Documente Academic

Documente Profesional

Documente Cultură

Two-Axis Motion Mechanism with Reduced Backlash

Încărcat de

Nile_JockeyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Two-Axis Motion Mechanism with Reduced Backlash

Încărcat de

Nile_JockeyDrepturi de autor:

Formate disponibile

.

US005243873A

United States Patent [19]

[11] Patent Number:

Demers

[45]

[54]

5,101,681

TWO-AXIS MOTION MECHANISM

[75] Inventor:

Robert E. Demers, Elk River, Minn.

.:

[ ] Appl N0 23,497

[22] F?ed:

4/1992 Shpigel ................................ .. 74/479

?jgfrggajbxr?asggbhmdt

[57]

Feb 26 1993

Sep. 14, 1993

Primary Examiner-Rodney H. Bonck

{73] Assignee: Honeywell Inc., Minneapolis, Minn.

21

Date of Patent:

5,243,873

. ABSTRACT

A two-axis motion mechanism with reduced backlash

.

includes two-axis motion that is transferred between a

[63l

Related U's' Apphcahon Data

Continuation-impart 0f Ser- NO- 824,632,1m 23, 1992,

moveable member and a ?rst and second shaft posi

tioned orthogonal to each other through three principle

[51]

bandmd ~

Int. c1.5 ........................................ .. 1325.1 17/00

[52]

US. Cl. ........ .............. .. 74/479 BW; 74/479 BJ;

bearings. Th e 1'1rst and second shf

a t are 1me d1 y pos1'

tioned so as to constrain motion 9mm about a ?rst and

second axis therethrongh, respectively The second axis

901/28; 901/29

is substantially orthogonal to the ?rst axis intersecting at

[58] Field of Search .................... .. 74/479; 901/28, 29,

901/27

[56]

References Cited

the center of the mechanism. An outer ring, having the

moveable member connected thereto and an inside ring

nested therein lies in a plane transverse to the second

shaft. Pins connect the outer ring with the inside ring. A

case member is positioned about the outer ring with the

US PATENT DOCUMENTS

1,557,214 10/1925

McClane . . . . . .

. . . . .. 74/471 XY

2,379,773

7/1945

Allen . . . . . . . . . . . .

. . . . . . . . .. 192/002

the inside ring to a rod extending across the inside ring

3/

giactway - - - - -

' - - - - ' - -~ ;4/271

and connected to the second shaft at the center of the

72963

M25032?a1' ' ' ' '

' ' ' ' " 7:54;?

mechanism. The ?rst duplex bearings allow rotation of

3:550:466 12/1970 Ham ......... ..'..IIIIIWWII: 74/471

the inside ring and he ?rst axis- Sewn! duplex bearings

3'095754

4,073,201

2/1978

?rst shaft mounted thereto. First duplex bearings couple

Taylor et al. . . . .

. . . .. 74/479 x

4,628,765 12/1986 Dien et a1. ..... ..

. 74/479 X

tween the inside ring and the outer ring. Third duplex

Couple the inside ring to the Pins to allow rotation be

4,686,866

3/1987

Rosheim - - - - - -

~ - - -- 74/479

bearings engage the case member and hold the outer

5/

0526?! ~ - - - - ~ ' ~ - ~

' ' ~ -- 74/479

ring allowing rotation of the outer ring and the move

62988

$8511.21: ' '

' ' '"

able member extending therefrom about the second

4:804:220 2/1989 Rosheim Ill-1....

:1: 74/479

axis

4,878,393

. . . ..

4748867

11/1989

Duta et al.

. .. .. . .

74/479

5,036,724 8/1991 Rosheim ............................. .. 74/479

9 Claims, 5 Drawing Sheets

US. Patent

Sep. 14, 1993

5,243,873

Sheet 1 of 5

111

/

16

BASE

17

/

Fig.1

PRIOR ART

US. Patent

Sep. 14, 1993

Sheet 2 of 5

5,243,873

3Nut

my?

\_-I

W01a.

\t?Q95

n&

>

= on

3

pawn

an. \an

Nn

9T\S

6

a

.Q

US. Patent

Sep.14,1993

Sheet 3 of 5

mop

5,243,873

, N8

OPP

+0?mop

mow

PCP

n.mt

US. Patent

Sep. 14, 1993

1.00

Sheet 4 of 5

5,243,873

U.S. ' Patent

Sep. 14, 1993

Sheet 5 of 5

5,243,873

14-1

'

}\?0

I

100

I

340

104

340

310

- :.:, .151:

320

107

I

120

~;

11o

308

109

109

5,243,873

sors 41 and 43 for this con?guration are attached to

TWO-AXIS MOTION MECHANISM

shafts 28 and 26 along axis 46 and 40, respectively. The

shafts 28 and 26 are then connected to sliding braces 32

This is a continuation-in-part of application Ser. No.

07/824,632, ?led Jan. 23, 1992 and now abandoned.

FIELD OF THE INVENTION

The present invention relates to a two-axis motion

and 30, respectively. The pivoting member 24 is at

tached to a base 34 at pivot 36. All pivoting member 24

motion relative to the base 34 is sensed by sensors 41

and 43 as shafts 28 and 26 turn, respectively.

The principle de?ciency of the sliding brace system

mechanism. More particularly, the present invention

15 stems from the tendency of the sliding braces 30 and

relates to a two-axis motion mechanism with reduced

32 to bind and/or deform and cause backlash thus re

backlash.

ducing the accuracy and repeatability of the device.

The sliding brace method does provide a way to hold

the two-axial sensors 41 and 43 stationary which creates

an advantage over the gimbal 10 previously described.

