Documente Academic

Documente Profesional

Documente Cultură

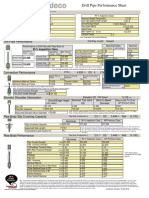

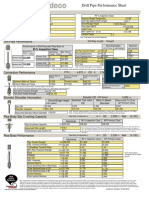

LandingString, 80%, 5.500 OD, 0.750 Wall, IEU, S-135.. XT57 (7.000 X 3.500)

Încărcat de

Garcia C L AlbertoDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

LandingString, 80%, 5.500 OD, 0.750 Wall, IEU, S-135.. XT57 (7.000 X 3.500)

Încărcat de

Garcia C L AlbertoDrepturi de autor:

Formate disponibile

Landing String Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Warning: Connection thread shear strength is too weak; the connection must be streamlined or a waiver must be signed. Warning: Connection ID is too large.

Note: Unbalanced Connection, Box weak (Connection OD should be larger or ID larger). Connection torsional strength is less than 80% pipe body torsional

strength.

80 % Inspection Class

(in) 5.500

Pipe Body OD

Drill Pipe Configuration

Pipe Body Wall Thickness

(in)

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

(in)

(in)

(in)

(in)

Box Tong

Landing String Rating

Drill Pipe Performance

(lbs)

Nominal Weight Designation

Drill Pipe Approximate Length

SmoothEdge Height

Tool Joint SMYS

Upset Type

Max Upset OD (DTE)

0.750

S-135

Range2

XT57

7.000

3.500

10

15

Friction Factor

Drill Pipe Length

Minimum MUT

59,700

0

52,700

Max Tension

(lbs)

1,170,600

1,084,400

Note: Oil field barrel equals 42 US gallons.

Range2

Drill Pipe Adjusted Weight

(lbs/ft)

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

(gal/ft)

(Bbls/ft)

(gal/ft)

(Bbls/ft)

(in)

(without

Coating)

Nominal

(with Coating)

44.51

0.68

0.0162

0.61

0.0146

3.375

(least accurate)

42.95

0.66

0.0156

0.64

0.0152

0.61

0.0145

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

XT57

Connection Performance

7.000

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

Maximum Make-up Torque

Minimum Make-up Torque

71,600

59,700

(lbs)

Tensile Limited

1,426,900

OD X

(in)

3.500

Tension at Connection

Yield

(lbs)

Tool Joint Torsional Strength

Tool Joint Tensile Strength

(ft-lbs)

ID

(in)

120,000

1,546,400

1,626,100

(psi)

Tool Joint Dimensions

Balanced OD

(in)

Minimum Tool Joint OD for API

Premium Class

(in)

Minimum Tool Joint OD for

Counterbore

Note: To maximize connection operational tensile, a MUT (T4) = 68,000 (ft-lbs) should be applied.

(in)

7.337

6.572

6.566

119,400

(lbs) 1,626,100

Elevator Shoulder Information

SmoothEdge OD

Box OD

Elevator Capacity

Assumed Elevator Bore

(in)

120,000

IEU

5.688

Best Estimates

1,170,600

1,043,400

0

43,900

(psi)

Based on:

80 % Inspection Class Pipe Body,

tool joint operational tensile, elevator OD, no applied drilling torque.

80 % Inspection Class

68,000

3/32 Raised

1.0

Performance of Drill Pipe with Pipe Body at

Recommended

MUT (T4)

(in)

Note: Tong spcae may include hardfacing.

807,700

Applied Make-up Operational Torque

Torque

(ft-lbs)

(ft-lbs)

38.05

31.8

(ft)

(in)

(lbs)

3/32 Raised

7.188

1,545,600

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Worn to Min TJ OD for

API Premium Class

7.000

1,315,600

6.572

813,300

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

Nominal

(lbs)

(in)

Pipe Body Performance

1,020,900

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

Cross Sectional Area of Pipe Body

(in^2)

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in^2)

(in^2)

(in^3)

(in^3)

5.5 (in) OD

80 % Inspection Class

807,700

Pipe Body Configuration

(lbs)

0.750 (in) Wall

S-135 )

API Premium Class

807,700

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

(in)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

5.812

Slip Crushing Capacity

Assumed Slip Length

Transverse Load Factor (K)

6.721

984,600

7.188

1,510,900

152,700

0.78

122,200

32,216

31,798

5.500

0.750

4.000

11.192

23.758

12.566

11.764

23.528

5.5 (in) OD

80 % Inspection Class

1,170,600

116,500

1.03

93,200

29,455

27,559

5.200

0.600

4.000

8.671

21.237

12.566

8.971

17.942

0.750 (in) Wall

S-135 )

API Premium Class

1,170,600

116,500

1.03

93,200

29,455

27,559

5.200

0.600

4.000

8.671

21.237

12.566

8.971

17.942

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is

intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions

(remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings,

acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID.

Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 02-03-2014

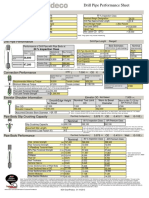

Operational Limits of Drill Pipe

Connection

Pipe Body

XT57

80 % Inspection Class

Tool Joint OD

(in)

7.000

Tool Joint ID

Pipe Body OD

(in)

5.5

Wall Thickness (in) 0.750

(in)

Combined Loading for Drill Pipe at

(ft-lbs)

0

3,000

6,000

8,900

11,900

14,900

17,900

20,900

23,900

26,800

29,800

32,800

35,800

38,800

41,800

44,700

47,700

50,700

53,700

56,700

(lbs)

S-135

Minimum Make-up Torque = 59,700

(ft-lbs)

Connection Max

Pipe Body

Max Tension Tension

(lbs)

1,170,600

1,170,200

1,169,000

1,167,100

1,164,400

1,160,900

1,156,600

1,151,600

1,145,600

1,139,100

1,131,600

1,123,200

1,113,900

1,103,700

1,092,600

1,080,900

1,067,900

1,053,800

1,038,700

1,022,700

Pipe Body Grade

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 71,600

Operational Assembly

Torque

Max Tension

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

3.500

Operational Assembly

Torque

Max Tension

(ft-lbs)

(lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(ft-lbs)

Connection

Max Tension

(lbs)

1,170,600 1,546,400

1,170,600

1,170,600

1,426,900

1,170,200 1,546,400

2,300

1,170,300

1,170,300

1,426,900

1,426,900

1,169,000 1,546,400

4,600

1,169,600

1,169,600

1,167,100 1,546,400

6,900

1,168,500

1,168,500

1,426,900

1,164,400 1,546,400

9,200

1,166,900

1,166,900

1,426,900

1,160,900 1,546,400

11,500

1,164,800

1,164,800

1,426,900

1,156,600 1,546,400

13,900

1,162,200

1,162,200

1,426,900

1,151,600 1,546,400

16,200

1,159,200

1,159,200

1,426,900

1,145,600 1,546,400

18,500

1,155,700

1,155,700

1,426,900

1,426,900

1,139,100 1,546,400

20,800

1,151,700

1,151,700

1,131,600 1,546,400

23,100

1,147,300

1,147,300

1,426,900

1,123,200 1,546,400

25,400

1,142,400

1,142,400

1,426,900

1,113,900 1,546,400

27,700

1,137,000

1,137,000

1,426,900

1,103,700 1,546,400

30,000

1,131,100

1,131,100

1,426,900

1,092,600 1,546,400

32,300

1,124,600

1,124,600

1,426,900

1,426,900

1,080,900 1,546,400

34,600

1,117,700

1,117,700

1,067,900 1,546,400

36,900

1,110,300

1,110,300

1,426,900

1,053,800 1,546,400

39,200

1,102,300

1,102,300

1,426,900

1,038,700 1,546,400

41,600

1,093,300

1,093,300

1,426,900

1,022,700 1,546,400

43,900

1,084,400

1,084,400

1,426,900

Operational drilling torque is limited by the Make-up Torque.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

59,700

61,000

62,300

63,700

65,000

66,300

67,600

69,000

70,300

71,600

Connection Max

Tension

(lbs)

1,426,900

1,458,000

1,489,100

1,522,500

1,553,600

1,584,700

1,615,800

1,604,500

1,575,400

1,546,400

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

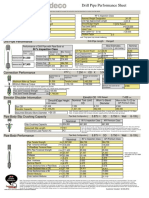

Connection Wear Table

Connection

XT57

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

7

6.961

6.921

6.882

6.842

6.803

6.763

6.724

6.684

6.645

6.605

6.566

Worn OD

(in)

7.000

Tool Joint ID

(in)

