Documente Academic

Documente Profesional

Documente Cultură

GM Facility Development Parts

Încărcat de

Seshagiri DeenadayaluDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

GM Facility Development Parts

Încărcat de

Seshagiri DeenadayaluDrepturi de autor:

Formate disponibile

PARTS EXCELLENCE

FACILITIES

DEVELOPMENT

General Motors Dealer Development Systems

PA RTS EXC E L L E N C E

Reference Library

This reference library is to be used in conjunction with and is complementary to

the Service and Parts Excellence Standards Manual. Essentially this library is a

collection of Dealership management and operating ideas gathered world-wide.

If, after reviewing a specific standard you have areas in your Dealership

organisation that fall into the needs improvement category, then there will be

ideas in this library that may help you solve your problems.

While the reference libraries contain hundreds of good ideas, it should never be

assumed that the ideas and examples presented are the only or desired means of

solving your problem. You may have some better ideas to achieve a desired

operating standard. This reference library provides How to make it happen

guidance.

The contents of this reference library contain the Parts Excellence area of:

FACILITIES DEVELOPMENT

2001 General Motors Automotive Limited

This publication is copyright. Other than for the purposes and subject to the

conditions prescribed under the Copyright Act no part of it may be

reproduced by any means without prior written permission. Enquiries should

be addressed to General Motors Automotive Limited.

General Motors Dealer Development Systems

FACILITIES DEV E LO P M E N T

Preface

PARTS EXCELLENCE

- A LONG-TERM APPROACH TO TOTAL

CUSTOMER SATISFACTION

Parts Excellence, a Dealer development system, is designed to organise your Parts

Department into seven functional areas that are discussed as separate Parts

Excellence modules. The seven modules of Parts Excellence are:

Dealer Development

Parts and Document Flow

Inventory Analysis

Purchase Planning

Personnel Development

Facilities Development

Market Development

Each module includes:

A 4-page Certification Report

Evaluators

A Dealer Action Guide (the main text)

Dealer Decision Grids

THE CERTIFICATION REPORT

The Certification Report is the way a Dealerships progress on the Module can be

reviewed. The Report is also the way a Dealership is certified as meeting the

required performance level for a Module.

The Certification Report includes:

(page 1) Dealer name and address, review and/or certification status,

plant representative and Dealer representative. A copy of the completed

document - whether for review or certification - must be forwarded to local

management as well as Detroit management. This information can also

assist in communicating those areas requiring additional focus in order to

achieve total customer satisfaction

(page 2) A summary of Evaluators, in graph form, by each standard area

of performance on which a Dealership will be measured. The document, if

kept up to date, can provide a quick and accurate summary of where the

Dealership is positioned, at any time, with regard to certification

(pages 3 and 4) The means for reviewing Dealership performance in the

standard areas to be measured

The principal areas that will be measured are shown under the column

titled Section.

PA RTS EXC E L L E N C E

Preface

Each principal area is comprised of specific standards that must be

maintained by the Dealership. These are indicated under the column

of Qualifiers.

Each specific standard, or qualifier is comprised of the evaluators used

to measure Dealership performance for that specific standard. Since

the evaluators require action by the Dealer, they are listed under the

notation Dealer Action.

Please note that each evaluator is assigned a point value in order to

avoid arbitrary measurement. A Dealer must achieve a minimum of

80% of the Modules total point value in order to achieve

certification.

To make the Certification Review form most useful, several columns

have been included to the right of the point value so that the Review

can be used as a check sheet for determining areas that require

attention.

Certification in a Module requires achieving 80% of the Modules total

possible points (page 4) as well as 80% of each sections possible point

value (page 2).

THE EVALUATORS

A page of Evaluators will be found at the beginning of each section in the

Module. These are duplicated on pages 3 thru 4 of the Certification document

and indicate both the Qualifier and the Dealer Action to be measured.

THE DEALER ACTION GUIDE (Main Text)

The Dealer Action Guide serves as reference for developing Dealer action plans

that fulfil the measurement criteria of each Module. The ideas, approaches and

techniques provided in the Guide are suggestions to help augment your

thinking regarding improvements to be made.

Carefully read the Qualifiers and Dealer Actions (evaluators) as well as the text

information in the Guide to clearly understand the intent of the standard areas.

ii

FACILITIES DEV E LO P M E N T

Preface

You can then decide if it feasible and practical to use the suggestions in the

Dealer Action Guide to bring your Dealership up to Parts Excellence standards.

You should find that many of the Guides suggestions offer practical application

in your Dealership. If you choose an alternate approach for improving the

situation it must be approved and documented by the Parts Excellence

representative.

Do not think you have to limit your use of this Module to the Evaluators

marked Qualify By or Will Not Qualify. There is always room for

improvement even in the best organisation. Review how you now run your parts

operation and compare it to the way the material in the Module relates to these

methods. You may find some new suggestions or you may be able to modify

some of the suggestions to improve your already successful business.

DEALER DECISION GRIDS

In addition to general text material, there are also Decision Grids which provide

specific suggestions to help organise and enhance a Dealerships approach to

solving problems and making changes.

APPROACH

It is suggested that you approach the materials in all Modules in an orderly

manner which consists of:

1

READ

Module

Contents

Justification

2

REVIEW

Forms

Operating

Assessment

3

ANALYSE

Evaluators

Standards

Potential

4

CHOOSE

Alternatives

Grid

Decide

5

IMPLEMENT

Suggestions

Specifics

Monitor

Outcome

This module has been developed by Mike Nicholas, Inc., Gresham, Oregon, in

co-operation with Asian Parts & Accessories Operations, GMC.

R. J. Kager

L. J. Sorchevich

Detroit

iii

PA RTS EXC E L L E N C E

Module Six - Table of Contents

TITLE

PAGE

Preface

Table of Contents

List of Illustrations

i-iii

iv

v

CERTIFICATION

Dealer Certification Review - Module No.6

1-4

INTRODUCTION

Facilities Development

System Overview

5

5

PHYSICAL LAYOUT

Evaluators

Analyse Resources

Relative Location - Dealership

Relative Location - Customers

Relative Location - Internal

Decision Grid

7

9

17

18

19

20

PARTS STORAGE

Evaluators

Storage Planning

Storage Equipment

Storage Areas

Specialised Bins

Supplies

Parts Organisation

Expansion

Decision Grid

21

23

29

35

37

38

39

41

44

CUSTOMER AREAS

Evaluators

Signage

Displays

Counter Design & Location

Decision Grid

45

47

51

58

61

SAFETY & SECURITY

Evaluators

Safety

Security

Decision Grid

63

65

69

72

APPENDIX A

APPENDIX B

iv

FACILITIES DEV E LO P M E N T

Module Six - List of Illustrations

PAGE

Systems Overview

Parts Facilities Guides Planning Potential

Parts Facilities Guides Inventory Value

Basic Floor Plan

Detailed Floor Plan

Space Allocation Guides

Parts Department Relative Location

Sample Manual Planograph

Modular Drawer Cabinet

Aisle Saver

Parts Carousels

Service Department Monorail

Double Decking Requirements

Potential Area for Expansion

Free Standing Deck

Retail Area Planograph

Counter Dimensions

Space Recommendations

Maintenance and Safety Schedule

6

10

11

12

13

16

17

27

31

32

33

34

41

42

43

55

60

60

68

PA RTS EXC E L L E N C E

THIS PAGE INTENTIONALLY LEFT BLANK

vi

FACILITIES DEV E LO P M E N T

Introduction - Facilities Development

PURPOSE

The purpose of this Module is to establish:

An understanding of the basic concepts that pertain to Facilities

Development

Methods for fully utilising the resources of space and equipment in a Parts

Department

The relationships between Facilities Development and sales, profit and

Customer Satisfaction

REALISTIC BENEFITS

Properly administering Facilities Development will result in:

Increased operational efficiency

Reduced parts handling time

A safer, more secure, Parts Department

Properly stored parts

Regular maintenance of equipment

Improved sales

Improved profit

Improved Customer Satisfaction

FACILITIES DEVELOPMENT IS VITAL

Space is a limited and expensive resource. Most Dealerships do not have the

luxury of being able to expand their Parts Department. Because of this, the

Dealership must take full advantage of the space available in the Parts

Department.

