Documente Academic

Documente Profesional

Documente Cultură

Flow Localization in Strain Hardening Crystalline Solids

Încărcat de

Chandra ClarkDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Flow Localization in Strain Hardening Crystalline Solids

Încărcat de

Chandra ClarkDrepturi de autor:

Formate disponibile

Scripta

METALLURGICA

Vol. 18, pp. 429-435, 1984

P r i n t e d in the U.S.A.

P e r g a m o n Press Ltd.

All r i g h t s r e s e r v e d

VIEWPOINT

SET NO.

FLOW LOCALIZATION IN STRAIN HARDENING CRYSTALLINE SOLIDS

R. J . A s a r o and A. N e e d l e m a n

Division of Engineering

Brown University, Providence9 Rhode Island

(Received

I.

February

21,

02912

1984)

Introduction

Plastic

d e f o r m a t i o n i n m e t a l s i s an i n h e r e n t l y

nonuniform process; whenever dislocation

s l i p o r t w i n n i n g o c c u r s t h e r e i s a s i z e s c a l e b e l o w w h i c h t h e d e f o r m a t i o n i s h e t e r o g e n e o u s and

discontinuous.

Hence, any reference to the uniformity of plastic

f l o w i m p l i e s some s c a l e o f

observation.

H o w e v e r , on a s i z e s c a l e o f t e n s o f m i c r o n s , e n c o m p a s s i n g s e v e r a l g r a i n s i n

polycrystals,

t h e d e f o r m a t i o n may a p p e a r u n i f o r m e v e n t h o u g h t h e m i c r o m e c h a n i c a l d e f o r m a t i o n

processes are nonuniform.

Localized microstructural

m o d e s c a n be o p e r a t i v e a t t h i s s i z e s c a l e

a s w e l l ; e x a m p l e s i n c l u d e m i c r o t w i n n i n g and t h e ' ~ i c r o b a n d s "

that Halin and Hatherly (1) have

shown t o g i v e r i s e t o t h e " s l i p b a n d s " commonly o b s e r v e d i n h i g h s t a c k i n g f a u l t e n e r g y

materials.

E v e n when t h e s e d e f o r m a t i o n m o d e s o c c u r , on a m a c r o s c o p i c l e v e l o f a t e n t h o f a

millimeter

or more, plastic

deformation can again appear uniform.

When s u f f i c i e n t

plastic

deformation has occurred, all such macroscopically

h o m o g e n e o u s d e f o r m a t i o n p a t t e r n s b r e a k down,

perhaps inevitably,

as Asaro (2) has remarked, into ones involving localized deformation in the

form of shear bands.

On t h e g r a i n s i z e s c a l e i t h a s b e e n r e p o r t e d t h a t s h e a r b a n d s c a n become t h e d o m i n a n t

deformation mechanism (3).

As s u c h t h e y d e t e r m i n e m a t e r i a l

s t r e n g t h and d e f o r m a t i o n k i n e m a t i c s ,

thereby contributing

directly

t o t h e d e v e l o p m e n t o f t e x t u r e and m a t e r i a l a n i s o t r o p y .

I n some

cases these shear bands lead to fracture

and thus serve as failure modes.

On a more m a c r o s c o p i c

level, shear bands often play an important role in limiting ductility

(4,5).

Once a m a c r o scopic shear band forms, very little

additional

overall straining

takes place while large

strains

accumulate in the ban~leading

to fracture.

In view of the dual significance

of shear

b a n d s i n d e t e r m i n i n g d e f o r m a t i o n p a t t e r n s and a s a p r e c u r s o r to f r a c t u r e ,

i t i s i m p o r t a n t t o be

able to predict their initiation

and d e s c r i b e t h e i r d e v e l o p m e n t .

H e r e , we d e s c r i b e some r e c e n t

p r o g r e s s i n d o c u m e n t i n g and a n a l y z i n g s h e a r b a n d s and i n d i c a t e ,

w h a t seem t o u s , some f r u i t f u l

areas for future investigation.

2.

A Framework f o r A n a l y z i n g

Localization

Although the initiation

of shear bands is frequently associated with softening,

for isothermal deformations there is little

evidence for material strain softening occurring prior to

localized

shearing except, perhaps, in special cases, e.g. radiation

damaged a l l o y s .

Indeed,

there are numerous reports indicating

that material within shear bands continues to harden, at

least until microfracture

occurs.

T h i s d o e s n o t r u l e o u t some s o r t o f s o f t e n i n g m e c h a n i s m f r o m

playing a role in precipitating

shear bands.

A particularly

interesting

s u g g e s t i o n , made b y

D i l l a m o r e e t a l . ( 6 ) , Chang a n d A s a r o ( 7 ) , and M o r i i and Nakayama ( 3 , 8 ) , i s t h a t " t e x t u r a l "

or

" g e o m e t r i c " s o f t e n i n g due t o l a t t i c e

reorlentation

during deformation leads to textures that are

"soft" with respect to shear bands.

On a m o r e m a c r o s c o p i c s c a l e t h e i n i t i a t i o n

and g r o w t h o f

v o i d s may l e a d t o a n e f f e c t i v e

softening although the surrounding matrix continues to strainharden.

These effects,

along with the path dependence of strain-hardening

c a n be a n a l y z e d w i t h i n a

framework that regards localization as a "material instability," where a material element is

considered to be subject to prescribed all around displacements that are consistent with a

homogeneous deformation.

Deformations in a localized band are permitted provided the velocity

field remains continuous and continuing equilibrium at the band interface is satisfied (9,10).