3.500

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

119,400

116,900

114,400

111,900

109,400

107,000

104,600

102,200

99,800

97,500

95,100

92,800

71,600

70,100

68,600

67,200

65,700

64,200

62,800

61,300

59,900

58,500

57,100

55,700

(ft-lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

Min MUT

(lbs)

1,546,400

1,523,700

1,498,000

1,470,100

1,396,700

1,322,900

1,252,100

1,182,200

1,115,100

1,050,800

987,400

926,800

Connection Max

Tension

(lbs)

(ft-lbs)

59,700

1,426,900

58,500

1,360,100

57,200

1,291,600

56,000

1,227,900

54,700

1,162,800

53,500

1,102,400

52,300

1,042,700

51,100

985,500

49,900

928,900

48,700

874,800

47,600

823,100

46,400

772,000

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

80 % Inspection Class

Pipe Body Torque

Pipe Body OD

10,600

21,200

(in)

5.5

31,800

42,400

Wall Thickness (in) 0.750

52,900

63,500

Pipe Body Grade

S-135

74,100

84,700

95,300

105,900

116,400

903,100

803,400

672,900

487,200

39,300

(ft-lbs)

Pipe Body Max

1,170,600 1,165,700 1,151,000 1,126,100 1,090,200 1,042,800 981,300

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

S-ar putea să vă placă și

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Sae J51-2004Document11 paginiSae J51-2004khhoseÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Tie Rod ManualDocument20 paginiTie Rod Manualseminoles1Încă nu există evaluări

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDe la EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerEvaluare: 5 din 5 stele5/5 (1)

- Drill Pipe Performance Data SheetDocument3 paginiDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- Drill Pipe Performance Data SheetDocument3 paginiDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- Drill Pipe Performance Data SheetDocument3 paginiDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 paginiAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89Încă nu există evaluări

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocument3 pagini4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizÎncă nu există evaluări

- Shear Load CalculationDocument8 paginiShear Load Calculationvinny1978Încă nu există evaluări

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADe la EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AÎncă nu există evaluări

- Drill Pipe Performance SheetDocument3 paginiDrill Pipe Performance SheetGarcia C L AlbertoÎncă nu există evaluări

- Drill Pipe Performance SheetDocument3 paginiDrill Pipe Performance SheetGarcia C L AlbertoÎncă nu există evaluări

- Drill Pipe Performance SheetDocument3 paginiDrill Pipe Performance SheetGarcia C L AlbertoÎncă nu există evaluări

- Drill CollarDocument1 paginăDrill CollarGuillermo Rangel AvalosÎncă nu există evaluări

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 paginiDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaÎncă nu există evaluări

- Reso Course PlannerDocument2 paginiReso Course PlannerSnehasishGhosh100% (1)

- Rev00-Gasket Installation & Bolt Torquing ProcedureDocument24 paginiRev00-Gasket Installation & Bolt Torquing ProcedureHansel FrancisÎncă nu există evaluări

- Xt39 Spec SheetDocument3 paginiXt39 Spec SheetjdcomptonÎncă nu există evaluări

- Drill pipe performance and operational limitsDocument3 paginiDrill pipe performance and operational limitsGarcia C L AlbertoÎncă nu există evaluări

- Drill Pipe Performance SheetDocument3 paginiDrill Pipe Performance Sheetjinyuan74Încă nu există evaluări

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 paginiDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoÎncă nu există evaluări

- 226 The O-CellDocument5 pagini226 The O-CellEvandro SantiagoÎncă nu există evaluări

- Wedge Thread Tool Joints Applications and EconomicsDocument9 paginiWedge Thread Tool Joints Applications and EconomicsalexintelÎncă nu există evaluări

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresDe la EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresEvaluare: 5 din 5 stele5/5 (1)

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDocument3 pagini5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraÎncă nu există evaluări

- HeavyWeight 3.5 25.58lbs NC-38Document3 paginiHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаÎncă nu există evaluări

- Drill Pipe Performance and SpecificationsDocument3 paginiDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаÎncă nu există evaluări

- Mass Spectroscopy: Submitted by Reenu - Thankachan First Semester, M Pharm Pharmaceutical AnalysisDocument38 paginiMass Spectroscopy: Submitted by Reenu - Thankachan First Semester, M Pharm Pharmaceutical AnalysisReenu ThankachanÎncă nu există evaluări

- Hvac Water BalancingDocument5 paginiHvac Water BalancingAwais Jalali100% (2)

