Documente Academic

Documente Profesional

Documente Cultură

4935-w0 Standard For Purchase of Full-Encirclement Welded Split Sleeves

Încărcat de

LorenaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

4935-w0 Standard For Purchase of Full-Encirclement Welded Split Sleeves

Încărcat de

LorenaDrepturi de autor:

Formate disponibile

Engineering Standards

Standard

4935

Page

1 of 3

STANDARD FOR PURCHASE OF

FULL ENCIRCLEMENT

WELDED SPLIT SLEEVES

Issue Date

07/89

Rev. No.

Date

1.

SCOPE

This standard specifies the minimum requirements for the design, materials and manufacture of full-encirclement,

welded, split sleeves for gas piping. The sleeves are intended for reinforcment or leak repair of welded joints or

mechanical couplings in existing piping.

2.

REFERENCED CODES AND STANDARDS

49 CFR Part 192 (DOT Part 192)

American Society for Testing and Materials (ASTM)

Manufacturer's Standardization Society (MSS) SP-25 and SP-75

3.

DESIGN

3.1

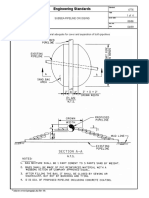

Each sleeve shall consist of two 180 halves which are to be field welded in place over the specified type

of pipe joint.

3.2

Unless specified otherwise, the sleeves shall be designed by the Manufacturer using material having a

combination of wall thickness and yield strength to meet the specified design pressure based on the

following pipe design formula in DOT Part 192, 192.105. As an option, the Purchaser may specify the

minimum wall thickness and specified minimum yield strength of the sleeve material and/or the

Manufacturer and catalog number.

P = 2(S)(t) (E)(F), where

D

P

D

S

t

E

F

=

=

=

=

=

=

Design pressure (psig) to be specified by Purchaser,

Outside diameter (inches) in the area of highest hoop stress (normally the largest diameter),

Specified minimum yield strength (psi) of sleeve material,

Wall thickness (inches) in the area of highest hoop stress,

Longitudinal joint efficiency will be 1.0,

Design factor to be specified by Purchaser (0.4 to 0.72),

3.3

For sleeve designs based on the formula above, the entire sleeve, including areas of transition and reduced

diameter, shall be designed and manufactured so as to have an equivalent pressure containing capability.

3.4

The ends of all sleeves shall have a nominal inside diameter which is the same as the nominal outside

diameter of the pipe size specified.

3.5

The body of the sleeve shall have a diameter and shape suitable for the specified purpose of the sleeve

which may include a formed groove suitable for a circumferential welded butt joint in pipe or an enlarged

body suitable for enclosure of a mechanical joint of a specified type such as a Dresser coupling.

3.6

The length of the sleeve shall be the manufacturer's standard unless specified otherwise.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4935

Page

2 of 3

STANDARD FOR PURCHASE OF

FULL ENCIRCLEMENT

WELDED SPLIT SLEEVES

Issue Date

07/89

Rev. No.

Date

4.

5.

6.

MATERIALS

4.1

Sleeves shall be fabricated from steel pipe or plate having a specified minimum yield strength (SMYS) of

35,000 psi or greater. The steel used shall be of suitable quality for field welding using a standard welding

process and procedure.

4.2

If pipe is used, it shall be manufactured in accordance with a specification listed in DOT Part 192 and

shall not have been subjected to cold expansion to achieve the SMYS. If plate is used, it shall be

manufactured in accordance with an ASTM specification and be a plate intended for use in fabrication of

pressure vessels.

4.3

Sleeves shall not contain a longitudinal seam in either half.

4.4

Chemical composition of the materials shall be determined in accordance with MSS SP-75, Section 7.

4.5

Physical properties of the materials shall be determined in accordance with MSS SP-75, Section 8, before

or after the manufacturing process; however if determined before manufacturing, the physical properties

shall not be altered detrimentally by the manufacturing process.

MANUFACTURE

5.1

The manufacture of sleeves shall be in accordance with MSS SP-75, Section 14, except that fabrication by

welding shall not be permitted.

5.2

Heat treatment shall be performed in accordance with MSS SP-75, Section 9, as necessary to restore or

obtain the required physical properties.

