Documente Academic

Documente Profesional

Documente Cultură

IKERD Consulting Customer Story PDF

Încărcat de

RameshBathalaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

IKERD Consulting Customer Story PDF

Încărcat de

RameshBathalaDrepturi de autor:

Formate disponibile

Autodesk Customer Success Story

COMPANY

IKERD Consulting

LOCATION

Dallas, Texas

SOFTWARE

Autodesk Advance Steel

IKERD Consulting

Advanced coordination for steel

IKERD Consulting uses Advance Steel to

develop construction-grade virtual models

for project coordination

With Advance Steel, we

can tackle construction

issues with a mouse and

a keyboard, instead of a

torch and a sledgehammer.

And compared to other

detailing solutions, it costs

less, requires less training, has

exceptional interoperability

with widely used design

solutions, works seamlessly

with laser-scanned data,

and is a familiar modeling

environment for current

and prospective staff.

Will Ikerd

Principal

IKERD Consulting

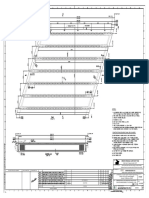

Image courtesy of IKERD Consulting.

The firm

IKERD Consulting is a Dallas-based structural

engineering firm that provides consulting services

for building owners, contractors, and designers

with a focus on integrated projects utilizing

Virtual Design amd Construction (VDC) and

Building Information Modeling (BIM). IKERDs

services include engineering and modeling of

trade content, often incorporating 3D laser

scanning data. The firm routinely uses Autodesk

solutions, including Autodesk Revit, Autodesk

Navisworks, and Autodesk ReCap.

The project

One of IKERDs recent projects was a new

three-story, 300,000 square-foot technology

center for the telecommunications company

CenturyLink, in Monroe, Louisiana. IKERD

provided overall BIM coordination services on

the project, as well as modeling services for a

variety of trades. One of these virtual models

was the buildings million-dollar monumental

staircase, prominently located in the buildings

atrium. The staircase spirals up three stories

around an oval pillar, which hides structural

steel columns surrounded by a cold-formed

metal frame. Curved LED acrylic panels cover

the frame and illuminate the staircase area.

The staircase is supported by a series of steel

beams that protrude from the oval pillar. The

treads of the stairs are several feet from the

pillar, creating the illusion of the staircase

floating up this pillar of light.

The challenges

The geometry of the building is very complicated,

with a lot of slopes and curves and very expensive

finishes, says Will Ikerd, a principal at IKERD

Consulting. The use of highly detailed 3D

models that accurately reflected planned and

in-process construction was essential for project

coordination. To facilitate that coordination,

IKERD was also hired, independently, by

several project subcontractors to develop these

construction-grade models of their building

trades, including the manufacturer of the

staircase. And all of the discipline-specific models

had to work seamlessly within the Navisworks

software environment used by IKERD for project

coordination and clash detection.

Autodesk Customer Success Story

IKERD Consulting

the planned staircaseultimately reducing

the number of requests for information (RFI)

during the construction phase.

The interoperability of Advance Steel with

other Autodesk products like ReCap, Revit, and

Navisworks is crucial on a project like this and

is a big advantage for our business, says Koller.

We dont have to worry about file formats or

unsupported model elements. They all just

work together.

Results

Image courtesy of IKERD Consulting.

The solution

IKERD used Autodesk Advance Steel,

Autodesks 3D model-based software solution

for steel detailing, to create a virtual model

of the central staircase that would match the

constructed staircase. This model was used

to coordinate the staircase with the adjoining

structural support beams, cold-formed metal

frame, and acrylic panels. Built on the AutoCAD

platform, the softwares parametric 3D modeling

environment and intelligent objects enables

firms to efficiently develop extremely precise

models of steel structures that contain all the

structural steel beams, plates, bracing, welded

assemblies, and so on down to fasteners

and connections.

Construction-grade level of detail

The geometry of this staircase is very

complicated, explains Trevor Koller, a project

coordinator for IKERD. The overall form mirrors

the oval-shaped central pillar as the stairs

spiral upwards and every tread of the staircase

is a unique quadrangle. The central structure

included numerous acrylic panels that were

manufactured remotely and represented the

majority of the staircases million-dollar price

tag. Needless to say, coordination between the

staircase and these panels was very important.