Improvement over the sliding brace method are de

scribed in US. Pat. No. 4,723,460 to Rosheim and in

U.S. Pat. No. 2,929,258 to Mackway. In both cases,

sliding braces have been replaced with an inner and

the prior art is provided by a gimbal. An alternative

outer rotary bearing ring. The outer race of the inner

system provided by the prior art is a pivotable member

restrained by a system of orthogonal semi-circular slid 20 bearing ring is coupled to the inner race of the outer

BACKGROUND OF THE INVENTION

In the ?elds of kinematics and mechanics, the solution

to the problem of generating or sensing motion in a

two-degree of freedom system with a mechanism, has

been approached in a number of ways. One solution of

ing braces.

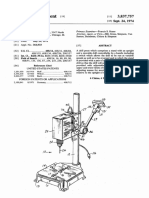

FIG. 1 shows a gimbal 10 of the prior art in a two-axis

drive system. The gimbal 10 includes a base 12 which

may be ?xed to ground 11. The base 12 includes a

swivel 17 with a bracket 14 attached thereto. The 25

bearing ring, thereby allowing rotation between the

two bearing rings. However, the mechanisms described

in Rosheim and Mackway rely on press ?ts for assem

bly. This makes them less suitable for transmitting large

forces and resisting abuse. Rosheim and Mackway also

both use a single rotary bearing for transmitting rotation

between a pivoting member and shafts for imparting

motion thereto or sensing motion thereof. The inner

race of the single rotary bearing is twisted out of the

swivel 19. In the gimbal 10 of the prior art, a ?rst motor 30 plane of the outer race, increasing wear and subse

quently producing backlash; the backlash increasing as

16 is located on the base 12 to generate angular motion

the bearings wear.

of the bracket 14 with respect to the base 12. A second

In summary, the prior art suffers from a number of

motor 18 is positioned to provide motion about an axis

drawbacks. The gimbal system of FIG. 1 suffers in that

generally orthogonal to the ?rst motor 16. As the mo

the second motor 18 needs to be incorporated in the

tors 18 and 16 are driven, the output member 22 re

moving bracket 14. This adds substantially to the

sponds accordingly.

weight of the mechanism and thus the cost and dif?

The principle de?ciency of the gimbal 10 stems from

culty of manufacture. The mechanism of FIG. 2 in

the need to locate the second motor 18 on the rotating

cludes the problems of dif?culty of mechanism repeat

bracket 14. Thus, for the prior art gimbal 10 to generate

motion for the output member 22, not only is a motor 16 40 ability, dif?culty of construction because the rails need

to be fairly small in relation to the pivoting member 24

required on the base 12 but also a motor 18 must be

to accomplish quick motion and the mechanism has a

mounted on the bracket 14.

degree of backlash because the brackets 30 and 32 tend

To communicate data from the second motor 18 to a

to bind and/or deform. In addition, the mechanisms of

controller attached to ground 11 may require difficult

Rosheim and Mackway make use of press ?ts which

and complex connections. Such connections may inter

simplify assembly, but which are a failure point along

fere with the operation of the gimbal 10. Difficult con

with the single rotary bearings used in the bearings

nections may also contribute to reduced reliability of

rings which are subject to ever increasing backlash,

the gimbal based, two-axis drive mechanism. The

bracket 14, accomplishes rotary motion about the

swivel 17 relative to the base 12. Attached to the

bracket 14 is a second swivel 19 with an output member

22 attached to a shaft 20 in axial alignment with the

weight of the gimbal 10 is also increased by the weight

especially under large loads.

of motor 18 making it less adaptable to various kine 50 Thus, it is a motive of the present invention to pro

vide a two-axis motion mechanism that provides a ro

matic drive tasks.

bust, backlash reduced means of generating or sensing

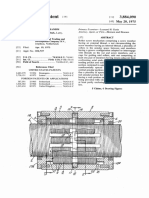

FIG. 2 shows a method of sensing two-axis motion of

two-axis motion while keeping the position of either the

a pivoting member 24. The mechanism of FIG. 2 pro

drive motors or sensors stationary, depending upon

vides a central pivoting member 24 which is restrained

by a ?rst semi-circular sliding b'race 30 and a second 55 whether the mechanism is used as a drive or sensor

mechanism.

semi-circular sliding brace 32. First semi-circular sliding

brace 30 is attached to ground 11 by pivots 38 and 39

SUMMARY OF THE INVENTION

which allows the brace 30 to rotate about a ?rst axis 40.

The present invention provides a two-axis motion

A second semi-circular sliding brace 32 is attached to

mechanism for use in generating or sensing motion in

ground 11 by pivots 42 and 44 which allow the brace 32

to rotate about a second axis 46. The second axis 46 is

two-axes about a center point. The two-axis motion

orthogonal to the ?rst axis 40 to provide sensor outputs

mechanism provides reduced backlash while maintain

in two axes. The member 24 is located within the inter

ing each axiss motor, or sensor, ?xed in relation to

ground. The mechanism is capable of sustaining large

section of the two semi-circular sliding braces 30 and

32. The sliding braces 30 and 32 work in a radial fashion 65 loads without failing or operating at a level of reduced

performance.

