Documente Academic

Documente Profesional

Documente Cultură

Informe TBC

Încărcat de

Jovany JimenezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Informe TBC

Încărcat de

Jovany JimenezDrepturi de autor:

Formate disponibile

Article

pubs.acs.org/IECR

Esterication Kinetics of Tributyl Citrate Production Using

Homogeneous and Heterogeneous Catalysts

Oscar M. Osorio-Pascuas, Miguel A. Santaella, Gerardo Rodriguez, and Alvaro Orjuela*

Department of Chemical and Environmental Engineering, Grupo de Investigacion en Procesos Qumicos y Bioqumicos, Universidad

Nacional de Colombia, 111321 Bogota D.C., Colombia

S Supporting Information

*

ABSTRACT: In this work, the production of tributyl citrate via catalytic and self-catalyzed esterication of citric acid with 1butanol was studied. Both, methanesulfonic acid (MSA) and Amberlyst 70 ion-exchange resin were evaluated as catalysts in the

reaction. The kinetic eects of the temperature (353393 K), the feed molar ratio of alcohol to acid (8:1 to 16:1), and catalyst

loadings (0.51.5 wt % of MSA, and the equivalent amount of Amberlyst 70) were evaluated. Experiments were carried out using

stirred batch reactors under isothermal operation. A BoxBehnken design was used to optimize the number of experiments

required to obtain a valid kinetic model. Chemical equilibrium conditions were evaluated independently from kinetic

experiments, reducing the number of parameters to adjust during data regression. Self-catalytic rate of reaction was also

evaluated, and it was included within the overall kinetic model. The obtained models show good agreement with experiments,

and they can be used for process analysis and simulation.

1. INTRODUCTION

Among the variety of citrate esters, tri-1-butyl citrate (TBC)

stands out as a widely used ingredient in cosmetic products and

as a raw material to produce acetyl tri-1-butyl citrate (ATBC).

The acetylated tributyl citrate provides even better results as a

plasticizing agent for polyvinyl chloride (PVC).10

TBC is manly produced by direct esterication of citric acid

(CA) (a major fermentation-derived commodity), with 1butanol (also available from fermentation) in a sequential

parallel reaction scheme, as shown in Figure 1. At the industrial

scale, TBC is produced in batch or batch fed stirred tank

reactors using a homogeneous acid catalyst.1214 Some reports

also indicate the benet of using of heterogeneous catalyst as

ion exchange resins to avoid the need for corrosion-resistant

materials.15 Although homogeneous catalysts can become very

corrosive to equipment and could be dicult to remove, they

are preferred because they are more active and ecient in

reaching high conversions to the trialkyl ester below the

decomposition temperature of citric acid (448 K).16

Each esterication step described in Figure 1 is strongly

limited by chemical equilibrium. Therefore, the continuous

removal of the water generated in the process and the use of

alcohol excess are common practices to achieve high

conversion. For that same reason, energy-intensive alcohol

recovery and recycling steps are required, involving higher

processing costs.

To reduce energy consumption and processing costs during

citrates production, intensication by reactive distillation (RD)

has been proposed for citrates production, specically for

triethyl citrate.11,15 In this case, removal of ethanol excess and

water was accomplished by distillation, while reaction was

Production and consumption of biobased chemicals have

gained pace in recent years because of the global trend for

moderating dependence on petrochemicals, the need for

reducing the environmental impacts of using fossil resources,

and also as a result of the public scrutiny over the potential

negative eects of being exposed to harmful chemicals. In

contrast to most petroleum-based chemicals, biobased products

are commonly renewable, biocompatible, and suitable for

biodegradation. In this regard, the substitution of petrochemicals with biobased alternatives in the formulation of consumer

goods is particularly important in the plasticizers sector. These

components are widely used in the fabrication and transformation of polymers, providing the exibility and plasticity

required in the nal products. The current world plasticizer

market amounts to c.a. 7 million tons per year, and it is

extensively dominated (86%) by phthalic acid esters of long

chain alcohols (e.g., 2-ethyl hexanol, nonanol). The remaining

nonphthalate plasticizers are used mainly in niche applications.1

Although phthalates are well-known as general-purpose

plasticizing agents and have been used in a variety of polymeric

materials,2,3 some studies indicate that they may represent

certain risks to human health and that they are not easily

biodegraded.48 Furthermore, in the traditional phthalic

anhydride synthesis processes (gas-phase oxidation of naphthalene or o-xylene3) some aromatic trace impurities may

remain in the plasticizer, preventing its use in products

designed for direct contact with humans. In contrast, even if

biobased plasticizers such as citric acid esters (with or without

acetylation) are not for general purpose, they are generally

recognized as safe (GRAS) by dierent international regulatory

agencies. This characteristic makes citrates suitable plasticizers

for pharmaceutical and cosmetic applications, medical devices,

food packaging, and toys.2,3,911

XXXX American Chemical Society

Received: September 26, 2015

Revised: November 22, 2015

Accepted: November 30, 2015

DOI: 10.1021/acs.iecr.5b03608

Ind. Eng. Chem. Res. XXXX, XXX, XXXXXX

Article

Industrial & Engineering Chemistry Research

Figure 1. Esterication of citric acid with 1-butanol.

2.2. Analysis. The analytic technique described here was

adapted from a previous report on citrates esterication.11 CA,

mono-1-butyl citrate (MBC), di-1-butyl citrate (DBC), and

TBC were analyzed by using a Dionex-Ultimate 3000 HPLCSystem, using a reversed phase C18 column (Acclaim 120, 3

150 mm, 3 m). The oven temperature was set at 373 K, and

the mobile phase ow rate was maintained as 1 mL/min using a

programmed gradient of acetonitrile (ACN)/water (pH 2.1) as

follows: 0% ACN (t = 0 min), 60% ACN (t = 20 min), 90%

ACN (t = 25 min), and 0% ACN (t = 28 min). Samples were

diluted in acetonitrile (3/100 v/v) before injection, and the

species were quantied by ultraviolet (UV) detection at a

wavelength of 210 nm. CA and TBC were identied by

comparison of the retention times of standards. Quantication

was carried out by previous calibration and response factor

determination. Solutions of known composition were prepared

and analyzed by triplicate, ensuring a detector linear response.

The maximum error of HPLC analysis in these components

was 0.5%.

