Documente Academic

Documente Profesional

Documente Cultură

ECOCON Plants For Production Non-Aerated Lightweight Cellular Concrete Products

Încărcat de

Oleg ZaretskiyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ECOCON Plants For Production Non-Aerated Lightweight Cellular Concrete Products

Încărcat de

Oleg ZaretskiyDrepturi de autor:

Formate disponibile

NON-AUTOCLAVE AERATED

LIGHTWEIGHT CELLULAR CONCRETE

PLANT AND KNOW-HOW FOR LIGHWEIGHT

CELLULAR CONCRETE PRODUCTION

www.ecocon.ae

I consider that ECOCON engineers have

acheived the substantial progress in developing non-autoclave aerated concrete technology and presently I do not see anybody who

is able to compete ECOCON in this particular

field.

Dr. Marcel Bikbau - professor, Member of Russian

Natural Sience Aademy,

General Director of Moscow Institue of

Materials and Effective Technologies

CONTENTS

INTRODUCTION

03

ECOCON PRODUCTS

04

ECOCON PLANT

05

ECOCON CONSTRUCTION SYSTEMS

06

ECOCON SPARES

07

SUCCESS STORY THAT COMES FROM DREAM

2008 - 2010

Scientific studies, laboratory tests and cerification

of plants Russia and Belarus

2012

ECOCON Group has

established in the UAE

been

2013

ECOCON WORLD CLASS PRODUCTS & SERVICES

In 2013 during Big 5 Intenrational

COnstruction Exhibition in Dubai,

ECOCON technology has gained

Gaya Award - main award for the

most green and innovative product

in the Middle East and Nothern

Africa

2014

The first fully fledged ECOCON Production facility has been launched in

Al Ghail Industrial Area in Ras Al Khaimah (UAE).

2014 - 2016

Successfull development of ECOCON technology in the UAE and worldwide. Recogintion and

acceptance of ECOCON products by the UAE certification and government authorities.

Construction of ECOCON plants in Ukraine, Saudi Arabia and Oman.

TODAY ECOCON IS A GLOBAL

LEADER IN DEVELOPMENT OF

TECHNOLOGY OF PRODUCTION

ECOCON AND APPLICATION OF NON-AUTOCALVE AERATED LIGHWEIGHT

CELLULAR CONCRETE

ECOCON PLANT

CELL-GENERATING

POWDER (CGP)

MIXERS AND

APPLICATION TOOLS

KNOW-HOW

TRANSFER, TRAINING

The heart of ECOCON Technology

is a plant that produces

non-autoclave aearted

lightweight cellular concrete

products, such as: masonry blocks,

dry mix for preparation of

lighweight concrete in-situ,

cladding and facade thermal

panels, decorative elements and

others. The design and

engineering of plant is produced

in a way that ensures durability,

low maintenance cost and

simplicity of equipment.

CGP is a specially designed

complex chemical additive that

initiate a chemical reaction that

produces aeration of ECOCON

mixture.

The mobile ECOCON high-rotary

speed mixers are used for

preparation of lighweight celluar

concrete in-situ and delivering the

mixture to place of application.

ECOCON shares all expirience and

new developments with

customers, ensuring the

continious operations and

business success. All new

developments and inventions

made by ECOCON engineers are

becoming a valuable domain to

all users of ECOCON technology.

Know-How Book provided to

custoemrs by ECOCON includes all

technological secrets and allows

customer to run the plant

independently.

Raw materials of ECOCON plant

are available everywhere . They

are: ordinary portland cement and

ordinary construction sand. Dune

sand, stone dust, fly ash can be

used as raw materials as well.

CGP has different components

that calculated in accordance with

available raw materials.

ECOCON has developed special

CGP formals allowing production

of lighweight cellular concretes

with various technical specifications such as: dry density,

compressive strength, drying

shrinkage.

FAST-TRACK SPARES

ECOCONs service doesnt stop the

moment when the plant is

erected: in-house engineering

department provides a wide

range of spare parts for all

ECOCON equipment. ECOCON

offers FAST-TRACK service,

combined with highly competitive rates.