5.3

The edges of both sleeves along the longitudinal seams shall be prepared for welding with a standard 30

or 37-1/2 bevel. The end circumferential edges shall be square.

MARKING

6.1

All sleeves shall be legibly marked in a manner and location consistent with the requirements of MSS SP25.

6.2

Markings shall include Purchaser's purchase order and item number, nominal size of pipe for which

sleeve is to be applied, material manufacturing specification and grade and wall thickness.

* Indicates revised paragraph, this Rev. No.

Standard

Engineering Standards

4935

Page

3 of 3

STANDARD FOR PURCHASE OF

FULL ENCIRCLEMENT

WELDED SPLIT SLEEVES

Issue Date

07/89

Rev. No.

Date

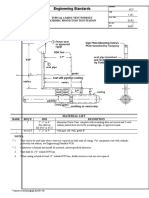

SPECIFICATION SHEET

Location:

Requisition No.

Project:

Project No.

Prepared By:

Date:

Purchase Order No.

Item Number

Tag Number

Quantity

Manufacturer (if applicable)

Mfr.'s Cat. # (if applicable)

Pipe Size (inches O.D.)

Design Pressure (psig)

Design Factor

Sleeve Wall Thickness (inches)

Material Grade (or SMYS)

Sleeve Length (inches)

Sleeve Type for:

Circumferential Weld Joint

Dresser Coupling - Style 38

Dresser Coupling - Style 40

Other Coupling:

(Type or Length & Diameter)

Additional Requirements:

* Indicates revised paragraph, this Rev. No.

Approved By:

Revision:

Revised Date:

P.O. Date:

S-ar putea să vă placă și

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsDe la EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsÎncă nu există evaluări

- Preventing Corrosion in Sulfur Storage TanksDocument20 paginiPreventing Corrosion in Sulfur Storage TanksMatt Schlabach100% (1)

- CPDocument55 paginiCParianaseri100% (2)

- HW1 15814Document2 paginiHW1 15814Lam NguyenÎncă nu există evaluări

- L51800 PDFDocument101 paginiL51800 PDFHernan GeovannyÎncă nu există evaluări

- Saep 37Document9 paginiSaep 37Anonymous 4IpmN7On100% (1)

- FuturePipe Installation Manual 18-7-05 PDFDocument25 paginiFuturePipe Installation Manual 18-7-05 PDFPaul WoworÎncă nu există evaluări

- Metal Sleeves Vs Composites Wrapping in Piping RepairDocument7 paginiMetal Sleeves Vs Composites Wrapping in Piping RepairEmad A.Ahmad100% (1)

- Piping Q&ADocument3 paginiPiping Q&AVijay KumarÎncă nu există evaluări

- Pipeline Welding InspectionDocument4 paginiPipeline Welding InspectionRizky TrianandaÎncă nu există evaluări

- Avoiding Common Pitfalls in CO2 Corrosion Rate Assessment For Upstream Hydrocarbon IndustriesDocument15 paginiAvoiding Common Pitfalls in CO2 Corrosion Rate Assessment For Upstream Hydrocarbon IndustriesKen's CornerÎncă nu există evaluări

- Ring Joint HandbookDocument7 paginiRing Joint HandbookchiliskyÎncă nu există evaluări

- Gas Tungsten Arc WeldingDocument15 paginiGas Tungsten Arc Weldingsushant47Încă nu există evaluări

- Ipc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDocument9 paginiIpc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDietmar WengerÎncă nu există evaluări

- API 5ct Grade k55 TubingsDocument1 paginăAPI 5ct Grade k55 TubingsMitul MehtaÎncă nu există evaluări

- Gate ValveDocument27 paginiGate ValveYogesh Kumar Bhatnagar0% (1)

- Garlock Metal - Gaskets TorqueDocument48 paginiGarlock Metal - Gaskets TorqueakenathorÎncă nu există evaluări

- Important Butt FusionDocument22 paginiImportant Butt Fusionvipul anandÎncă nu există evaluări

- V8 Import Spreadsheet Rev 11Document5.363 paginiV8 Import Spreadsheet Rev 11Raymond de WeeverÎncă nu există evaluări

- What Exactly Is Subsea Piping - Q&A Oil ProDocument7 paginiWhat Exactly Is Subsea Piping - Q&A Oil ProAsadAliÎncă nu există evaluări

