Documente Academic

Documente Profesional

Documente Cultură

Ucmp R13 Syll

Încărcat de

N Dhanunjaya Rao Borra0 evaluări0% au considerat acest document util (0 voturi)

178 vizualizări2 paginiThis document outlines the course objectives, units, textbook, and outcomes for an unconventional machining processes course. The course aims to identify classifications of unconventional machining, understand principles and metal removal mechanisms, and study process parameters and their effects. The 6 units cover introduction and various processes like ultrasonic, electrochemical, thermal, laser and plasma machining. Processes like abrasive jet, water jet, magnetic abrasive finishing are also discussed. The textbook and references are provided. After completing the course, students will understand working principles, metal removal mechanisms, process parameters and applications of different unconventional machining processes.

Descriere originală:

Titlu original

UCMP R13 SYLL

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document outlines the course objectives, units, textbook, and outcomes for an unconventional machining processes course. The course aims to identify classifications of unconventional machining, understand principles and metal removal mechanisms, and study process parameters and their effects. The 6 units cover introduction and various processes like ultrasonic, electrochemical, thermal, laser and plasma machining. Processes like abrasive jet, water jet, magnetic abrasive finishing are also discussed. The textbook and references are provided. After completing the course, students will understand working principles, metal removal mechanisms, process parameters and applications of different unconventional machining processes.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

178 vizualizări2 paginiUcmp R13 Syll

Încărcat de

N Dhanunjaya Rao BorraThis document outlines the course objectives, units, textbook, and outcomes for an unconventional machining processes course. The course aims to identify classifications of unconventional machining, understand principles and metal removal mechanisms, and study process parameters and their effects. The 6 units cover introduction and various processes like ultrasonic, electrochemical, thermal, laser and plasma machining. Processes like abrasive jet, water jet, magnetic abrasive finishing are also discussed. The textbook and references are provided. After completing the course, students will understand working principles, metal removal mechanisms, process parameters and applications of different unconventional machining processes.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

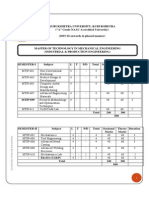

4-1 Mechanical Engineering R13

UNCONVENTIONAL MACHINING PROCESS

Course Objectives: The course aims in unconventional identifying the classification of machining

processes. To understand the principle, mechanism of metal removal of various unconventional

machining processes. To study the various 'process parameters and their effect on the component

machined on various unconventional machining processes. To understand the applications of different

processes.

UNIT-1

Introduction: Need for non-traditional machining methods- classification of modern machining processes

- considerations in process selection, applications.

Ultrasonic machining - Elements of the process, Mechanics of material removal, MRR process

parameters, economic considerations, applications and limitations.

UNIT - 2

Electro - Chemical Machining: Fundamentals of electro chemical machining, electrochemical grinding,

electro chemical honing and deburring process, metal removal rate in ECM, Tool design, Surface finish,

and accuracy, economic aspects of ECM - Simple problems for estimation of metal removal rate,

fundamentals of chemical, machining, advantages and applications.

UNIT - 3

Thermal Metal Removal Processes: General principle and applications of Electric Discharge Machining,

Electric Discharge grinding, and wire EDM - Power circuits of EDM, Mechanics of metal removal in

EDM process parameters, selection of tool electrode and dielectric fluids, surface finish and machining

accuracy, characteristics of spark eroded surface.

UNIT - 4

Electron Beam Machining, Laser Beam Machining - Basic Principle and theory, mechanics of material

removal, process parameters, efficiency, accuracy and applications.

UNIT- 5

Plasma Machining: Application of plasma for machining, metal removal mechanism, process

parameters, accuracy and surface finish and other applications of plasma in manufacturing industries.

UNIT -6

Abrasive jet machining, Water jet machining and abrasive water jet machining; Basic principles,

equipments, process variables, mechanics of material removal, MRR, application and limitations.

Magnetic abrasive finishing, abrasive flow finishing, Electro stream drilling, shaped tube electrolytic

machining.