Proper management of the facility leads to improved operating efficiency. If less

time is spent receiving, stocking, maintaining and retrieving parts, then greater

profits can be realised through reduced personnel expense. Less time retrieving

parts also leads to greater Customer Satisfaction.

SYSTEM OVERVIEW

An overview of the Facilities Development System is shown on the next page. In

order to present a logical review of the materials, the System will be discussed in

the four major sections:

Physical layout

Parts Storage

Customer Areas

Safety & Security

Each of these areas has an impact on sales, profit and Customer Satisfaction. The

diagram on the following page points out the relationships.

PA RTS EXC E L L E N C E

Introduction - System Overview

PHYSICAL

LAYOUT

PARTS

STORAGE

OPERATING EFFICIENCY

SAFETY &

SECURITY

CUSTOMER

SATISFACTION

SALES

CUSTOMER

AREAS

PROFIT

FACILITIES DEV E LO P M E N T

Physical Layout - Evaluators

QUALIFIER

DEALER ACTION

ANALYSE

RESOURCES

Parts Department space resources

are analysed to determine if they

are most effectively utilised

Facilities Guides

Floor Plan

10

15

RELATIVE

LOCATION

DEALERSHIP

Parts Department to be easily

accessible to all other departments,

especially Service and Body Shops

20

RELATIVE

LOCATION

CUSTOMERS

Parts Department to be organised in

a manner that is convenient and logical

for customers

Retail and Wholesale Counter

Cashier

15

10

Parts Department to be organised in a

manner which maximises work-flow

efficiency

Technician

Shipping and Receiving

Parts Managers Office

10

10

10

RELATIVE

LOCATION

INTERNAL

Assessment Score (100 points possible)

Certification requires a score of 80 or above

VALUE

PA RTS EXC E L L E N C E

Physical Layout - Introduction

INTRODUCTION

In this section methods for optimising floor space will be addressed. In some

Dealerships, the Parts Department accounts for up to thirty-three per cent of the

total Dealership building space. Efficient use of that space is critical.

In most Dealerships, personnel expense accounts for the greatest portion of total

Parts Department expenses. Proper layout of the facility maximises not only

space but the efficiency of personnel as well.

Every Parts Department should show evidence of planning. Efficient layouts do

not just happen, they are planned. Plans should take into account current and

future needs of the Parts Department.

PURPOSE

There are two objectives to the layout of the Department:

1. To get parts from inventory to a customer (SALES)

2. To do it at minimum cost (OPERATING EFFICIENCY)

The layout of the Parts Department is the key element in obtaining the least cost

of handling parts. There are a number of good reasons for improving the

effectiveness of layout planning. Space is becoming more expensive with higher

building materials, labour and land costs. Also, when a layout is changed or an

expansion has to be made, we need to minimise the effect of the change on the

parts operations.

The strongest reason to obtain the best possible layout is that most of the

handling operations that are performed in the Department are repeated daily all

year long. If the shortest and most direct method of handling is not practised,

each increment of wasted time by people quickly reduces the total effectiveness

and profit of the Parts Department. Ineffective planning of Department layout

can build a space penalty which may take years to overcome.

FACILITIES DEV E LO P M E N T

Physical Layout - Analyse Resources

FACILITIES GUIDES

Facilities Guides are used to aid the Dealership in determining the appropriate

amount of space to devote to the Parts Department. They are used to assist the

Parts Manager in determining the adequacy of existing facilities and estimating

what is needed for projected growth.

Total Parts Department square footage (metres) recommendations are based on:

1. Planning Potential

2. Inventory Value

PLANNING POTENTIAL

Planning Potential is a reasonable expectation of annual new car or truck unit

sales level for a Dealership. It is particularly helpful to use Planning Potential as

a basis for total Parts Department floor space when a major expansion or new

facility is being considered.

Planning Potential guidelines have been included for reference purposes only

and should not be the principal factor in estimating floor space requirements for

an existing Parts Department. The guides cannot replace individual experience

and familiarity with local market conditions. Each Dealership must analyse its

own current parts business and set goals for future sales levels.

INVENTORY VALUE

Facilities Guides based on Inventory Value are also available. As it is used here,

Inventory Value refers to the dollar value of on-hand parts and accessories at the

most recent factory price. The guidelines were developed based on the following

assumptions:

No obsolete parts

Balanced inventory of normally stocked parts

3 to 4 turns per year

Maximum of 10% inactive parts

30% wholesale business

The following pages provide Facilities Guides based on both Planning Potential

and Inventory Value.

PA RTS EXC E L L E N C E

Physical Layout - Analyse Resources

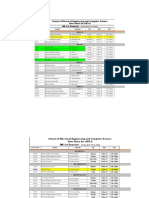

PARTS FACILITIES GUIDES

Based on Planning Potential

Planning

Potential

Cars and Lt.

Duty Trucks

Sq. Feet

Cars and Lt.

Duty Trucks

Sq. Metres

50

100

200

300

400

500

600

700

800

900

1,000

1,100

1,200

1,300

1,400

1,500

1,600

1,700

1,800

1,900

2,000

2,100

2,200

2,300

2,400

2,500

2,600

2,700

2,800

2,900

3,000

1,200

1,600

2,000

2,800

3,800

5,000

5,800

6,600

7,400

8,200

9,000

9,300

9,600

9,900

10,200

10,500

10,800

11,100

11,400

11,700

12,000

12,500

13,000

13,500

14,000

15,500

16,000

16,500

17,000

17,500

18,000

112

149

186

260

353

465

540

614

688

763

837

865

893

921

949

977

1,005

1,033

1,060

1,088

1,116

1,163

1,209

1,256

1,302

1,442

1,488

1,535

1,581

1,628

1,674

3,000

and Over

Add 500 sq. ft. Add 50m2

Per 100 P.P. Per 100 P.P.