Bifurcation and imperfection analyses within this framework have proved useful in revealing the

influence of constitutive features and stress and strain state on localization (I0~11).

429

0 0 3 6 - 9 7 4 8 / 8 4 $3.00 + .00

C o p y r i g h t (c) 1984 P e r g a m o n Press

Ltd.

430

FLOW

LOCALIZATION

IN C R Y S T A L L I N E

SOLIDS

Vol.

18,

No.

M a t h e m a t i c a l l y , a s h e a r band b i f u r c a t i o n c o i n c i d e s w i t h l o s s o f e l l i p t i c i t y

of the

g o v e r n i n g i n c r e m e n t s 1 e q u a t i o n s , H i l l ( 9 ) , Rice ( 1 0 ) ; t h e g o v e r n i n g e q u a t i o n s become e i t h e r

p a r a b o l i c or h y p e r b o l i c i n c h a r a c t e r and v e r y d i f f e r e n t b e h a v i o r s are a s s o c i a t e d w i t h t h e s e two

possibilities.

Rice's (I0) three dimensional generalization of the imperfection analysis of

Marciniak and Kuczynskl (12), is important since, for example, a localization bifurcation is

ruled out for rate dependent materials but it can occur when there are very small

i n h o m o g e n e i t i e s . Q u i t e g e n e r a l l y , l o c a l i z a t i o n i n v o l v e s a change i n l o a d i n g d i r e c t i o n so t h a t

i n a s s e s s i n g t h e r o l e o f m i c r o s t r u c t u r a l f e a t u r e s , such as t e x t u r a l s o f t e n i n g on l o c a l i z a t i o n ,

i t i s n e c e s s a r y t o e v a l u a t e e f f e c t s on t h e s t i f f n e s s g o v e r n i n g t h e r e s p o n s e t o a change i n

loading path.

There are however l i m i t a t i o n s to t h i s d e s c r i p t i o n o f l o c a l i z a t i o n .

For example, l o c a l i z a t i o n o c c u r s s i m u l t a n e o u s l y w i t h i n t h e band so t h a t t h e a n a l y s i s i s i n c a p a b l e o f d e s c r i b i n g t h e

p r o p a g a t i o n o f a r e g i o n o f l o c a l i z a t i o n from some l o c a l s t r a i n c o n c e n t r a t o r .

A l s o , no l e n g t h

s c a l e e n t e r s t h e a n a l y s i s u n l e s s i t i s e x p l i c i t l y p u t t h e r e by b e i n g i n c o r p o r a t e d i n t o t h e

constitutive relation.

I t should be emphasized t h a t t h e s e l i m i t a t i o n s are n o t i n h e r e n t t o t h e

continuum d e s c r i p t i o n b u t a r e c o n s e q u e n c e s o f i t s a p p l i c a t i o n t o ( p i e c e w i s e ) homogeneous and

homogeneously deformed m a t e r i a l e l e m e n t s . When t h e s e r e s t r i c t i o n s a r e r e l a x e d , by c a r r y i n g out

a f u l l s o l u t i o n t o t h e r e l e v a n t boundary v a l u e problem, r e g i o n s o f l o c a l i z a t i o n p r o p a g a t e , q u i t e

t y p i c a l l y , from s t r a i n c o n c e n t r a t i o n s and t h e d e f o r m a t i o n f i e l d g r a d i e n t s i n t r o d u c e an i m p l i c i t

l e n g t h . F u r t h e r m o r e , i t i s t h e n p o s s i b l e to e x p l i c i t l y i n c l u d e s p a t i a l d i s t r i b u t i o n s o f

m a t e r i a l inhemogeneitles into the a n a l y s i s .

In t h e s e more g e n e r a l c i r c , - , s t a n c e s , t h e o n s e t o f

l o c a l i z a t i o n and i t s i n i t i a l d i r e c t i o n o f p r o p a g a t i o n a r e r a t h e r w e l l r e p r e s e n t e d by a m a t e r i a l

i n s t a b i l i t y a n a l y s i s , a l t h o u g h t h e s u b s e q u e n t d e v e l o p m e n t i s g r e a t l y a f f e c t e d by g r a d i e n t s i n

the surrounding field.

Not a l l c i r c u m s t a n c e s where s t r a i n c o n c e n t r a t e s i n t o a more o r l e s s w e l l d e f i n e d band

c o r r e s p o n d to whet i s meant h e r e by l o c a l i z a t i o n .

F i g u r e 1, t a k e n from LeMonds (13) shows two

s t a g e s o f d e f o r m a t i o n i n a c a l c u l a t i o n o f a p l a n a r b i - c r y s t a l model s u b j e c t t o p l a n e s t r a i n

t e n s i o n . A c r o s s t h e c e n t e r o f t h e b i - c r y s t a l t h e r e i s an i n i t i a l l a t t i c e m i s o r i e n t a t i o n t h a t

t r i g g e r s inhomogeneous d e f o r m a t i o n . In F i g u r e l a , t h e o r i e n t a t i o n o f t h e band o f i n c r e a s e d

s t r a i n i s s e t by t h e boundary c o n d i t i o n s .

At a s l i g h t l y g r e a t e r s t r a i n , F i g u r e l b , t h e d e f o r m a t i o n p a t t e r n has s h i f t e d to one where t h e band o r i e n t a t i o n i s c h a r a c t e r i s t i c o f t h e m a t e r i a l ,

which i s i n e x c e l l e n t agreement w i t h t h a t g i v e n by a b i f u r c a t i o n a n a l y s i s .