The team began by using the architects Revit

model to develop a Revit structural model of the

staircase and surrounding steel and supports.

These models were then used in Navisworks for

clash detection and clearance checking. But

design models can be both highly precise and

horribly inaccurate at the same time, says Ikerd.

The level of detail and tolerances of design

models are sometimes insufficient for

construction-grade spatial coordination,

especially on a project like this with such tight

clearances and complicated geometry. We

decided that we needed to model every little

detail of the staircase and supporting structure,

down to the connection level. And thats when

we turned to Advance Steel. says Koller. The

parametric modeling flexibility of the Advance

Steel software and its specialized tools and

wizards for stairs made it easy for us to develop

the model, helping us figure out the tread size

and spacing of the stairs as they curved around

the oval center.

Moreover, the level of detail in the Advance

Steel model helped us study the constructability

of the staircase, says Ikerd. For example, would

the fireproofing material on the main steel create

interferences, was there enough room to fit up

the staircase connections, and so on.

Short learning curve

Although the IKERD team on this project had

experience with Autodesk modeling solutions

such Revit and AutoCAD, this was the firms first

use of Advance Steel. With Advance Steel, it

is very easy to model steel objects and connect

them, says Koller. The software is very intuitive

and easy to learn and use.

We found Advance Steel to be much simpler

to learn than some of the other steel detailing

tools we had used in the pasteasily 30 percent

faster, adds Ikerd. In particular, our AutoCAD

users quickly took to Advance Steel.

Laser accuracy

In addition to creating a construction-grade

model of the staircase, IKERD also used a laser

scanner to capture the as-built conditions of

the central pillars core and metal frame. It

was important to know exactly where steel

beams would penetrate the metal frame and

these acrylic panels, says Ikerd. The ReCap

software was used to process the data and

create a point cloud of the as-built structural

beams and metal framing. That data and the

Advance Steel model were imported into

Navisworks to validate the position of the

new construction and coordinate it against

Autodesk, the Autodesk logo, AutoCAD, Navisworks, ReCap, and Revit are registered trademarks or trademarks of Autodesk, Inc., and/or its

subsidiaries and/or affiliates in the USA and/or other countries. All other brand names, product names, or trademarks belong to their respective

holders. Autodesk reserves the right to alter product and services offerings, and specifications and pricing at any time without notice, and is not

responsible for typographical or graphical errors that may appear in this document. 2015 Autodesk, Inc. All rights reserved.

A designers drawings and models represent

design intent, says Koller. But, as the saying

goes, the devil is in the details. Advance

Steel helped us quickly model those details

and reduce the RFIs between the contractors

and design teams, saving our client costly

construction schedules delays.

IKERD has been using Advance Steel for over

a year since this project, and continues to use

the software for fabrication/construction-level

coordination. With Advance Steel, we can

tackle construction issues with a mouse

and a keyboard, instead of a torch and a

sledgehammer, says Ikerd. And compared

to other detailing solutions, it costs less,

requires less training, has exceptional

interoperability with widely used design

solutions, works seamlessly with laser-scanned

data, and is a familiar modeling environment

for current and prospective staff, says Ikerd.

For more information, visit

www.autodesk.com/advancesteel

The interoperability of Advance

Steel with other Autodesk

products like ReCap, Revit,

and Navisworks is crucial on

a project like this and is a big

advantage for our business.

We dont have to worry about

file formats or unsupported

model elements. They all just

work together.