For the MBC and DBC, there were no commercial

chromatography standards available. Moreover, according to

the chemical structure, the occurrence of two isomers was

expected for both intermediate esters (dicult to resolve by

standard HPLC), because esterication can occur in the

terminal or middle carboxylic group of the CA. In all reaction

samples, two peaks were observed in the chromatography plots

for each intermediate ester. For quantication purposes, the

two unresolved peaks of each intermediate ester were

considered as a single component. Because similar detector

responses for CA and TBC were obtained, the response factors

of the missing citrates were calculated based upon the degree of

substitution. Those were obtained by interpolating a linear

relationship between the molecular weight of CA and TBC and

their corresponding response factors. Adequacy of this

assumption was veried by keeping track of the total amount

of moles of citric species that had to be constant in each

experiment. Finally, the concentrations of water (H2O) and 1butanol (BtOH) were determined by reaction stoichiometry

and by mole balance. By using the considerations described

above, and because the response factors for some citric species

were assumed, it was observed that the maximum relative error

close to the total mass balance was 5% in the sum of the

experimental mass fractions of all components. This was

considered acceptable taking into account the lack of

commercial chromatography standards for calibration of

intermediate citrates.

2.3. Heterogeneous Catalyst Pretreatment and Preliminary Tests. As-received Amberlyst 70 was washed in

ethanol under agitation for 2 h using a stirred glass container.

promoted by Amberlyst 15 as catalyst. According to these

reports, it is recommended that operation occur at high

temperatures to benet the reaction rate, but the temperature

should be maintained below 393 K to avoid thermal damage of

the catalyst.17

Despite RD having been also proposed for the production of

other CA esters,12 there is a lack of kinetic and thermodynamic

information in the open literature allowing process modeling

and design, particularly when using commercial homogeneous

or heterogeneous catalysts such as methanesulfonic acid and

Amberlyst 70. Methanesulfonic acid (MSA) is widely used as a

liquid catalyst in esterication processes because of its good

activity, lower corrosiveness compared with stronger acids

(sulfuric or hydrochloric), and less degradation of the product

(color darkening). On the other hand, Amberlyst 70 ionexchange resin can operate at higher temperatures than most

commercial ion exchange resins (maximum operating temperature of 463 K18), and similarly to other solid catalysts, it can be

easily recovered and regenerated in continuous process

systems. Although reports indicate Amberlyst 70 has lower

acid sites concentration in the polymeric matrix (>2.55 eq/

kg18) than other ion exchange catalysts, it has shown good

performance in dierent etherications and also in esterications of poly(carboxylic acid)s operating in RD units.1927

In this regard, this work describes a study on the

esterication of CA with 1-butanol using MSA and Amberlyst

70 as homogeneous and heterogeneous catalyst, respectively.

The eect of the catalyst concentration, reactants molar ratio,

and temperature over the rate of reaction was evaluated for

each catalyst. Because the autocatalytic eect was considered

important based on preliminary experiments, it was also studied

and incorporated within the complete kinetic models. The

obtained models are intended to be used in the modeling of

reactive distillation processes.

2. EXPERIMENTAL DETAILS

2.1. Material. For reaction experiments, anhydrous citric

acid (99.9%, FG) was obtained from Sucroal S.A. (Colombia)

and 1-butanol (99.5%, for analysis) was purchased from

Panreac (Spain). The concentration of all chemicals was

checked by gas chromatography or high-performance liquid

chromatography (HPLC), and the chemicals were used without

further purication. Tributyl citrate (98%, Aldrich, United

States) and citric acid (99.9%, Sigma-Aldrich) standards were

used for calibration purposes. Methanesulfonic acid (98%) was

obtained from Alfa Aesar (Germany) and Amberlyst 70 resin

was supplied by Dow Chemical Company (United States).

Acetonitrile (99.9% HPLC grade, Panreac, Spain) and

deionized water were used as HPLC solvents.

B

DOI: 10.1021/acs.iecr.5b03608

Ind. Eng. Chem. Res. XXXX, XXX, XXXXXX

Article

Industrial & Engineering Chemistry Research

below the desired temperature, the required amount of MSA

was loaded into reactor through the sampling port using a

syringe. After the mixture reached the reaction temperature (it

normally took 1015 min), the reaction time was started.

When operating with the self-catalytic system, the stirring

rate was maintained at 700 rpm from the beginning of the

operation. When using Amberlyst 70, reagents and catalyst

were charged to the reactor from the beginning. Then, the

reactor was closed and operated at room temperature and 700

rpm for about 10 min to allow CA dissolution. Later, the

heating was started, and after the mixture reached the required

temperature, the stirring rate was adjusted to 1100 rpm. At this

point, the time recording was initiated.

During all experiments, 0.20.3 cm3 samples were withdrawn

at specic time intervals through the sampling port by using a

syringe. The samples were transferred to an ice bath before

analysis. Eight to ten samples were obtained in each 8 h

reaction experiment.

2.5. Chemical Equilibrium Experiment. Reaction equilibrium experiments were carried out in sealed glass tubes of 10

mL, which were attached to a rotating rod within an isothermal

oven (Figure 3). The reactants together with the MSA were

An ethanol resin volumetric ratio of 1:4 was used during this

process, and it was repeated at least three times. The rinsing

process was repeated with deionized water until constant

conductivity of the supernatant solution was measured.

Afterward, the resin was ltered and dried under vacuum at

353 K until constant weight. The dried catalyst was maintained

in a hermetic container within a vacuum oven until the nal use

in kinetic experiments.

From preliminary experiments using Amberlyst 70 as

catalyst, it was found that external mass-transfer resistances

were negligible when operating at stirring rates above 800 rpm.

For this reason, further reactions were run above this agitation

rate. Additional experiments evaluating the eects of catalyst

particle sizes on the reaction rate allowed ensuring the absence

of internal mass-transfer limitations when working with particle

sizes below 300 m. Because the mean particle size of highly

monodisperse Amberlyst 70 beads is around 500 m,18 the

catalyst was subjected to grinding before use in the kinetic

experiments. This process was performed in a mortar using

liquid nitrogen to cool the solid, avoiding the temperature rise

caused by friction during the milling process. To ensure the

thermal stability of the acid sites, the ion exchange capacity of

the resin was measured before and after the grinding process.

Details of the standard method to evaluate ion exchange

capacity are described elsewhere.28 The concentration of acid

sites before and after this treatment was nearly constant, and it

was 4.01 0.12 eq/dry kg.