such that the member 24 is free to move within the

The two-axis motion mechanism of the present inven

sliding braces 30 and 32 while being constrained by the

tion includes a moveable member and a ?rst shaft hav

sliding braces 30 and 32 and bearing 36. The axial sen

5,243,873

ing a ?rst and second end. The ?rst end of the ?rst shaft

is fixedly positioned so as to constrain motion of the ?rst

shaft in all degrees of freedom except about a ?rst axis

therethrough. A second shaft having a ?rst and second

end is ?xedly positioned so as to constrain motion of the

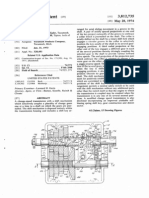

prised of two nested rings, an outer ring 106 and an

second shaft in all degrees of freedom except about

second axis therethrough. The second axis is substan

shaft 103 is ?xed on a rod 110 set crosswise in the inside

a center substantially the same as the center of the mo

sion ball bearings 109, FIG. 5. The ball bearings 109

allow the inside ring 101 to rotate on the rod 110. The

inner ring 101. The two rings are centered at a common

point at which Z axis 140, Y axis 130, and X axis 120

intersect. Shaft 103 is perpendicular to a plane contain

ing the nested outer ring 106 and inner ring 101. The

ring 101. Shaft 103 is constrained in all degrees of free

dom except for rotation about the axis 140, which is

tially orthogonal to the ?rst axis and the two axes inter

allowed by supporting the end of the shaft 103 in a set

sect at substantially a center of the motion mechanism.

The mechanism further includes an outside ring having 10 of bearings 302. The .ends of the rod 110 are set in preci

tion mechanism and aligned in a plane transverse to the

second shaft and the second axis therethrough. The

bearings 109 are selected by size, dependent on the load

moveable member is connected to and extends from the

outside ring. A inside ring is nested within the outside

ring in the plane transverse to the second drive shaft

and the second axis therethrough. Pins connect the

expected on rod 110. The smallest possible commer

outside ring to the inside ring with the pins being rigidly

preloading is accomplished by choosing a predeter

cially available bearings capable of handling such a load

are selected. Bearings 109 are preloaded against each

other to reduce backlash in this joint. The degree of

mined length for rod 110 such that when nuts 308, 310

connected to the outside ring. A case member is posi

tioned about the outer ring with the second end of the 20 are tightened on threaded ends of rod 110, the duplex

set of bearings 109 are preloaded against one another

?rst shaft mounted thereto. First duplex bearings couple

with a desired preloaded force. However, the amount of

the inside ring to a rod extending across the inside ring

preloading must be balanced with the friction created

which is substantially orthogonal to the pins. The rod is

due to this preloading force. In other words, a tradeoff

connected to the second end of the second shaft at

substantially the center of the drive mechanism. The 25 between reduced backlash and friction must be consid

?rst duplex bearings allow rotation of the inside ring

ered.

Perpendicular to rod 110, are pins 104 and 108 which

connect the inside ring 101 tothe outside ring 106. The

pins 104, 108 each have a ?rst end which is ?xed to the

third duplex set of bearings engage the case member and 30 outside ring 106 by screws 312 and 314, respectively.

Duplex precision ball bearings 107, set in the inside ring

hold the outside ring. The third duplex set of bearings

101 have an inner race which engages the pins 104, 108

allow for rotation of the outer ring and the member

allowing for rotation between the inside ring 101 and

extending therefrom about the second shaft and the

the outside ring 106. The duplex set of bearings 107 are

second axis therethrough.

'

In an additional embodiment of the invention, the 35 preloaded against each other by selecting pins 104 and

108 of sufficient length to achieve preloading when

pins of the mechanism include a ?rst and second pin,

screws 312 and 314 are tightened, respectively. The

each orthogonal to the rod and each having a ?rst and

degree of preload force is selected to reduce backlash

second end. The ?rst end of the ?rst pin is rigidly con

with the tradeoff of friction being considered.

nected to the outer ring and the second end of the ?rst

about the rod and about the ?rst axis. Second duplex

bearings couple the inside ring to the pins to allow

rotation between the inside ring and the outside ring. A

pin is rotationally coupled to the inside ring by the

second duplex bearings. The ?rst end of the second pin

is rotationally coupled to the inside ring by the second

duplex bearings and the second end of the second pin is

The output or movable member 111 is attached to the

outside ring 106 by screws 340, FIG. 5. The outside ring

106 is held between a preloaded duplex set of large

diameter bearings 102, preferably thin section bearings.

The bearings 102 are preloaded against each other by

rigidly connected to the outer ring.

In yet another embodiment of the invention, the ?rst, 45 means of a case member 105 surrounding and engaging

the outer race of bearings 102; the inner race of bearings

second and third duplex bearings each include ?rst and

102 engaging the outer ring 106. The preloading of

second bearings which are preloaded against one an

bearings 102 is accomplished by means of case member

other.

BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 shows a gimbal based two-axis drive mecha

nism of the prior art.

FIG. 2 shows a sliding brace two-axis sensor mecha

nism of the prior art.

105. The case member 105 includes case portions 330

and 332 which are coupled by screws 334, FIG. 4. Be

cause of the cutaway view of FIG. 4, only one screw is

apparent. I-Iowever, screws 334 exist around the periph

ery of the portion 330 about the outer ring 106. The case

105 which surrounds the outer races of the large diame

FIG. 3 shows an isometric diagram of a two-axis 55 ter bearings 102, provides support for the other ele

motion mechanism in accordance with the present in

vention.

ments assembled, applies the pre-load for reduced back

lash, and also supplies a mounting point for the second

shaft 112, via screws 320. The second shaft 112 is con

FIG. 4 shows a two-dimensional cut-away view of

strained in all degrees of freedom except for rotation

the mechanism shown in FIG. 3.

FIG. 5 shows a two~dimensional cut-away view of 60 about the axis 120. The shaft 112 is allowed to rotate

only about the X-axis by supporting the end of the shaft

the invention shown in FIG. 3 orthogonal to the view in

112 in a set of bearings 303.