Trevor Kolle

Project Coordinator

IKERD Consulting

S-ar putea să vă placă și

- 004 GiDocument2 pagini004 GiRameshBathalaÎncă nu există evaluări

- Bhosari Shed20.02.2014Document1 paginăBhosari Shed20.02.2014RameshBathalaÎncă nu există evaluări

- Case IdDocument6 paginiCase IdRameshBathalaÎncă nu există evaluări

- Topic - Connections - Typical Joints PDFDocument56 paginiTopic - Connections - Typical Joints PDFKanako NozawaÎncă nu există evaluări

- 2911 1 1CONCRETE+PILES +Driven+Cast+in Situ+Concrete+PilesDocument44 pagini2911 1 1CONCRETE+PILES +Driven+Cast+in Situ+Concrete+PilesfcernapÎncă nu există evaluări

- Proposed Section of Building Staineywadi, DadarDocument1 paginăProposed Section of Building Staineywadi, DadarRameshBathalaÎncă nu există evaluări

- Administrator's Release Notes 2017Document44 paginiAdministrator's Release Notes 2017RameshBathalaÎncă nu există evaluări

- INTERGRAPH - PPM Analysis VisualVesselDesign PorductSheet Global EN PDFDocument2 paginiINTERGRAPH - PPM Analysis VisualVesselDesign PorductSheet Global EN PDFRameshBathalaÎncă nu există evaluări

- Revit Structure and AutoCAD Feb07Document19 paginiRevit Structure and AutoCAD Feb07welwelÎncă nu există evaluări

- SPLMInstall UserGuideDocument125 paginiSPLMInstall UserGuideseowwei627Încă nu există evaluări

- Structural - LaneDocument37 paginiStructural - LaneAngel Lisette Lao100% (1)

- Ddb-403-r0-Dimension Detail of Superstructure 32m Span-Drawing - PDF SH 1 of 2Document1 paginăDdb-403-r0-Dimension Detail of Superstructure 32m Span-Drawing - PDF SH 1 of 2RameshBathalaÎncă nu există evaluări

- DDB-403-R0-DIMENSION DETAIL OF SUPERSTRUCTURE 32M SPAN-DRAWING - PDF SH 1 of 2 PDFDocument1 paginăDDB-403-R0-DIMENSION DETAIL OF SUPERSTRUCTURE 32M SPAN-DRAWING - PDF SH 1 of 2 PDFRameshBathalaÎncă nu există evaluări

- INTERGRAPH - PPM Analysis VisualVesselDesign PorductSheet Global EN PDFDocument2 paginiINTERGRAPH - PPM Analysis VisualVesselDesign PorductSheet Global EN PDFRameshBathalaÎncă nu există evaluări

- Revit Structure and AutoCAD Feb07Document19 paginiRevit Structure and AutoCAD Feb07welwelÎncă nu există evaluări

- Mode Acceleration Approach For Generation of Floor Spectra Including Soil-Structure InteractionDocument17 paginiMode Acceleration Approach For Generation of Floor Spectra Including Soil-Structure Interactionali_mirgozarÎncă nu există evaluări

- Revit Structure and AutoCAD Feb07Document19 paginiRevit Structure and AutoCAD Feb07welwelÎncă nu există evaluări

- Revit Structure and AutoCAD Feb07Document19 paginiRevit Structure and AutoCAD Feb07welwelÎncă nu există evaluări

- RD3.9 Handling DocumentsDocument21 paginiRD3.9 Handling DocumentsRameshBathalaÎncă nu există evaluări

- C MiningDocument12 paginiC MiningRameshBathalaÎncă nu există evaluări

- Model Concrete Reinforcement in RevitDocument88 paginiModel Concrete Reinforcement in Revitrealdaross100% (4)

- Advance Steel 2017 Getting Started Guide ImperialDocument55 paginiAdvance Steel 2017 Getting Started Guide ImperialRameshBathalaÎncă nu există evaluări

- Stiffener CalculationDocument24 paginiStiffener CalculationRameshBathala100% (6)

- Advance Steel 2017 Whats New PresentationDocument21 paginiAdvance Steel 2017 Whats New PresentationRameshBathalaÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Búsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDocument5 paginiBúsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDavidCPÎncă nu există evaluări

- Design of RC Building - ExerciseDocument6 paginiDesign of RC Building - Exercisesajeerala100% (1)

- Lecturer Notes On Pipe Sizing BasicsDocument32 paginiLecturer Notes On Pipe Sizing BasicsTactical Blackhawk BatamÎncă nu există evaluări

- FGS80HAS 100 V 50-60 HZ 1Document3 paginiFGS80HAS 100 V 50-60 HZ 1Tomas GuaiquireÎncă nu există evaluări