- Drill Pipe Performance SheetDocument3 paginiDrill Pipe Performance SheetGarcia C L AlbertoÎncă nu există evaluări

- Bio PharmaceuticsDocument48 paginiBio PharmaceuticsRajan Kashyap100% (2)

- Reflow Soldering: Apparatus and Heat Transfer ProcessesDe la EverandReflow Soldering: Apparatus and Heat Transfer ProcessesÎncă nu există evaluări

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 paginiDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoÎncă nu există evaluări

- UI5 TrainingDocument110 paginiUI5 TrainingShailesh KumarÎncă nu există evaluări

- CO2 Production PlantsDocument4 paginiCO2 Production PlantsBoojie Recto100% (1)

- Concrete Compressive StrengthDocument4 paginiConcrete Compressive StrengthklynchelleÎncă nu există evaluări

- Drill Pipe Performance SheetDocument3 paginiDrill Pipe Performance SheetSaurav SenguptaÎncă nu există evaluări

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 paginiDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaÎncă nu există evaluări

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 paginiDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaÎncă nu există evaluări

- 2.500 X 1.375 DC With MW20 SlickDocument1 pagină2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanÎncă nu există evaluări

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 paginiPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoÎncă nu există evaluări

- Trispiral XT39Document1 paginăTrispiral XT39Cerón Niño SantiagoÎncă nu există evaluări

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 paginăPerformance Sheet Drill Pipe: Pipe Body: Tubular Assemblymsm.ele2009Încă nu există evaluări

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 paginiPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoÎncă nu există evaluări

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pagini5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoÎncă nu există evaluări

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 paginiPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoÎncă nu există evaluări

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 paginăPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaÎncă nu există evaluări

- 5 7/8" VM-165 R2 Pipe SpecsDocument2 pagini5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoÎncă nu există evaluări

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 paginăPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoÎncă nu există evaluări

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDocument4 paginiLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezÎncă nu există evaluări

- Section 19 - Appendix C - FormsDocument52 paginiSection 19 - Appendix C - Formsfivehours5Încă nu există evaluări

- 2.875 N80 6.51ppf EUEDocument1 pagină2.875 N80 6.51ppf EUEANSARAKUÎncă nu există evaluări

- Beam End Connection ReportDocument6 paginiBeam End Connection ReportHibri HalimÎncă nu există evaluări

- ITEM 564.00010001 - Bridge Hanger Fabrication and InstallationDocument14 paginiITEM 564.00010001 - Bridge Hanger Fabrication and InstallationKY PengÎncă nu există evaluări

- Type 501 453 UniversalDocument1 paginăType 501 453 Universalrambala123Încă nu există evaluări

- Principle of Operation: Target Inline FlowmeterDocument7 paginiPrinciple of Operation: Target Inline Flowmeterابزار دقیقÎncă nu există evaluări

- Grinnell Figure 772 Grooved Rigid CouplingDocument4 paginiGrinnell Figure 772 Grooved Rigid CouplingJuanÎncă nu există evaluări

- Technical Literature Plasma 12 Strand Tech SheetDocument2 paginiTechnical Literature Plasma 12 Strand Tech Sheetthanhtam3819Încă nu există evaluări

- AF-650 GP General Purpose Drive: Brake Resistor Design GuideDocument30 paginiAF-650 GP General Purpose Drive: Brake Resistor Design GuideonafetsÎncă nu există evaluări

- 6-15-0003 Rev 4Document9 pagini6-15-0003 Rev 4cynideÎncă nu există evaluări

- Oil Sands Fact SheetDocument47 paginiOil Sands Fact SheetAnonymous B7pghhÎncă nu există evaluări

- DTW 1213 Protective Fabric Sleeve For Single Hydraulic HosesDocument6 paginiDTW 1213 Protective Fabric Sleeve For Single Hydraulic HosesRaymundo68Încă nu există evaluări

- Assembly and Tensioning of High Strength Bolts andDocument14 paginiAssembly and Tensioning of High Strength Bolts andKirtichandraKomarrajuÎncă nu există evaluări

- New Industry Standards To Increase The ReliabilityDocument14 paginiNew Industry Standards To Increase The ReliabilitydjeramÎncă nu există evaluări

- Federal Brake Lining Specifications - CID a-A-52522BDocument6 paginiFederal Brake Lining Specifications - CID a-A-52522BBrian RenekerÎncă nu există evaluări