- PetroSync - ASME B31.3 Process Piping Code Design Requirements 2017Document5 paginiPetroSync - ASME B31.3 Process Piping Code Design Requirements 2017Engr Khurram Jaan RamayÎncă nu există evaluări

- Finding and Mitigating SCC ...Document7 paginiFinding and Mitigating SCC ...grimaguilÎncă nu există evaluări

- 3 o Ring Guide Issue 7 PDFDocument32 pagini3 o Ring Guide Issue 7 PDFthailanÎncă nu există evaluări

- Selection of Pipe Repair Methods DOT Project 359Document174 paginiSelection of Pipe Repair Methods DOT Project 359Jorge D BalseroÎncă nu există evaluări

- Greater Noida Institute of Technology: Under-Water WeldingDocument12 paginiGreater Noida Institute of Technology: Under-Water WeldingEr Raghvendra SinghÎncă nu există evaluări

- 1 PipelineDocument69 pagini1 PipelineEhab MohammedÎncă nu există evaluări

- Full Scale Experimental Analysis of Stress States in Sleeve Repairs of Gas Pipelines PDFDocument9 paginiFull Scale Experimental Analysis of Stress States in Sleeve Repairs of Gas Pipelines PDFzemog001100% (1)

- Socket WeldDocument7 paginiSocket WeldahmedÎncă nu există evaluări

- TPP Equipment and ServicesDocument24 paginiTPP Equipment and ServicesmanojkumarÎncă nu există evaluări

- Analysis of Chemical Tracer Flowback in Unconventional Reservoirs - SPE-171656-MSDocument22 paginiAnalysis of Chemical Tracer Flowback in Unconventional Reservoirs - SPE-171656-MSkarenomalleyÎncă nu există evaluări

- API Specifications and StandardsDocument2 paginiAPI Specifications and StandardsAlvin Smith100% (1)

- Piping QuestionnaireDocument33 paginiPiping QuestionnaireNitin Shinde100% (3)

- D/Stream Pipeline Corrosion Defects & Remedy: Pipeline & Storage Tanks Integrity Assessment WorkshopDocument45 paginiD/Stream Pipeline Corrosion Defects & Remedy: Pipeline & Storage Tanks Integrity Assessment Workshopshakirhamid6687Încă nu există evaluări

- ASME B31.4 Section Committee InterpretationsDocument93 paginiASME B31.4 Section Committee InterpretationsmaninventorÎncă nu există evaluări

- Pump Definition Types Advantages Disadvantages Applications With PDFDocument8 paginiPump Definition Types Advantages Disadvantages Applications With PDFSatyam BÎncă nu există evaluări

- Flexible Steel Pipe Applications: Dana FraserDocument15 paginiFlexible Steel Pipe Applications: Dana FraseraishahÎncă nu există evaluări

- PiggingDocument5 paginiPiggingDendi AriyonoÎncă nu există evaluări

- Effect of Metallurgy On Pygas Fouling PDFDocument6 paginiEffect of Metallurgy On Pygas Fouling PDFstreamtÎncă nu există evaluări

- Reinforced Branch Connection Set-On TypeDocument3 paginiReinforced Branch Connection Set-On Typeedgar paglinawanÎncă nu există evaluări

- Fatigue Performance of Sour Deepwater Riser WeldsDocument21 paginiFatigue Performance of Sour Deepwater Riser WeldsshervinyÎncă nu există evaluări

- INGAADocument108 paginiINGAAEric NusinowÎncă nu există evaluări

- Investigation of Weld Repair Without Post-Weld Heat Treatment For P91 PDFDocument10 paginiInvestigation of Weld Repair Without Post-Weld Heat Treatment For P91 PDF55312714Încă nu există evaluări

- Gas Pipeline Failures: by Failure Analysis Group WRD, CmrdiDocument44 paginiGas Pipeline Failures: by Failure Analysis Group WRD, Cmrdiروشان فاطمة روشانÎncă nu există evaluări

- Failure Analysis of Fifth Wheel Coupling SystemDocument7 paginiFailure Analysis of Fifth Wheel Coupling SystemAndri OdeÎncă nu există evaluări

- Hottappingrequirement1 160722152313 PDFDocument94 paginiHottappingrequirement1 160722152313 PDFadel100% (1)