03

ECOCON DRY MIX FOR PRODUCTION

LIGHTWEIGHT CONCRETE IN-SITU

ECOCON Dry Mix is a two-components dry

powder for producing non-autoclave

lightweight cellular concrete in-situ by

simple mixing with water.

ECOCON Dry Mix production is based on

usage of scientific innovations in nano-technologies in line with innovative selection

and processing of raw materails.

ECOCON Dry Mix is used for construction of

lightweigh floor screeds, filling walls and

partitions, road and pipeline bedding

MASONRY UNITS (BLOCKS)

ECOCON Lightweight Blocks are used in virtually all areas of the construction

industry, such as housing, industrial and agricultural construction, the construction of schools, hospitals, administrative and public buildings, etc. ECOCON block

is an economical and efficient building material whose properties allow to

quickly construct buildings for various purposes.

In addition, ECOCON blocks can be used for restoration or reconstruction of old

buildings (due to low weight) or half-timbered houses (due to simple processing). In world practice, cellular concrete has long been used in the renovation of

old buildings, while building their height.

ECOCON PLANT PRODUCT PRODUCTION

AND APPLICATION DIAGRAM

KNOW - HOW ADDITIVE

cell-generating

powder (CGP)

To customers for

cosntruction of

floor screeds,

filling walls,

roads and

pipelines

bedding

4 THERMAL FACADE & CALDDING

PANELS

RAW MATERIALS

chemicals

sand

(filler)

cement

fibre

water

Dry Line Processing

Storage

Construction

Adhesives

(limited qty)

Packing

ECOCON

Dry

Mix

Wet Processing & Cutting Line

5

2

Masonry Units

(400 - 800 kg/m3)

Cladding &

Facade

Panels

Superlight

blocks

(250 kg/m3)

Final curing at storage (15 - 25 days)

Cutting Process

To customers

SUPER-LIGHT BLOCKS & PANELS

ECOCON Superlightweight Blocks (less than 275 kg/m3) can be perfectly applied

as filler (hoardy) blocks for pre-cast panels production. The perfect thermal

insulation of superlight blocks allow to avoid usage of expensive and fire

dangerous polysterene.

ECOCOCN Thermal Panels are kind of block with

thickness up to 100 mm. Panels can be applied

for thermal insulation of RCC structures and fire

protection of elevator shafts, staircase shafts,

steel structures and construction of fire

protected walls and partitions

To customers for

execution

masonry works

To customers for

facade and

cladding works

Decorative

elements

BUILDING DECORATIVE

ELEMENTS

ECOCON decorative elements are produced by

special processing of lighweight concrete

massives that gives them required shape and

form. Due to their light weight, reasonable

strength and special way of finishing ECOCON

decorative elements are excellent replacement

to heavy RCC or expensive GRC (GRP)

structures.

ECOCELL Construction System

(construction with pre-cast

sandwich panels with ECOCON

superlight concrete infilling)

ECOCON Construction System

(combination of LGS and

lighweight concrete)

This diagram is for ECOCON plant E-P type. Other designs and

configuration of the plant may change the diagram.

04

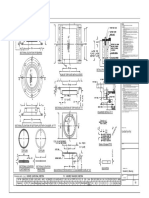

ECOCON PLANT E-N TYPE

DESCRIPTION

ECOCON E-N Plant is designated for

production of lighweight cellular concrete

blocks with 600 - 800 kg/m3 density and

minimum comressive strength 2.0 - 4.0

Mpa. These blocks can be used for

construction of thermal-insulated

bearing and non-bearing walls and

partitions.

12

4

9

RAW MATERIALS

13

ADVANTAGES

affordable price

10

11

possibility to use raw materials locally

available

5

14

low electricity consumption

* - moisture content of filler should not be more

than 10%

pre-planned expansion possibility

15

13

14

14

17

14

13

13

Ordinary Portland Cement is used as binding

material. Any type of sand (dune sand, ordinary

construction sand), stone dust, fly ash and other

neutral materials are used as filler*. Cell

Generating Powder is based on alluminum

powder with addition special chemicals that

initiate and control the aeration (expansion)

process.