10

Full-Line

Heavy Duty

Trucks

Sq. Feet

Full-Line

Heavy Duty

Trucks

Sq. Metres

1,700

2,000

2,500

2,900

3,800

5,000

5,800

6,600

7,400

8,200

9,000

158

186

233

270

353

465

540

614

688

763

837

FACILITIES DEV E LO P M E N T

Physical Layout - Analyse Resources

PARTS FACILITIES GUIDES

Based on Inventory Value

Inventory

Value $

Total

Sq. Feet

Required*

Total

Sq. Metres

Required*

Total

Sq. Feet

Required**

Total

Sq. Metres

Required**

25,000

50,000

75,000

100,000

125,000

150,000

175,000

200,000

225,000

250,000

275,000

300,000

325,000

350,000

375,000

400,000

425,000

450,000

475,000

500,000

1,790

3,000

4,040

5,040

6,010

7,020

7,970

8,890

9,700

10,550

11,300

12,030

12,830

13,520

14,270

14,980

15,680

16,300

16,900

17,500

167

279

376

469

559

653

741

835

902

981

1,051

1,119

1,194

1,258

1,327

1,394

1,459

1,516

1,572

1,628

895

1,500

2,020

2,520

3,005

3,510

3,985

4,490

4,850

5,275

5,650

6,015

6,415

6,760

7,135

7,490

7,840

8,150

8,450

8,750

84

140

188

235

280

327

371

418

451

491

526

560

597

629

664

697

729

758

786

814

* Using Standard Bins

** Using High Density Bins

11

PA RTS EXC E L L E N C E

Physical Layout - Analyse Resources

FLOOR PLAN

Regardless of size, most Dealership Parts Departments have a similar set of

functional requirementsbasic, common business needs that must be supported

by the appropriate facilities. Limitations are imposed on any Parts Department

by the physical size of the Dealership and the available floor space. Further

limitations are introduced by building design and construction. The Parts

Manager must make the best possible use of that floor space to meet or exceed

Departmental objectives.

A Floor Plan is an architects rendering of the fixed construction features of the

building. The basic floor plan is normally an overhead view, looking straight

down at the floor space, drawn to scale and showing the exact location of walls,

doorways, windows, pillars and other non-moveable building elements. The

Floor Plan of a typical Parts Department is shown below.

BASIC PARTS DEPARTMENT FLOOR PLAN

Body Shop

Parts Department

Order

Dept.

Inventory

Mgmt

Office

Parts

Mgrs.

Office

Retail &

Wholesale

Counter

Cashier

Other construction drawings show the location and capacity of electrical wiring,

fixtures and outlets, plumbing, heating and air-conditioning elements. All of this

information can be important in planning the cost-effective use of existing floor

space, particularly where only rearrangement and a minimum in alterations are

desired.

12

FACILITIES DEV E LO P M E N T

Physical Layout - Analyse Resources

If the primary planning tool, a basic Floor Plan, is not available, one can be

developed. All that is needed is a tape measure, a sketch pad and the time to

measure and record dimensions and locations, transferring the data into Floor

Plan format on graph paper to maintain the scale relationships. In any case, the

Floor Plan should be a reference drawing, altered only when changes are made

to the fixed construction.

Arrangement of storage equipment should be planned by using a layout

drawing. A layout is a working drawing, a tracing or reproduced copy of the

Floor Plan.

A layout of the Parts Department should be used to plan, in advance,

rearrangement of functional elements such as bin and rack locations, aisleways,

shipping and receiving areas, counter service space and so on. A detailed layout

indicates the placement of storage equipment within the Floor Plan.

DETAILED PARTS DEPARTMENT LAYOUT

13

PA RTS EXC E L L E N C E

Physical Layout - Analyse Resources

OVERALL FLOOR PLAN

Scaled to size cutouts of bin units, desks, chairs and almost every other moveable

item of equipment can be prepared. Moving these cutouts around on the layout

drawing, to arrive at the best arrangement for space utilisation is the most

practical way to plan for optimum function and usage. There are also computer

software programs available that can be used to develop Floor Plan layouts.

Obviously, the planned allocation in any particular Dealership should be

determined by actual and projected needs. Comparisons are helpful, however, in

evaluating how other successful Dealerships parts operations are handling the

same kind of space utilisation challenges.

The following is not a complete list in evaluating a Floor Plan; however, here are

some items to be considered:

Parts Managers office should be located so as to afford maximum

visibility of Department

The inventory control system should be located near the Parts Managers

office when practical

A separate area should be used by telephone order interpreters for

incoming wholesale parts orders, whenever practical, to avoid confusion

at counter

Complete physical security

The Cashier should be located near the retail counter

Shipping and receiving areas should provide easy access to public streets

and adequate area for vehicle manoeuvring

Large body panels should be stored in a location convenient to the

shipping area and as near the Body Shop as is practical

Elevators, winches, forklift trucks or conveyors should be employed as

practical

Department should be inaccessible to anyone other than Parts

Department employees

14

FACILITIES DEV E LO P M E N T

Physical Layout - Analyse Resources

TO IMPROVE AVAILABILITY OF FLOOR

SPACE

If the Dealership does not currently have adequate area to meet the needs of the

Parts Department:

Make sure all existing obsolete and excess parts are removed from

Inventory. Re-evaluate your need for additional area

Buy, rent or lease additional area

Measure the area currently used for bulky parts storage-fenders,

mufflers, etc.

Determine if this area might be used more profitably for storing faster

moving, smaller parts

If a favourable decision is reached, consider using nearby suitable

buildings or an area within a building for storing bulky parts

Consider double-decking the existing area. Adequate height must be

available to permit building a mezzanine and adhering to local building

and safety codes

Use a trailer for obsolete parts

TOTAL AREA

The Floor Plan of the Parts Department must be efficiently laid out. An efficient

Floor Plan can have a significant effect on how quickly parts are located, picked

and re-stocked. Also, it will reduce both customer and technician waiting time.

The Parts Department requires approximately twenty to thirty-three per cent of

the total Dealerships building area depending on the planning potential.

Efficiency in the Parts Department begins with its relationship to the Service

Department. A central location that allows fast distribution to service

technicians in the customer service area and the Body Shop is the best.

The configuration of the service area will influence the amount of efficiency and

control that is possible. For instance, a long drive-through in the Service

Department with the Parts Department at one end tends to reduce parts

distribution efficiency in proportion to its length. This is important to keep in

mind when planning for eventual expansion of the service area. The question

should always be: How will the service area expansion affect parts distribution?

15

PA RTS EXC E L L E N C E

Physical Layout - Analyse Resources

SPACE ALLOCATION

As a rule of thumb, the total floor space allocated to the parts operation is

distributed in the following proportions:

PARTS DEPARTMENT

SPACE ALLOCATION GUIDES

AREA

% of Total

Parts Space

Regular Parts Bins

Bulky Parts

Other Bins and Racks

Shipping and Receiving

Counter

Supplies

Office

TOTAL

25

25

25

10

6

5

4

100

All percentages include aisles

New storage concepts such as Modular Drawing Cabinets, Aisle Savers and

Carousels will be discussed in the parts storage section of this Module. These

modern storage units allow a Dealership to store more parts in much less space.

16

FACILITIES DEV E LO P M E N T

Physical Layout

- Relative Location, Dealership

RELATIVE LOCATION - OTHER

DEPARTMENTS

The Parts Department must be located to provide convenient access to the

Service and Body Shops, whiles also allowing easy access for wholesale and retail

walk-in customers. Oversights in the planning stage can create a significant

amount of additional operating expense through inefficiency.

The primary Parts Department customers are the Dealerships own Service and

Body Shops. They require replacement parts, materials and accessories to service

and maintain customers vehicles. Adequate servicing of vehicles is a major

concern to the Dealership. The location of the Parts Department, relative to the

Service and Body Shops, is an important factor for efficient operations.

The arrangement shown below replaces the Parts Department in an

advantageous location. This location permits more efficient service and parts

distribution for internal sales as well as for wholesale and retail customers.

PARTS DEPARTMENT RELATIVE

LOCATION

Body Shop

Parts Dept.

Quick Service

Service Dept.