Figure la corresponds to a g e o m e t r i c a l l y i n d u c e d s t r a i n c o n c e n t r a t i o n ; F i g u r e l b i l l u s t r a t e s

localization.

LeMonds' a n a l y s i s (13) may a l s o p r o v i d e a s t a r t i n g p o i n t f o r a n a l y z i n g t h e model p r o p o s e d by

Morii and Nakayama (3) f o r m i c r o - s h e a r band i n i t i a t i o n a t t w i n c l u s t e r s as d i s c u s s e d a g a i n i n

Section 3.

Figure 1

lo.o,ilT:::

T M

I o~0,06

o,

%~//// ~

~///

o ~6

'/~> .>/

016

0.4~

o"

0.70

%'

(o)

(b)

'

Contours o f c o n s t a n t

maximum p r i n c l p l e

logarithmic strain in

a bl-crystal subject to

plane strain tension.

There i s an i n i t i a l

lattice mlsorlentation

o f 10 a c r o s s t h e c e n t e r

of the bi-crystal.

(a) at an extension of 0.12,

before shear bands

(b) at an extension of 0.15,

after shear bands.

From LeMonds (13).

Vol.

2.1

18,

No.

FLOW

LOCALIZATION

IN C R Y S T A L L I N E

SOLIDS

431

Localization in Single Crystals

Within the continuum sllp framework for crystal plasticity, Asaro (2) carried out a

bifurcation analysis for a two dimensional model crystal oriented for symmetric double slip,

drawing on Hill and Hutchinson's (14) general analysis of bifurcation in plane strain tension.

Asaro's (2) analysis points out the vital role of geometrical softening in shear band initiation

in single crystals, as is also brought out by the experimental studies of Saimoto et al. (6),

Chang and Asaro (7) and Morii and Nakayama (3,8). Three essentially different types of bifurcation mode occur: (i) a shear band bifurcation mode which involves continued double slipping in

the shear band and which is such as to induce a lattice rotation that causes the dominant slip

system to undergo geometrical softening; (ii) a localization mode where shearing occurs parallel

to the tensile axis and the shearing mode itself leads to unloading on one of the currently

active slip systems - as discussed by Peirce et al. (15,16) it is this mode that leads to

'patchy' slip; and (iii) a mode that involves an excess of conjugate slip in a band that is most

closely aligned with the primary slip system. Although there is an initial geometrical

softening accompanying this latter mode, eventually the conjugate system geometrically hardens

(as does the primary system) so that very large strains do not accumulate in the band (16).

Which of these phenomenologies develops depends on the crystal geometry and material

hardening properties. Latent hardening plays a particularly important role in this regard.

For

a geometry representative of an f.c.c, crystal oriented for symmetric double slip, and when the

latent hardening ratio does not exceed Taylor's isotropic hardening, shear band formation is the

preferred localization mode. Pelrce et al. (15) carried out a full finite element analysis of

shear band development based on the planar double slipping model of Asaro (2) and using a small

geometric imperfection to initiate diffuse necking. When using material parameter values representative of Chang and Asaro's (7) hard, lightly hardening aluminum-copper alloy crystals, the

computed lattice rotations are in close correspondence with the experimental measurements.

Also, consistent with the observations, the shear bands form abruptly after very little diffuse

necking and a r e s h a r p l y d e l i n e a t e d .

In the c a l c u l a t i o n s f o r s o f t e r , h i g h e r h a r d e n i n g c r y s t a l s

diffuse necking is found to induce lattice rotations which promote geometric softening, as

suggested by Saimoto et al. (17), and the bands form gradually and are rather broad (15). This

is most likely a case where the shear band thickness is set by gradients in the surrounding

field, although the possibility of some numerical mesh induced shear band broadening cannot be

ruled out. By way of contrast, there is nothing in the continuum analysis to set a minimum

width for shear bands so that the fineness of the calculated shear bands in the stronger, low

hardening crystals is undoubtedly limited by the mesh.

Peirce et al. (16) also found that latent hardening rates sufficiently greater than self

hardening rates led to the development of "patchy" slip. However, for somewhat greater latent

hardening ratios, but still within the range 1.0 - 1.4 found by Kocks (18) to encompass much of

the available data, the incremental equilibrium equations become parabolic in character and the

numerical procedure of Peirce et al. (15) could not obtain a unique solution. Interestingly,

the critical condition for parabolic behavior occurs only slightly before failure of the condition for slip mode uniqueness under prescribed stress rates. This behavior is not an artifact

of the planar double slipping model as Peirce (19) found that this type of instability also

occurred in an actual three dimensional f.c.c, geometry. Indeed, it appears that this loss of

constitutive uniqueness, and the associated inability to obtain solutions to boundary value

problems, is inherent to the rate independent idealization of crystal plastihity for a significant range of material properties. There is a related, long appreciated lack of uniqueness in

the choice of active slip systems in multi-slip modes. This behavior of the rate independent

idealization apparently precludes a unique, consistent prediction of lattice rotations and hence

of finite strain polycrystalline response from single crystal properties. Rate dependent

plasticity formulations do, however, lead to uniquely determinedslipping rates on each system-Pan and Rice (20) and Peirce et al. (16)--so that even for materials with no perceptible rate

dependence over the full range of quasi-static strain rates the inherent rate dependence of

plasticity plays an essential role. It is worth noting in this regard that, although a rate

dependent plasticity formulation appears essential for the calculation of macroscopic properties, rate independent phenumenological theories of plasticity, suitable for use in localization

analyses, can be formulated which do not suffer the constitutive nonuniqueness of rate independent crystalline plasticity formulations (although the effect of material rate sensitivity on

localization is itself an important issue (35,36)).