1 - Sand Receiveing Hopper

2 - Sand Transporter

3 - Cement Silo with Accessories

4 - Cement Vertical Conveyor

5 - Cement Receiving Hopper

6 - Primary Curing Chambers

7 - Manipulator for lifting and moving moulds

8 - Retrieving carrageway

9 - Reserve space for expansion

10 - Primary cutting machine

11 - Main cutting machine

12 - Secondary curing chambers

13 - Distribution carrageways

14 - Distribution trolleys

15 - Vibrating table

16 - Weghting, mixing and filling station

17 - Final curing area

PRODUCTION CAPACITY

Plant:

E-N-1/1 E-N-1/2 E-N-2/3

Blocks

80 m3

120 m3

240 m3

Production capcity is given for 24-hours

production cycle for blocks with dimension 200 x

200 x 600 mm

Manipulator for lifting mould

Mould on the trolley

DELIVERY

The plant will be produced, delivered , erected

and tested in 6 months period down payment

for planning and engineering. The plant will

be packed and deliveredin 3 containers.

Cutting complex control panel

OTHER REQUIREMENTS

Production area ..................... 1,500 m2

Total land plot ...................... 5,000 m2

Power connection ................... 200 kW

Water consumption ................ 150 l/day

Working shift .............................. 6 - 8 people**

** - including forklift operator and storage

workers

Filling Station

Automatic Cutting Complex: a) main cutting machine; b) primary

cutting machine

05

ECOCON PLANT E-P TYPE

2

3

4

25

11 - Primary cutting machine

12 - Main cutting machine

13 - Wastage removal conveyor

14 - Reserve space for expansion

15 - Secondary curing chambers

1 - Cement Silo

2 - Pipes for cement loading

3 - Sand Vertical Conveyor

4 - Sand Silo

5 - Cement Receiving Hoppe

6 - Intermediate silo

7 - Wet mixer

8 - Primary curing chambers

9 - Retrieving carrageway

10 - Mould manipulator

24

10

11

12

13

14

15

23

16

7

22

21

16

20

Dry mixer for mixing

components

DESCRIPTION

ECOCON E-N Plant is designated for

production of lighweight cellular concrete

blocks with 250 - 800 kg/m3 density and

minimum comressive strength 1.0 - 4.0 Mpa.

Except of this the plant will produce special

dry mix for preparation of lighweight

cellular concrete in-situ by simple mixing it

with water (filling of walls, making floor

screeds, road basements, etc.)

The high quality of products is achieved due

to application of specially deisgned and

produced rotary, high-rpm speed mill that

provides milling of all materials up to nano

dimensions.

19

17

21 - Packing machine

22 - Rotary mill

23 - Weight batch hopper

24 - Screw conveyors

25 - Steel structures

26 - Final curing area

16

ADVANTAGES

A -Weight batch hopper;

B - Rotary mill

RAW MATERIALS

manufacturing of different types of products

possibility to use raw materials locally

available

high level of automation

pre-planned expansion possibility

Plant:

23

18

17

E-P-1/2

Blocks

120 m

Dry Mix

40 t

Ordinary Portland Cement is used as binding

material. Any type of sand (dune sand, ordinary

construction sand), stone dust, fly ash and other

neutral materials are used as filler*. Cell

Generating Powder is based on alluminum

powder with addition special chemicals that

initiate and control the aeration (expansion)

process.

Touchscreen control panel

* - moisture content of filler should not be

more than 10%

PRODUCTION CAPACITY

E-P-2/3

240 m

DELIVERY

The plant will be produced, delivered ,

erected and tested in 9 months period

down payment for planning and

engineering. The plant will be packed

and deliveredin 5 containers.

OTHER REQUIREMENTS

3

80 t

Production capcity is given for 24-hours

production cycle for blocks with dimension 200 x

200 x 600 mm

Dry mix packing station

16

17

16 - Distribution carrageways

17 - Distribution trolleys

18 - Vibrating table

19 - Mould with trolley

20 - FIlling station

Production area ..................... 1,500 m2

Total land plot ...................... 5,000 m2

Power connection ................... 200 kW

Water consumption ................ 150 l/day

Working shift .............................. 6 - 8 people**

** - including forklift operator and storage

workers

Silos with steel

structures

06

BENEFITS OF USING ECOCON

WELLCOME TO ECOCON

When Customer enters ECOCON he

will have uncountable benefits and

peace of mind knowing that ECOCON

is the only manufacturer of this type of

equipment that has operated with the

same name and principles for over 5

years from product innovation to

production of the most cost effective

machinery.