17

PA RTS EXC E L L E N C E

Physical Layout

- Relative Location, Customers

Within the Parts Department there are three areas which external customers

must approach:

Retail Counter

Wholesale Counter

Cashier

The customers perceptions of ease of doing business with the Dealership are

affected by these areas.

RETAIL AND WHOLESALE COUNTER

If the Retail and Wholesale Counter (often the same counter) area is so small

that it creates customer traffic problems and it cannot be expanded, relieve

some of the pressure by making the waiting area comfortable and pleasant. Use

a numbered tag system to determine who is to be waited on next. If space

permits, install food and beverage vending machines to increase customer

comfort and Dealership revenues.

Consider moving microfiche readers and catalogues to a separate parts

administration area to provide additional counter space.

Use imagination to discover ways to display parts and accessories without using

valuable counter space. The key to successfully planning this area is to keep it

convenient and functional for both the Dealership and its customers.

CASHIER

The Cashier area should be located near the:

Retail and Wholesale Counter

General Office

Repair Order Rack

Correct location of the Cashier makes it convenient for customers to pay for

parts and accessories and also prevents them from leaving without paying.

By locating the Cashier near the general office it is easier to review customers

accounts. Past due receivables and customer credit limits become readily

accessible.

Locating the Cashier near the repair order rack speeds up paper flow. When a

repair order is closed and the hard copy is turned in, it can be handed

immediately to the Cashier for labour posting and parts pricing.

18

FACILITIES DEV E LO P M E N T

Physical Layout

- Relative Location, Internal

The location of three main areas within the Parts Department have a

significant impact on operating efficiency. They are:

Technicians Counter

Shipping and Receiving Area

Parts Managers Office

TECHNICIANS COUNTER

If possible, separate technician and customer traffic. A counter for each allows

both to be serviced without having problems arise from the different nature of

each customers transaction.

Keep the Technician and Retail/Wholesale Counters close enough to one

another to allow one counterperson to service both of them.

As much as possible, store fast-moving parts and supplies near the Technicians

Counter to save time for both the counterperson and technician.

SHIPPING AND RECEIVING

Although the Shipping and Receiving area is part of the inventory storage space,

it should be clearly separated. Ideally, Shipping and Receiving functions should

be separated from each other and identified with signs to avoid confusion. If this

is not possible, separate doors for this area may provide enough separation. Or,

at a minimum, different coloured stripes on the floor can be used to designate

the appropriate area for each function.

The Shipping and Receiving area should be close to the outside receiving door.

This promotes quicker unloading and loading, better security against

wandering delivery people, and better control for checking in deliveries. The

receiving clerk should have a desk and workspace for shipping information

books, packing slips and other paperwork.

PARTS MANAGERS OFFICE

The location of the Parts Managers Office should provide adequate visibility of

the Parts Department while working on administrative activities.

If possible, the office should be designed for privacy (when needed), for

planning, for working on sensitive financial information, for paperwork and for

employee counselling.

If the Department is short of space, consider placing the inventory control

system in the Parts Managers Office. This critical, time consuming function

should be isolated from the rest of the Department so it can receive the

concentration it requires.

19

PA RTS EXC E L L E N C E

Physical Layout - Decision Grid

RESPONSIBILITIES

EXPECTATION

RESPONSE

PHYSICAL LAYOUT

Department is organised to facilitate

sales

PURPOSE

Department is organised to maximise

operating efficiency

APPROPRIATE

AMOUNT OF

SPACE, BINS AND

RACKS AVAILABLE

Adequate total space based on

inventory value

Adequate total space based on planning

potential

Sufficient number of regular bins

Sufficient number of bulky bins

Sufficient number of other bins and

racks

Suitable shop counter space

Suitable retail and wholesale counter

space

Satisfactory shipping and receiving area

Satisfactory office space area

20

FACILITIES DEV E LO P M E N T

Parts Storage - Evaluators

QUALIFIER

DEALER ACTION

STORAGE

PLANNING

Parts Department space resources are

planographed to determine if they are

most effectively utilised

STORAGE

EQUIPMENT

STORAGE

AREAS

PARTS

ORGANISATION

EXPANSION

VALUE

Parts Department utilises appropriate

types and adequate number of bins and

racks

Regular Bins

Bulky Bins

Racks

Special areas are designated for the

following types of parts

Special order

Warranty

Return

Cores

Supplies

The Parts Department has

A logical and easy to use bin

locating system

Same quantity and location

in bins as in system

Correct labels on bins

Parts Department is capable of

expanding upward and outward

Assessment Score (100 points possible)

Certification requires a score of 80 or above

21

10

10

12

6

6

6

6

6

12

5

4

10

PA RTS EXC E L L E N C E

Parts Storage - Introduction

INTRODUCTION

Storage space in a Dealerships Parts Department is always at a premium. There

never seems to be enough room. Even in a new facility, empty space fills up

almost overnight.

Methods for storing parts will be covered in this section. In some Parts

Departments, parts storage accounts for up to eighty-five percent of the total

Parts Department area. As space and manpower are so important to the Parts

Department, it is vital to have good organisation and location of parts, proper

storage equipment and room for expansion.

One of the responsibilities of a Parts Manager is planning for effective inventory

storage. This plan should consider not only current parts storage requirements,

but also those needed for the future.

PURPOSE

The objectives of this section on Parts Storage are:

1.

2.

3.

4.

5.

To plan for storage areas

To utilise proper storage equipment

To have special purpose areas

To locate and retrieve parts accurately and easily

To plan for growth

22

FACILITIES DEV E LO P M E N T

Parts Storage - Storage Planning

STORAGE PLANNING

Good planning avoids the use of critically needed parts storage areas for other

Dealership needs. These needs often include utilities (e.g. electrical and

telephone terminal areas) and remote service equipment (e.g. air compressors

and bulk fluid storage tanks). These installations frequently end up in the Parts

Department almost as an afterthought in overall Dealership design. The location

of utilities somewhere other than the Parts Department will facilitate future

expansion.

The Parts Departments space resources should be analysed to determine if they

are being utilised most effectively. The Parts Manager should make every effort

to ensure that all available space in the Parts Department is being used as well as

it could. It also implies that consideration for expansion (upward and/or

outward) has been made.

PLANOGRAPHING

Before growing outward and upward, the existing storage areas in a Parts

Department should be utilised in a logical and efficient manner.

A Planograph can be of considerable help before setting up bins in a new facility

or making major alterations in an existing one. A Planograph is simply a drawing

which establishes how parts best fit into existing bin space.

Planographing, computerised or manual, is virtually the only available method

that systematically assures adequate storage space for every part in a specific

inventory. The benefits of Planographing include:

Maximising storage efficiency

Reducing labour expense

Planning for future storage requirements

A Planograph drawing, one for each bin unit, represents a full front view of

where every part will be located in each bin space or opening. Necessary shelf

heights and spaces between dividers (where appropriate) are laid out in advance,

to accommodate the various sizes and quantities of each item to be carried in

stock. Surplus or open space on the shelves, usually designated by an S is

included for future growth and expansion. Ideally, the inventory should include

no obsolete parts and a minimum of inactive parts.

23

PA RTS EXC E L L E N C E

Parts Storage - Storage Planning

To obtain good information for developing a Planograph the Dealership should

have a computerised parts inventory control system. The system should have

been operating for at least one year. It also should be able to generate a piece sales

report (i.e. number of piece sales over the past twelve months by part number).

If any of these conditions are not met the Dealership would be better off not

investing the time and money on a Planograph.