432

FLOW

LOCALIZATION

IN C R Y S T A L L I N E

SOLIDS

Vol.

18,

No.

The rate dependent constitutive formulation of Peirce et al. (16) did permit a calculation

of all three modes of localization noted above. One particularly interesting phenomenology that

developed in these calculations was that the lattice rotations associated with patchy slip could

act as a kinematic barrier to shear band propagation and, hence, patchy slip could tend to

increase the crystal's ductility. The role of lattice misorientations, either within a grain or

at grain boundaries, in inhibiting shear band propagation appears to merit further attention.

Figure I is from an initial study of shear bend propagation across such e boundary.

2.2

Phenomenological Models for Shear Band Development in Polycrystalline Solids

Much of the effort in theoretical analyses of localization in polycrystalline metals has

aimed at identifying the constitutive features triggering the observed localization. For

example, observations of void nucleation and growth within shear bands are not uncommon. One

possibility is that an inherent instability of the plastic flow process initiates shear banding

and the large strains that accumulate in the band then lead to the initiation of ductile

rupture. Another possibility is that the weakening induced by void nucleation end growth itself

triggers the observed localization; as remarked in (ll),which of these possibilities occurs can

be stress state dependent for a given material. Significant recent progress has been made, for

example by Tvergaard (21-23), Fisher and Gurland (24), Hancock, MacKenzie and Brown (25,26) and

Saje et al. (27), in developing a quantitative description of microvoid induced shear band

localization.

It has also been shown (28) how void induced shear band localization coupled with

the kinematic constraint of axisymmetry naturally gives rise to the familiar cup-cone fracture

in simple tension.

When microrupture effects are absent and when the material response is appropriately

idealized as rate independent, the key feature of plastic material response for localization is

the vertex yield surface structure implied by the discrete nature of crystallographic slip. A

yield surface vertex results in a much reduced stiffness to a change in loading path and, as

noted above, it is this stiffness that plays a primary role in the onset of localization (for

rate dependent solids there is also a vertex llke reduction in this overall stiffness but its

characterization is more complex (20,42)).

The phenomenological corner theory of plasticity

introduced by Christoffersen and Hutchinson (29) embodies this feature and another aspect of

p o l y c r y s t a l l i n e p l a s t i c r e s p o n s e t h a t g r e a t l y a f f e c t s s u b s e q u e n t s h e a r band d e v e l o p m e n t ; w i t h

increasing shearing in the shear band, the shear stiffness increases, modeling the effect of

some inltially active slip systems unloading as the deformation path shifts from the prelocalization one. This mechanism strongly influences the spatial distribution of shear bands as

illustrated in the numerical calculations of Tvergaard et al. (30); a manifestation of this

vertex stiffening being that initially formed shear bands saturate, giving increased straining

in a nearby region which results in further shear band initiation.

Such phenomenological continuum analyses give a picture of macroscopic shear band development at least qualitatively in accord with observation (30,31).

However, quite typically localization initiates locally around some local strain concentrator or in some favorably oriented

grains, Clausing (32), Hahn and Rosenfield (33), Anand and Spitzig (34). These bands ultimately

can lead to a band extending across the entire specimen when some macro-banding condition is

met. The details of this transition are not fully explained and are important in particular in

relation to the role of localization in setting fracture toughness.

A quantitative comparison between macroscopic shear band predictions based on phenomenological corner theory and experiment is contained in the study of Larsson et al. (5) on internally pressurized copper and aluminum alloy tubes. The calculations gave good agreement for the

deformed shapes of the tubes and for the angle at which shear failure ultimately occurred.

Although the representation of the effective stress effective strain hardening properties was

based on measured uniaxial response for the tube materials, the additional corner properties

which quantify the response to a loading path change were chosen arbitrarily. Larsson et al.

(5) attribute, at least in part, quantitative discrepancies between their calculated and measured

pressure-radius values to different hardening rates under plane strain and axisym~etric conditions, i.e., to texture effects. Also, the use of corner theory presumes that the stability

against flow localization is limited by the plastic flow process itself with the initiation of

ductile rupture ensuing in the highly strained shear band. This appeared an appropriate conclusion for the aluminum allo~ but Larsson et al. (5) note that for the copper tubes the

weakening of void nucleation and growth could also play a role in precipitating the

localization.

Vol.

18,

No.

FLOW

LOCALIZATION

IN C R Y S T A L L I N E

SOLIDS

433

The examples of shear band analyses and observations described above illustrate the need

f o r a c c u r a t e m a t e r i a l c h a r a c t e r i z a t i o n and c o n s t i t u t i v e d e s c r i p t i o n i n t h e p r e d i c t i o n o f s h e a r

b a n d s . This i s known t o be p a r t i c u l a r l y t r u e i n t h e c a s e o f h e a v i l y r o l l e d m e t a l s and a l l o y s

where s h e a r bands p l a y a v i t a l r o l e i n d e t e r m i n i n g d e f o r m a t i o n p a t t e r n s , t e x t u r e and u l t i m a t e l y

ductility.

The phenomenology o f s h e a r band f o r m a t i o n i n r o l l i n g has b e e n w e l l documented

experimentally and it is known that prexisting rolling textures themselves are important in

causing shear bands which then lead to texture changes. In closing, a brief description of the

reported phenomenology is given and we propose that an important topic for future study is the

theoretical analysis of shear bands in heavily rolled polycrystalline metals.

3.