2.4. Batch Kinetic Experiment. The esterication

reactions were performed under batch conditions in a set of

three well-mixed 100 cm3 stainless steel jacketed reactors, each

one equipped with a circulating oil bath for isothermal

operation and a stirring plate (see Figure 2). Also, a sampling

Figure 3. Scheme of equipment used for chemical equilibrium

experiments.

previously added into tubes at the desired concentrations. The

stirring rate was adjusted between 90 and 100 rpm, and the

temperature was maintained constant within 0.1 K by using a

PID controller. The tubes where maintained at reaction

conditions for 2872 h, and at the end the equilibrium

conditions were obtained by HPLC analysis of the reactive

media.

Figure 2. Scheme of equipment used for batch kinetic experiments.

3. RESULTS AND DISCUSSION

A BoxBehnken experimental design was implemented to

reduce the required number of experiments to t the kinetic

model. BoxBehnken is a type of response surface design used

when each factor has only three levels, and it is recommended

when the region of interest and the region of operability are

nearly the same. Because it requires fewer evaluation points, it

is less computationally expensive than central composite

designs (such as the factorial design).29 In our case, three

dierent factors at three levels are considered: initial reactants

molar ratio (8:1 to 16:1), reaction temperature (363393 K),

and catalyst loading (0.51.5 wt %). In the case of Amberlyst

70, the required weight of catalyst was calculated using the

port and a temperature probe were located over the reactor

cover to follow the reaction conditions with time. Inside the

reactor, at the end of the sampling port, a stainless steel lter

was located to avoid catalyst removal during operation.

Initially, when using the homogeneous catalyst (MSA), the

desired amount of CA and BtOH were added into the reactor

at room temperature. After the reactor was closed, the magnetic

stirring was set at 500 rpm and maintained for 10 min to mix

reactants and dissolve the CA. Thereafter, heating was initiated

by allowing the bath uid to pass through the reactor jacket,

and the stirring rate was adjusted to 700 rpm. Around 5 K

C

DOI: 10.1021/acs.iecr.5b03608

Ind. Eng. Chem. Res. XXXX, XXX, XXXXXX

Article

Industrial & Engineering Chemistry Research

Table 1. Evaluation of Internal Mass-Transfer Resistances at

Initial Reaction Conditions Using the WeiszPrater

Criterion

cat (kg/m3) (swollen)

dp (m) (swollen)

CCAo (mole fraction) (solution)

wcat (kgcat/kgsol)

BtOH association factor WilkeChang

CA molar volume at TB (cm3/mol)a

19

experimental run

T (K)

robs (mol CA/mol.s)

sol (kg/m3)

liquid (cp)36

DCA (m2/s)

De (m2/s)

w

1000

378

0.058

0.0264

1.0

223.14

0.57

3b

363.15

9.68 106

818

0.633

1.43 109

4.63 1010

0.0662

0.258

0.996

4b

393.15

4.35 105

794

0.389

2.51 109

8.16 1010

0.173

0.419

0.988

Figure 5. Self-catalyzed esterication of CA with BtOH. Conditions of

run 22. Molar ratio 12:1 (alcohol:acid), 393 K. (, CA; , MBC; ,

DBC; , TBC; , BtOH; , H2O).

Aspen Plus v. 7.3, Database.

Figure 4. Initial reaction rate of CA with BtOH for various catalyst

concentrations: () MSA and () Amberlyst 70. Experiments

performed with a reactant molar ratio, 8:1 (alcohol:acid) and 378 K.

(*Mass concentration of catalyst corresponding to MSA acid

equivalents. Datum at 0 wt %, cat corresponds to the self-catalytic

experiment.)

Figure 6. Mole fraction-based equilibrium constants (KEQ) for

esterication of CA with BtOH catalyzed with MSA at dierent

temperatures. , Keq 1; , Keq 2; , Keq 3.

Table 2. Kinetic Parameters Adjusted for Self-Catalyzed

Reactions

same acid equivalents of MSA in the reactive phase. Some

additional experiments were carried out to analyze the eect of

temperature, concentration of catalyst, and the self-catalytic

reaction. Conditions of kinetic experiments are summarized in

Table S1 in the Supporting Information, and the full set of

kinetic plots (Figures S2S41) are also available there.

3.1. Mass-Transfer Considerations on the Heterogeneous System of Reaction. In preliminary CABtOH

esterication experiments using Amberlyst 70 as catalyst,

negligible external liquidsolid mass-transfer limitations were

observed when operating with agitation rates above 800 rpm.

On the other hand, intraparticle mass-transfer eects were

analyzed by taking into consideration the WeiszPrater module

(w). As a general criterion, absence of intraparticle masstransfer limitations can be assumed when w is much less than

parameter

ko self,1

ko self,2

ko self,3

Eaself,1

Eaself,2

Eaself,3

Keq 1

Keq 2

Keq 3

units

values

condence interval

1/s

1/s

1/s

J/mol

J/mol

J/mol

3.207 10

8.873 106

1.166 107

71 433

77 346

80 894

8.68

3.56

1.04

6

1.183 105

4.517 105

1.776 106

237

1099

3693

DOI: 10.1021/acs.iecr.5b03608

Ind. Eng. Chem. Res. XXXX, XXX, XXXXXX

Article

Industrial & Engineering Chemistry Research

Table 3. Kinetic Parameters Adjusted for Catalyzed Reaction of Homogeneous and Heterogeneous System

parameter

units

MSA

condence interval

Amberlyst 70

condence interval

ko cat,1

ko cat,2

ko cat,3

Ea1

Ea2

Ea3

Keq 1

Keq 2

Keq 3

1/(%wt cat)*s

1/(%wt cat)*s

1/(%wt cat)*s

J/mol

J/mol

J/mol

2.678 105

3.103 105

4.247 105

57 917

60 065

66 406

8.68

3.56

1.04

4.877 104

3.333 104

2.342 104

1850

1114

585

1.543 105

1.275 105

8.255 104

65 582

67 529

70 561

8.68

3.56

1.04

8.573 103

6.755 103

6.037 103

872

263

1140

= robs/(wcat

sol )

robs

(2)

Here, robs is the rate of reaction per unit volume of reacting

liquid phase. In this study, this is evaluated as the consumption

rate of CA with time. In eq 2, wcat

is the catalyst loading

(kilogram of catalyst per kilogram of reacting phase), and sol is

the density of reacting phase.