FIG. 4.

The principle function of the mechanism 100 is to

DESCRIPTION OF THE PREFERRED

control the driving or sensing of moveable member 111

EMBODIMENT

65 motion such that axial displacement of the moveable

member 111 about the axis 140 is accurately and repeat

Referring to FIGS. 3, 4 and 5, a two-axis motion

edly sensed or driven and that axial displacement of the

mechanism 100 in accordance with the present inven

moveable member 111 about the axis 120 is accurately

tion shall be described. The mechanism 100 is com

5,243,873

and repeatedly sensed or driven. In order to allow the

extending therefrom to precisely match the rotation of

mechanism 100 to function as a drive mechanism, drive

motors 201 and 202 are positioned with respect to shafts

the shaft 103 about the Z axis 140. The bearings 109, on

the other hand, allow the moveable member 111 to

rotate independently about the X axis 120.

In order for the moveable member 111 to indepen

dently rotate about both the X axis 120 and the Z axis

103 and 112, respectively; the shafts being set in sets of

bearings to allow rotation along the respective axis. On

the other hand, to allow the mechanism 100 to function

as a sensing mechanism, sensing elements are positioned

in place of the drive motors to sense rotation of shafts

103 and 112, respectively, along the axes 140 and 120.

Such sensing elements and drive motors are commonly

140, the inside ring 101 and the outside ring 106 must

freely rotate with respect to each other about the pins

108, 104. The duplex set of bearings 107 allow for such

rotation with a minimum of backlash. When both shafts

103 and 112 are driven, the motion of the moveable

known to one skilled in the art.

member 111 is in a logical hemisphere generally de?ned

by the arrows 141 and 121. The relative motion of the

For brevity, the invention shall further be described

with reference to the mechanism 100 as a drive mecha

motors 201 and 202 to accomplish displacement of

rod bearings 109, the pin bearings 107, and the outside

ring bean'ngs 102 provides the means by which the

moveable member 111. One skilled in the art should

moveable member 111 can move in an arbitrary direc

nism wherein shafts 103 and 112 are rotated by drive

clearly recognize the applicability of the mechanism

tion around the center of the mechanism 100. Thus, the

100 as a sensing mechanism in lieu of the drive mecha

degree of freedom afforded by the three principle bear

ings of the apparatus provide a mechanism that is free to

Rotation of the shaft 112 by drive motor 202 is trans 20 drive a moveable member around two axes.

The three principle duplex sets of bearings may be

ferred to the case 105 and then to the outside ring 106

nism description.

implemented with bushings or sliding bearings, ball

bearings, rolling bearings, and/or any other bearing

via the duplex set of large diameter bearings 102. The

moveable member 111, ?xed to the outside ring 106 via

hardware 340, rotates with the outside ring 106. Using

the duplex set of bearings 102 increases the load capac

ity, reduces wear, and allows the joint to be preloaded.

The torque load from the rotating shaft 112 is split into

a force couple, with half the load going to each bearing

102. The bearings 102 are subjected to purely radial

type which will allow the relative motion between the

25 elements of the motion mechanism as described herein.

The present invention is in no manner limited to those

speci?cally listed, but also includes those which per

form the functions of the duplex bearings as described

and which fall within the scope of the invention.

Those in the art will recognize that only preferred

loads where they have the most carrying capacity. This

embodiments of the present invention have been dis

closed herein, other advantages may be found and real

ings 102 against each other. This allows slop in the

ized and various modi?cations may be suggested by

bearings to be taken out in a controllable fashion.

those versed in the art, and it should be understood that

The rotation of the moveable member 111 precisely

matches the rotation of the shaft 112 due to this preload 35 the embodiment shown here may be altered and modi

?ed without departing from the true spirit and scope of

ing. With the moveable member 111 being ?xed to the

the invention as de?ned in the accompanying claims.

outside ring 106 and the outside ring 106 being ?xed to

What is claimed is:

the inner races of the bearings 102, the outside ring 106

1. A two-axis motion mechanism, comprising:

is free to rotate about the axis of the bearings 102. While

the moveable member 111 is constrained to rotate only 40 a moveable member;

a ?rst shaft having a ?rst and second end, said ?rst

about the X axis 120 with rotation of shaft 112, the

reduces bearing wear. The case 105 preloads the bear

end of said ?rst shaft ?xedly positioned so as to

rotation of moveable member 111 rotation about the Z

axis 140 is totally independent.

Rotation of the shaft 103 about Z axis 140 is trans

ferred to the rod 110 and then to the inside ring 101 via 45

the bearings 109. Rotation of the inside ring 101 is trans

ferred to the outside ring 106 and hence the moveable

constrain motion of the ?rst shaft in all degrees of

freedom except about a ?rst axis therethrough;

a second shaft having a ?rst and second end, said ?rst

end of said second shaft ?xedly positioned so as to

constrain motion of the second shaft in all degrees

member 111, via the pins 108, 104 and the bearings 107.

of freedom except about a second axis there

With regard to the transfer of rotation from shaft 103 to

rod 110, the input torque of shaft 103 is split into a force

couple acting on the ends of rod 110. This reduces the

load that each of the duplex bearings 109 must carry to

half the original and also converts it to a purely radial

through, said second axis substantially orthogonal

load against which the bearings have the most strength.

Preloading the bearings 109 against each other removes

slop in the joint and provides for a precise matching of

rotation between the input shaft 103 and the inside ring

to said ?rst axis and intersecting at substantially a

center of the motion mechanism;

an outer ring having a center substantially the same as

55

101.