Shear Bands in Rolled Metals and the Development of Texture

The texture of heavily rolled f.c.c, metals is generally described as the "pure metal" type

or "alloy" type as typified by copper and a-brass, respectively. In the pure metal texture the

orientations of the sheet normal and rolling direction are contained in a band extendin~__from

{110} <112> to the region on the <100> - <111> symmetry boundary lying between {211} <III> and

{311} <uvw>. This texture is predicted from simple slip theory assuming slip on the f.CoC, slip

systems {111} <110>. The alloy texture is characterized by a predominance of orientations of

the sheet plane near {110}; the texture component near the "ideal texture" {211} <111> is absent

and this is the most fundamental difference in the two textures. The reasons for these differences is reported to lie in the different mechanisms and deformation patterns that develop in

these materlals, vlz. twinning versus ~lip, the operation of shear bands and the different

mlcrostructures that result.

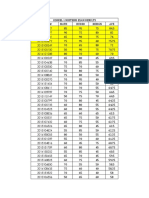

Figure 2

DEFORMATION

MODES

{111} SLiP

o

~o

30

i

I

>"

p-

506070

I

I

,

=

I

~,

=

,..~1

AT ROOM

TEMPERATURE

ROLLING

IN COPPER

80

,

SHEAR

: Ip~j ....

I TO ALLIGNED

TW,NS

REDUCTION, %

90

i

I

I

I BANOS

95

I

98

I

DEFORMATION MODES

~

IN ( 2 - BRASS

...... s . ~ , . / , . R o s

~

( HO}

2

{111)

I O

TRUE

2.0

ROLLING

30

"Inverse pole figure"

data of the d e n s i t y of

crystallographic planes

p a r a l l e l to t h e r o l l i n g

p l a n e o f s - b r a s s deformed

by p l a n e s t r a i n r o l l i n g

a t room t e m p e r a t u r e

( t a k e n .from Vuggan e t a l .

(37)). The p r e d o m i n a n t

micro-structural

d e f o r m a t i o n modes i n t h e

associated strain

i n t e r v a l s f o r c~-brass and

c o p p e r deformed a t room

t e m p e r a t u r e , deduced from

t h e work o f M o r l i and

Nakayama ( 3 , 8 ) and

Duggan et al. ( 3 7 ) ,

are indicated on the

figure.

40

STRAIN

Figure 2 contains data, taken from Duggan et al. (37), on the development of texture in 7030 brass deformed by rolling at room temperature. The character of the deformation at various

stages of rolllng, as deduced from the recent work of Morli and Nakay,ma (3,8) and Duggan et al.

(37), is briefly discussed on the figure. During approximately the first 30 percent reduction

in thickness the texture that develops in brass is very similar to the pure metal texture, as

indicated by an increase in the {110} sheet plane component and rapid decrease in the {IIi}

component. The deformation mode in brass in this strain interval is octahedral slip of extended

dislocations (37). In pure copper, on the other hand, Malin and Hatherly (37) report that after

i0 percent reduction the primary deformation mode involves the formation of "microbands." In

brass the primary deformation mechanism in the strain interval between 30 and 50 percent reduction is twinning which occurs by the formation of fine microtwins, aligned at nearly 30 to the

434

FLOW

LOCALIZATION

IN C R Y S T A L L I N E

SOLIDS

Vol.

18,

No.

rolling plane preferentially in grains having the {211} <III> texture component. At 50 percent

reduction the rolling textures of copper and s-brass are quite similar except that the occurrence of twins contributes a {255} <5it> component in brass. Beyond 50 percent, as indicated in

Figure 2, the brass texture undergoes a transition characterized by a buildup of a {III} component of the sheet plane which is later transformed into a {II0} component. This transition is

characterized by the appearance of shear bands that become the dominant deformation mode.

Shear bands form at approximately 35 to the rolling plane, although as discussed by

Hatherly and Malin (38) they are observed to form within a range of angles near 35 . They are

between 0.I and 1 ~m wide and propagate across grain boundaries with little change in trajectory. The number of bands, and therefore their volume fraction, increases monotonically with

strain. Eventually, at near 90 percent reduction, they occupy as much as 90 percent of the

volume whereupon further deformation can again be described as occurring by {Iii} <Ii0> sllp.

Morii and Nakayama (3) have shown that the phenomenology in copper rolled at liquid nitrogen

temperatures is very similar to that found in e-brass. Shear bands develop very large strains;

in low SFE materials or in high SFE materials deformed at very low temperatures(the strains are

as large as 10),whereas in high SFE materials deformed at room temperature the strains are somewhat less. In low SFE materials, such as s-brass, shear bands account for nearly all the strain

between reductions of 50-90 percent; in high SFE materials deformation by {iii} sllp continues

to be important concomitant with the shear bands. In both high and low SFE materials the

observations suggest that one set of shear bands tend to dominate. In brass a conjugate set

forms at later strains.

Between 50 and 70 percent reduction in thickness the deformation in brass occurs essentially by slip along those {III} planes parallel to the microtwins and by shearing along the

"primary" set of shear bands. This leads to what has been described as an extreme form of

"overshooting" that causes the twins to reorient parallel to the rolling plane. An effect of

this is the texture transition {211} <III> M + {255} <5iI> T ~ {iii} <211> M + {III} <2ii->T where M

and T refer to matrix and twinned regions respectively. In copper, slip in the matrix between

shear bands offsets the rotation caused by the shear bands which stabilizes the {211} texture

component (3,41).