In preliminary tests, it was found that dry Amberlyst 70

particles could swell up to double their volume when contacted

with BtOH. Therefore, the particle diameter at reacting

conditions (dp) can be calculated as

d p/d pdry =

(VPswollen/VPdry )

Taking into account that after the catalyst was grinded before

use, obtained particle size distribution was in-between 150 and

300 m. The higher value of this interval (300 m) was used to

estimate the swollen particle diameter with eq 3, obtained a dp

value of 378 m. The particle diameter used in this calculation

was conservative taking into account that WeiszPrater module

increase with the particle size.

Alcohol adsorption within the macroreticular structure of

Amberlyst 70 modies its density because of the swelling eect.

The catalyst density under reaction conditions has been

previously reported as 1000 kg/m3 in similar reactive

media,19,32,33 so this value was used for WeiszPrater module

evaluation. The eective diusivity (De) was calculated based

upon the liquid-phase diusion coecient (DCA) estimated

from the WilkeChang model,34 using eq 4.

Figure 7. Calculated data versus experimental data for esterication

between citric acid and 1-butanol catalyzed with methanesulfonic acid

(, CA; , MBC; , DBC; , TBC; , BtOH; , H2O).

De = (/ )DCA = 2DCA

(4)

As observed, eective diusivity was computed as the

quotient of particle porosity () and pore tortuosity (), or

assuming that is the inverse of .32,33 Then, the observed

WeiszPrater modulus can be used to calculate the

eectiveness factor of the reaction () taking into consideration

the Thiele modulus () for spherical particles using the

following expression:

Figure 8. Calculated data versus experimental data for esterication

between citric acid and 1-butanol catalyzed with Amberlyst 70 resin

(, CA; , MBC; , DBC; , TBC; , BtOH; , H2O).

W = 2 = 3( coth 1)

the unity. For a spherical particle the WeiszPrater module can

be calculated as30,31

)cat (d p/6)2 /(DeCCAo)

W = (robs

(3)

(5)

Equation 5 represents the WeiszPrater modulus for a

spherical pellet assuming a rst-order reaction in CA, which

is considered to be a valid assumption in this case because of

the large excess of alcohol used in experiments.

The calculated values of w for an initial molar ratio of 16:1

(BtOH:CA) and at 363.15 and 393.15 K are shown in Table 1.

Results indicate that the main eect in the reaction is the

kinetic one because w 1 (internal mass-transfer resistance

can be negligible30) and the eectiveness factor is nearly

unity.30,35 As observed, this analysis was performed in the

(1)

where robs

is the observed rate of reaction per mass of catalyst

and cat and dp are the catalyst density and particle diameter,

respectively. De is the eective diusivity of CA within the

catalyst particle, and CCAo is the concentration of CA in the

bulk liquid at the beginning of the reaction. For the calculation

of the observed reaction rate (robs

) the following equation can

be used:

E

DOI: 10.1021/acs.iecr.5b03608

Ind. Eng. Chem. Res. XXXX, XXX, XXXXXX

Article

Industrial & Engineering Chemistry Research

temperature limits of the kinetic study, ensuring that observed

reaction rates during experiments corresponded to intrinsic

kinetics. This was also experimentally conrmed by performing

kinetics runs using dierent catalyst particle sizes. As shown in

Figure S1 of the Supporting Information, there are no

dierences when working with particles below 250 m.

3.2. Eect of Catalyst Loading. The eect of varying the

catalyst concentration (MSA and Amberlyst 70) in the reaction

is presented in Figure 4. In this case, only the reaction rate at

time zero for the rst step of esterication (CA consumption)

was considered. As observed, for both homogeneous and

heterogeneous catalysts, reaction rate is directly proportional to

catalyst loading. Additionally, the slope of the trend line for

Amberlyst 70 is smaller than that for MSA. This indicates that

for an equivalent amount of active sites, MSA is more eective

as catalyst than Amberlyst 70 resin. This was expected because

of the mobility of the homogeneous catalyst. Another

important nding of these preliminary experiments is that

reaction occurs even without catalyst. This indicates that is

important to consider the self-catalytic reaction, which is

expected to be more signicant at high temperatures.

Another important nding of these preliminary experiments

is that reaction occurs even without catalyst. This indicates that

is important to consider self-catalytic reaction, which will be

more signicant at high temperatures.

3.3. Self-Catalytic Reaction. Self-catalytic reaction was

evaluated according to conditions reported in Table S1 (runs

1725). The temperature and molar ratio ranges correspond to

those evaluated for the catalytic systems. In this case, the

reaction is promoted by the acidic groups of the citric species

(CA, MBC, and DBC). A typical reaction prole of selfcatalytic reaction is observed in Figure 5. All the kinetic proles

obtained in the self-catalytic experiments are also available in

the Supporting Information.

3.4. Kinetic Model Description. In a batch reactor, the

change in the composition of the chemical species can be

expressed as follows:

dNi /dt = NT(dxi /dt ) = irv , iV

(6)

where Ni is number of moles of component i, NT the total

number of moles in the reactor, xi the mole fraction of

component i in the liquid reactive media, i the stoichiometric

coecients of component i, and rv,i the volumetric reaction rate

for component i. Because of the large excess of alcohol required

to dissolve CA, the mixture density can be considered nearly

constant with time. For this reason, and taking into account

that the total number of moles is conservative, eq 6 can be

simplied to eq 7.

dxi /dt = ri

(7)

According with literature, the esterication reaction can be

described by using a power law kinetic model assuming an

Arrhenius-type temperature dependence and a rst order with

respect to each reactant.11 Therefore, for a typical esterication,

the kinetic model can be expressed in a pseudohomogeneous

model as

rj = Ccatk w, j(xAcidxAlcohol x Esterx Water /KEQ, j)

(8)

where CCat is the catalyst or active sites concentration and kw

and KEQ are the reaction rate constant and the equilibrium

constant of reaction j, respectively. Here, an approximate mole

fraction-based model is used when a thermodynamic model is

Figure 9. Esterication of CA with BtOH. Molar ratio 8:1

(alcohol:acid), 393 K, and 1 wt % of catalyst loading. (a) MSA, (b)

Amberlyst 70, and (c) Self-catalytic (, CA; , MBC; , DBC; ,

TBC; , BtOH; H2O).

F

DOI: 10.1021/acs.iecr.5b03608

Ind. Eng. Chem. Res. XXXX, XXX, XXXXXX

Article

Industrial & Engineering Chemistry Research

not available to describe phase equilibria of the reactive media

(otherwise, an activity-based model is preferred). For a catalytic

esterication, the rate constant of reaction j is termed kCatj, and

it can be expressed as

k Catj = ko,Catj exp[ Ea Cat, j/(RT )]

KEQj = xi , ij,j

Here, i,j is the stoichiometric coecient of component i in the

reaction step j. The values of the equilibrium constants were

determined by measuring the nal concentration of reaction

(after 3 days or more) at temperatures between 342 and 373 K.