TEXT BOOK:

1. Advanced machining processes/ VK Jain/ Allied publishers.

REFERENCES:

1. Modern Machining Process / Pandey P.C. and Shah H.S., TMH.

2. New Technology / Bhattacharya A/ The Institution of Engineers. India 1984.

Course outcomes: After completion of course, the student shall understand the principle of working,

mechanism of metal removal in the various unconventional machining process. The student is able to

identify the process parameters, their effect and applications of different processes.

S-ar putea să vă placă și

- Electrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyDe la EverandElectrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyEvaluare: 4 din 5 stele4/5 (1)

- Un Conventional Machining Processes SyllabusDocument2 paginiUn Conventional Machining Processes SyllabusKalai ArasanÎncă nu există evaluări

- Jawaharlal Nehru Technological University AnantapurDocument1 paginăJawaharlal Nehru Technological University AnantapurManu RavuriÎncă nu există evaluări

- Modern Manufacturing MethodsDocument3 paginiModern Manufacturing MethodsSree MurthyÎncă nu există evaluări

- First Lecturer PTDocument8 paginiFirst Lecturer PTnashk18Încă nu există evaluări

- NTM Module 1Document19 paginiNTM Module 1RishiJpÎncă nu există evaluări

- Un Conventional Machining Process NotesDocument174 paginiUn Conventional Machining Process Notesban murthy0% (1)

- ME8073 - UNCONVENTIONAL MACHINING PROCESSES SyllabusDocument2 paginiME8073 - UNCONVENTIONAL MACHINING PROCESSES SyllabusP.N. MohankumarÎncă nu există evaluări

- # 1 - IntroductionDocument42 pagini# 1 - IntroductionRohan RautÎncă nu există evaluări

- Me 8073 UcmpDocument21 paginiMe 8073 UcmpAjay SriramÎncă nu există evaluări

- Handouts: Kongunadu College of Engineering and Technology (Autonomous)Document59 paginiHandouts: Kongunadu College of Engineering and Technology (Autonomous)Akilesh SÎncă nu există evaluări

- Ucm SyllabusDocument5 paginiUcm SyllabusDhana MuruganÎncă nu există evaluări

- Gujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807Document2 paginiGujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807ganeshÎncă nu există evaluări

- Mech Vi Non Traditional Machining (10me665) NotesDocument45 paginiMech Vi Non Traditional Machining (10me665) Notesnikhil0% (1)

- Machining Science: Jigs & FixturesDocument77 paginiMachining Science: Jigs & FixturesChidu KÎncă nu există evaluări

- Ucmp Assignment QuestionsDocument2 paginiUcmp Assignment QuestionsKalai ArasanÎncă nu există evaluări

- M.tech Mechanical Engg. (I &P)Document44 paginiM.tech Mechanical Engg. (I &P)Upender DhullÎncă nu există evaluări

- 02 Ucm SyllabusDocument1 pagină02 Ucm SyllabusSamuelHericÎncă nu există evaluări

- Soumya Seminar ReportDocument21 paginiSoumya Seminar ReportDillip MahakhudaÎncă nu există evaluări

- Bmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lDocument3 paginiBmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lKrijayÎncă nu există evaluări

- UCM Course InformationDocument14 paginiUCM Course InformationThiyagu SundaramÎncă nu există evaluări

- MMP SyllabusDocument1 paginăMMP SyllabusShiba Narayan SahuÎncă nu există evaluări

- Unconvetional Machining ProcessDocument2 paginiUnconvetional Machining ProcessmaheshÎncă nu există evaluări

- Me Manufacturing Curriculum-2Document11 paginiMe Manufacturing Curriculum-2Arun KumarÎncă nu există evaluări

- Ucm - Unitwise Notes (r2017)Document168 paginiUcm - Unitwise Notes (r2017)A. AKASH 4001-UCE-TKÎncă nu există evaluări

