Documente Academic

Documente Profesional

Documente Cultură

Presentation 1

Încărcat de

Thalapathy VenkatDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Presentation 1

Încărcat de

Thalapathy VenkatDrepturi de autor:

Formate disponibile

4/13/2016

Whatisasupplychainnetwork?

Supplychainsandsupplynetworksbothdescribetheflowand

movementofmaterials&information,bylinkingorganisationstogether

toservetheendcustomer

A SupplyChainNetwork(SCN) isanevolutionofthebasic supplychain.

Duetorapidtechnologicaladvancement,organisationswithabasic

supplychaincandevelopthischainintoamorecomplexstructure

involvingahigherlevelofinterdependenceandconnectivitybetween

moreorganisations,thisconstitutesasupplychainnetwork

Example:SupplyChain

Example:SupplyChainNetwork

Theabovediagramisanexampleofasimplifiedsupplychain;thesupplychain

showsthemovementofmaterialflowfromtheApplefarmrightthroughthe

productionprocesstotheendusers.

Theaboveexampledemonstratesasimplified

versionofasupplychainnetworkofanAppleJuice

organisation.Theorganisationwillhaveanupstream

networkandadownstreamnetwork.

Organisationsarelinkedviatwotypesofflows:

Togetacompletepictureofanorganisationssupply

chainnetwork;information&materialflowshould

bemapped. Inefficiencycanthenbelocatedand

removed.

Materialflow: Isthemovementofgoodsfromraw

primarygoods(suchasWool,TreesandCoaletc.)to

completegoods(TVs,RadiosandComputers)that

aretobedeliveredtothefinalcustomer.

Informationflow: Isthedemandfromtheend

customertoprecedingorganisationsinthenetwork.

DistributionNetwork

Adistributionnetworkisaninterrelatedarrangementofpeople,storage

facilitiesandtransportationsystemsthatmovesgoodsandservicesfrom

producerstoconsumers.

Adistributionnetworkisthesystemacompanyusestogetproducts

fromthemanufacturertotheretailer.Afastandreliabledistribution

networkisessentialtoasuccessfulbusinessbecausecustomersmustbe

abletogetproductsandserviceswhentheywantthem.

4/13/2016

TheRoleofDistribution

intheSupplyChain

FactorsInfluencing

DistributionNetworkDesign

Distribution:thestepstakentomoveandstorea

productfromthesupplierstagetothecustomer

stageinasupplychain

Distributiondirectlyaffectscostandthecustomer

experienceandthereforedrivesprofitability

Choiceofdistributionnetworkcanachievesupply

chainobjectivesfromlowcosttohigh

responsiveness

Examples:WalMart,Dell,Proctor&Gamble,

Grainger

Distributionnetworkperformanceevaluatedalong

twodimensionsatthehighestlevel:

Customerneedsthataremet

Costofmeetingcustomerneeds

Distributionnetworkdesignoptionsmusttherefore

becomparedaccordingtotheirimpactoncustomer

serviceandthecosttoprovidethislevelofservice

FactorsInfluencing

DistributionNetworkDesign

ServiceandNumberofFacilities

Elementsofcustomerserviceinfluencedbynetwork

structure:

Responsetime

Productvariety

Productavailability

Customerexperience

Ordervisibility

Returnability

Numberof

Facilities

Supplychaincostsaffectedbynetworkstructure:

Inventories

Transportation

Facilitiesandhandling

Information

ResponseTime

TheCostResponseTimeFrontier

High

InventoryCostsandNumber

ofFacilities

Inventory

Costs

LocalFG

Mix

RegionalFG

LocalWIP

Cost

CentralFG

CentralWIP

CentralRawMaterialandCustomproduction

Customproductionwithrawmaterialatsuppliers

Low

Low

ResponseTime

High

Numberoffacilities

4/13/2016

TransportationCostsand

NumberofFacilities

FacilityCostsandNumber

ofFacilities

Transportation

Costs

Facility

Costs

Numberoffacilities

Numberoffacilities

Variation in Logistics Costs and Response

Time with Number of Facilities

Total Costs Related to

Number of Facilities

TotalCosts

TotalCosts

ResponseTime

TotalLogisticsCosts

Facilities

Inventory

Transportation

NumberofFacilities

DesignsforaDistributionNetwork

ManufacturerStoragewithDirectShipping

ManufacturerStoragewithDirectShippingandIn

TransitMerge

DistributorStoragewithCarrierDelivery

DistributorStoragewithLastMileDelivery

ManufacturerorDistributorStoragewithConsumer

Pickup

RetailStoragewithConsumerPickup

NumberofFacilities

ManufacturerStoragewithDirectShipping

(DropShipping)

Mfr

Retailer

Customer

ProductFlow

InformationFlow

4/13/2016

PerformanceCharacteristicsofManufacturerStoragewithDirectShipping

Network

CostFactor

Performance

Inventory

Lowercostsbecauseofaggregation.Benefitsofaggregation arehighestforlow

demand,highvalueitems.Benefitsareverylargeifproductcustomizationcanbe

postponedatemanufacturer.

