders in the Mackay area, at

the end of the week. This was not noticed in the course of this work.

Average values of A, with standard deviations, are set out in Table IV.

TABLE IV-Variation

in power during the week

Except for some inherent change in design of the shredder the

difference in this case is hard to explain.

A Comment on Test No. 4: Test No. 4 was done on the day before the

shredder choked. This test stands out as having a high power usage and

good preparation. The hammers were in a very worn state. It is thought

that the high power input and good preparation were caused by the

blunt hammers retarding the continuous flow of feed through the

shredder, resulting in the cane receiving more blows from the hammers

before discharge. This is an unstable condition and choking is likely at

any time. The practical procedure is to rely on close settings to give a

high power input and sharp hammers to give clean discharge.

Some Thoughts on Automatic Control: The strong dependence of degree

of preparation on horse-power input suggests that it would be sound

practice to try to keep the horse-power at a constant value and as high

as practicable. This would mean that the degree of preparation would

vary depending on crushing rate and cane properties. Obviously the

best that can be done in any given situation is to put in as much power as

possible.

Practically this could take the form of a moveable anvil bar and

grid bar system capable of infinite adjustment, within the range required,

by some operating medium such as a hydraulic ram with position control. An averaged horse-power figure, such as that given by a Golds

relay current averaging meter, over a period of about three minutes,

could provide a signal on which the ram could act to close in the settings

very slowly if power is too low, and vice versa. It may also be feasible

to incorporate a fast release of settings at a predetermined high average

peak current value to prevent a choke and heavy motor overloads.

Period uf Oscillation and Swing Back of Hammers: Towards the end of

the 1969 season, closer adjustment of shredder settings had not been

accompanied by the anticipated increase in power consumption or

improved preparation. It was therefore decided to investigate hammer

192

THIRTY-SEVENTH CONFERENCE

1970

characteristics using formulas suggested by Shann and Cuilen (1968) and

Crawford (1969).

It has been suggested that the frictional resistance between the eye of

the hammer and the pivot rod could dampen out hammer swing before

the hammer again came into contact with the cane. However, the

periodic time of oscillation of the hammer used was checked. Using

the formula for period of oscillation given by Crawford it was found

that the hammer would be swinging back as it again came into contact

with the feed when approaching the anvil bar.

Although four alternative hammer shapes were considered this

undesirable characteristic could not be significantly improved owing to

the limitation imposed on the dimension "h" (the distance from the

centre of gravity of the hammer to the centre of the pivot rod) by the

internal dimension of the shredder from pivot rod to the inside of the

shredder casing at the breaker section.

Swing Back Angle of Hammer

As most hammer wear had been confined to the leading wear face of

the hammers in use, with little or no wear on the second face, it was

inferred that hammer swing-back was affording some measure of

protection from wear to this face. An angle of swing-back of 15" was

calculated using the formula of Shann and Cullen and about four

degrees (neglecting friction) using Crawford's formula.

The geometry of hammer swing in relation to any given breaker bar

increased the setting by one eighth of an inch for a swing-back angle of

eight degrees. These considerations when viewed in the light of shredder

performance at the closer settings would seem to indicate that the hammer

swing-back angle may have been as great at eight degrees.

To concentrate the hammer mass as far as possible towards the tip

to reduce the swing-back angle and to minimize the effect of increase in

setting produced by swing-back, a hammer profile as shown in Figure 5

has been devised for future trials.

From considerations of power imported per hammer, the swingback angle must be reduced by doubling the number of hammers fitted

to the rotor, and the shredder is to be so assembled in the coming

season.

Fig. 5-Hammer

profile design for concentrating hammer mass as far as possible towards

the tip.

1970

THIRTY-SEVENTH CONFERENCE

193

Conclusions

1. The factors which have the greatest bearing on the degree of

preparation achieved are :

(a) the energy absorbed per ton of fibre

(b) the nature of the cane.

2. The degree of preparation achieved at a given energy consumption

falls off quite markedly as the fibre content increases.

3. To keep the shredder operating in a stable and eficient manner,

and to maintain a high horse-power input to optimise cell breakage,

attention must be given to the follovving:~

(a) the shape and number of hammers.

(b) provision of a steady feed to the shredder.

(c) provision of some form of automatic control of shredder settings.

The authors wish to thank the management of the Farleigh Cooperative Sugar Milling Association for permission to publish this

paper, the Sugar Research Institute for the use of their computer, Mr.

P. G. Wright for his work in processing the data and those others who

have helped by their discussion and comments.

REFERENCES

Blake, H. J. (1964). Fibre in cane by dry substance method. Proc. Qd. Soc. Sug. Cane

Technol., thirty-first Conf.