There are three primary methods of organising parts:

By piece movement

By size or weight

By group and part number sequence

Normally, parts are stored by a combination of these three rather than by just

one. The Parts Manager must prioritise them. Historically, group and part

number sequence was of primary importance followed by size/weight and then

piece movement.

Modern facilities are being driven more by efficiency than by group and part

number logic. Given this, the first priority is piece movement followed by

size/weight then group and part number sequence. Fast moving parts are close to

the front and slow movers are toward the rear. Bulky parts have special storage

areas. Parts that are not fast, slow or bulky are then organised by group and part

number.

These three criteria must apply whether the Parts Manager chooses manual or

computerised Planographing.

24

FACILITIES DEV E LO P M E N T

Parts Storage - Storage Planning

COMPUTERISED PLANOGRAPHING

Computerised Planographing is a recent innovation that provides parts storage

suggestions in very little time. Creating a computer generated Planograph is the

quickest and easiest way to plan the storage space required for a Dealerships

inventory.

Many bin companies provide Planographing services. There are also companies

that specialise in creating Planographs for dealers.

The physical dimensions of the majority of service parts can usually be obtained

from the vehicle manufacturers parts operation. The Planograph computer

program combines this information with the Dealerships bin dimensions.

With Computerised Planographing individual bin units are blue-printed to

show the spacing of shelves, locations of dividers and the part number shown for

each opening. Part numbers are assigned to bin locations dependent upon their

piece movement, size/weight and group sequence based on the priority chosen

by the Parts Manager.

A computer can automatically add the desired percentage of open bin space

desired for future expansion. A twenty-five percent surplus is recommended as a

minimum.

25

PA RTS EXC E L L E N C E

Parts Storage - Storage Planning

While it is faster and easier to have specialists perform the Planographing, a Parts

Manager can prepare his own Planographs using simple tools and information

available within the Dealership. This Manual Planographing requires a great deal

of time and a considerable amount of calculations. However, it can produce the

same kind of customised results as a computer based Planographing process.

The first step in Manual Planographing is the preparation of a complete listing

of every part number in inventory. The listing should not include parts to be

returned or scrapped, or special order parts that normally are not carried in the

inventory. The Parts Manager should decide the criteria by which parts will be

stored. The use of an inventory pad will be helpful and reduce writing. During

this phase, the following information should be determined for each part or

accessory:

Piece sales by part number

Group and part number, in sequence

Quantity or guide level to be carried in stock

Number of units per package

Items to be stored in drawers

An R notation for sheet metal and other parts to be stored in racks

A B notation for items to be stored in bulky bins

An MR notation for moulding racks

With a computer based inventory control system, the inventory company can

furnish an up to date list of part numbers by piece sales, as well as the

recommended stocking quantity for each part. A listing by numeric sequence

will also be helpful.

The second step is determining the physical size (length, width and height) of

each part or package. These dimensions should be recorded next to the part

number on the inventory listing or inventory pad.

The third step is combining the stocking levels and dimensions of each part to

determine the bin size opening needed for each part number.

After all information has been compiled an organised parts storage system can

be properly planned. Prepare an outline drawing of the front view of each type

of storage unit. The dimensions should be drawn to scale on graph paper to

simplify the Planograph layout.

26

FACILITIES DEV E LO P M E N T

Parts Storage - Storage Planning

SAMPLE MANUAL PLANOGRAPH

Provision should be made for a 3 inch (7.6cm) dust plate at the bottom of the

bin. Also allow for the 1 inch (2.5cm) flange on the front of each shelf and on

each bin side and divider, although this will vary with different equipment

designs. A copy of the drawing for each type of standard bin or rack can be used

to make the actual Planographs for individual units of that type. Follow these

steps:

Plan the regular parts bins first

Number each bin Planograph consecutively

Start with regular parts bin number one

Determine a top shelf position by the height needed for the first four or five

number openings. If, for example, the first parts were to require 6 inch by 6 inch

(15.2cm x 15.2cm) bin openings, the uppermost shelf should be positioned 6

inches (15.2cm) down from the top. Draw a line on the Planograph to show that

shelf location. Develop a percentage of surplus space, shelf by shelf, so new part

numbers or an expanded stock of existing part numbers can be added without

major rearrangement .

27

PA RTS EXC E L L E N C E

Parts Storage - Storage Planning

MANUAL PLANOGRAPHING

Continue the same process for each shelf, looking ahead on the inventory list to

select the most efficient shelf space for each row of parts depending on the

priority of criteria.

After regular parts bin number one has been planned completely, number two

should be laid out then bin number three and so forth, until all the regular parts

in inventory (or recommended for stocking) have been included in the storage

plan.

Storage of bulky parts can be planned manually following the same procedures

used for Planographing the regular parts bins.

From the inventory printout or pad, all the items with a B notation are

assigned shelf space on the bulky bin Planographs. Follow these tips:

Group number and part number sequence should be maintained within

the bulky bin storage section

Surplus space should be allowed for addition of new parts or increased

quantities of existing inventory

Bulky parts bins are usually for parts of such a size that bin dividers are not

required. A bin label, in the middle of the assigned space on a shelf is used to

designate the parts location.

A similar process should be used for sheet metal and moulding racks.

28

FACILITIES DEV E LO P M E N T

Parts Storage - Storage Equipment

Bins and racks are the building blocks used to put a stock room together.

Commercial bins and racks are available to provide optimum storage for almost

any type of automotive part. Most are manufactured in standard sizes to fit

together for compact arrangement.

REGULAR BINS

Regular bins are available in a range of standard sizes. Almost any shape and size

can be ordered to fit a particular requirement. Adjustable shelves and dividers

provide the flexibility needed for the most effective use of total bin space.

Regular Bins used for storing small parts are designed with a shelf depth of 6

inches (15.2cm) to 36 inches (91.4cm). They are available in 6 inch (15.2cm)

increments.

The most commonly used unit is 36 inches (91.4cm) wide by 84 inches (2.1m)

high by 12 inches (30.5cm) deep. Each unit requires 3 square feet (27.9 sq. dm)

of floor space and an aisle width of 36 inches (91.4cm).

BULKY BINS

Bulky Bins are used to store parts that usually do not require bin dividers. They

typically come in depths of 18 inches (45.7cm). 24 inches (61cm) and 36 inches

(91.4cm).

The most commonly used unit is 36 inches (91.4cm) wide by 84 inches (2.1m)

high by 24 inches (61cm) deep. Each Bulky Bin unit requires 6 square feet (55.8

sq. dm.) of floor space and an aisle width of 36 inches (91.4cm).

RACKS

In addition to Regular Bins and Bulky Bins other storage units called Racks are

used for odd shaped parts. Although prefabricated Racks are available for a Parts

Department, most are assembled from components to meet the specific needs of

a Dealership.

The majority of Racks are constructed in the Dealership using commercially

available steel framing materials. Most uprights and cross members can be

obtained in convenient pre-cut lengths. Most types interact and require no

special tools to assemble. From a range of steel thicknesses, a selection can be

made to support virtually any weight.

29

PA RTS EXC E L L E N C E

Parts Storage - Storage Equipment

Racks can be used to store the following:

Mouldings

Wheels

Tail pipes

Mufflers

Tyres

Sheet metal

Windshields

Pallets

The actual design of a Rack will depend on the storage required and the available

floor space. Ingenuity is the key to effective Rack design. Carefully consider the

shapes, sizes and weights of the parts to be stored. Then draw the possible

construction layouts on graph paper. This should result in a Rack that meets the

exact storage need and uses a minimum amount of floor space.