- Ucmp NotesDocument46 paginiUcmp NotesAnonymous fowICTKÎncă nu există evaluări

- Ucm Two MarksDocument23 paginiUcm Two Marksarun kumarÎncă nu există evaluări

- Advanced Manufacturing Process: Course Code:13ME1149 L TPC 4 0 0 3Document3 paginiAdvanced Manufacturing Process: Course Code:13ME1149 L TPC 4 0 0 3anuragÎncă nu există evaluări

- Materials and MachiningDocument116 paginiMaterials and MachiningGian RemundiniÎncă nu există evaluări

- B Tech - Manufacturing Technology - 4th Year SyllabusDocument28 paginiB Tech - Manufacturing Technology - 4th Year SyllabusSuraj OjhaÎncă nu există evaluări

- Machining Science: Jigs & FixturesDocument15 paginiMachining Science: Jigs & FixturesChidu KÎncă nu există evaluări

- Me6004 Unconventional Machining Processes Assignment 1,2,3,4,5Document5 paginiMe6004 Unconventional Machining Processes Assignment 1,2,3,4,5BIBIN CHIDAMBARANATHANÎncă nu există evaluări

- Ucmp First Mid Course FileDocument160 paginiUcmp First Mid Course FileAraveetiCSReddyÎncă nu există evaluări

- Basics of Metal Cutting 1Document70 paginiBasics of Metal Cutting 1Saideep GhimireÎncă nu există evaluări

- Machining Science: Jigs & FixturesDocument29 paginiMachining Science: Jigs & FixturesChidu KÎncă nu există evaluări

- UCM SylabusDocument4 paginiUCM SylabusajitsssÎncă nu există evaluări

- MMP NotesDocument81 paginiMMP NotestatiÎncă nu există evaluări

- MP302 Advanced Materials and Manufacturing SystemsDocument4 paginiMP302 Advanced Materials and Manufacturing SystemsDr. Mubarak AliÎncă nu există evaluări

- Gujarat Technological University: Metal Cutting & Advanced Manufacturing ProcessesDocument3 paginiGujarat Technological University: Metal Cutting & Advanced Manufacturing ProcessesAoneÎncă nu există evaluări

- Modern Manufacturing TechnologyDocument15 paginiModern Manufacturing TechnologyTHE NORTHCAP UNIVERSITYÎncă nu există evaluări

- Non Traditional MachiningDocument71 paginiNon Traditional MachiningShamanth SHÎncă nu există evaluări

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909Document3 paginiGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909ShahinÎncă nu există evaluări

- Maharshi Dayanand University Rohtak: Syllabus and Courses of Reading For M.Tech (Mechanical Engineering)Document22 paginiMaharshi Dayanand University Rohtak: Syllabus and Courses of Reading For M.Tech (Mechanical Engineering)Ramesh PandaÎncă nu există evaluări

- 4th Semester SyllabusDocument14 pagini4th Semester Syllabus507 20L SK DarainÎncă nu există evaluări

- Amp Qb.Document6 paginiAmp Qb.svkarthik83Încă nu există evaluări

- Third Year Second Semester: Department of Mechanical Engineering - Course CatalogueDocument8 paginiThird Year Second Semester: Department of Mechanical Engineering - Course CatalogueSudeep GamerÎncă nu există evaluări

- r05010302 Engineering MechanicsDocument39 paginir05010302 Engineering Mechanicsdassault megecÎncă nu există evaluări

- ME306 Advanced Manufacturing TechnologyDocument4 paginiME306 Advanced Manufacturing Technologynandan144Încă nu există evaluări

- Syllabus PDF 1Document3 paginiSyllabus PDF 1gowrisankar32Încă nu există evaluări

- Energy Systems LM - 7 Credits: Main Objectives and Contents of The CourseDocument4 paginiEnergy Systems LM - 7 Credits: Main Objectives and Contents of The CourseAbhishek TiwariÎncă nu există evaluări

- AdvMan Technology QbankDocument24 paginiAdvMan Technology QbankSandeepKattaÎncă nu există evaluări