Crawford, W. R. (1969). Mechanics of swing hammer design. Proc. Qd. Soc. Sug. Cane

Technol., thirty-sixth Conf.

Henderson, C. (1970). Pol per cent open cells in prepared cane. Proc. Qd. Soc. Sug. Cane

Technol., thirty-seventh Conf.

Mackay Institute of Sugar Milling Engineers (1964). Some notes on preparation plant in

Mackay and district mills in 1963. Proc. Qd. Soc. Sug. Cane Technol., thirty-first

Gonf.

Nicklin, J ~ H(1967).

.

Power and energy requirements for cane preparation. Proc. Qd. Sug.

Cane Technol., thirty-fourth Conf.

Shann, D. and Cullen, R. (1968). Some aspects of shredder hammer design. Proc. Qd. Soc.

Sug. Cane ~echnol.,thirty-fifth-conf.

Sugar Research Institute (1958). The influence of degree of preparation on No. 1 mill

performance. Technical Report No. 49.

Appendix I

Motor Power Factor

At the time of compilation of this paper exact data on power factor

were not available, but the value should be about 0.8 at very low loads

rising to about 0.9 at high loads. Therefore a value of 0.83 was assumed

in the calculations performed for average conditions.

Appendix 2

(A) Analysis of Fibre

This was carried out by the method described by Blake (1964). For

speed of analysis the first expressed juice was not filtered. It is thought

that the fibre figures so produced, while low, are a measure of the changes

in fibre content. The drying of the cane was done in a Spencer oven in

duplicate.

(B) Analysis of Prepared Cane

This was done by the method described by Henderson (1970).

194

THIRTY-SEVENTH CONFERENCE

1970

Appendix 3

Derivation of Dimensionless Groups

The eight variables given above can be expressed in general terms

as a functional relationship

P=F(f,p,l,d,k,W,g).

If the form of the relationship is a product of powers of the variables,

dimensional analysis will allow a logical grouping of the variables.

Therefore, P = K f a pb lc dXkYwt g :

Since P is dimensionless and K is a dimensionless constant, the

product of all the dimensions on the right hand side is zero when the

dimension equation is written.

Note that W is dimensionless by -definition.

Each dimension must appear to the power zero.

For the dimension, ton

a +X t z = 0

For the dimension, h

-a-b-2z=0

For the dimension, lbf

b -I--y-z=O

For the dimension, ft

b + c - - 3 x - 2y 4 - z - = O

These four equations with six unknowns can be solved in terms of a

and b.

After solving, and rewriting in terms of a and b, like terms can be

grouped to give

where K, a, b and c are constants.

Appendix 4

Table V sets out the average values of A associated with each shredder setting number, and the number of observations associated with

each average of A.

of A and 1

TABLE V-Dependence

Number

of poinv

If the regression equation is of the form

A = a bl, where 1 is shredder setting X 10--3,the values of a and b

for best fit are

b =

' --A where 6 denotes average value of A.

El2 - nT2

The averages are weighted averages.

From the above figures,

1970

THIRTY-SEVENTH fONFERENCE

=1.872

=1.860

.Zp = 125.178

Z1A = 121.237.

Hence b 0.463

a = 0.993

.: A = 0.993 0.463 1 is the line of best fit.

~igure'

6 shows the scatter of each point about this line.

Fig. 6-Regression

equation of A vs shredder setting.

S-ar putea să vă placă și

- Steam Plant OperationDocument794 paginiSteam Plant Operationgladiatork00793% (14)

- Article - Bolted Joint DesignDocument15 paginiArticle - Bolted Joint DesignPiyush YardiÎncă nu există evaluări

- Molienda 1Document8 paginiMolienda 1Jesús Eduardo Oviedo GalloÎncă nu există evaluări

- Eth 8147 01 PDFDocument6 paginiEth 8147 01 PDFKopTer JacopÎncă nu există evaluări

- Quadrotor Helicopter Flight Control PDFDocument5 paginiQuadrotor Helicopter Flight Control PDFKopTer JacopÎncă nu există evaluări

- Industrial Boiler Engineering ManualDocument26 paginiIndustrial Boiler Engineering ManualnoxleekÎncă nu există evaluări

- Belt and Chain DrivesDocument10 paginiBelt and Chain DrivesJagdip ShethÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Physics 211 Lab 1Document2 paginiPhysics 211 Lab 1Randy KingeryÎncă nu există evaluări

- Unit ConversionDocument21 paginiUnit ConversioninsidereaderÎncă nu există evaluări

- SD 33Document8 paginiSD 33Neddy Bdo Veras Estevez100% (2)