ADDITIONAL STORAGE IDEAS

Store heavy items on the lowest shelves and bulky items overhead or hung in a

rack. Never cover ventilators with bins, cases or other storage racks.

Another way to get more storage from the same amount of space is to change to

smaller depth bins. By replacing 18 inch (45.7cm) or 24 inch (61cm) deep bins

with 12 inch (30.5cm) bins an extra row can be added in the same space.

Open space above existing parts bins might be a source of additional storage

capacity. With 2 feet (61cm) of space over the bins, units known as quarter bins

can be added. These 18 inch (45.7cm) high bins are available in depths to match

the units on which they are placed. As the name quarter bin implies, about

twenty-five per cent can be added to the existing storage capacity without the

need for additional floor space.

When quarter bins are used step stools are needed for bin access. The most

convenient type of stool is on castors that lock when anyone steps on the stool.

These stools can be rolled easily to wherever they are needed and yet are stable

and safe during use.

30

FACILITIES DEV E LO P M E N T

Parts Storage - Storage Equipment

MODERN EQUIPMENT

Many new pieces of equipment are available for parts storage. These high density

storage and retrieval systems are configured to take advantage of the space

available in the Parts Department.

MODULAR DRAWER CABINETS

Modular Drawer Cabinets allow more parts to be stored in less space. They hold

approximately twice the amount of inventory in the same amount of floor space

as conventional storage systems.

They are available in various dimensions and drawer configurations. Within each

drawer, a number of parts may be stored. This helps to speed order picking and

stocking and therefore lowers labour costs.

MODULAR DRAWER CABINET

31

PA RTS EXC E L L E N C E

Parts Storage - Storage Equipment

AISLE SAVERS

Aisle Savers are moveable storage systems that create space by eliminating the

need for aisles. This type of system also condenses the amount of space needed

to store parts into almost half of that required using standard aisles.

Only one aisle is needed in this type of system. Shelves on wheels are connected

to a track. A parts picker can open to the aisle required for the desired part. This

system works well in small Dealerships.

AISLE SAVER

32

FACILITIES DEV E LO P M E N T

Parts Storage - Storage Equipment

PARTS CAROUSELS

Parts Carousels are a series of bins on a motorised track. Parts are stored in

containers on adjustable shelving. The parts picker simply dials the bin desired

and the parts carousel automatically brings it to the counter.

This system increases storage capacity by nearly one third compared to

conventional storage. It also reduces the time required to pick parts. Carousel

systems work well in Dealerships with a large inventory of fast moving parts.

PARTS CAROUSELS

33

PA RTS EXC E L L E N C E

Parts Storage - Storage Equipment

SERVICE DEPARTMENT MONORAILS

Service Department Monorails are overhead dispatch systems that automatically

deliver parts to the technicians work area. The part is placed in a special basket

that hangs from the Monorail. The basket travels along the monorail from the

Parts Department to its pre-determined destination within the Service

Department for use by the technician.

SERVICE DEPARTMENT MONORAIL

This system eliminates the need for parts runners and does not require

technicians to walk to the counter to request parts. An intercom system or

computer terminal between the technicians work area and the parts counter is

necessary for this system to operate properly.

34

FACILITIES DEV E LO P M E N T

Parts Storage - Storage Areas

Within the Parts Department, specific storage areas should be dedicated to the

storage of Special Order Parts, Warranty Parts, Return Parts, Cores and Supplies.

Because these parts are not kept with normal inventory they require their own

locations.

SPECIAL ORDER PARTS

Special Order Parts should be maintained separately from the rest of the stock.

They can be organised alphabetically and by the customers last name to facilitate

storage and retrieval. Standard procedures should be established to notify the

customer that the ordered part has arrived.

Even though customers often have paid a deposit and are aware that their Special

Order Parts are available, some are negligent in picking up the part or arranging

for its installation by the Service Department. All Special Order Parts should be

reviewed periodically. After reasonable customer notification and follow-up

(approximately 60 days) parts not picked up, if returnable, should be returned.

A specific person in the Parts Department should be responsible for the handling

of Special Order Parts. When received, follow up all special orders with both a

mailed notice and telephone call to the customers home or business.

Special orders that sit for long periods of time waiting to be picked up by

customers take up valuable space. The space required will vary greatly depending

upon the volume of Special Orders, length of time held and follow-up

effectiveness.

35

PA RTS EXC E L L E N C E

Parts Storage - Storage Areas

WARRANTY PARTS

Dealership procedures for the handling of parts replaced under warranty terms

are critical to customer satisfaction and Dealership profit. These parts should be

stored in a separate area until their disposition is determined. The area, of course,

should not interfere with traffic flow, but it should be accessible, secure, well

ventilated and well lit.

Having an area assigned for storage of Warranty Parts reduces obsolescence and

helps avoid loss due to misplacement. A central location for Warranty Parts

improves control over these items and provides a place for those scheduled for

return or inspection.

The Warranty Parts area should be separate from the general parts storage area

because of the static nature of Warranty Parts. It also should be located near

shipping and receiving.

Administration of Warranty Parts is usually hampered by lack of space.

Overflowing bins or empty boxes in the Parts Department are a common

problem. Allow about three per cent of the total Parts Department for the

Warranty Parts return area. There are many configurations which can be used to

create an efficient Warranty Parts area. Depending upon individual needs and

Warranty Parts volume, consider the following examples as possible solutions.

TEN BIN SYSTEM

In the Ten Bin System, the storage area is divided into ten sections with each

section numbered to correspond with the last digit of either the repair order

number or the warranty claim number.

10

36

FACILITIES DEV E LO P M E N T

Parts Storage - Special Bins

CALENDAR SYSTEM

The Calendar System has a bin number that corresponds to the day of the

month on a repair order or the warranty claim.

10 11

12 13 14

15

16

17

18 19

20 21 22 23

24

25

26 27

28 29 30

31

Regardless of the system used, it is imperative to purge parts from warranty bins

regularly.

RETURN PARTS

Return Parts bins should be used to consolidate parts to be returned for credit.

Items designated for return may include:

Special Order Parts (not normally stocked) which have not been picked

up by the customer

Parts received in error

Parts ordered in error (and coded returnable)

Items damaged in shipment (awaiting disposition) from the factory.

Incorrectly unitised parts

CORES

Cores and other exchange parts should have their own storage area. An area near

shipping and receiving is a logical choice. Existing policies and procedures

should dictate how frequently they are returned.

37

PA RTS EXC E L L E N C E

Parts Storage - Supplies

SUPPLIES

It is common practice to store office supplies, sales promotion materials, forms

and housekeeping supplies in the Parts Department. But it is not good business

when these supplies occupy storage space that could be better used to store

money-making parts and accessories.

Common office supplies and forms should be stored in the general office area.

Housekeeping supplies should also be stored outside the Parts department.

Bulk stored fluids such as oil, anti-freeze and transmission fluid should be kept

in above ground tanks or in drums located in the Service Department. Usage

should be controlled by a meter system and monitored by the Parts Department.

In the ideal Parts Department, the only items that should be stored, other than

parts and accessories, are the counter tickets required for the month and

disbursable shop materials.