Our plants are designed in such way

that will result in increased profits to

our customers. Equipment is designed

to be user friendly and our plants

require less personnel to run.

SMART SORCING

ECOCON uses only components of the

highest quality, all of which are

sourced from internationally

recognized brands. This not only

ensures that ECOCON provides the

highest quality components but also

has a strong network of suppliers

throughout the world reducing lead

times and offering superior customer

support.

SERVICES

ECOCON offers a comprehensive

solutions ranging from full turn-key

project for specific output requirements

to individual or specific product

solutions.

Our customers have the freedom to

decide whether they wish to pursue a

full turn-key plant or more target

specific plant options. ECOCON

technical expertise is always available to

respond to your needs.

ECOCON will work within your budget.

In some cases ECOCON can even

provide assistance for non ECOCON

auxillary equipment .

In most cases ECOCON can offer

assistance in many languages (English,

Arabic, Russian, and French).

AFTER SALES SUPPORT

With a Service Support team of

highly qualified technical operatives

and service engineers, ECOCON will

ensure that all your after sales

requirements are met with total

professionalism and quality.

SPARE PARTS

ECOCON carries a large stock of all

ECOCON genuine spare parts and

consumables. In order to reduce plant

down time ECOCON can offer soonest

dispatch on the most items

ENIVIRONMENTAL

CONSIDIRATIONS

ECOCON takes environmental

responsibility seriuosly. Our plant is

certified by EPDA (Environmental

Protection Agency). We have

implemented the program of

reducing electricity and water

consumption and maintain the

wastage free facility.

ECOCON Industries L.L.C.

ECOCON Technologies F.Z.C

ECOCON General COntracting L.L.C.

Tel.: +971 4 4542418

Fax: +971 4 4542419

1104, JBC2, JLT, P.O. Box: 36408,

Dubai, United Arab Emirates

Email: info@ecocon.ae

www.ecocon.ae

www.facebook.com/ecocongroup

07

S-ar putea să vă placă și

- CLC CostingDocument34 paginiCLC CostingpipestressÎncă nu există evaluări

- Present & Future of Lightweight ConcreteDocument7 paginiPresent & Future of Lightweight ConcreteGlobal_FriendshipÎncă nu există evaluări

- Adding Value To ConcreteDocument16 paginiAdding Value To ConcreteFrancois KokÎncă nu există evaluări

- Project Design Document (PDD) : CDM - Executive BoardDocument84 paginiProject Design Document (PDD) : CDM - Executive BoardParakh AgrawalÎncă nu există evaluări

- Autoclaved Aerated Concrete: A Sustainable Alternate of Clay Brick Masonry in Form of Light Weight ConcreteDocument6 paginiAutoclaved Aerated Concrete: A Sustainable Alternate of Clay Brick Masonry in Form of Light Weight ConcreteGRD JournalsÎncă nu există evaluări

- Presentation Foamed Concrete 2009Document25 paginiPresentation Foamed Concrete 2009Mukut DasÎncă nu există evaluări

- Fly Ash Bricks PPT FrantDocument13 paginiFly Ash Bricks PPT FrantRavi Shankar100% (1)

- Difference Between Aac and CLC - Foam Generator Suppliers in Pune, CLC Block Making Plant in Mumbai, Pune, Gujarat, Nashik, Akola, Nellore - Foam Generator Manfacturer IndiaDocument2 paginiDifference Between Aac and CLC - Foam Generator Suppliers in Pune, CLC Block Making Plant in Mumbai, Pune, Gujarat, Nashik, Akola, Nellore - Foam Generator Manfacturer IndiaGitesh Gaurav0% (1)

- CLC Plant DetailDocument17 paginiCLC Plant DetailSibiyarasu Rock RiderÎncă nu există evaluări

- CLC Block PresentationDocument14 paginiCLC Block PresentationNikhilesh KadukarÎncă nu există evaluări