With regard to the transfer of rotation from the inside

ring 101 to moveable member 111, torque on the inside

ring 101 is transferred to the outside ring 106 and thus

the moveable member 111 via a force couple on the pins

108, 104 and the bearings 107. As before, using a duplex

set of bearings 107 allows the load to be divided and

redirected into purely radial forces on the bearings, 65

reducing wear and increasing load capacity.

The rod 110 and pins 108, 104 constrain the rotation

of the outside ring 106 and the moveable member 111

the center of the motion mechanism and lying in a

plane transverse to said second shaft and said sec

ond axis therethrough, said moveable member con

nected to and extending from said outer ring; _

an inside ring nested within said outer ring in the

_ plane transverse to said second shaft and second

axis therethrough;

pinning means for connecting said outer ring to said

second ring, said pinning means rigidly connected

to said outside ring;

a case member positioned about said outer ring, said

second end of said ?rst shaft mounted to said case

member;

?rst duplex bearings for coupling said inside ring to a

rod extending across said inside ring and orthogo

nal to said pinning means, said rod connected to

5,243,873

said second end of said second shaft at substantially

the center of the motion mechanism, said ?rst du

duplex bearings.

plex bearings for allowing rotation of said inside

6. A mechanism according to claim 1, wherein said

ring and about said rod and about said ?rst axis;

second duplex bearings for coupling said inside ring

pinning means comprises ?rst and second pin, each pin

5 being orthogonal to said rod and having a ?rst and

to said pinning means to allow rotation between

second end, said ?rst end of said ?rst pin rigidly con

said inside ring and said outer ring; and

third duplex bearings engaging said case member for

holding said outer ring, said third duplex bearings

nected to said outer ring, said second end of said ?rst

pin being rotationally coupled to said inner ring by said

second duplex bearings, said ?rst end of said second pin

for allowing rotation of said outer ring and said

moveable member extending therefrom about said

second shaft and said second axis therethrough.

2. A mechanism according to claim 1, wherein each

of said ?rst, second and third duplex bearings include

?rst and second bearings which are preloaded against 15

one another.

3. A mechanism according to claim 2, wherein said

rod includes a ?rst and second threaded end sized for

receiving a ?rst and second nut thereon to preload said

?rst duplex bearings.

to said second case portion and for preloading said third

being rotationally coupled to said inner ring by said

second duplex bearings and said second end of said

second pin being rigidly connected to said outer ring.

7. A mechanism according to claim 1, wherein said

third duplex bearings are a duplex set of large diameter

thin section bearings.

8. A mechanism according to claim 1, further com

prising ?rst drive means coupled to said ?rst end of said

?rst shaft for rotating said ?rst shaft and second drive

20 means coupled to said ?rst end of said second shaft for

rotating said second shaft.

9. Apparatus according to claim 1, further comprising

4. A mechanism according to claim 2, wherein said

pinning means includes hardware means for ?xedly

attaching said pinning means to said outer ring and said

?rst sensor means coupled to said first end of said ?rst

second duplex bearings.

shaft for sensing rotation of said ?rst shaft and second

5. A mechanism according to claim 2, wherein said 25 sensor means coupled to said ?rstvend of said second

shaft for sensing rotation of said second shaft.

*

i

i

i

I

portion, and means for attaching said ?rst case portion

case member includes a ?rst case portion, a second case

30

35

50

55

65

S-ar putea să vă placă și

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheDe la EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheEvaluare: 4.5 din 5 stele4.5/5 (2)

- Patent Brake System for DrawworksDocument9 paginiPatent Brake System for DrawworksardserÎncă nu există evaluări

- Diseño ElectricoDocument5 paginiDiseño ElectricoemernelsonmanÎncă nu există evaluări

- Shaft Mounting Device Measures and Controls Thrust LoadsDocument7 paginiShaft Mounting Device Measures and Controls Thrust LoadsNicandroGonzalesÎncă nu există evaluări

- Bob Teal MagnaPulsion US4024421Document6 paginiBob Teal MagnaPulsion US4024421kishbudÎncă nu există evaluări

- US Patent 3884090Document5 paginiUS Patent 3884090sthollanderÎncă nu există evaluări

- Tree Climbing Motor Patent from 1903Document4 paginiTree Climbing Motor Patent from 1903monem2014Încă nu există evaluări

- Four-Speed Transmission Shift MechanismDocument18 paginiFour-Speed Transmission Shift MechanismJoão Paulo Canto RibeiroÎncă nu există evaluări

- United States Patent (19) : Miiller (45) Date of PatentDocument8 paginiUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaÎncă nu există evaluări

- United States Patent (191 (11) Patent Number: 4,857,881Document9 paginiUnited States Patent (191 (11) Patent Number: 4,857,881Harish MahadevanÎncă nu există evaluări

- Us 8210068us 8210068us 8210068us 8210068Document9 paginiUs 8210068us 8210068us 8210068us 8210068JameszouqunÎncă nu există evaluări

- Project ZDocument31 paginiProject ZADITYAÎncă nu există evaluări

- Us2127655 PDFDocument5 paginiUs2127655 PDFbelchior alvaroÎncă nu există evaluări

- Thrust Reverser Hook Latch System PatentDocument13 paginiThrust Reverser Hook Latch System PatentkevnwongÎncă nu există evaluări

- US3982767Document6 paginiUS3982767takanobu ouraÎncă nu există evaluări

- Transmision US3650349Document8 paginiTransmision US3650349Dejan ZdravkovskiÎncă nu există evaluări

- Us955823 PDFDocument3 paginiUs955823 PDFSashikant SharmaÎncă nu există evaluări