- 5 MPDocument3 pagini5 MPASIST MechÎncă nu există evaluări

- Machining Science: Jigs & FixturesDocument26 paginiMachining Science: Jigs & FixturesChidu KÎncă nu există evaluări

- MCMT SyllabusDocument3 paginiMCMT SyllabusshahazadÎncă nu există evaluări

- Syllabus ITI MechanicalDocument3 paginiSyllabus ITI MechanicalRavindra MahadeokarÎncă nu există evaluări

- Me2026 UmpDocument74 paginiMe2026 Umpashoku24007Încă nu există evaluări

- Advanced Noncontact Cutting and Joining Technologies: Micro- and Nano-manufacturingDe la EverandAdvanced Noncontact Cutting and Joining Technologies: Micro- and Nano-manufacturingÎncă nu există evaluări

- Multiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessDe la EverandMultiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessÎncă nu există evaluări

- Reliability Investigation of LED Devices for Public Light ApplicationsDe la EverandReliability Investigation of LED Devices for Public Light ApplicationsÎncă nu există evaluări

- MCMT Mid-1 P-QusDocument5 paginiMCMT Mid-1 P-QusN Dhanunjaya Rao BorraÎncă nu există evaluări

- Unit-1: Fundamentals of MachiningDocument2 paginiUnit-1: Fundamentals of MachiningN Dhanunjaya Rao BorraÎncă nu există evaluări

- Unit 1Document5 paginiUnit 1N Dhanunjaya Rao BorraÎncă nu există evaluări

- CAMD QuestionsDocument3 paginiCAMD QuestionsN Dhanunjaya Rao Borra100% (1)

- Composite Materials QuotationDocument1 paginăComposite Materials QuotationN Dhanunjaya Rao BorraÎncă nu există evaluări

- Part A5 Cotter JointsDocument8 paginiPart A5 Cotter JointsN Dhanunjaya Rao BorraÎncă nu există evaluări

- Assembly DrawingsDocument15 paginiAssembly DrawingsN Dhanunjaya Rao BorraÎncă nu există evaluări

- Part A5 Cotter JointsDocument8 paginiPart A5 Cotter JointsN Dhanunjaya Rao BorraÎncă nu există evaluări

- Part A4 Keyed JointsDocument8 paginiPart A4 Keyed JointsN Dhanunjaya Rao BorraÎncă nu există evaluări

- Assembly DrawingsDocument15 paginiAssembly DrawingsN Dhanunjaya Rao BorraÎncă nu există evaluări

- Part A5 Cotter JointsDocument6 paginiPart A5 Cotter JointsN Dhanunjaya Rao BorraÎncă nu există evaluări

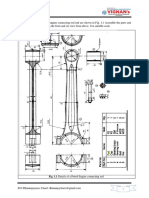

- Part-B1-Petrol Engine Connecting RodDocument5 paginiPart-B1-Petrol Engine Connecting RodN Dhanunjaya Rao BorraÎncă nu există evaluări

- Service Cum No Objection CertificateDocument1 paginăService Cum No Objection CertificateN Dhanunjaya Rao BorraÎncă nu există evaluări

- Lesson11 ANSI PDFDocument93 paginiLesson11 ANSI PDFN Dhanunjaya Rao BorraÎncă nu există evaluări

- Advanced NDE Lesson 1Document190 paginiAdvanced NDE Lesson 1N Dhanunjaya Rao BorraÎncă nu există evaluări

- Catia V5 CATIA Generative Sheetmetal Design: Student GuideDocument3 paginiCatia V5 CATIA Generative Sheetmetal Design: Student GuideN Dhanunjaya Rao BorraÎncă nu există evaluări

- Pi 2007 - QP PDFDocument16 paginiPi 2007 - QP PDFN Dhanunjaya Rao BorraÎncă nu există evaluări

- PQR FormDocument2 paginiPQR Formpokok assamÎncă nu există evaluări

- Lathe Machine & OperationsDocument63 paginiLathe Machine & Operationsvikas_1989100% (2)