- The Fly Ash Brick Production TechnologyDocument18 paginiThe Fly Ash Brick Production TechnologyVishal KedarÎncă nu există evaluări

- CLC Brick ProductionDocument14 paginiCLC Brick ProductionKrishna YarlagaddaÎncă nu există evaluări

- Utilization of Fly Ash in Rural Road Construction in India and Its Cost EffectivenessDocument6 paginiUtilization of Fly Ash in Rural Road Construction in India and Its Cost Effectivenessceanil100% (1)

- Analisa Harga Akasia PDFDocument13 paginiAnalisa Harga Akasia PDFAlifanda CahyanantoÎncă nu există evaluări

- Auto Aerated ConcreteDocument6 paginiAuto Aerated ConcreteLeo GohÎncă nu există evaluări

- Earth Based Technologies: 17 Types of BlocksDocument8 paginiEarth Based Technologies: 17 Types of BlocksHiwi Negash100% (1)

- Autoclaved Areated Concrete or Light Weight ConcreteDocument16 paginiAutoclaved Areated Concrete or Light Weight ConcreteMohammed Khaja NaseerÎncă nu există evaluări

- Block Egg LayingDocument17 paginiBlock Egg LayingDebasishSwainÎncă nu există evaluări

- CLC BlocksDocument2 paginiCLC BlocksAmit ChouguleÎncă nu există evaluări

- Autoclaved Aerated Concrete BlockDocument53 paginiAutoclaved Aerated Concrete BlocksharanyaÎncă nu există evaluări

- Flyash BricksDocument62 paginiFlyash Bricksbhaskar_jdÎncă nu există evaluări

- Geo Polymer Mix DesignDocument12 paginiGeo Polymer Mix DesignpulendralkÎncă nu există evaluări

- Different Types of Admixtures in Concrete Structure - A Review PDFDocument8 paginiDifferent Types of Admixtures in Concrete Structure - A Review PDFKalyanasundaram Thirugnanasambandam100% (1)

- Cement Concrete Tiles and Paving BlocksDocument8 paginiCement Concrete Tiles and Paving BlocksNipan DekaÎncă nu există evaluări

- Construction Materials and TestingDocument61 paginiConstruction Materials and TestingAliñabo RoqueÎncă nu există evaluări

- RMC Civil EngineeringDocument27 paginiRMC Civil EngineeringPavan Kumar100% (1)

- Non-Autoclaved Aerated Concrete (NAAC) Blocks: An Alternative Building Construction MaterialDocument5 paginiNon-Autoclaved Aerated Concrete (NAAC) Blocks: An Alternative Building Construction MaterialIJRASETPublicationsÎncă nu există evaluări

- Oman Ophiolite Precast - Corporate BrochureDocument24 paginiOman Ophiolite Precast - Corporate BrochurePSPÎncă nu există evaluări

- Green ConcreteDocument15 paginiGreen Concrete19pgcl003TARANGKUMAR LAKHANIÎncă nu există evaluări

- Manufacturing Process of Aac Block: Anurag WahaneDocument8 paginiManufacturing Process of Aac Block: Anurag Wahanemshabanero2359Încă nu există evaluări

- Brick Making-ProcessDocument20 paginiBrick Making-ProcessRafaelÎncă nu există evaluări

- Building Materials Final Solution After Cor.Document64 paginiBuilding Materials Final Solution After Cor.TarunÎncă nu există evaluări

- CLC Project Report.Document6 paginiCLC Project Report.polakisagar100% (1)

- Project:: Use of Metakaoline and Alccofine As A Admixture in ConcreteDocument52 paginiProject:: Use of Metakaoline and Alccofine As A Admixture in ConcreteAnonymous wlbOBqQWDÎncă nu există evaluări

- Orilite AAC Block FAQDocument16 paginiOrilite AAC Block FAQAshish JainÎncă nu există evaluări

- Improved Clay Brick ProductionDocument4 paginiImproved Clay Brick ProductionBrajesh SumanÎncă nu există evaluări

- SRD Project Doc FinalDocument65 paginiSRD Project Doc FinalRavi JoshiÎncă nu există evaluări