- March 26, 1957:1. - RUSSELL 2,786,361 Gimbal MechanismsDocument2 paginiMarch 26, 1957:1. - RUSSELL 2,786,361 Gimbal MechanismsjemanuelvÎncă nu există evaluări

- transmission-inertia-brake-ball-ramp-actuationDocument15 paginitransmission-inertia-brake-ball-ramp-actuationolduren53Încă nu există evaluări

- Gas Turbine Star Gear Train Coupling SystemDocument11 paginiGas Turbine Star Gear Train Coupling SystemKrozeÎncă nu există evaluări

- Variable Speed Transmission for VehiclesDocument10 paginiVariable Speed Transmission for VehiclesFernandoÎncă nu există evaluări

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Document8 paginiApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiÎncă nu există evaluări

- BALER FOR TYING ROUND BALE USING TWINEDocument16 paginiBALER FOR TYING ROUND BALE USING TWINEN. P. JAGANÎncă nu există evaluări

- Analysis of Friction Clutch Plate Using FEADocument7 paginiAnalysis of Friction Clutch Plate Using FEAnileshvranaÎncă nu există evaluări

- Combined GearboxDocument8 paginiCombined Gearboxkats2404Încă nu există evaluări

- United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986Document3 paginiUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986wahaha06Încă nu există evaluări

- Patent conversion device rotates wire linearlyDocument7 paginiPatent conversion device rotates wire linearlyRockerss RockerssÎncă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0112687 A1Document7 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0112687 A1Robert DeaconuÎncă nu există evaluări

- Variable-Speed Gearing Patent from 1901Document4 paginiVariable-Speed Gearing Patent from 1901belchior alvaroÎncă nu există evaluări

- Diagrama Electrico de ControlDocument7 paginiDiagrama Electrico de ControlemernelsonmanÎncă nu există evaluări

- Multi-Stage Torque Converter Integrates DamperDocument12 paginiMulti-Stage Torque Converter Integrates DamperanachingpainÎncă nu există evaluări

- US3173686 (Coin-Op Kiddie Ride)Document8 paginiUS3173686 (Coin-Op Kiddie Ride)EÎncă nu există evaluări

- Sewing MachineDocument6 paginiSewing MachinesadagoapanÎncă nu există evaluări

- Variable displacement compressor hinge mechanismDocument13 paginiVariable displacement compressor hinge mechanismSelvaraji MuthuÎncă nu există evaluări

- Boite Seamless XtracDocument13 paginiBoite Seamless Xtracdudule01Încă nu există evaluări

- Rig-E???': Gill!Document6 paginiRig-E???': Gill!luiscremaschiÎncă nu există evaluări

- Kinematics and Dynamics of Machinery - Experiments PDFDocument47 paginiKinematics and Dynamics of Machinery - Experiments PDFUtkarsh SinghÎncă nu există evaluări

- Ulllted States Patent (19) (11) Patent Number: 5,937,809Document15 paginiUlllted States Patent (19) (11) Patent Number: 5,937,809LazarÎncă nu există evaluări

- Bag cutting mechanism for adjustable bag lengthDocument3 paginiBag cutting mechanism for adjustable bag lengthJhonnatan E Avendaño Florez100% (1)

- Us 5775636Document6 paginiUs 5775636wewewewÎncă nu există evaluări

- United States Patent (19) 11 3,750,485: Blakemore (45) Aug. 7, 1973Document11 paginiUnited States Patent (19) 11 3,750,485: Blakemore (45) Aug. 7, 1973IkshwakÎncă nu există evaluări

- US4458549Document8 paginiUS4458549Chandru VelÎncă nu există evaluări

- Patent Application Publication (10) Pub. No.: US 2013/0130855A1Document7 paginiPatent Application Publication (10) Pub. No.: US 2013/0130855A1Billel LouniciÎncă nu există evaluări

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 paginiWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaÎncă nu există evaluări

- NOV-9, 1943. A. Ca. Schneider: Planetary Turbine TransmissionDocument6 paginiNOV-9, 1943. A. Ca. Schneider: Planetary Turbine Transmissionbelchior alvaroÎncă nu există evaluări

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 paginiIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioÎncă nu există evaluări

- April 2, 1940.: P. Ravigneaux - 2,195,783Document9 paginiApril 2, 1940.: P. Ravigneaux - 2,195,783Stefan IlicÎncă nu există evaluări

- Hydraulic engine mount with variable movement absorptionDocument17 paginiHydraulic engine mount with variable movement absorptionmarcglebÎncă nu există evaluări

- FLEX BEAM Bell 206Document7 paginiFLEX BEAM Bell 206Lewis MarcvsÎncă nu există evaluări

- Us2333680 PDFDocument8 paginiUs2333680 PDFbelchior alvaroÎncă nu există evaluări

- Electric Rear Wheel Steering ActuatorDocument10 paginiElectric Rear Wheel Steering ActuatorPCezzzÎncă nu există evaluări

- Mini Project 1Document10 paginiMini Project 1Sarvesh Kulhari100% (1)

- Us3443375 PDFDocument3 paginiUs3443375 PDFRamos GabeÎncă nu există evaluări

- United States Patent (19) : Brown (45) Date of PatentDocument9 paginiUnited States Patent (19) : Brown (45) Date of Patentapsint12Încă nu există evaluări

- TEPZZZ89Z4 - 4B - T: European Patent SpecificationDocument25 paginiTEPZZZ89Z4 - 4B - T: European Patent Specificationzweisteine777Încă nu există evaluări