Until microfracture begins shear bands are observed to harden and so material strain

softening does not appear to be a cause. In brass, or in copper deformed at low temperatures,

shear bands are observed to initiate only in twinned regions. Morii and Nakayama (3) have

observed that shear bands initiate within twin lamella and have proposed that the critical

micromechanical events involve "local lattice rotatlon(s)" which cause a geometrical softening

of the slip systems responsible for the concentrated straining in the bands. In copper at

higher temperatures, they have proposed that similar local "lattice curvatures" can develop in

"tangled dislocation wall(s)." These ideas are a direct microscopic analog to the experimental

and detailed theoretical findings of Chang and Asaro (7), Asaro (2) and Peirce et al. (15,16)

for macroscopic shear bands. In these studies it has been shown that the kinematics of necking

in single crystals causes nonuniform lattice rotations and geometrical softening that, in turn,

promote localized shearing. Dillamore et al. (6) have suggested "textural softening" occurs in

heavily rolled materials and is responsible for the overall softening which drives the localized

shearing mode. This idea has been pursued very recently by Canova et al. (39), among others,

who, following Dillamore et al. (6), describe the effect in terms of the evolution of the

"Taylor factor." This is defined as the ratio of the cumulative glide strains on all operative

slip systems (in a grain) to the maximum principal strain.

If the Taylor factors decrease due

to the particular prevailing texture and strain state, this implies less strain hardening and a

less stiff response.

The concepts of geometrical and textural softening provide a unifying set of mechanisms for

explaining how shear bands develop in strain hardening materials. Lattice rotations within

individual grains as well as effects of texture and misorientations across grain boundaries in

polycrystals can be rigorously analyzed within a comprehensive mechanics framework, although to

date only a few solutions to complete boundary value problems for single crystals are available.

Theoretical study of shear bands in plane strain compression, or rolling, would be of great

value and would require two separate analyses. The first involves the propagation of shear

bands in textured polycrystals. This requires a constitutive model which accounts for material

anlsotropy. We are carrying out studies directed toward developing such models (42) which can

then be incorporated within the theoretical framework described in Section 2. The second

analysis involves a study of the initiation of shear bands within individual grains. A first

Vol.

18,

No.

FLOW

LOCALIZATION

IN C R Y S T A L L I N E

SOLIDS

435

attempt at this could be pursued along the lines developed by Peirce et al. (15,16) for

analyzing macroscopic shear bands in single crystals and used in the hi-crystal analysis of

LeMonds (13). Here it may be possible to include the mechanisms suggested by Morii and Nakayama

(3) for the initiation of shear bands from microtwin clusters. Including such microstructural

features explicitly in the modelling should lead to a specification, or prediction, of shear

band width from the analysis. Such an analysis would undoubtedly provide considerable new

insight into the mechanics of shear band formation as well as help delineate the range of

microscale phenomena that can he described with continuum analysis.

Acknowledgments

R.J.A. gratefully acknowledges support from the Metallurgy Section of the U.S. National

Science Foundation under grant DMR26190. A.N. is grateful for the support provided by the U.S.

National Science Foundation Solid Mechanics Program under grant MEA-8101948.

Re f e r e n c e s

i.

2.

3.

4.

5.

A.

R.

K.

G.

M.

S. Malin and M. Hatherly, Metal Sci. 13, 463 (1979).

J. Asaro, Acta Met. 27, 445 (1979).

Morii and Y. Nakayama, Trans. Japan Inst. Met. 22, 857 (1981).

R. Speich and W. A. Spitzig, Met. Trans., 13A, 2239 (1983).

A. Larsson, A. Needleman, V. Tvergaard and B. Storakers, J. Mech. Phys. Solids, 30, 121

(1982).

6.

7.

8.

9.

I0.

ii.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

I. L. Dillamore, J. G. Roberts and A. C. Bush, J. Met. Sci. 13, 73 (1979).

Y. W. Chang and R. J. Asaro, Acta Met. 29, 241 (1981).

K. Morii, M. Mera and Y. Nakayama, Trans. Japan Inst. Met. 18, 7 (1977).

R. Hill, J. Mech. Phys. Solids, iO, i (1962).

J. R. Rice in "Theoretical and Applied Mechanics," Proc. 14th Int. Congr. Theoret. Appl.

Mech., edited by W. T. Koiter, North Holland, Amsterdam, p. 207 (1977).