MSA was used as catalyst during these experiments because its

activity is higher than that of Amberlyst 70, and no solidliquid

equilibria might aect results. In addition, the higher activity of

MSA helps to ensure a real chemical equilibrium condition in

the time frame of the experiments. The temperature dependence of the chemical equilibrium constants are presented in

Figure 6 as the linear form of a vant Ho-type relationship.

The equilibrium constant for the formation of MBC (Keq 1)

was measured only at 373 K adding 5 wt % of water to the

reactive mixture. This was done because after several attempts

to determinate the chemical equilibrium constant, the nal

concentration of CA was well below the uncertainty of the

chromatographic technique. The addition of water helped to

shift the chemical equilibrium to the reactants, allowing

measurable concentrations of CA, and to obtain a reproducible

experiment. The other equilibrium constants, Keq 2 and Keq 3,

were evaluated with initial mixture of CA and BtOH only, at all

temperatures. As observed, molar-based equilibrium constants

are nearly independent of temperature, indicating that reactions

are virtually thermoneutral (i.e., negligible heat of reaction).

The averaged Keq 1, Keq 2, and Keq 3 values obtained were 8.68,

3.56, and 1.04, respectively.

3.6. Determination of Kinetic Parameters. The kinetic

parameters (pre-exponential factors and energies of activation)

were calculated from the numerical integration of the kinetic

rate expressions. The model was integrated using a commercial

software (Matlab), solving eqs 1214 (without catalyst) and eq

1517 (with catalyst) via an ODE23 function (fourth-order

RungeKutta), using the initial mole fraction concentration of

components (t = 0) as the initial condition in the solution of

the set of ordinary dierential equations. The molar balance

was calculated to determine the concentration proles of

species in the batch reactor, as described in eqs 1924.

(9)

As for the self-catalyzed reaction kSelf j, it can be expressed as

k Selfj = ko,Selfj exp[ EaSelf, j/(RT )]

(10)

Herein, R is the ideal gas constant and T is the absolute

temperature; koi and Eai are the pre-exponential factor and the

activation energy of reaction i, respectively. Regarding the CCat

parameter in eq 8, for the catalytic reaction, it can be assumed

as the catalyst loading in weight percent (wcat, kilograms of

catalyst/100 kilograms of reactive phase). In the case of the

self-catalytic system, CCat can be expressed as the molar

concentration of acid equivalents from citric species (xacid):11

xacid = 3xCA + 2xMBC + xDBC

(11)

Here, we assumed that the self-catalytic activity is proportional

to the total concentration of hydrogen ions present in CA

(three hydronium ions), MBC (two hydronium ions), and

DBC (one hydronium ion). Dierently from the catalytic

reaction, in the self-catalytic system the concentration of active

sites (xacid) changes with time; having its maximum at time zero

and gradually decreasing over time until reaching a value near

to zero.

Taking into account the above, the kinetic models for the

self-catalytic reactions during CA esterication can be dened

as follows:

rSelf,1 = xacidk Self,1(xCAxBtOH xMBCx H 2O/KEQ1)

(12)

rSelf,2 = xacidk Self,2(xMBCxBtOH xDBCx H 2O/KEQ2)

(13)

rSelf,3 = xacidk Self,3(xDBCxBtOH xTBCx H 2O/KEQ3)

(14)

(18)

In this case of the catalytic reaction, there is a synergic eect

of the self-catalytic reaction. For this reason, the kinetic model

is described as the linear combination of both eects as follows:

r1 = (xacidk Self,1 + wCatk Cat,1)(xCAx BtOH xMBCx H2O/KEQ1)

(15)

r2 = (xacidk Self,2 + wCatk Cat,2)(xMBCxBtOH xDBCx H 2O/KEQ2)

(16)

r3 = (xacidk Self,3 + wCatk Cat,3)(xDBCxBtOH x TBCx H 2O/KEQ3)

(17)

Equations 1517 are the complete kinetic models that describe

CA esterication with BtOH using either homogeneous or

heterogeneous catalyst. Because the number of parameters is

large (15 in total) to t with few kinetic experiments, and there

is lack of thermodynamic models to calculate the phase and

chemical equilibrium of the system, the kinetic equations were

mole fraction-based as a simplication, and the equilibrium

constants were experimentally obtained. Additionally, the

kinetic parameters of self-catalytic reaction were obtained by

tting data from noncatalytic experiments only (runs 1725).

3.5. Reaction Equilibrium Constants. The chemical

equilibrium constants for the three reaction steps can be

estimated in a mole fraction-basis as follows:

dxCA /dt = r1

(19)

dxMBC/dt = r1 r2

(20)

dx DBC/dt = r2 r3

(21)

dx TBC/dt = r3

(22)

dx BtOH/dt = r1 r2 r3

(23)

dx H2O/dt = r1 + r2 + r3

(24)

The kinetic parameters were determined by the minimization

of the objective function described in eq 25, using a genetic

algorithm method from Matlab libraries.

NC

Fmin = [ (xi ,exptl xi ,calcd)2 ]/NC

i=1

(25)

Here, NC is the number of citric species; xi,exptl and xi,calcd are

the experimental and calculated mole fractions, respectively,

obtained from the concentration proles with time. Initially, the

kinetic parameters for self-catalytic system were calculated.

Later, the same optimization function was used to t the

catalytic parameters including the self-catalytic parameters

G

DOI: 10.1021/acs.iecr.5b03608

Ind. Eng. Chem. Res. XXXX, XXX, XXXXXX

Industrial & Engineering Chemistry Research

previously calculated. The nal values of the kinetic parameters

are presented in the Tables 2 and 3. Fmin values obtained in

each optimization were 1.19 105, 2.68 105, and 1.97

105 for self-catalytic, homogeneous, and heterogeneous

systems, respectively.

As expected, the MSA catalyst showed lower energies of

activation and higher pre-exponential factors in each reactions

step than the heterogeneous catalyst. This agrees with the

higher turnover frequency (6 times higher) for the same

amount of acid equivalents, as observed in the slopes of the

trend lines of Figure 4. The kinetic parameters here obtained

agree with similar reports on esterication reaction of

poly(carboxylic acid).11,19

Figures 7 and 8 are parity plots of the whole set of

experiments compared with calculations from the developed

models. Also, Figure 9 presents the good agreement between

experimental and calculated kinetic proles under dierent

catalysts and operating conditions. The whole set of experiments and plots are included in the Supporting Information. As

observed, there is good agreement between the obtained kinetic

expressions and the experimental observations. This indicates

that the obtained models can be used with condence for

process design and up-scaling purposes.