38

FACILITIES DEV E LO P M E N T

Parts Storage - Parts Organisation

BIN LOGIC

In addition to having proper equipment and storage areas for parts, a Parts

Department should have a logical bin locating system. This not only contributes

to efficienct operation, but also to improved customer service and profit.

There are two primary methods by which bins are organised:

1. Group numeric sequence

2. Bin number location

Using a group numeric sequence, parts are first organised by group number and

then sequentially by part number within each group. There are a number of

benefits to having a Parts Department organised in this fashion:

Easy to locate parts

Easy to stock parts

Parts of similar function are stocked together

A second method is to organise by bin number location. This type of logic is best

utilised in a Dealership which has a computerised inventory control system.

Whereas the previous method is organised by group number, this method

organises by movement and size. Parts are stored where they best fit into a bin

rather than rearranging the bins to fit group numbers.

The advantages of storing parts by bin number location are:

Faster moving parts are located near the counter

Any part can be stored where it best fits into the storage system, provided

ample space is available for the size of the particular part

BIN LOCATION

Bin Locations should be specific and should be easy to locate for new employees.

Combining numeric and letter codes seems to work best. For example the first

letter might indicate the following:

A Regular storage area, main level

B Upstairs storage area

C Counter area high density storage cabinets

39

PA RTS EXC E L L E N C E

Parts Storage - Parts Organisation

The next number would indicate groups of bins or cabinets within a single

section. For example the number 15 could indicate 15 sets of bins from the

front of the Parts Department. The following letter could indicate the shelf or

row of a cabinet. These letter codes usually start with A at the bottom and go

up from there. Finally, a number code could indicate from left to right how

many slots over, or in, the part is located.

Bin location A15C4 could indicate that the part is stocked on the main level, 15

sets of bins from the front, third shelf from the bottom and fourth location from

the left.

Bin location C4B1 - 3 could indicate the fourth high density storage cabinet in

the counter area, second drawer, first row, third section.

BIN CHECKS

It is a good practice to occasionally conduct a Bin Check. The purpose is to

ensure that the Bin Location and quantity shown in the computer system match

the physical location and inventory.

Randomly select twenty-five part numbers. Find their location and on hand

quantity in the computer system, and compare it to the actual physical

inventory. Any discrepancies with the bin location should be corrected

immediately. Discrepancies with quantities need to be investigated further.

BIN LABELS

Bins should be identified with readable labels. Bin Labels should be used to

identify all parts storage locations.

Good labelling assists not only parts locating but restocking and inventory

taking. Poor labelling can result in:

Lost sales of stocked parts

Emergency orders of stocked parts

Picking incorrect parts

Unintentionally stocking a part in multiple locations.

Bin Labels are available from vendors or the Parts Manager may prefer to create

his own.

40

FACILITIES DEV E LO P M E N T

Parts Storage - Expansion

Important features for planning expansion include:

Ceiling height

Reinforced floors

Outside wall for expansion

Another important consideration for expansion is the ability to double deck the

Parts Department.

CEILING HEIGHT

Although parts facilities are typically planned for only one level, a provision

should be made for increased ceiling height. A minimum height of 17 feet

(5.2m) of unobstructed space will allow upward expansion for an eventual

second level for parts storage. 25 Feet (7.3m) would allow for triple decking.

This also lends itself to more efficient use of working floor space. The cost of

extra ceiling height is small when weighed against the possibility of insufficient

space or the additional cost of construction at a later date.

DOUBLE DECKING REQUIREMENT

41

PA RTS EXC E L L E N C E

Parts Storage - Expansion

REINFORCED FLOORS

Reinforced Flooring is also considered an essential construction feature to permit

double decking. Local building codes specify the load bearing capacities of

various types of reinforced flooring. Codes should be considered before plans are

finalised. Again the initial construction price is small compared to the cost of

additional modifications at a later date.

OUTSIDE WALL FLOOR EXPANSION

A second deck may not be sufficient for parts storage. The Parts Manager may

need additional storage space to accommodate increased sales. When designing

a new facility, one wall of the Parts Department should always be a non-loadbearing outside wall to allow for expansion. In the following diagram, the shaded

portion shows an area for possible expansion.

POTENTIAL AREA FOR EXPANSION

Body

Shop

Service

Dept.

Parts

Dept.

Office

Showroom

DOUBLE DECKING

Double Decking or mezzanine storage is a method of creating a second floor

for parts storage by using metal grating above the first floor parts bins. This

method has the advantage of being economical while not restricting heat,

lighting, visibility or voice communication as a solid floor would. There are,

however, physical factors that must be considered:

Existing ceiling height

Floor load limitations

Stairway locations

Sprinkler head locations

Ventilation duct locations

Lighting arrangement

42

FACILITIES DEV E LO P M E N T

Parts Storage - Expansion

The specifications and locations for all of these must be analysed. A separate

network of lights might be needed for each level. The existing location and

capacity of sprinklers and vents will determine the extent of alterations or

additions which may be required.

Installation of a stairway to the mezzanine level should connect the lower main

aisle to the upper main aisle. These aisles must be wide enough to sustain a heavy

flow of traffic and be arranged to provide the highest level of convenience and

accessibility. A vertical lift or conveyor can provide more efficiency for receiving

and picking of inventory.

A pallet setdown area on the upper level will be needed when materials are

elevated by a lift truck. This setdown area should be located directly above or as

close as possible to the shipping and receiving area. Regardless of type, the

unloading area should be large enough to allow convenient unloading and

temporary stocking.

There are two basic types of Double Decks. One type is supported by framing

over the top of existing shelving. The lower level provides the support.

A second type is freestanding. It is designed to span the first floor without relying

on existing shelving or racks for support. Following is an example of this type:

FREESTANDING DECK

Most bin supply companies are able to specify a multideck renovation that

complies with local building codes. Typically, Dealerships rely on the suppliers

expertise to advise on Double Decking.

43

PA RTS EXC E L L E N C E

Parts Storage - Decision Grid

RESPONSIBILITIES

EXPECTATION

RESPONSE

MAXIMUM

OPERATING

EFFICIENCY

Fastest moving parts are stored near counters

Nuts and bolts are stored near counters

Shop supplies are stored near counters

Bin number sequence is logical

Bin locations are easily found

Obsolete inventory is regularly removed

SPACE IS WELL

UTILISED

There is room for expansion

Bins are not overstocked

Parts are not on the floor

Parts are not on top of bins

Bins, shelves and dividers are easily adjusted

SPECIALISED

BINS ARE

AVAILABLE

Warranty bins exist

Return bins exist

Special order bins exist

Core bins exist

PART NUMBER

INFORMATION

IS ACCURATE

System on hand count equals actual shelf

inventory

System bin location is correct

Multiple bin locations are recorded

44

FACILITIES DEV E LO P M E N T

Customer Areas - Evaluators

QUALIFIER

DEALER ACTION

SIGNAGE

Dealership provides adequate

Parts Department signage

Outdoors

Parking

Entrance

Indoors

5

5

5

15

Parts and accessories are displayed

throughout the Dealership

Parts Counter

Customer Lounge

Showroom

Cashier

Service Reception

20

5

10

5

5

Various types of parts displays

are utilised

15

Counter area is easily accessible to

customers and designed to be customer

friendly

10

DISPLAYS

COUNTER

DESIGN AND

LOCATION

Assessment Score (100 points possible)

Certification requires a score of 80 or above

45

VALUE

PA RTS EXC E L L E N C E

Customer Areas - Introduction

INTRODUCTION

Customer Areas should be clean, attractive and visually stimulating for

customers. These areas are often overlooked by Dealers and Parts Managers.