- Fly Ash Fly Ash: Utility Bonanza From DustDocument8 paginiFly Ash Fly Ash: Utility Bonanza From DustRajanmyth Mala100% (1)

- KERALITE BrochureDocument8 paginiKERALITE BrochurejayanthÎncă nu există evaluări

- CLC BricksDocument19 paginiCLC BricksAJ Darphynit100% (1)

- ALC The Intelligent Building SystemDocument7 paginiALC The Intelligent Building SystemkucingmioewÎncă nu există evaluări

- Solid Block Manufacturing ProcessDocument4 paginiSolid Block Manufacturing Processa paul jayakumarÎncă nu există evaluări

- Knowledge Sharing On Aac1Document16 paginiKnowledge Sharing On Aac1parthÎncă nu există evaluări

- Investment Guidelines For CLC BlockDocument38 paginiInvestment Guidelines For CLC BlockSibiyarasu Rock Rider100% (2)

- Bendable ConcreteDocument18 paginiBendable ConcreteScarlordÎncă nu există evaluări

- CLC Plant-Project ReportDocument14 paginiCLC Plant-Project ReportMahadeo86% (7)

- 003 Bt3-Manufacturing of Concrete by ArtDocument58 pagini003 Bt3-Manufacturing of Concrete by ArtItzuki FujiwaraÎncă nu există evaluări

- Fixed Chimney-Bull's Trench KilnDocument9 paginiFixed Chimney-Bull's Trench KilnadagooodÎncă nu există evaluări

- Study and Experimentation of Autoclaved Aerated Concrete by Using Fly AshDocument5 paginiStudy and Experimentation of Autoclaved Aerated Concrete by Using Fly AshInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Construction of Earthen Houses Using Cseb - Bangladesh PerspectiveDocument7 paginiConstruction of Earthen Houses Using Cseb - Bangladesh PerspectiveshainojkÎncă nu există evaluări

- AITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)Document8 paginiAITC-H - Flexural Tensile Strength of Brick Unit (15!09!14)runkirÎncă nu există evaluări

- Studies On Quarry Dust As Partial Replacement of Fine Aggregates in ConcreteDocument3 paginiStudies On Quarry Dust As Partial Replacement of Fine Aggregates in ConcreteEditor IJLTEMASÎncă nu există evaluări

- Aac Block Plants: WWW - Buildmate.InDocument12 paginiAac Block Plants: WWW - Buildmate.InAzmat Ali KhanÎncă nu există evaluări

- CSEB Auroville Pondicherry PDFDocument9 paginiCSEB Auroville Pondicherry PDFifrah100% (1)

- Project Report On Cellular Light Weight ConcreteDocument21 paginiProject Report On Cellular Light Weight ConcreteVishal Kumar100% (1)

- Liapor Industry PDFDocument20 paginiLiapor Industry PDFfoad-7Încă nu există evaluări

- Project Report On Aac Block Manufacturing PlantDocument7 paginiProject Report On Aac Block Manufacturing PlantEIRI Board of Consultants and PublishersÎncă nu există evaluări

- Chapter 1Document56 paginiChapter 1Surbhi JainÎncă nu există evaluări

- Production of Eco Bricks From Industrial Waste Using Alkali Activated Technology - Civil Engineering Project TopicsDocument6 paginiProduction of Eco Bricks From Industrial Waste Using Alkali Activated Technology - Civil Engineering Project TopicsmynameisgunaÎncă nu există evaluări

- ACICO Light Weight Building BlocksDocument64 paginiACICO Light Weight Building BlocksDanny MokdadÎncă nu există evaluări

- Worked Example 1:: SolutionDocument3 paginiWorked Example 1:: SolutionARVIND SINGH RAWATÎncă nu există evaluări

- 09 HDB SOR - Jul 2014Document238 pagini09 HDB SOR - Jul 2014သူ ရိန်Încă nu există evaluări

- Flexible Duct Insulated & Non InsulatedDocument4 paginiFlexible Duct Insulated & Non Insulatedali faragallahÎncă nu există evaluări