Figure 9 presents the agreement of the experimental and

calculated kinetic proles under dierent catalysts and

conditions. The whole set of experiments and plots are

included in the Supporting Information.

ACKNOWLEDGMENTS

This work was supported by Departamento de Administrativo

de Ciencia, Tecnologia e Innovacion Colciencias, under the

Project named Produccion de plastif icantes a partir de acido

citrico

usando procesos hibridos

de reaccion y separacion

simultanea, code: 1101-569-33201. M.A.S. thanks Jardin

Botanico de Bogota Jose Celestino Mutis for partial support

of his research.

ACN = Acetonitrile

ATBC = Acetyl Tri-n-butyl citrate or Acetyl Tri-1-butyl

citrate

BtOH = 1-butanol

CCat = Catalyst or active sites concentration

CCAo = Concentration of CA in the bulk liquid at beginning

of the reaction

CA = Citric acid

Cat = Catalyst/catalytic

dp = Catalyst particle diameter swollen

dp dry = Catalyst particle diameter dry

DBC = Di-n-butyl citrate or Di-1-butyl citrate

De = Eective diusivity of CA in the catalyst particle

Ea = Energy activation (J/mol)

Fmin = Minimization function

H2O = Water

HPLC = High performance liquid chromatography

kj = Reaction rate constant of forward of j (1/s)

koj = Pre-exponential factor of forward reaction j (1/s)

kw,j = Reaction rate global constant of j (1/s)

Keq = Equilibrium constant

MBC = Mono-n-butyl citrate or mono-1-butyl citrate

MSA = Methanesulfonic acid

NC = Number of citric component evaluated

Ni = Number of moles of component i

NT = Total number of moles in the reactor o in the reaction

mixture

PID = Proportionalintegralderivative (control system)

PVC = Polyvinyl chloride

R = Ideal gas constant

RD = Reactive distillation

Rf = Initial molar ratio (alcohol:acid)

r1 = Reaction rate for MBC production or AC consumption

r 2 = Reaction rate for DBC production or MBC

consumption

r3 = Reaction rate for TBC production or DBC consumption

ri = Reaction rate of component i (1/s)

robs = Observed rate of reaction

robs = Observed rate of reaction per mass of catalyst (mol/

kgcat.s)

rv,i = Volumetric reaction rate of component i (1/cm3.s)

Self = Self-catalysis

t = Time

T = Temperature (K)

TBC = Tri-n-butyl citrate or tri-1-butyl citrate

UV = Ultraviolet

V = Volume (cm3)

VP = Catalytic particle volume

wcat = Catalyst loading (% wt)

wcat

= Catalyst loading, kg of catalyst per kg of reacting phase

xacid = Mole fraction of acid species in self-catalytic reaction

ASSOCIATED CONTENT

S Supporting Information

*

The Supporting Information is available free of charge on the

ACS Publications website at DOI: 10.1021/acs.iecr.5b03608.

List of kinetic experiments performed for citric acid

(CA)/1-butanol (BtOH) esterication, kinetic proles

obtained with Amberlyst 70 using dierent particle

diameters, and kinetic proles obtained in experiments

(PDF)

NOMENCLATURE

List of Symbols and Abbreviations

4. CONCLUSIONS

A kinetic study of the esterication of citric acid with 1-butanol

using methanesulfonic acid and Amberlyst 70 resin as a catalyst

was performed. Experimental runs were carried out at dierent

temperatures (353393 K), feed molar ratios (8:1 to 16:1),

and catalyst loadings (0.51.5 wt % equivalent to MSA).

Independent experiments allowed obtaining the chemical

equilibrium constant for the three steps of reaction, and they

were found to be nearly temperature-independent. A

preliminary analysis indicated that self-catalytic reactions had

to be considered during the catalytic process, and the

parameters of a mole fraction-based were obtained for selfcatalytic and catalytic reactions. As expected, the homogeneous

catalyst demonstrated higher activity in the esterication

reaction. After comparison with the whole set of experiments,

the models show good agreement and can be used for process

design and up-scaling purposes.

Article

AUTHOR INFORMATION

Corresponding Author

*Phone: (+57) 1 3165000, ext. 14303. E-mail: aorjuelal@unal.

edu.co.

Notes

The authors declare no competing nancial interest.

H

DOI: 10.1021/acs.iecr.5b03608

Ind. Eng. Chem. Res. XXXX, XXX, XXXXXX

Article

Industrial & Engineering Chemistry Research

xi = Mole fraction of component i

(18) Rohm and Haas. Amberlyst 70. Dow Chemical Company, 2006;

p 2.

(19) Orjuela, A.; Yanez, A. J.; Santhanakrishnan, A.; Lira, C. T.;

Miller, D. J. Kinetics of Mixed Succinic Acid/acetic Acid Esterification

with Amberlyst 70 Ion Exchange Resin as Catalyst. Chem. Eng. J. 2012,

188, 98107.

(20) Orjuela, A.; Kolah, A.; Hong, X.; Lira, C. T.; Miller, D. J. Diethyl

Succinate Synthesis by Reactive Distillation. Sep. Purif. Technol. 2012,

88, 151162.

(21) Bringue, R.; Iborra, M.; Tejero, J.; Izquierdo, J.; Cunill, F.; Fite,

C.; Cruz, V. Thermally stable ion-exchange resins as catalysts for the

liquid-phase dehydration of 1-pentanol to di-n-pentyl ether (DNPE). J.

Catal. 2006, 244, 3342.

(22) Siril, P.; Cross, H.; Brown, D. New polystyrene sulfonic acid

resin catalysts with enhanced acidic and catalytic properties. J. Mol.

Catal. A: Chem. 2008, 279, 6368.

(23) Pappu, V.; Kanyi, V.; Santhanakrishnan, A.; Lira, C.; Miller, D.

Butyric acid esterification kinetics over Amberlyst solid acid catalysts:

The effect of alcohol carbon chain length. Bioresour. Technol. 2013,

130, 793797.

(24) Komon, T.; Niewiadomski, P.; Oracz, P.; Jamroz, M.