A. Needleman and J. R. Rice in "Mechanics of Sheet Metal Forming," edited by

D. P. Koistinen and N.-M. Wang, Plenmm, New York, p. 237 (1978).

K. Marciniak and K. Kuczynski, Int. J. Mech. Sci., 2, 609 (1967).

J. LeMonds, M.S. Thesis, Brown University, June 1983.

H. Hill and J. W. Hutchinson, J. Mech. Phys. Solids 23, 239 (1975).

D. Peirce, R. J. Asaro and A. Needleman, Acta Met. 30, 1087 (1982).

D. Peirce, R. J. Asaro and A. Needleman, Acta Met. 31, 1951 (1983).

S. Saimoto, W. F. Hosford, Jr., and W. A. Backofen, Philos. Mag. 12, 319 (1965).

U. F. Kocks, Met. Trans. l, 1121 (1970).

D. Peirce, J. Mech. Phys. Solids, 31, 133 (1983).

J. Pan and J. R. Rice, Int. J. Solids Struct., 1 9 9 973 (1983).

V. Tvergaard, J. Mech. Phys. Solids, 30, 265 (1982).

V. Tvergaard, J. Mech. Phys. Solids, 30, 399 (1982).

V. Tvergaard, Int. J. Solids Struct., 18, 659 (1982).

J. R. Fisher and J. Gurland Met. Sci., 15, 185 (1981).

J. W. Hancock and A. L. Mackenzie, J. Mech. Phys. Solids, 14 9 107 (1976).

J. W. Hancock and D. K. Brown, J. Mech. Phys. Solids, 31, i (1983).

M. Saje, J. Pan and A. Needleman, Int. J. Fract., 19, 163 (1982).

V. Tvergaard and A. Needleman, Acts Met., in press.

J. Christoffersen and J. W. Hutchinson, J. Mech. Phys. Solids, 27, 465 (1979).

V. Tvergaard, A. Needleman and K. K. Lo, J. Mech. Phys. Solids, 29, 115 (1981).

A. Needleman and V. Tvergaard in "Finite Elements - Special Problems in Solid Mechanics,"

edited by J. T. Oden and G. F. Carey, Prentice-Hail, New York, p. 94 (1983).

D. P. Clausing, "Comparison of Plane Strain and Axisymmetric Plastic Flow and Fracture,"

U.S. Steel Research Laboratory Report 36.066-001 (2) (1972).

G. T. Hahn and A. Rosenfield, Met. Trans. 6A, 653 (1975).

L. Anand and W. Spitzig, J. Mech. Phys. Solids 28, 113 (1980).

J. W. Hutchinson and K. W. Neale, Acta Met., 25, 839 (1977).

J. Pan, M. Saje and A. Needleman, Int. J. Fract., 21, 261 (1983).

B. J. Duggan, M. Hatherly, W. B. Hutchinson and P. T. Wakefield, Metal Sci. 12, 343 (1978).

M. Hatherly and A. S. Malin, Viewpoint contained in this volume.

G. R. Canova, U. F. Kocks and M. G. Stout, Scripta Met., this issue.

U. F. Kocks, G. R. Canova, J. J. Jonas, Acta Met. 31, 1243 (1983).

K. Brown, J. Inst. Metals i00, 341 (1972).

R. J. Asaro and A. Needleman, research in progress.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- IELTS Life Skills - Sample Paper A Level A1 PDFDocument4 paginiIELTS Life Skills - Sample Paper A Level A1 PDFAnonymous QRT4uuQ100% (1)

- AutoCAD Mechanical 2015 Overview Brochure - A4Document4 paginiAutoCAD Mechanical 2015 Overview Brochure - A4Raul ReynosoÎncă nu există evaluări

- FDA Food - Code 2017 PDFDocument767 paginiFDA Food - Code 2017 PDFfitri widyaÎncă nu există evaluări

- 50 Powerful Sales QuestionsDocument19 pagini50 Powerful Sales QuestionsChandra Clark100% (3)

- Review of MEP Textbooks FinalDocument10 paginiReview of MEP Textbooks FinalvickyÎncă nu există evaluări

- Review of MEP Textbooks FinalDocument10 paginiReview of MEP Textbooks FinalvickyÎncă nu există evaluări

- What Is A One-Pager?: - E.M. Forster "Only Connect." - E.M. ForsterDocument1 paginăWhat Is A One-Pager?: - E.M. Forster "Only Connect." - E.M. ForsterChandra Clark100% (1)

- Short Circuit Calculation GuideDocument5 paginiShort Circuit Calculation Guideashok203Încă nu există evaluări

- Carrier - Rtu - 4 8 F C Da 0 4 A 2 A 5 - 0 A 0 A 0Document158 paginiCarrier - Rtu - 4 8 F C Da 0 4 A 2 A 5 - 0 A 0 A 0Chandra ClarkÎncă nu există evaluări

- Milbank - U5300 O 75Document2 paginiMilbank - U5300 O 75Chandra ClarkÎncă nu există evaluări

- Rheem Prestige Series Package Gas Electric UnitDocument36 paginiRheem Prestige Series Package Gas Electric UnitChandra ClarkÎncă nu există evaluări

- TB08104003E Tab 1Document152 paginiTB08104003E Tab 1priyanka236Încă nu există evaluări

- Electrical Symbols CS: PVC Film, On SheetDocument13 paginiElectrical Symbols CS: PVC Film, On SheetChandra ClarkÎncă nu există evaluări

- ANSYS Release Notes 190 PDFDocument146 paginiANSYS Release Notes 190 PDFAle100% (1)

- Commercial Product Specifications: Packaged Gas / ElectricDocument48 paginiCommercial Product Specifications: Packaged Gas / ElectricChandra ClarkÎncă nu există evaluări

- Short Circuit Calculation GuideDocument5 paginiShort Circuit Calculation Guideashok203Încă nu există evaluări

- Electrical CodeDocument11 paginiElectrical CodeChandra ClarkÎncă nu există evaluări

- Duct FittingsDocument31 paginiDuct FittingsSam Jose100% (7)

- Biscay: Tentative Forward ScheduleDocument5 paginiBiscay: Tentative Forward ScheduleChandra ClarkÎncă nu există evaluări

- Won't Crack. - . It Just Stretches: Technical DataDocument2 paginiWon't Crack. - . It Just Stretches: Technical DataChandra ClarkÎncă nu există evaluări

- Physics and Phenomenology of Strain Hardening The FCC Case PDFDocument103 paginiPhysics and Phenomenology of Strain Hardening The FCC Case PDFChandra ClarkÎncă nu există evaluări

- Modeling Texture, Twinning and HardeningDocument25 paginiModeling Texture, Twinning and HardeningChandra ClarkÎncă nu există evaluări

- Konsep Sistem InformasiDocument30 paginiKonsep Sistem InformasiNijar SetiadyÎncă nu există evaluări