Transportation

Facilitiesandhandling

Information

Highertransportationcostsbecauseofincreaseddistance anddisaggregate

shipping.

Lowerfacilitycostsbecauseofaggregation.Somesavingonhandlingcostsif

manufacturercanmanagesmallshipmentsorshipfromproductionline.

ServiceFactor

Performance

ResponseTime

Longresponsetimeofonetotwo weeksbecauseofincreaseddistance

andtwostagesfororderprocessing.Responsetimemayvaryby

product,thuscomplicatingreceiving.

ProductVariety

Easytoprovideaveryhighlevelofvariety.

ProductAvailability

Easytoprovide ahighlevelofproductavailabilitybecauseof

aggregationatmanufacturer.

CustomerExperience

Goodin termsofhomedeliverybutcansufferiforderfromseveral

manufacturersissentaspartialshipments.

Timetomarket

Fast,withtheproduct availableassoonasthefirstunitisproduced.

Ordervisibility

Moredifficultbutalsomoreimportantfromacustomerservice

perspective.

Returnability

Expensiveanddifficulttoimplement.

Significant investmentininformationinfrastructuretointegratemanufacturerand

retailer.

PerformanceCharacteristicsofInTransitMerge

IntransitmergeNetwork

CostFactor

Factories

Intransitmerge

ByCarrier

Retailer

Customers

Performance

Inventory

Similartodropshipping.

Transportation

Somewhatlowertransportationcoststhandropshipping.

Facilitiesandhandling

Handlingcostshigherthandropshippingatcarrier;receivingcosts

loweratcustomer.

Information

Investment issomewhathigherthanfordropshipping.

ServiceFactor

Performance

ResponseTime

Similar todropshipping;maybemarginallyhigher.

Productvariety

Similar todropshipping.

ProductAvailability

Similartodropshipping.

Customerexperience

Betterthandropshippingbecauseasingleorderhastobereceived.

Customers

ProductFlow

InformationFlow

DistributorStoragewithCarrierDelivery

Factories

DistributorStorage

Timetomarket

Similartodropshipping.

Ordervisibility

Similartodropshipping.

Returnability

Similartodropshipping.

PerformanceCharacteristicsofDistributorstoragewithCarrierDelivery

CostFactor

Performance

Inventory

Higher thanmanufacturerstorage.Differenceisnotlargeforfastermoving

items.

Transportation

Lower thanmanufacturerstorage.Reductionishighestforfastermoving

items.

Facilities andhandling

Somewhat higherthanmanufacturerstorage.Thedifferencecanbelargefor

veryslowmovingitems.

Information

Simpler infrastructurecomparedtomanufacturerstorage.

ServiceFactor

Performance

Response Time

Faster thanmanufacturerstorage.

Product variety

Lower thanmanufacturerstorage.

Productavailability

Higher costtoprovidethesamelevelofavailabilityasmanufacturerstorage.

Customer experience

Better thanmanufacturerstoragewithdropshipping.

Time tomarket

Higher thanmanufacturerstorage.

Order visibility

Easier thanmanufacturerstorage.

Returnability

Easier thanmanufacturerstorage

Customers

ProductFlow

InformationFlow

https://www.facebook.com/ialwaysthinkprettythings

4/13/2016

PerformanceCharacteristicsofDistributorStoragewithLastMileDelivery

DistributorStoragewithLastMileDelivery

CostFactor

Performance

Inventory

Higherthandistributorstoragewithpackagecarrierdelivery.

Transportation

Veryhighcostgivenminimal scaleeconomies.Higherthanany

otherdistributionoption.

Facilitiesandhandling

Facilitycostshigherthanmanufacturerstorageordistributor

storagewith packagecarrierdelivery,butlowerthanachainof

retailstores.

Information

Similartodistributorstoragewithpackagecarrierdelivery.