- Manual F700GS 2013Document164 paginiManual F700GS 2013j gfatggÎncă nu există evaluări

- Lecture 10 - Dry Etching PDFDocument7 paginiLecture 10 - Dry Etching PDFSiddhant ModiÎncă nu există evaluări

- If This Paper Were in Chinese, Would Chinese People Understand the Title? An Exploration of Whorfian Claims About the Chinese Language If This Paper Were in Chinese, Would Chinese People Understand the Title? An Exploration of Whorfian Claims About the Chinese Language If This PaperDocument69 paginiIf This Paper Were in Chinese, Would Chinese People Understand the Title? An Exploration of Whorfian Claims About the Chinese Language If This Paper Were in Chinese, Would Chinese People Understand the Title? An Exploration of Whorfian Claims About the Chinese Language If This PaperDavid MoserÎncă nu există evaluări

- SOP's For All Digital Marketing ActivitesDocument3 paginiSOP's For All Digital Marketing ActivitesSavijeet Singh50% (2)

- DesignScript Summary User ManualDocument20 paginiDesignScript Summary User ManualEsper AshkarÎncă nu există evaluări

- Review For Mastery: VocabularyDocument3 paginiReview For Mastery: VocabularyHala EidÎncă nu există evaluări

- SM 1201r9 UsxrayDocument500 paginiSM 1201r9 UsxrayMurat KaanÎncă nu există evaluări

- Sal de CrosetatDocument3 paginiSal de CrosetatMădălina Pisău100% (1)

- CHM 556 Experiment 5Document12 paginiCHM 556 Experiment 5Amar Safwan100% (1)

- OOPS using C++ Question BankDocument32 paginiOOPS using C++ Question BankPushpa Bg100% (1)

- MQTT RGB Light For HomeDocument3 paginiMQTT RGB Light For HomearevazhagunvcÎncă nu există evaluări

- FFA Furfural Fire and Health HazardsDocument2 paginiFFA Furfural Fire and Health HazardsYuga Pria PungkasanÎncă nu există evaluări

- Session5 Automotive PackagingDocument72 paginiSession5 Automotive PackagingShivprasad Savadatti100% (1)

- 5-Unsymmetrical Fault AnalysisDocument5 pagini5-Unsymmetrical Fault Analysisvirenpandya0% (1)

- Newtons CowsDocument9 paginiNewtons CowsLawrence Lim Ah KowÎncă nu există evaluări

- Statistical Properties of Population Stability IndexDocument60 paginiStatistical Properties of Population Stability IndexВячеславÎncă nu există evaluări

- The Importance of Calculators in Math ClassDocument6 paginiThe Importance of Calculators in Math Classchloe shanice bordiosÎncă nu există evaluări

- 2 (Molecular Diffusion in Gases)Document66 pagini2 (Molecular Diffusion in Gases)Nasir ShamsÎncă nu există evaluări

- Reso Course PlannerDocument2 paginiReso Course PlannerSnehasishGhosh100% (1)

- Is It Simple To Explain Simple Experiments The Heavy Newspaper' Stick BreakDocument6 paginiIs It Simple To Explain Simple Experiments The Heavy Newspaper' Stick Break이온유Încă nu există evaluări

- SASMO 2020 Grade 6 + SolutionDocument24 paginiSASMO 2020 Grade 6 + SolutionBentley Leopold Halim94% (18)

- in 01 en KATALOGDocument50 paginiin 01 en KATALOGSigma Ragam ManunggalÎncă nu există evaluări

- Analyze Sales Performance with Key FiguresDocument192 paginiAnalyze Sales Performance with Key Figurespanirbanonline3426Încă nu există evaluări

- CNT SVX15D E4 1111Document60 paginiCNT SVX15D E4 1111Mihai IavorschiÎncă nu există evaluări

- Synchronised Ujt Triggering CircuitDocument2 paginiSynchronised Ujt Triggering Circuitsvinod s67% (3)

- 5.1.2. Biological Indicators of SterilisationDocument1 pagină5.1.2. Biological Indicators of SterilisationSurendar KesavanÎncă nu există evaluări