- Us2765819 PDFDocument8 paginiUs2765819 PDFAzri LunduÎncă nu există evaluări

- Aliko Dangote University of Science and Technology Wudi1Document5 paginiAliko Dangote University of Science and Technology Wudi1Aliyu HussainiÎncă nu există evaluări

- Rotor Rim-Ventilated Generator with Turning Vanes for Rotor Inlet Coolant Gas FlowDocument4 paginiRotor Rim-Ventilated Generator with Turning Vanes for Rotor Inlet Coolant Gas FlowHamedJamshidiÎncă nu există evaluări

- US20010024927A1Document7 paginiUS20010024927A1MahnooshÎncă nu există evaluări

- Us2703500 PDFDocument7 paginiUs2703500 PDFbelchior alvaroÎncă nu există evaluări

- Z Parachute PRDocument4 paginiZ Parachute PRNile_JockeyÎncă nu există evaluări

- The Mathematics of ParachutesDocument13 paginiThe Mathematics of ParachutesNile_JockeyÎncă nu există evaluări

- Penic, Tom - Engineering Acoustics (WWW - Teicontrols.com 2000)Document36 paginiPenic, Tom - Engineering Acoustics (WWW - Teicontrols.com 2000)Corneliu ParaschivÎncă nu există evaluări

- NJ-ebooks: Quantitative Remote Sensing in Thermal InfraredDocument298 paginiNJ-ebooks: Quantitative Remote Sensing in Thermal InfraredNile_JockeyÎncă nu există evaluări

- NJ ScPapersDocument12 paginiNJ ScPapersNile_JockeyÎncă nu există evaluări

- NJ-Patents: (20150176752)Document37 paginiNJ-Patents: (20150176752)Nile_JockeyÎncă nu există evaluări

- NJ ScPaperDocument12 paginiNJ ScPaperNile_JockeyÎncă nu există evaluări

- NJ-ebooks: Fundamental Optical DesignDocument311 paginiNJ-ebooks: Fundamental Optical DesignNile_JockeyÎncă nu există evaluări

- Optical Remote Sensing Science and Technology Optical EngineeringDocument493 paginiOptical Remote Sensing Science and Technology Optical EngineeringadlakhadkÎncă nu există evaluări

- Scanning apparatus with spherical 5-bar linkageDocument18 paginiScanning apparatus with spherical 5-bar linkageNile_JockeyÎncă nu există evaluări

- Handbook of Near-Infrared Analysis 3rd Edition (2008)Document836 paginiHandbook of Near-Infrared Analysis 3rd Edition (2008)Ivan Felipe Barrera Rincon83% (6)

- Pulsed Time-Of-Flight Laser Range Finder Techniques For Fast, High Precision Measurement ApplicationsDocument98 paginiPulsed Time-Of-Flight Laser Range Finder Techniques For Fast, High Precision Measurement ApplicationsHABI_HARISÎncă nu există evaluări

- ACT RPT NRG ARI 03 2201 Non Mechanical Laser Beam SteeringDocument40 paginiACT RPT NRG ARI 03 2201 Non Mechanical Laser Beam SteeringNile_JockeyÎncă nu există evaluări

- Free Form Optical System Design With Differential EquationsDocument8 paginiFree Form Optical System Design With Differential EquationsNile_JockeyÎncă nu există evaluări

- Geometric Algebra and Its Application To Mathematical Physics - C. DoranDocument187 paginiGeometric Algebra and Its Application To Mathematical Physics - C. DorantamthientaiÎncă nu există evaluări

- Materials For Infrared OpticsDocument6 paginiMaterials For Infrared OpticsNile_JockeyÎncă nu există evaluări

- IR TheoryDocument10 paginiIR TheoryBenjamin Emenike Onyido JnrÎncă nu există evaluări

- NJ-ebooks: High Speed Optical ModulatorsDocument6 paginiNJ-ebooks: High Speed Optical ModulatorsNile_JockeyÎncă nu există evaluări

- John Deere X145 Lawn Tractor Service Repair Technical Manual (TM113319)Document16 paginiJohn Deere X145 Lawn Tractor Service Repair Technical Manual (TM113319)zhuangfuqian31Încă nu există evaluări

- SAFETY DATA SHEET TITLEDocument8 paginiSAFETY DATA SHEET TITLESukanta ChowdhuryÎncă nu există evaluări

- Preparatory Year Program Computer Science (PYP 002)Document34 paginiPreparatory Year Program Computer Science (PYP 002)Hassan AlfarisÎncă nu există evaluări

- SHIP HANDLING WITH ESCORT TUGS A REFERENCE MANUAL FOR MASTERS PILOTS GIANO Tug SpecsDocument8 paginiSHIP HANDLING WITH ESCORT TUGS A REFERENCE MANUAL FOR MASTERS PILOTS GIANO Tug SpecsMahmoud ElsherifÎncă nu există evaluări

- Fitter ToolsDocument7 paginiFitter ToolsSainadhReddy100% (1)

- Assist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Document49 paginiAssist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Hundee HundumaaÎncă nu există evaluări

- Robohawks Team HandbookDocument11 paginiRobohawks Team Handbookapi-376756259Încă nu există evaluări

- Motivation and Leadership in Engineering ManagementDocument24 paginiMotivation and Leadership in Engineering ManagementChen Marie DyÎncă nu există evaluări

- Geberit Sanitary Catalogue 2017 2018Document348 paginiGeberit Sanitary Catalogue 2017 2018Po MoÎncă nu există evaluări

- EN 12663-1 - 2010 - IndiceDocument6 paginiEN 12663-1 - 2010 - IndiceOhriol Pons Ribas67% (3)