Factories

Distributor/

Retailer

Warehouse

Customers

ProductFlow

InformationFlow

Servicefactor

Performance

Responsetime

Veryquick.Samedaytonextdaydelivery.

Productvariety

Somewhatlessthandistributorstoragewithpackagecarrierdelivery

butlargerthanretailstores.

Productavailability

Moreexpensive toprovideavailabilitythananyotheroptionexcept

retailstores.

Customerexperience

Verygood,particularlyforbulkyitems.

Timetomarket

Slightlyhigherthandistributorstoragewithpackagecarrierdelivery.

Ordertraceability

Lessofanissueand easiertoimplementthanmanufacturerstorageor

distributorstoragewithpackagecarrierdelivery.

Returnability

Easiertoimplementthanotheroptions.Harderandmoreexpensive

thanaretailnetwork.

ManufacturerorDistributorWarehouseStoragewithConsumer

Pickup

CustomerFlow

ProductFlow

Retailer

Information

Flow

Factories

CrossDockDC

PickupSites

Customers

PerformanceCharacteristicsofNetworkwithConsumerPickupsites

CostFactor

Performance

Inventory

Can matchanyotheroption,dependingonthelocationofinventory.

Transportation

Lower thantheuseofpackagecarriers,especiallyifusinganexisting

deliverynetwork.

Facilities andhandling

Facility costscanbeveryhighifnewfacilitieshavetobebuilt.Costsare

lowerifexistingfacilitiesareused.Theincreaseinhandlingcostatthe

pickupsitecanbesignificant.

Information

Service Factor

Performance

Responsetime

Similartopackagecarrierdelivery withmanufacturerordistributorstorage.

Samedaydeliverypossibleforitemsstoredlocallyatpickupsites.

Productvariety

Similartoother manufacturerordistributorstorageoptions.

Product availability

Similartoother manufacturerordistributorstorageoptions.

Customer experience

Lowerthanother optionsbecauseofthelackofhomedelivery.Inareaswith

highdensityofpopulation,lossofconveniencemaybesmall.

Time tomarket

Similar tomanufacturerstorageoptions.

Order visibility

Difficult butessential.

Returnability

Somewhat easiergiventhatpickuplocationcanhandlereturns.

Significant investmentininfrastructurerequired.

4/13/2016

FrameworkforNetworkdesignDecisions

CompetitiveStrategy

InternalConstraints

Capital,GrowthStrategy

ProductionTechnologies

Cost,scale/scopeimpact

Competitive

Environment

AggregateFactorsand

Logisticscosts

Phase1

SC

Strategy

FrameworkforNetworkDesignDecisions

Phase I: Design a Supply Chain Strategy Starts with a clear definition of

the firms competitive strategy as the set of customer needs that the

supply chain aims to satisfy. Managers must forecast the likely evolution

of global competition and whether competitors in each market will be

local or global players. Constraints on available capital and whether

growth will be accomplished by acquiring existing facilities, building new

facilities or partnering.

GlobalCompetition

Tariffs&TaxIncentives

Phase2

Reg

Facility

Conifig

Phase3

Desirable

sites

RegionalDemand

Size,growth,

homogeneity

Political,ExchangeRate

andDemandRisk

AvailableInfra

structure

ProductionMethods

Factorcosts

Phase4

LogisticsCost

Location

Choices

https://www.facebook.com/ialwaysthinkprettythings

Phase II: Define the Regional Facility Configuration Forecast of the

demand by country. Include a measure of the size of the demand as well

as a determination of whether the customer requirements are

homogenous or variable across different countries. Homogenous

requirements favor large consolidated facilities whereas requirements that

vary across countries favor smaller, localized facilities. If economies of

scale are significant in reducing costs, it may be better to have few

facilities serving many markets. If economies of scale are not significant , it

may be better for each market to have its own facility. They must identify

demand risk, exchange rate risk, political risk, tax incentives and regional

tariffs for local production. They must also decide whether a facility needs

to be located close to or far from a competitors facility.

SiteSelection:WheretoLocate

Modelsforfacilitylocationandcapacity

allocation

Infrequentbutimportant

Goalistomaximizetheoverallprofitabilitywhileprovidingcustomerswith

appropriateresponsiveness.

beingintherightplaceatthe

righttime

Revenuescomefromsaleofproducts,whereascostarisesfromfacilities,labor,

transportation,materialandinventories.

Amanagermustconsidermanytradeoffsduringnetworkdesign.Ex:building

manyfacilitiesreducestransportationcostandprovidesfastresponsetime,butit

increasesthefacilityandinventorycost.