- Simon Frost 2011Document23 paginiSimon Frost 2011bluemasÎncă nu există evaluări

- Pipelines Leak RepairDocument6 paginiPipelines Leak Repairathar_abbas_1100% (2)

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 paginiEnbridge Pipeline Repair Workplan Welding PDFquiron2014Încă nu există evaluări

- White Paper RX Large Dia PipeDocument15 paginiWhite Paper RX Large Dia Pipetirtha sarmaÎncă nu există evaluări

- Full Encirclement Steel Reinforcing Sleeves For PipingDocument4 paginiFull Encirclement Steel Reinforcing Sleeves For PipinglaythÎncă nu există evaluări

- Pipeline Maintenance Inspection & RepairDocument49 paginiPipeline Maintenance Inspection & RepairIrsyad Rosyidi100% (1)

- PipeDocument47 paginiPipemohanÎncă nu există evaluări

- CRA Pipes: Corrosion TestDocument2 paginiCRA Pipes: Corrosion TestNavafÎncă nu există evaluări

- Bend Pipes (1996 N3.2)Document2 paginiBend Pipes (1996 N3.2)dmitos100% (1)

- 07 - Ajie Manggala Putra (TML) - 26in BOC - BOD Pipeline ReplacementDocument8 pagini07 - Ajie Manggala Putra (TML) - 26in BOC - BOD Pipeline ReplacementSamuel JohnÎncă nu există evaluări

- Pipeline RepairsDocument44 paginiPipeline RepairsMohamad PizulÎncă nu există evaluări

- Standards Australia - IsO 21500 Guide To Project ManagementDocument2 paginiStandards Australia - IsO 21500 Guide To Project ManagementJosé Fabricio Figueiredo CainelliÎncă nu există evaluări

- CLASS 11175: DEP 31.38.01.12-Gen Class 11175, Rev. I Page 1 of 14Document14 paginiCLASS 11175: DEP 31.38.01.12-Gen Class 11175, Rev. I Page 1 of 14SaguesoÎncă nu există evaluări

- Asset Integrity Management A Complete Guide - 2020 EditionDe la EverandAsset Integrity Management A Complete Guide - 2020 EditionÎncă nu există evaluări

- Series 1500 Cooling Tower SpecificationDocument9 paginiSeries 1500 Cooling Tower SpecificationLorenaÎncă nu există evaluări

- 4802-w2 Concrete Anchor Block - Installation DetailsDocument2 pagini4802-w2 Concrete Anchor Block - Installation DetailsLorenaÎncă nu există evaluări

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 pagină4910-w1 Engineering Guideline For Flexible Metal HoseLorenaÎncă nu există evaluări

- 4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSDocument2 pagini4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSLorenaÎncă nu există evaluări

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocument1 pagină4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaÎncă nu există evaluări

- 4760-w0 Typical Stream or Ditch Pipeline UndercrossingDocument1 pagină4760-w0 Typical Stream or Ditch Pipeline UndercrossingLorena100% (1)

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDocument1 pagină4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorenaÎncă nu există evaluări

- 4776 Subsea Pipeline CrossingDocument4 pagini4776 Subsea Pipeline CrossingLorenaÎncă nu există evaluări

- 4737-w2 Typical Casing Vent Without Junction Box AssemblyDocument1 pagină4737-w2 Typical Casing Vent Without Junction Box AssemblyLorenaÎncă nu există evaluări

- 4758-w0 Restoration of TerracesDocument1 pagină4758-w0 Restoration of TerracesLorenaÎncă nu există evaluări

- 4780-w8 Selection and Design of Branch Connections and ReinforcementDocument8 pagini4780-w8 Selection and Design of Branch Connections and ReinforcementLorenaÎncă nu există evaluări

- 4861 Gathering System - Type 10 Drip For 4,6 & 8 Gathering Lines-Dwg Available From Eng. RecordsDocument2 pagini4861 Gathering System - Type 10 Drip For 4,6 & 8 Gathering Lines-Dwg Available From Eng. RecordsLorenaÎncă nu există evaluări

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 pagină4910-w1 Engineering Guideline For Flexible Metal HoseLorenaÎncă nu există evaluări

- 4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)Document3 pagini4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)LorenaÎncă nu există evaluări