- Boom and Trailer Mounted Boom Annual Inspection Report PDFDocument1 paginăBoom and Trailer Mounted Boom Annual Inspection Report PDFlanza206Încă nu există evaluări

- Colorado Passenger Tramway Safety Board Adam Lee Accident ReportDocument28 paginiColorado Passenger Tramway Safety Board Adam Lee Accident ReportMichael_Lee_RobertsÎncă nu există evaluări

- Electrical Power Transmission & DistributionDocument18 paginiElectrical Power Transmission & DistributionMd Saif KhanÎncă nu există evaluări

- BOnd Strength ASTM-F904-98Document1 paginăBOnd Strength ASTM-F904-98akash.biradarÎncă nu există evaluări

- Beam and Slab DesignDocument41 paginiBeam and Slab DesignSridhara MunimakulaÎncă nu există evaluări

- Aerodrome Controller (ADC) ExamDocument5 paginiAerodrome Controller (ADC) ExamaxnpicturesÎncă nu există evaluări

- Cava v6 1x Install enDocument29 paginiCava v6 1x Install enWael SalahÎncă nu există evaluări

- Column and Wall Load Take Down Spreadsheet v1.0 - CLDocument28 paginiColumn and Wall Load Take Down Spreadsheet v1.0 - CLBilal KhattabÎncă nu există evaluări

- Revision Plan-II (DPP # 2) - Physics - EnglishDocument12 paginiRevision Plan-II (DPP # 2) - Physics - EnglishBhriguKansra50% (2)

- Furuno GMDSS Installation Manual PDFDocument64 paginiFuruno GMDSS Installation Manual PDFEric PskdÎncă nu există evaluări

- Technical Information HANSA-FLEX Hose ConnectionsDocument75 paginiTechnical Information HANSA-FLEX Hose ConnectionshorsanicuÎncă nu există evaluări

- History of JS: From Netscape to Modern WebDocument2 paginiHistory of JS: From Netscape to Modern WebJerraldÎncă nu există evaluări

- Reliability and Integrity Management 1Document37 paginiReliability and Integrity Management 1Giannos Kastanas100% (1)

- Lime Metering Tomal GB PDFDocument6 paginiLime Metering Tomal GB PDFJose Antonio Caballero BeldaÎncă nu există evaluări

- Phoenix Contact 3247055 enDocument6 paginiPhoenix Contact 3247055 enDGÎncă nu există evaluări

- Conversion Factors GuideDocument2 paginiConversion Factors GuideAndri MPÎncă nu există evaluări

- Catalogo-Wellhead-Marvic (Valvulas WKM EXPANDING)Document41 paginiCatalogo-Wellhead-Marvic (Valvulas WKM EXPANDING)mantilla7Încă nu există evaluări

- Cooling Tower PDFDocument3 paginiCooling Tower PDFmaimslapÎncă nu există evaluări

- Dual vs Core 2 DuoDocument5 paginiDual vs Core 2 Duomahisharma123456Încă nu există evaluări

- Free Space Optical Communication PDFDocument233 paginiFree Space Optical Communication PDFIgor Novid100% (1)

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (137)

- Advanced Modelling Techniques in Structural DesignDe la EverandAdvanced Modelling Techniques in Structural DesignEvaluare: 5 din 5 stele5/5 (3)

- Modeling and Dimensioning of Structures: An IntroductionDe la EverandModeling and Dimensioning of Structures: An IntroductionÎncă nu există evaluări

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDe la EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsÎncă nu există evaluări

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Marine Structural Design CalculationsDe la EverandMarine Structural Design CalculationsEvaluare: 4.5 din 5 stele4.5/5 (13)

- Transmission Pipeline Calculations and Simulations ManualDe la EverandTransmission Pipeline Calculations and Simulations ManualEvaluare: 4.5 din 5 stele4.5/5 (10)

- Built: The Hidden Stories Behind Our StructuresDe la EverandBuilt: The Hidden Stories Behind Our StructuresEvaluare: 4 din 5 stele4/5 (27)

- Design and Construction of Soil Anchor PlatesDe la EverandDesign and Construction of Soil Anchor PlatesEvaluare: 5 din 5 stele5/5 (1)

- Pile Design and Construction Rules of ThumbDe la EverandPile Design and Construction Rules of ThumbEvaluare: 4.5 din 5 stele4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDe la EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingÎncă nu există evaluări

- Piezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringDe la EverandPiezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringÎncă nu există evaluări

- Advanced Design Examples of Seismic Retrofit of StructuresDe la EverandAdvanced Design Examples of Seismic Retrofit of StructuresEvaluare: 1 din 5 stele1/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDe la EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresEvaluare: 1 din 5 stele1/5 (2)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDe la EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsEvaluare: 4 din 5 stele4/5 (16)

- 3D Concrete Printing Technology: Construction and Building ApplicationsDe la Everand3D Concrete Printing Technology: Construction and Building ApplicationsÎncă nu există evaluări

- Matrix Methods for Advanced Structural AnalysisDe la EverandMatrix Methods for Advanced Structural AnalysisEvaluare: 5 din 5 stele5/5 (1)

- Offshore Pipelines: Design, Installation, and MaintenanceDe la EverandOffshore Pipelines: Design, Installation, and MaintenanceEvaluare: 4.5 din 5 stele4.5/5 (2)

- Pipeline Planning and Construction Field ManualDe la EverandPipeline Planning and Construction Field ManualEvaluare: 5 din 5 stele5/5 (3)

- Experiment and Calculation of Reinforced Concrete at Elevated TemperaturesDe la EverandExperiment and Calculation of Reinforced Concrete at Elevated TemperaturesEvaluare: 5 din 5 stele5/5 (2)