Managersusenetworkdesignmodelsin2situations:

1. Todecideonlocationswherefacilitieswillbeestablishedandthecapacity

tobeassignedtoeachfacility.(longterm)

2. Modelsareusedtoassigncurrentdemandtotheavailablefacilitiesand

identifylanesalongwhichproductwillbetransported.(annualbasis)

13April2016

Phase III: Select a Set of Desirable Potential Sites Hard infrastructure

requirements include the availability of suppliers, transportation services,

communication, utilities and warehousing infrastructure. Soft infrastructure

facilities include the availability of skilled workforce, workforce turnover

and the community receptivity to business and industry.

Phase IV: Location Choices Maximize total profits taking into account the

expected margin and demand in each market, various logistics and facility

costs, and the taxes and tariffs at each location.

35

Mustconsiderotherfactors,

especiallyfinancialconsiderations

Locationdecisionsmademore

oftenforserviceoperationsthan

manufacturingfacilities

Locationcriteriaforservice

accesstocustomers

Copyright 2011 John Wiley & Sons, Inc.

Locationcriteriafor

manufacturingfacility

natureoflaborforce

laborcosts

proximitytosuppliersandmarkets

distributionandtransportationcosts

energyavailabilityandcost

communityinfrastructure

qualityoflifeincommunity

governmentregulationsandtaxes

Supplement 7-36

4/13/2016

NetworkOptimizationModels

DemandAllocationModel

Allocatingdemandtoproductionfacilities

Locatingfacilitiesandallocatingcapacity

Whichmarketisservedby

whichplant?

Whichsupplysourcesareused

byaplant?

xij =Quantityshippedfromplant

siteitocustomerj

KeyCosts:

Fixedfacilitycost

Transportationcost

Productioncost

Inventorycost

Coordinationcost

n m

Min cij xij

i 1 j 1

s.t.

n

xij D j

i 1

m

xij K i

j 1

xij 0

Whichplantstoestablish?Howtoconfigurethenetwork?

GlobalSupplyChainFactors

PlantLocationwithMultipleSourcing

yi =1ifplantislocated

atsitei,0otherwise

xij =Quantityshipped

fromplantsiteito

customerj

n m

i 1

i 1 j 1

Min f i y i cij xij

s.t.

n

xij D j

i 1

n

xij K i y i

j 1

Governmentstability

Governmentregulations

Political&economicsystems

Economicstability&growth

Exchangerates

Culture

Export/importregulations,duties

&tariffs

Rawmaterialavailability

y i k ; y i {0,1}

Climate

Number&proximityof

suppliers

Transportation&distribution

system

Laborcost&education

Availabletechnology

Commercialtravel

Technicalexpertise

Crossbordertraderegulations

Grouptradeagreements

i 1

Supplement 7-40

LocationIncentives

LocationAnalysisTechniques

Tax credits

Relaxed government regulation

Job training

Infrastructure improvement

Money

Location factor rating

Center-of-gravity

Load-distance

Supplement 7-41

Supplement 7-42

4/13/2016

LocationFactorRating

LocationFactorRating

Inthe locationfactorrating system,factorsthatareimportantinthe

locationdecisionareidentified.Eachfactorisweightedfrom0to

1.00toprioritizethefactorandreflectitsimportance.Asubjective

scoreisassigned(usuallybetween0and100)toeachfactorbasedon

itsattractivenesscomparedwithotherlocations,andtheweighted

scoresaresummed.Decisionstypicallywillnotbemadebasedsolely

ontheseratings,buttheyprovideagoodwaytoorganizeandrank

factors.

Identify important factors

Weight factors (0.00 - 1.00)

Subjectively score each factor (0 - 100)

Sum weighted scores

Supplement 7-44

LocationFactorRating

LocationFactorRating

SCORES (0 TO 100)

LOCATION FACTOR

Labor pool and climate

Proximity to suppliers

Wage rates

Community environment

Proximity to customers

Shipping modes

Air service

WEIGHTED SCORES

WEIGHT

Site 1

Site 2

Site 3

Site 1

Site 2

Site 3

.30

.20

.15

.15

.10

.05

.05

80

100

60

75

65

85

50

65

91

95

80

90

92

65

90

75

72

80

95

65

90

24.00

20.00

9.00

11.25

6.50

4.25

2.50

77.50

19.50

18.20

14.25

12.00

9.00

4.60

3.25

80.80

27.00

15.00

10.80

12.00

9.50

3.25

4.50

82.05

Site 3 has the

highest factor rating

Weighted Score for Labor pool and climate for

Site 1 = (0.30)(80) = 24

Supplement 7-45

CenterofGravityTechnique

Supplement 7-46

CenterofGravityTechnique

Locate facility at center of movement in

geographic area

Based on weight and distance traveled;

establishes grid-map of area

Identify coordinates and weights shipped for

each location

Supplement 7-47

Ingeneral,transportationcostsareafunctionofdistance,

weight,andtime.