- Table 6.6 of Irc:112 Autogenous Shrinkage Strain of ConcreteDocument2 paginiTable 6.6 of Irc:112 Autogenous Shrinkage Strain of ConcretefaÎncă nu există evaluări

- Transformation of Former County Jail Near Completion: Journal WCDocument22 paginiTransformation of Former County Jail Near Completion: Journal WCRon SchottÎncă nu există evaluări

- Different Types of Wood JointDocument2 paginiDifferent Types of Wood Joint[AP-STUDENT] Resty GarciaÎncă nu există evaluări

- Technical Query Register - PC KETAPANG II LTD JDA2 UpdateDocument7 paginiTechnical Query Register - PC KETAPANG II LTD JDA2 Updatezigwied SirÎncă nu există evaluări

- Kansai Structur PDFDocument29 paginiKansai Structur PDFsantoso100% (1)

- M08Document3 paginiM08Iwan AbdurahmanÎncă nu există evaluări

- Job Description of A Structural EngineerDocument2 paginiJob Description of A Structural EngineerNuelboborÎncă nu există evaluări

- Guidance On Façades and FiresDocument45 paginiGuidance On Façades and Firesahmed qutobÎncă nu există evaluări

- Plywood PDFDocument4 paginiPlywood PDFaulad999Încă nu există evaluări

- Structural Stability ReportDocument13 paginiStructural Stability ReportMuhammadWazimAkram75% (4)

- The Effect of Price Changes of Some Major Construction Materials On The Economic Input of Sri Lankan Construction IndustryDocument30 paginiThe Effect of Price Changes of Some Major Construction Materials On The Economic Input of Sri Lankan Construction IndustryRohitha PethiyagodaÎncă nu există evaluări

- Invoice # OC - OAK - M112002Document6 paginiInvoice # OC - OAK - M112002Denzel WillingtonÎncă nu există evaluări

- Guided (L) Bearing DrawingDocument1 paginăGuided (L) Bearing Drawingtrichandra maharjanÎncă nu există evaluări

- Metsec Wall Construction PDFDocument40 paginiMetsec Wall Construction PDFCal MoranÎncă nu există evaluări

- J Slab Track - Taiwan HSR PDFDocument49 paginiJ Slab Track - Taiwan HSR PDFGaurav SrivastavaÎncă nu există evaluări

- Smoke Control System DesignDocument4 paginiSmoke Control System DesignHermi DavidÎncă nu există evaluări

- Seismic Behaviour and Design of RC Shear Wall Using ETABS SoftwareDocument8 paginiSeismic Behaviour and Design of RC Shear Wall Using ETABS SoftwareIJRASETPublicationsÎncă nu există evaluări

- ProFlex 24 Ft. Paver Edging Project Kit in Black - The Home Depot CanadaDocument5 paginiProFlex 24 Ft. Paver Edging Project Kit in Black - The Home Depot Canadaming_zhu10Încă nu există evaluări

- Data Sheet: 4x2x0,22snDocument2 paginiData Sheet: 4x2x0,22snSerhiy ShvaykaÎncă nu există evaluări

- Mechanics of Rigid Bodies ( o )Document18 paginiMechanics of Rigid Bodies ( o )Isabelle LunaÎncă nu există evaluări

- Curriculum Vitae: Personal InformationDocument10 paginiCurriculum Vitae: Personal InformationBehairy AhmedÎncă nu există evaluări

- Safety in Electrical Installations & Lifts in ConstructionDocument13 paginiSafety in Electrical Installations & Lifts in ConstructionMock ProjectÎncă nu există evaluări

- Bridges and Their TypesDocument8 paginiBridges and Their TypesAbhishek PawarÎncă nu există evaluări

- Hawaii Historic Housing Study-SchofieldDocument20 paginiHawaii Historic Housing Study-SchofieldPat Appel100% (1)

- Wet and Dry Installation of Natural Stone CladdingDocument12 paginiWet and Dry Installation of Natural Stone CladdinglakshmiÎncă nu există evaluări

- Dr. Sabih HashimDocument593 paginiDr. Sabih Hashimmohamedyahai100% (1)

- Heat Pump RTU SCADocument49 paginiHeat Pump RTU SCAJhoÎncă nu există evaluări