- Eng Sicor Catalogue GearlessDocument52 paginiEng Sicor Catalogue GearlessEmeka Pius OramunwaÎncă nu există evaluări

- Siemons - Cello Bowing TechniqueDocument15 paginiSiemons - Cello Bowing TechniqueMassa Awaj100% (2)

- Design of Flywheel: Prepared By:-Mourya Sachin BabulalDocument16 paginiDesign of Flywheel: Prepared By:-Mourya Sachin BabulalSachin MouryaÎncă nu există evaluări

- CAT4-2 Complete ENDocument264 paginiCAT4-2 Complete ENalltheloveintheworldÎncă nu există evaluări

- Accelerator Design For Proton Therapy: OutlineDocument8 paginiAccelerator Design For Proton Therapy: OutlineriomjÎncă nu există evaluări

- 5.4.1 INV5.4.1HessLawLab - Sem2 2017-HaleemMohamedAli EditDocument7 pagini5.4.1 INV5.4.1HessLawLab - Sem2 2017-HaleemMohamedAli EditHaleem MohamedÎncă nu există evaluări

- Rupsha Power Plant PDFDocument19 paginiRupsha Power Plant PDFHossain Mohammad MahbubÎncă nu există evaluări

- Analogue Addressable Repeater - MFAREP Fire Detection SystemDocument20 paginiAnalogue Addressable Repeater - MFAREP Fire Detection SystemShadi AbdelsalamÎncă nu există evaluări

- Hydraulic Turbines: Turbines and That Con Vert Mechanical Energy IntoDocument22 paginiHydraulic Turbines: Turbines and That Con Vert Mechanical Energy IntosaitejaÎncă nu există evaluări

- Reporte HOMER WIND 5kW-PV 6.36kWDocument10 paginiReporte HOMER WIND 5kW-PV 6.36kWlandoa junÎncă nu există evaluări

- GLA100Document2 paginiGLA100Al De LeonÎncă nu există evaluări

- 3 TRIGON XL 1 CHP 1 Buffer LLH 1 VT Heating Circuit 2 Gemini CalorifiersDocument1 pagină3 TRIGON XL 1 CHP 1 Buffer LLH 1 VT Heating Circuit 2 Gemini Calorifiersadyro12Încă nu există evaluări

- Unit 2B.1Document16 paginiUnit 2B.1PualeilehuaÎncă nu există evaluări

- RT30 Operate InstrukcjaDocument97 paginiRT30 Operate Instrukcjaallegro.ds.spinÎncă nu există evaluări

- VLSI Design Unit-2 Mosfet TransistorDocument5 paginiVLSI Design Unit-2 Mosfet Transistorselvi0412Încă nu există evaluări

- 2.1 CPRS, DRS, CGS, Steel PipelineDocument31 pagini2.1 CPRS, DRS, CGS, Steel PipelinePawan Chaturvedi50% (4)

- Technip Introduces New Diving Support Vessel Deep ExplorerDocument2 paginiTechnip Introduces New Diving Support Vessel Deep Explorermuhammad ilyasÎncă nu există evaluări

- Cylinder Cover Assembly KG170-02000: Fuel Oil System KG170-09000Document1 paginăCylinder Cover Assembly KG170-02000: Fuel Oil System KG170-09000Александр ЩеблыкинÎncă nu există evaluări

- 08-Com101 AMDocument11 pagini08-Com101 AMHồng HoanÎncă nu există evaluări

- Technical Article 1 MMD Sizers: MMD Group of CompaniesDocument13 paginiTechnical Article 1 MMD Sizers: MMD Group of CompaniesIgnacia PinoÎncă nu există evaluări

- California Air Tools 20040SPCAD Owner's Manual 11-18Document16 paginiCalifornia Air Tools 20040SPCAD Owner's Manual 11-18mmeneses07Încă nu există evaluări

- BTech Project Midterm ReviewDocument12 paginiBTech Project Midterm ReviewNikhil WaghalkarÎncă nu există evaluări

- EPF FW Demand Calculation NoteDocument14 paginiEPF FW Demand Calculation NoteEmamokeÎncă nu există evaluări

- GE Gas Turbine Generator Frame 6 Spare PartsDocument2 paginiGE Gas Turbine Generator Frame 6 Spare PartsAxelrose04100% (1)

- Station Area Planning Guide October 2017 PDFDocument116 paginiStation Area Planning Guide October 2017 PDFAnonymous EnrdqTÎncă nu există evaluări

- Atoms, Electron Structure and Periodicity HWDocument14 paginiAtoms, Electron Structure and Periodicity HWLuke WilliamsonÎncă nu există evaluări

- Motion in A Plane PDFDocument38 paginiMotion in A Plane PDFaman btechÎncă nu există evaluări