The centerofgravity, or weightcenter, techniqueisa

quantitativemethodforlocatingafacilitysuchasawarehouse

atthecenter ofmovementinageographicareabasedon

weightanddistance.

Thismethodidentifiesasetofcoordinatesdesignatinga

centrallocationonamaprelativetoallotherlocations.

Supplement 7-48

4/13/2016

CenterofGravityTechnique

GridMapCoordinates

y

2 (x2, y2), W2

y2

x=

3 (x3, y3), W3

y3

x1

y=

x2

x3

Wi

i=1

1 (x1, y1), W1

yiWi

i=1

y1

xiWi

i=1

Wi

i=1

where,

x, y = coordinates of new facility at

center of gravity

xi, yi = coordinates of existing facility i

Wi = annual weight shipped from

facility i

TheBurgerDoodlerestaurantchainpurchases

ingredientsfromfourdifferentfoodsuppliers.The

companywantstoconstructanewcentral

distributioncenter toprocessandpackagethe

ingredientsbeforeshippingthemtotheirvarious

restaurants.Thesupplierstransportingredient

itemsin40foottrucktrailers,eachwithacapacity

of38,000pounds.Thelocationsofthefour

suppliers,A,B,C,andD,andtheannualnumberof

trailerloadsthatwillbetransportedtothe

distributioncenter areshowninthefollowing

figure:

Supplement 7-49

CenterofGravityTechnique

Supplement 7-50

CenterofGravityTechnique

y

700

600

(135)

500

Miles

x

y

W

C

(105)

A

200

200

75

B

100

500

105

C

250

600

135

D

500

300

60

xW

i i

x=

i=1

n

(200)(75) + (100)(105) + (250)(135) + (500)(60)

= 238

75 + 105 + 135 + 60

(200)(75) + (500)(105) + (600)(135) + (300)(60)

= 444

75 + 105 + 135 + 60

W

i

i=1

400

300

200

(60)

yW

i i

(75)

y=

i=1

n

W

i

100

i=1

100 200 300 400 500 600 700 x

Miles

Supplement 7-51

LoadDistanceTechnique

CenterofGravityTechnique

y

700

600

Miles

500

C

(135)

B

(105)

400

300

200

x

y

W

A

200

200

75

B

100

500

105

C

250

600

135

D

500

300

60

Center of gravity (238, 444)

D

(60)

(75)

100

0

Supplement 7-52

100 200 300 400 500 600 700 x

Miles

Supplement 7-53

Avariationofthecenterofgravitymethodfordetermining

thecoordinatesofafacilitylocationisthe loaddistance

technique. Inthismethod,asinglesetoflocation

coordinatesisnotidentified.Instead,variouslocationsare

evaluatedusingaloaddistancevaluethatisameasureof

weightanddistance.

Theloaddistancetechniqueisappliedbycomputingaload

distancevalueforeachpotentialfacilitylocation.The

implicationisthatthelocationwiththelowestvaluewould

resultintheminimumtransportationcostandthuswouldbe

preferable.

Copyright 2011 John Wiley & Sons, Inc.

Supplement 7-54

4/13/2016

LoadDistanceTechnique

LoadDistanceCalculations

n

Compute(LoadxDistance)foreachsite

Choosesitewithlowest(LoadxDistance)

Distancecanbeactualorstraightline

ld

LD =

i=1

where,

LD =

load-distance value

li =

load expressed as a weight, number of trips or units

being shipped from proposed site and location i

distance between proposed site and location i

di

di

(xi - x)2 + (yi - y)2

where,

(x,y) = coordinates of proposed site

(xi , yi) = coordinates of existing facility

Copyright 2011 John Wiley & Sons, Inc.