Esterification of acrylic acid with 2-ethylhexan-1-ol: Thermodynamic

and kinetic study. Appl. Catal., A 2013, 451, 127136.

(25) Santhanakrishnan, A.; Shannon, A.; Peereboom, L.; Lira, C.;

Miller, D. Kinetics of Mixed Ethanol/n-Butanol Esterification of

Butyric Acid with Amberlyst 70 and p-Toluene Sulfonic Acid. Ind. Eng.

Chem. Res. 2013, 52, 18451853.

(26) Leyva, F.; Orjuela, A.; Miller, D.; Gil, I.; Vargas, J.; Rodrguez, G.

Kinetics of Propionic Acid and Isoamyl Alcohol Liquid Esterification

with Amberlyst 70 as Catalyst. Ind. Eng. Chem. Res. 2013, 52, 18153

18161.

(27) Bringue, R.; Ramrez, E.; Iborra, M.; Tejero, J.; Cunill, F.

Kinetics of 1-hexanol etherification on Amberlyst 70. Chem. Eng. J.

2014, 246, 7178.

(28) Helerich, F. Ion Exchange; McGraw Hill: New York, 1962.

(29) Box, G.; Behnken, D. Some New Three Level Designs for the

Study of Quantitative Variables. Technometrics 1960, 2, 455475.

(30) Weizz, P. B.; Prater, C. D. Interpretation of Measurements in

Experimental Catalysis. Adv. Catal. 1954, 6, 143196.

(31) Froment, G. F.; Bischo, K. B.; Wilde, J. D. Chemical Reactor

Analysis and Design, 3rd ed.; John Wiley & Sons, Inc.: New York, 2011.

(32) Dogu, T.; Aydin, E.; Boz, N.; Murtezaoglu, K.; Dogu, G.

Diusion Resistances and Contribution of Surface Diusion in TAME

and TAEE Production Using Amberlyst-15. Int. J. Chem. React. Eng.

2002, 1. DOI: 10.2202/1542-6580.1012

(33) Ali, S. H.; Tarakmah, A.; Merchant, S. Q.; Al-Sahhaf, T.

Synthesis of Esters: Development of the Rate Expression for the

Dowex 50 Wx8400 Catalyzed Esterification of Propionic Acid with

1-Propanol. Chem. Eng. Sci. 2007, 62, 31973217.

(34) Wilke, C. R.; Chang, P. Correlation of Diffusion Coefficients in

Dilute Solutions. AIChE J. 1955, 1, 264270.

(35) Fogler, H. S. Elements of Chemical Reaction Engineering, 4th ed.;

Prentice Hall PTR,Upper Saddle River, NJ, 2006.

(36) Lide, D. R.; Kehiaian, H. V. CRC Handbook of Thermophysical

and Thermochemical Data, Vol. 1; CRC Press: Boca Raton, FL, 1994.

Greek Letters

= Particle porosity

= Eectiveness factor of reaction

i = Ratio of stoichiometric coecients of component i

cat = Catalyst particle density

sol = Density of reacting phase

= Pore tortuosity

= Thiele modulus

w = WeiszPrater modulus

Subscripts and Superscripts

calcd = Calculate data

exptl = Experimental data

i = component identication

j = reaction step identication (1, 2, or 3)

REFERENCES

(1) Cullen, S.; Company, E. C. Global Plasticizer Update. In SPI

Flexible Vinyl Products Conference; 2012; p 37.

(2) Rahman, M.; Brazel, C. The Plasticizer Market: An Assessment of

Traditional Plasticizers and Research Trends to Meet New Challenges.

Prog. Polym. Sci. 2004, 29, 12231248.

(3) Wypych, G. Plasticizer Types. Handbook of Plasticizers; ChemTec

Publishing: Toronto, 2000; pp 771.

(4) Heudorf, U.; Mersch-Sundermann, V.; Angerer, J. Phthalates:

Toxicology and Exposure. Int. J. Hyg. Environ. Health 2007, 210, 623

634.

(5) Saillenfait, A.-M.; Laudet-Hesbert, A. Phtalates (II). EMC Toxicol. 2005, 2, 137150.

(6) Van Haveren, J.; Oostveen, E. a; Micciche, F.; Weijnen, J. G. J.

How Biobased Products Contribute to the Establishment of

Sustainable, Phthalate Free, Plasticizers and Coatings. In Feedstocks

for the Future; Bozell, J. J., Patel, M. K., Eds.; American Chemical

Society: Washington DC, 2006; pp 99115.

(7) Wilkinson, C. F.; Lamb, J. C., IV The Potential Health Effects of

Phthalate Esters in Children S Toys: A Review and Risk Assessment.

Regul. Toxicol. Pharmacol. 1999, 30, 140155.

(8) Kawakami, T.; Isama, K.; Matsuoka, A. Analysis of Phthalic Acid

Diesters, Monoester, and Other Plasticizers in Polyvinyl Chloride

Household Products in Japan. J. Environ. Sci. Health, Part A: Toxic/

Hazard. Subst. Environ. Eng. 2011, 46, 855864.

(9) Reinecke, H.; Navarro, R.; Perez, M. Plasticizers. Handbook of

Polymer Science and Technology; John Wiley & Sons, Inc.: New York,

2011; pp 127.

(10) Arendt, W. D.; Joshi, M. Specialty Plasticizers. In Handbook of

Vinyl Formulating; John Wiley & Sons, Inc.: New York, 2008; pp 239

286.

(11) Kolah, A. K.; Asthana, N. S.; Vu, D. T.; Lira, C. T.; Miller, D. J.

Reaction Kinetics of the Catalytic Esterification of Citric Acid with

Ethanol. Ind. Eng. Chem. Res. 2007, 46, 31803187.

(12) Miller, D. J.; Asthana, N.; Kolah, A.; Vu, D. T.; Lira, C. T.

Process for Reactive Esterication Distillation. U.S. Patent 7667068

B2, 2010.

(13) Schroter, J.; Konetzke, G.; Weidemann, F.; Klein, T.; Bohnen,

H.; Bergrath, K.; Schmidt, K. Method for Producing Citric Acid Esters.

WO2003008369, 2003.

(14) Bohnen, H.; Bergrath, K.; Klein, T. Citric Esters and a Process

for Their Preparation. U.S. Patent 2002/0198402 A1, 2002.

(15) Kolah, A. K.; Asthana, N. S.; Vu, D. T.; Lira, C. T.; Miller, D. J.