- Modeling Texture, Twinning and Hardening PDFDocument12 paginiModeling Texture, Twinning and Hardening PDFChandra ClarkÎncă nu există evaluări

- Solid Mechanics 94 10Document89 paginiSolid Mechanics 94 10landatoÎncă nu există evaluări

- Tensor AnalysisDocument30 paginiTensor AnalysisChandra ClarkÎncă nu există evaluări

- Waves 2008 11 26Document20 paginiWaves 2008 11 26Chandra ClarkÎncă nu există evaluări

- ASME & IEEE Engineering Career Fair - Information Package v11Document2 paginiASME & IEEE Engineering Career Fair - Information Package v11Chandra ClarkÎncă nu există evaluări

- Foundations of Tensor Analysis For Students of Physics and Engineering With An Introduction To Theory of Relativity (Nasa)Document92 paginiFoundations of Tensor Analysis For Students of Physics and Engineering With An Introduction To Theory of Relativity (Nasa)Silver Olguín CamachoÎncă nu există evaluări

- Groma Bako PhysRevLet 2000Document4 paginiGroma Bako PhysRevLet 2000Chandra ClarkÎncă nu există evaluări

- Lecture 1: Encoding Language: LING 1330/2330: Introduction To Computational Linguistics Na-Rae HanDocument18 paginiLecture 1: Encoding Language: LING 1330/2330: Introduction To Computational Linguistics Na-Rae HanLaura AmwayiÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument22 paginiDisclosure To Promote The Right To InformationJGD123Încă nu există evaluări

- 171 - New CAN-filter For Cran Com. SCS4 and MidrangeDocument4 pagini171 - New CAN-filter For Cran Com. SCS4 and MidrangeMohamed ElnagdyÎncă nu există evaluări

- Windows Mbox Viewer User Manual 1.0.3.4Document33 paginiWindows Mbox Viewer User Manual 1.0.3.4Billy NoelÎncă nu există evaluări

- FOT - CG Limitation A320neo - Web ConferenceDocument7 paginiFOT - CG Limitation A320neo - Web Conferencerohan sinha100% (2)

- Sec 2 French ImmersionDocument1 paginăSec 2 French Immersionapi-506328259Încă nu există evaluări

- Introducing WESAD, A Multimodal Dataset For Wearable Stress and Affect DetectionDocument9 paginiIntroducing WESAD, A Multimodal Dataset For Wearable Stress and Affect DetectionJhónatan CarranzaÎncă nu există evaluări

- Steam Drive Correlation and Prediction PDFDocument10 paginiSteam Drive Correlation and Prediction PDFEmre CengizÎncă nu există evaluări

- Product - 20V4000G24F 3B FODocument32 paginiProduct - 20V4000G24F 3B FOmohammed khadrÎncă nu există evaluări

- How To Publish A Package in RDocument14 paginiHow To Publish A Package in Rtoton1181Încă nu există evaluări

- Bab 8Document29 paginiBab 8Nurul AmirahÎncă nu există evaluări

- DS Ac0801 GBDocument20 paginiDS Ac0801 GBHossein Jalali MoghaddamÎncă nu există evaluări

- Wartsila CPP PaperDocument4 paginiWartsila CPP Papergatheringforgardner9550Încă nu există evaluări

- Is A Calorie Really A Calorie - Metabolic Advantage of Low-Carbohydrate DietsDocument6 paginiIs A Calorie Really A Calorie - Metabolic Advantage of Low-Carbohydrate DietsGustavo CastroÎncă nu există evaluări

- Toyo ML210 thread cutting gear assembly drawingsDocument12 paginiToyo ML210 thread cutting gear assembly drawingsiril anwarÎncă nu există evaluări

- Tech Note 14Document2 paginiTech Note 14meteohrÎncă nu există evaluări

- Tradesman Electronics PDFDocument13 paginiTradesman Electronics PDFsandeepxrÎncă nu există evaluări

- Hydrogen and Its Compound.1Document10 paginiHydrogen and Its Compound.1abhishekÎncă nu există evaluări

- Grade 5 Mtap Compilation 2011,2013 2015 2016 2017 Division OralsDocument5 paginiGrade 5 Mtap Compilation 2011,2013 2015 2016 2017 Division OralsChristine De San JoseÎncă nu există evaluări

- QAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023Document1 paginăQAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023LeroyÎncă nu există evaluări

- Apriori AlgorithmDocument13 paginiApriori AlgorithmKiran JoshiÎncă nu există evaluări

- Ey-H3l Yh1576Document44 paginiEy-H3l Yh1576jorgeÎncă nu există evaluări

- 13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilDocument9 pagini13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilJenifer TejadaÎncă nu există evaluări

- Design of Shaft Straightening MachineDocument58 paginiDesign of Shaft Straightening MachineChiragPhadkeÎncă nu există evaluări

- THKDocument1.901 paginiTHKapi-26356646Încă nu există evaluări

- ICSE Mathematics X PapersDocument22 paginiICSE Mathematics X PapersImmortal TechÎncă nu există evaluări

- Midterm Exam Result Ce199-1l 2Q1920Document3 paginiMidterm Exam Result Ce199-1l 2Q1920RA CarpioÎncă nu există evaluări

- F 2786538d6cdc0bb1Document245 paginiF 2786538d6cdc0bb1Daniel HarutyunyanÎncă nu există evaluări

- Gabion Retaining Wall Design GuideDocument30 paginiGabion Retaining Wall Design GuideThomas Hill80% (5)