Supplement 7-55

LoadDistance

LoadDistance

Potential Sites

Site

X

1

360

2

420

3

250

Y

180

450

400

A

200

200

75

X

Y

Wt

Suppliers

B

C

100

250

500

600

105

135

Site 2 dA = 333

D

500

300

60

dB =

(xA - x1)2 + (yA - y1)2

)2

(xB - x1 + (yB - y1

dC = 434.2

)2

dD = 269.3

ld

i

i=1

(200-360)2 + (200-180)2 = 161.2

(100-360)2

Compute load-distance

LD =

Compute distance from each site to each supplier

Site 1 dA =

dB = 323.9 dC = 226.7 dD = 170

Site 3 dA = 206.2 dB = 180.3 dC = 200

(500-180)2

= 412.3

dD = 184.4

Site 1 = (75)(161.2) + (105)(412.3) + (135)(434.2) + (60)(434.4) = 125,063

Site 2 = (75)(333) + (105)(323.9) + (135)(226.7) + (60)(170) = 99,789

Site 3 = (75)(206.2) + (105)(180.3) + (135)(200) + (60)(269.3) = 77,555*

* Choose site 3

ImpactofUncertaintyinNetworkDesign

Supplychainnetworkdesigndecisionsinclude

Facilitylocation(numberoffacilities)

Capacityallocation(sizeofeachfacility)

Marketandsupplyallocation(distribution)

ImpactofUncertaintyinNetworkDesign

Hence,itissuggestedthatwhenwemakenetworkdesigndecisions,

we mustconsiderbothsupplyanddemanduncertaintyandthe

financialuncertainty

Ifenoughcareisnottaken,theimpactof uncertaintywillmakeit

operationaltobevarycostlyandcomplex.

These decisions, once made, cannot be changed easily

in the short-term, they remain in place for several years

Demand, prices, exchange rates, and the competitive

market change constantly

A decision that looks very good under the current

environment may be quite poor if the situation changes

10

4/13/2016

EvaluatingNetworkDesignDecisionsUsing

DecisionTrees

ImpactofUncertaintyinNetworkDesign

Supplier

Manufacturer

Distributor

Retailer

Customer

Building flexibility into supply chain operations allows

the supply chain to deal with uncertainty more

effectively

Amanagermustmakemanydifferentdecisionswhen

designingasupplychainnetwork

Manyoftheminvolveachoicebetweenalongterm(orless

flexible)optionandashortterm(ormoreflexible)option

Ifuncertaintyisignored,thelongtermoptionwillalmost

alwaysbeselectedbecauseitistypicallycheaper

Suchadecisioncaneventuallyhurtthefirm,however,

becauseactualfuturepricesordemandmaybedifferent

fromwhatwasforecastedatthetimeofthedecision

Adecisiontree isagraphicdevicethatcanbeusedto

evaluatedecisionsunderuncertainty

662

DecisionTrees

DecisionTrees

Adecisiontreeisagraphicdeviceusedtoevaluate

decisionsunderuncertainty

1.

2.

3.

4.

5.

6.

Identifythedurationofeachperiodandthenumberoftime

periodsT tobeevaluated

Identifythefactorsassociatedwiththeuncertainty

Identifytherepresentationofuncertainty

Identifytheperiodicdiscountratek

Representthetree,identifyingallstatesandtransition

probabilities

StartingatperiodT,workbacktoperiod0identifytheexpected

cashflowsateachstep

DecisionTreeMethodology

1. Identifythedurationofeachperiod(month,quarter,etc.)and

thenumberofperiodsToverwhichthedecisionistobe

evaluated.

2. Identifyfactorssuchasdemand,price,andexchangerate,whose

fluctuationwillbeconsideredoverthenextTperiods.

3. Identifyrepresentationsofuncertaintyforeachfactor;thatis,

determinewhatdistributiontousetomodeltheuncertainty.

4. Identifytheperiodicdiscountratekforeachperiod.

5. Representthedecisiontreewithdefinedstatesineachperiod,as

wellasthetransitionprobabilitiesbetweenstatesinsuccessive

periods.

6. StartingatperiodT,workbacktoperiod0,identifyingthe

optimaldecisionandtheexpectedcashflowsateachstep.

Expectedcashflowsateachstateinagivenperiodshouldbe

discountedbackwhenincludedinthepreviousperiod.