They should be viewed as opportunities to enhance the image of the Parts

Department in the eyes of the customer and to sell additional parts.

Signs and displays show customers where the Parts Department is and what is

has to sell. Customers can be made aware that the Dealership is a merchandiser

of parts and accessories.

PURPOSE

The objectives of this section on Customer Areas are:

1. To have signs in the Dealership which make it easier for customers to

do business with the Parts Department

2. To have displays throughout the Dealership which promote parts and

accessories sales

Proper signage facilitates doing business with the Dealership. It also enhances

Customer Satisfaction.

Nearly two out of three buying decisions are made at the point of purchase.

Dealerships should take advantage of the variety of opportunities they have to

sell parts and accessories throughout the facility.

46

FACILITIES DEV E LO P M E N T

Customer Areas - Signage

SIGNAGE

Signs used to inform, such as the location of the Parts Department, are a courtesy

to customers. Signs make it easier and more pleasant for people to do business

with the Dealership and minimise the communication load on employees.

They are also important merchandising tools. Signs can be used to direct peoples

eyes toward displays or specials.

GENERAL GUIDELINES

All signs should have a specific purpose. They should be:

Useful

Positive

Professional

Customers should be provided with information that the Dealership wants to

convey. Signs can also be used to make them feel comfortable in an unfamiliar

setting. They should be used only where there is a genuine need. Customers

could be annoyed by signs that demand their attention but provide no useful

information.

Keep signs positive. Negative impressions should be avoided. Signs which read

Customers not allowed or We do not accept... are negative signs. Instead,

signs should provoke a positive reaction. The previous examples could be made

positive by saying Employee Area or We accept...

Signs should be professionally created. They should also conform to the

appearance of other signs used in the Dealership. Parts Department signs should

be prepared in co-operation with other departments.

Because a sign is intended to inform it should be placed where it is needed and

will be seen. The message should be stated as simply as possible. This is true

regardless of whether the sign is outdoors or indoors.

47

PA RTS EXC E L L E N C E

Customer Areas - Signage

OUTDOOR CURB

This type of sign is designed for outdoor use to attract people to the Parts

department and identify its location. Curb signs should be located at all

entrances to the Dealership facility.

If the curb signs are of the portable variety, a Parts Department employee should

be assigned the responsibility of placing the signs in designated locations when

the retail parts area opens. They should also be returned to a secure location

when the area closes.

POLE OR WALL

The pole or wall sign can be utilised either indoors or outdoors to identify the

retail parts location to customers. As the name implies these signs are mounted

on either poles or walls around the Dealership. If the retail area is open at night,

consider using lighted signs.

Utilise a pole or wall sign outdoors where a curb sign is not practical, or use the

pole or wall sign to offer further assistance to customers in locating the Parts

Department once they are at or near the Dealership facility.

Note: Before placing any outdoor curb, pole or wall signs, the Dealership should

check with the local government to ensure compliance with local ordinances and

regulations.

PARKING

Identified parking spaces should be reserved for wholesale and retail parts

customers. Since parking convenience can make a substantial difference in

outside sales, these spaces should be located as close as possible to the Parts

Department entrance.

A sign should clearly indicate that this area is for Parts Customers Parking. The

parking area itself should be paved or blacktopped and each parking space

defined by painted lines to obtain maximum use of the area. A professional

parking lot striping service can provide expert advice.

It should be stressed that employees are not to use these spaces, even for

temporary parking. This area should be checked periodically to see that it is

adequate for parts customers and that it is not used for other purposes.

48

FACILITIES DEV E LO P M E N T

Customer Areas - Signage

ENTRANCES

Whenever possible, a separate entrance from the parking area to the Parts

Department permits easier access for wholesale and retail customers. Controlled

access makes it easier to monitor this traffic for security reasons. It also tends to

reduce unnecessary congestion in the Service Department. A prominent sign to

this entrance assists customers.

OVERHEAD

An overhead sign is designed to hang from the ceiling to tell customers that they

have found the retail parts area. The sign should be placed at the entrance to, or

inside of, a retail parts display area.

FEATURE BOARD

A feature board is typically placed near the entrance to the Parts Department or

near the counter. This type of sign is hung on a wall or mounted on a tripod

stand. It can be a letter board, chalk board or even an electronic sign that has

messages moving across it.

It permits the Parts Department to communicate a variety of information to

customers such as:

Store hours

Promotional messages

Special prices or sales

New product offerings

The feature board should be positioned so that customers can easily read it when

entering the retail display area.

SHELF TALKERS

As the name implies, shelf talkers are signs that direct customers eyes to

particular items displayed on shelves. They often use starbursts and bold letters

to draw attention to special items.

INDOOR DIRECTIONAL

Indoor directional signs are designed to guide customers around the Dealership.

Indoor directional signs should be placed in hallways, walkways, the customer

lounge, the showroom or any area that has direct access to a retail parts display.

49

PA RTS EXC E L L E N C E

Customer Areas - Signage

Proper signage is necessary to help the customer find various departments and

facilities within the Dealership, plus make them aware of services offered and

procedures and policies affecting their transactions.

The following list denotes locations, services and policies to be appropriately

designed:

Locations

Customer Parking

Entrance

Parts Counter

Other Departments

Customer Lounge

Cashiers Window

Restrooms

Services

Days Open for Business

Hours Open for Business

Sales and Discounts Offered

Employees Names and Years of Experience

Policies

Customer Relations Policy

Special Order Policy

Credit Policy

Acceptable Methods of Payment

Pricing Policy

Return Policy

Safety Precautions

50

FACILITIES DEV E LO P M E N T

Customer Areas - Displays

Parts Departments can truly manage the facility well with a variety of displays.

Seeing the merchandise often reminds the buyer of what he/she needs. Displays

create a desire to buy and because people are more likely to buy something if they

can see it, displays can sell parts and accessories.

To attract attention, displays should be bright, clean and colourful. They should

be located conveniently near electrical outlets in case additional lighting is

needed, or for use with displays which have moving parts requiring electrical

power.

DISPLAY LOCATIONS

There are a variety of areas where parts and accessories can be displayed. It is

important to consider the type of customer that will be in a particular area and

the types of parts he/she is most likely to purchase.

There are five primary areas where parts and accessories should be displayed:

Parts Counter

Customer Lounge

Showroom

Cashier

Service Reception

PARTS COUNTER

The Parts Counter is the most obvious location to set up parts and accessories

displays. Displays near the retail counter should feature do-it-yourself (DIY)

products, car care products, accessories which require only minor installation

skills, chemicals and solvents. The types of products that may be included are:

DIY Products

Belts

Hoses

Filters (petrol, oil, air)

Ignition Parts

Mufflers

Lubricants

Car Care Products

Waxes

Polishes

Fabric Sealant

Paint Sealant

Glass Cleaner

51

PA RTS EXC E L L E N C E

Customer Areas - Displays

Accessories

(minor installation)

Baby Seats

Floor Mats

Emergency Kits

Floodlights (Hand Held)

Touch-Up Paints

Mudflaps

Driving and Foglights

Wiper Blades

Chemicals and Solvents

Loctite

Lockeze

Anti-freeze Coolant

Oil Supplements

Gas Supplements

Coolant Rust Inhibitor

These products should be merchandised in the parts counter area, since

customers are typically these to purchase parts for either the repair or

maintenance of their vehicle.