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pagini5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoÎncă nu există evaluări

- DPPS PDFDocument2 paginiDPPS PDFStowartÎncă nu există evaluări

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 paginiPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoÎncă nu există evaluări

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pagini5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoÎncă nu există evaluări

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 paginiPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoÎncă nu există evaluări

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 paginăPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoÎncă nu există evaluări

- DPPSDocument2 paginiDPPSGarcia C L AlbertoÎncă nu există evaluări

- WS36-01 DPPSDocument2 paginiWS36-01 DPPSGarcia C L AlbertoÎncă nu există evaluări

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pagini3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 paginiPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoÎncă nu există evaluări

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 paginiDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaÎncă nu există evaluări

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 paginiDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaÎncă nu există evaluări

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 paginiDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaÎncă nu există evaluări

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 paginiDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaÎncă nu există evaluări

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 paginiDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaÎncă nu există evaluări

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pagini3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 paginiDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaÎncă nu există evaluări

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pagini3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 paginiDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaÎncă nu există evaluări

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 paginiDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaÎncă nu există evaluări

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Document3 paginiDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Garcia C L AlbertoÎncă nu există evaluări

- Grade 6 MathDocument12 paginiGrade 6 Mathapi-264682510Încă nu există evaluări

- Full Text 01Document110 paginiFull Text 01GumbuzaÎncă nu există evaluări

- Ecen 326 - Lab 2 ReportDocument7 paginiEcen 326 - Lab 2 Reportapi-241454978Încă nu există evaluări

- To Design and Simulate Priority EncoderDocument6 paginiTo Design and Simulate Priority EncoderShubham GargÎncă nu există evaluări

- A Tour Through Mathematical Logic: Robert S. WolfDocument4 paginiA Tour Through Mathematical Logic: Robert S. WolfUrahara JefÎncă nu există evaluări

- Refining of MaterialsDocument38 paginiRefining of MaterialsJAWAD AHMAD BURTÎncă nu există evaluări

- FGS80HAS 100 V 50-60 HZ 1Document3 paginiFGS80HAS 100 V 50-60 HZ 1Tomas GuaiquireÎncă nu există evaluări

- Búsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDocument5 paginiBúsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDavidCPÎncă nu există evaluări

- Babcock University Bookshop An Babcock University BookshopDocument11 paginiBabcock University Bookshop An Babcock University BookshopAdeniyi M. AdelekeÎncă nu există evaluări

- 925E II 24 PG A4 Broch - 12 - 2020 - DCECDocument13 pagini925E II 24 PG A4 Broch - 12 - 2020 - DCECekkyagungÎncă nu există evaluări

- Amd690gm-M2 1219Document34 paginiAmd690gm-M2 1219rmartins_239474Încă nu există evaluări

- Periodization: Effects of Manipulating Volume and Intensity. Part 2Document7 paginiPeriodization: Effects of Manipulating Volume and Intensity. Part 2nachox_99Încă nu există evaluări

- Practicals ListDocument1 paginăPracticals ListDisha AminÎncă nu există evaluări

- Awk Quick GuideDocument42 paginiAwk Quick GuideMurat TanırÎncă nu există evaluări

- Schottky DiodeDocument5 paginiSchottky Diodeilg1Încă nu există evaluări

- Install and Configure Computer SystemsDocument18 paginiInstall and Configure Computer SystemsAlbino LarozaÎncă nu există evaluări

- Reflective Essay 2Document1 paginăReflective Essay 2Luell CajayonÎncă nu există evaluări

- 626178a42e9a0 Visual Programming Final PaperDocument8 pagini626178a42e9a0 Visual Programming Final PaperSaim AhmedÎncă nu există evaluări

- Esolutions Manual - Powered by CogneroDocument31 paginiEsolutions Manual - Powered by CogneroAll About MusicÎncă nu există evaluări

- TR01B - Muhammad Aditya Prana Yoga - Analisa Listrik Chapter8.3Document3 paginiTR01B - Muhammad Aditya Prana Yoga - Analisa Listrik Chapter8.3AzeedÎncă nu există evaluări

- Cagayan State University: Republic of The PhilippinesDocument21 paginiCagayan State University: Republic of The PhilippinesblessaÎncă nu există evaluări

- Hydrogen in 1 ShotDocument86 paginiHydrogen in 1 ShotSaloum Muhammed Islam0% (1)