By

Pon Vivek Narayan

Venkatesh

Regan

11

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Resume (Sample)Document11 paginiResume (Sample)Steven ChoÎncă nu există evaluări

- Account Statement: Thenmozhi V No 115 Justice V Ramasamy Street Kamaraj Avenue Adyar ChennaiDocument1 paginăAccount Statement: Thenmozhi V No 115 Justice V Ramasamy Street Kamaraj Avenue Adyar ChennaiThalapathy VenkatÎncă nu există evaluări

- Impact of Individual and Organisational Characteristics On Risk Analysis in Strategic Investment DecisionsDocument1 paginăImpact of Individual and Organisational Characteristics On Risk Analysis in Strategic Investment DecisionsThalapathy VenkatÎncă nu există evaluări

- Account Statement: Thenmozhi V No 115 Justice V Ramasamy Street Kamaraj Avenue Adyar ChennaiDocument1 paginăAccount Statement: Thenmozhi V No 115 Justice V Ramasamy Street Kamaraj Avenue Adyar ChennaiThalapathy VenkatÎncă nu există evaluări

- Voucher NH2003069007378Document3 paginiVoucher NH2003069007378Thalapathy VenkatÎncă nu există evaluări

- Account Statement: Thenmozhi V No 115 Justice V Ramasamy Street Kamaraj Avenue Adyar ChennaiDocument1 paginăAccount Statement: Thenmozhi V No 115 Justice V Ramasamy Street Kamaraj Avenue Adyar ChennaiThalapathy VenkatÎncă nu există evaluări

- Gokila (0 0)Document4 paginiGokila (0 0)Thalapathy VenkatÎncă nu există evaluări

- A Study On Investment Preference and Behaviour of Individual Investors in Coimbatore CityDocument5 paginiA Study On Investment Preference and Behaviour of Individual Investors in Coimbatore CityBONFRING0% (1)

- Excel Stats Nicar2013Document6 paginiExcel Stats Nicar2013yaktamerÎncă nu există evaluări

- Pack 1Document9 paginiPack 1Thalapathy VenkatÎncă nu există evaluări

- Project On Investment in IndiaDocument58 paginiProject On Investment in IndiaRahul MalikÎncă nu există evaluări

- All of Himachal in 11 Days: Search 10 NightsDocument12 paginiAll of Himachal in 11 Days: Search 10 NightsThalapathy VenkatÎncă nu există evaluări

- IRCTC Ticekt PDFDocument1 paginăIRCTC Ticekt PDFThalapathy VenkatÎncă nu există evaluări

- CorporateDocument63 paginiCorporateThalapathy VenkatÎncă nu există evaluări

- 1organization Chart As On 20.11.2015 Ministry of Ayush: MOS (Independent Charge)Document3 pagini1organization Chart As On 20.11.2015 Ministry of Ayush: MOS (Independent Charge)Thalapathy VenkatÎncă nu există evaluări

- IRCTC Ticekt PDFDocument1 paginăIRCTC Ticekt PDFThalapathy VenkatÎncă nu există evaluări

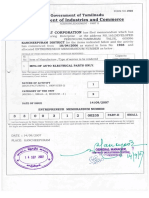

- MSME CertificateDocument1 paginăMSME CertificateThalapathy VenkatÎncă nu există evaluări

- 97967ISO & ISO-TS CertificateDocument3 pagini97967ISO & ISO-TS CertificateThalapathy VenkatÎncă nu există evaluări

- BookingDocument1 paginăBookingThalapathy VenkatÎncă nu există evaluări

- Gravity and Low Pressure Die CastingDocument10 paginiGravity and Low Pressure Die CastingtumoyeÎncă nu există evaluări

- Annual Report 2015Document210 paginiAnnual Report 2015Thalapathy VenkatÎncă nu există evaluări

- Hotel BillsDocument4 paginiHotel BillsThalapathy VenkatÎncă nu există evaluări

- Annual Report 2015Document210 paginiAnnual Report 2015Thalapathy VenkatÎncă nu există evaluări

- Train TicketDocument1 paginăTrain TicketThalapathy VenkatÎncă nu există evaluări

- Ifbm 0102580102 PDFDocument8 paginiIfbm 0102580102 PDFThalapathy VenkatÎncă nu există evaluări

- Notes PDFDocument6 paginiNotes PDFThalapathy VenkatÎncă nu există evaluări

- 01 - Title PageDocument1 pagină01 - Title PageThalapathy VenkatÎncă nu există evaluări

- 01 TitleDocument1 pagină01 TitleThalapathy VenkatÎncă nu există evaluări

- An Analysis of Success Case StudyDocument7 paginiAn Analysis of Success Case StudyThalapathy VenkatÎncă nu există evaluări