Triethyl Citrate Synthesis by Reactive Distillation. Ind. Eng. Chem. Res.

2008, 47, 10171025.

(16) Verho, F. H. Citric Acid. Ullmanns Encyclopedia of Industrial

Chemistry; Wiley-VCH Verlag GmbH & Co KGaA: Weinheim, 2005;

p 69.

(17) Rohm and Haas. Amberlyst 15DRY. Dow Chemical Company,

2006; p 2.

I

DOI: 10.1021/acs.iecr.5b03608

Ind. Eng. Chem. Res. XXXX, XXX, XXXXXX

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Prostar 210 User ManualDocument112 paginiProstar 210 User ManualMartinÎncă nu există evaluări

- Marza I Oli 2012Document6 paginiMarza I Oli 2012Wulan AgustinaÎncă nu există evaluări

- Best Practices For Sample Storage UrineDocument41 paginiBest Practices For Sample Storage UrinekinnusaraiÎncă nu există evaluări

- Triterpenoid SaponinsDocument308 paginiTriterpenoid Saponinsrodolfo_soberón100% (2)

- Determination of Organic Acids and Sugars in Cheese, Milk and Whey by High Performance Liquid Chromatography W. J. Mullin & D. B. EmmonsDocument5 paginiDetermination of Organic Acids and Sugars in Cheese, Milk and Whey by High Performance Liquid Chromatography W. J. Mullin & D. B. EmmonsJohana Marcela AcostaÎncă nu există evaluări

- Determination of Total Carbohydrates in Algal Biomass: Laboratory Analytical Procedure (LAP)Document17 paginiDetermination of Total Carbohydrates in Algal Biomass: Laboratory Analytical Procedure (LAP)MadhanÎncă nu există evaluări

- Microbial Transformation of Neomycin by A Mutant of Neomycin Producing Streptomyces FradiaeDocument9 paginiMicrobial Transformation of Neomycin by A Mutant of Neomycin Producing Streptomyces FradiaeThieu J TienÎncă nu există evaluări

- An 70049 Environmental Water Applications Notebook AN70049 EDocument214 paginiAn 70049 Environmental Water Applications Notebook AN70049 ECheolhyeon ChoÎncă nu există evaluări

- 29 Vol. 7 Issue 11 November 2016 IJPSR RA 6749Document8 pagini29 Vol. 7 Issue 11 November 2016 IJPSR RA 6749manoj bhattaraiÎncă nu există evaluări

- Exercises 3: Efficiency, Selectivity and ResolutionDocument4 paginiExercises 3: Efficiency, Selectivity and ResolutionCynthia SalasÎncă nu există evaluări

- 920-Lc Marketing SlidesDocument120 pagini920-Lc Marketing SlidesKennyKalyangoHuiosÎncă nu există evaluări

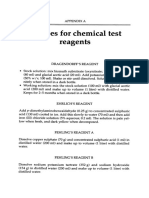

- Recipes For Chemical Test Reagents: ML) ML)Document15 paginiRecipes For Chemical Test Reagents: ML) ML)andyrojasÎncă nu există evaluări

- Estudo Hepasfera Versus BeadDocument6 paginiEstudo Hepasfera Versus BeadAlexandre Campos Moraes AmatoÎncă nu există evaluări

- An Experimental Design Approach To Optimization of The Liquid Chromatographic Separation Conditions For The Determination of Metformin and Glibenclamide in Pharmaceutical FormulationDocument8 paginiAn Experimental Design Approach To Optimization of The Liquid Chromatographic Separation Conditions For The Determination of Metformin and Glibenclamide in Pharmaceutical FormulationhdmnauÎncă nu există evaluări

- HPLCDocument22 paginiHPLCKafi Mahmood NahinÎncă nu există evaluări

- Formulation and Evaluation of Thymoquinone NiosomesDocument25 paginiFormulation and Evaluation of Thymoquinone NiosomesHuỳnh NgânÎncă nu există evaluări

- Convolution Study On Lansoprazole Delayed-Release Capsules - Application of Similarity Factor To in - Vitro DissolutionDocument11 paginiConvolution Study On Lansoprazole Delayed-Release Capsules - Application of Similarity Factor To in - Vitro DissolutionAnand UbheÎncă nu există evaluări

- Prep SystemDocument32 paginiPrep SystemzgtothÎncă nu există evaluări

- Analysis of The Antitumor Activity of Bioactive Compounds of Cannabis Flowers Extracted by Green SolventsDocument6 paginiAnalysis of The Antitumor Activity of Bioactive Compounds of Cannabis Flowers Extracted by Green SolventsJesusÎncă nu există evaluări

- LC Determination in Sac Intestine Model PDFDocument12 paginiLC Determination in Sac Intestine Model PDFJose PerezÎncă nu există evaluări

- Romiplastim QBDDocument12 paginiRomiplastim QBDvenkynmÎncă nu există evaluări

- Modern Sample Preparation For Chromatography 2Nd Edition Serban Moldoveanu Download PDF ChapterDocument51 paginiModern Sample Preparation For Chromatography 2Nd Edition Serban Moldoveanu Download PDF Chaptergerardo.patterson771100% (8)

- WHO On PropoxurDocument25 paginiWHO On Propoxurgilang kusumasariÎncă nu există evaluări

- Amoxicillin and Potassium Clavulanate Oral Suspension - PHAN TU HOC CHO DK41Document3 paginiAmoxicillin and Potassium Clavulanate Oral Suspension - PHAN TU HOC CHO DK41HoaiPhongÎncă nu există evaluări

- Purity Vs AssayDocument1 paginăPurity Vs AssayRagu RajeshÎncă nu există evaluări

- 1.3 JP2021195320A - TranslationDocument5 pagini1.3 JP2021195320A - TranslationNilesh PatelÎncă nu există evaluări

- Senior Scientist or Analytical ChemistDocument4 paginiSenior Scientist or Analytical Chemistapi-78322462Încă nu există evaluări

- Transdermal Delivery of Curcumin Via MicroemulsionDocument7 paginiTransdermal Delivery of Curcumin Via MicroemulsionAmarpreet Singh MalhanÎncă nu există evaluări

- Antidepressants in Breast Milk Comparative Analysis of Excretion RatiosDocument8 paginiAntidepressants in Breast Milk Comparative Analysis of Excretion RatiosRubiÎncă nu există evaluări

- Topic 1 Revision SACE ChemistryDocument15 paginiTopic 1 Revision SACE ChemistryMustafa RezaieÎncă nu există evaluări