- Aquapump Industries: Single Phase Dmh1 MonoblockDocument8 paginiAquapump Industries: Single Phase Dmh1 MonoblockVickyÎncă nu există evaluări

- MS-01-179 Tubing Tools and AccessoriesDocument12 paginiMS-01-179 Tubing Tools and AccessoriesJacques StrappeÎncă nu există evaluări

- Hydrophore Set (Mectron Engineering)Document2 paginiHydrophore Set (Mectron Engineering)KelvinÎncă nu există evaluări

- Blucher VamzdziaiDocument32 paginiBlucher VamzdziaigmlopesÎncă nu există evaluări

- Status Document Spec, RFQ, DatasheetDocument12 paginiStatus Document Spec, RFQ, DatasheetBoy AlfredoÎncă nu există evaluări

- Road Signs: 1. - IND-2007 0137 CZ - EN - 20070322 - PROJETDocument19 paginiRoad Signs: 1. - IND-2007 0137 CZ - EN - 20070322 - PROJETNtemou EleniÎncă nu există evaluări

- Samsung GI PJT DB41 PDFDocument351 paginiSamsung GI PJT DB41 PDFNuno Costa67% (3)

- Hydroforming PDFDocument5 paginiHydroforming PDFdramiltÎncă nu există evaluări

- Sabp A 036Document40 paginiSabp A 036RJSQ100% (2)

- Inverted SiphonsDocument6 paginiInverted SiphonsRaju ShresthaÎncă nu există evaluări

- Asme Sec Viii D1 C PT UhaDocument15 paginiAsme Sec Viii D1 C PT Uhakcp1986Încă nu există evaluări

- Table 6 - Mechanical Products PDFDocument18 paginiTable 6 - Mechanical Products PDFSharad NanapureÎncă nu există evaluări

- As 4118 2 1 1995 Fire Sprinkler Systems Piping General PDFDocument7 paginiAs 4118 2 1 1995 Fire Sprinkler Systems Piping General PDFMarwaÎncă nu există evaluări

- Hangzhou Marine Gearbox ManualDocument68 paginiHangzhou Marine Gearbox Manualprojash0% (1)

- Efficient Pneumatic ConveyingDocument14 paginiEfficient Pneumatic Conveying설동하100% (2)

- D3350Document7 paginiD3350Luis Fernando Morales100% (1)

- Prssurised Flushing SystemDocument19 paginiPrssurised Flushing SystemjeiohkotaÎncă nu există evaluări

- Approaches and MethodologyDocument10 paginiApproaches and MethodologyRobins MsowoyaÎncă nu există evaluări

- Section 8 - Cooling System - Group 08Document31 paginiSection 8 - Cooling System - Group 08Miodrag HuberÎncă nu există evaluări

- Installation Procedure EQOBRUSH For Heat Exchangers and CondensersDocument16 paginiInstallation Procedure EQOBRUSH For Heat Exchangers and CondensersWatco GroupÎncă nu există evaluări

- Complaint CodesDocument35 paginiComplaint CodesRajneesh JaswalÎncă nu există evaluări

- SPM Flow Line Safety Restraint System FSR Installation Guide PDFDocument42 paginiSPM Flow Line Safety Restraint System FSR Installation Guide PDFYounes MakÎncă nu există evaluări

- TCS K 10001 R0 PDFDocument38 paginiTCS K 10001 R0 PDFShahrukh AnsariÎncă nu există evaluări

- Joe Cell Treatment WaterDocument14 paginiJoe Cell Treatment WaterRuddyMartini100% (1)

- Heat Pipe - Scientific AmericanDocument10 paginiHeat Pipe - Scientific AmericanEduardo Ocampo HernandezÎncă nu există evaluări

- Reading Plumbing PlansDocument12 paginiReading Plumbing Planssolupa2000100% (1)

- Crane Deming A40Document54 paginiCrane Deming A40Mark BukerÎncă nu există evaluări

- Id Number Title Year OrganizationDocument17 paginiId Number Title Year OrganizationJ T Mendonça SantosÎncă nu există evaluări

- 1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pagini1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh Binh0% (1)

- 1 - Jacketed PipingDocument6 pagini1 - Jacketed PipingJorge Hugo CorreaÎncă nu există evaluări