- Binder1 PDFDocument6 paginiBinder1 PDFThalapathy VenkatÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Chapter 14 HomeworkDocument22 paginiChapter 14 HomeworkCody IrelanÎncă nu există evaluări

- Discussion QuestionsDocument3 paginiDiscussion Questionspeeyushjain2020Încă nu există evaluări

- World ScaleDocument2 paginiWorld ScalethunderburdÎncă nu există evaluări

- ECON 2113 - Multiple-Choice Practice QuestionsDocument49 paginiECON 2113 - Multiple-Choice Practice QuestionsMichael LeeÎncă nu există evaluări

- Industry Research Template Two WheelersDocument22 paginiIndustry Research Template Two WheelersHarvey100% (1)

- HOMW Chap8&9Fall2009Document4 paginiHOMW Chap8&9Fall2009Kawtar AallamÎncă nu există evaluări

- 03 Quiz 1 AubDocument3 pagini03 Quiz 1 Aubken dahunanÎncă nu există evaluări

- Oil Special Report - A Post-Sanctions WorldDocument15 paginiOil Special Report - A Post-Sanctions WorldasaÎncă nu există evaluări

- The Surprising Incidence of Tax Credits For The Toyota PriusDocument32 paginiThe Surprising Incidence of Tax Credits For The Toyota PriusAkandÎncă nu există evaluări

- MR DiyDocument2 paginiMR DiySyamala 29Încă nu există evaluări

- Accounting ReviewDocument68 paginiAccounting Reviewcrazycoolnisha75% (4)

- Cash Conversion CycleDocument7 paginiCash Conversion Cyclebarakkat72Încă nu există evaluări

- 18 Renewable Energy Charts, Fun Renewable Energy FactsDocument12 pagini18 Renewable Energy Charts, Fun Renewable Energy FactspchattanrÎncă nu există evaluări

- Unit 2 BeDocument16 paginiUnit 2 BeAnkitÎncă nu există evaluări

- Marathon Petroleum: HistoryDocument17 paginiMarathon Petroleum: HistoryusmanÎncă nu există evaluări

- Q1Document2 paginiQ1racquelcamatchoÎncă nu există evaluări

- (R) PencilsDocument51 pagini(R) PencilsMohammad Ruhul0% (2)

- Cps Nep 2013 2017 Ea SummaryDocument7 paginiCps Nep 2013 2017 Ea Summaryakyadav123Încă nu există evaluări

- 8th Annual New York: Value Investing CongressDocument53 pagini8th Annual New York: Value Investing CongressVALUEWALK LLCÎncă nu există evaluări

- Estudo Consumidor 2018 PDFDocument35 paginiEstudo Consumidor 2018 PDFCoragem ConcretaÎncă nu există evaluări

- Inventory Valuation: A 5,000 P185 P230 P35 B 20,000 69 100 30 C 15,000 31 43 15 D 18,000 75 105 37Document3 paginiInventory Valuation: A 5,000 P185 P230 P35 B 20,000 69 100 30 C 15,000 31 43 15 D 18,000 75 105 37ellaine villafaniaÎncă nu există evaluări

- Class1 Introduction Updated 2Document37 paginiClass1 Introduction Updated 2hiuyeehilaryÎncă nu există evaluări

- M3 Business Engine Data Model IntroductionDocument58 paginiM3 Business Engine Data Model IntroductionVINEETH100% (2)

- Fashion OrientationDocument7 paginiFashion OrientationRAHUL16398Încă nu există evaluări

- Properties of Stock OptionsDocument15 paginiProperties of Stock OptionsSupreet GuptaÎncă nu există evaluări

- Purchase Order Saudia Hypermarket Rayyan Shafi Street-New Rayyan Doha Qatar-Po Box:63073 Shafi Street - PO BOX:63073 Doha-QatarDocument1 paginăPurchase Order Saudia Hypermarket Rayyan Shafi Street-New Rayyan Doha Qatar-Po Box:63073 Shafi Street - PO BOX:63073 Doha-QatarIzzathÎncă nu există evaluări

- MR Project Soln Electric CarsDocument8 paginiMR Project Soln Electric CarsSaurabh SharmaÎncă nu există evaluări

- This Study Resource Was: Vietnam AirlinesDocument9 paginiThis Study Resource Was: Vietnam AirlinesNgọcc Lann100% (2)

- Fee ScheduleDocument3 paginiFee ScheduleAnonymous HH3c17osÎncă nu există evaluări

- Cost AccountingDocument5 paginiCost AccountingBella0% (1)