- Previous Years Gate Questions On Casting 2007-2013 - Engineering Tutorials PDFDocument5 paginiPrevious Years Gate Questions On Casting 2007-2013 - Engineering Tutorials PDFnallsrajj100% (1)

- Ch11 CastingProcessesDocument102 paginiCh11 CastingProcessesFahmi PrayogiÎncă nu există evaluări

- Presentation Topic:: Soldering and BrazingDocument27 paginiPresentation Topic:: Soldering and BrazingSarath ChandraÎncă nu există evaluări

- Electric Welding MCQs - Page 2 of 4 - ElectricalvoiceDocument5 paginiElectric Welding MCQs - Page 2 of 4 - ElectricalvoiceSudip MondalÎncă nu există evaluări

- ISO 5817 Weld Defects AnalysisDocument82 paginiISO 5817 Weld Defects Analysisaravindan50% (2)

- 03 Welding Imperfections 30-03-07 (2Document20 pagini03 Welding Imperfections 30-03-07 (2geokovoorÎncă nu există evaluări

- Xylem Lowara Onderdelen Reservedelen PDFDocument220 paginiXylem Lowara Onderdelen Reservedelen PDFJhonatan FernandezÎncă nu există evaluări

- Clause Out of Z662 For AttachmentsDocument1 paginăClause Out of Z662 For AttachmentsRandy SauderÎncă nu există evaluări

- 3475331Document41 pagini3475331Nguyen Trong TanÎncă nu există evaluări

- American Society of Mechanical Engineers (ASME) CodesDocument11 paginiAmerican Society of Mechanical Engineers (ASME) CodesfrdnÎncă nu există evaluări

- An Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape CharacteristicsDocument5 paginiAn Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape Characteristicstejap314Încă nu există evaluări

- Basic HolemakingDocument5 paginiBasic HolemakingdramiltÎncă nu există evaluări

- Oring Chart SizesDocument7 paginiOring Chart SizesCarlos OrozcoÎncă nu există evaluări

- Weld Cheat SheetDocument1 paginăWeld Cheat SheetBruce BrownÎncă nu există evaluări

- Advanced Manufacturing ScienceDocument2 paginiAdvanced Manufacturing Sciencemukesh3021Încă nu există evaluări

- PPC Master MarchDocument148 paginiPPC Master MarchSandip JadhavÎncă nu există evaluări

- 27 AprvdSawDocument19 pagini27 AprvdSawMarleneLopesÎncă nu există evaluări

- Asme Section Ix QuestionsDocument18 paginiAsme Section Ix QuestionsBalakumar80% (10)

- F Number ER70S 6Document1 paginăF Number ER70S 6josel213Încă nu există evaluări

- Simboluri SudareDocument8 paginiSimboluri SudarecornelutsÎncă nu există evaluări

- WPS FGPDocument1 paginăWPS FGPShabbir HussainÎncă nu există evaluări

- Answer Any Five of The Following (1×5 5) : ST THDocument2 paginiAnswer Any Five of The Following (1×5 5) : ST THaghosh704Încă nu există evaluări

- Approved Vendor List - CD Live Org Awcd4Document44 paginiApproved Vendor List - CD Live Org Awcd4Rohith KommuÎncă nu există evaluări

- Manufacturing Engineering Guide BookDocument2 paginiManufacturing Engineering Guide BookGiridharan SharmaÎncă nu există evaluări

- Sand Casting: Pouring Cup Cope Down Sprue RiserDocument71 paginiSand Casting: Pouring Cup Cope Down Sprue Riservenkat4Încă nu există evaluări

- ME 2201 - MANUFACTURING TECHNOLOGY - I 3rd MechDocument3 paginiME 2201 - MANUFACTURING TECHNOLOGY - I 3rd Mechkarthiksubramanian94Încă nu există evaluări

- Casting CH 1Document20 paginiCasting CH 1osman_razaaÎncă nu există evaluări