Documente Academic

Documente Profesional

Documente Cultură

Supplier Document Requirements SDR GDF

Încărcat de

Fahd Bin RiasatDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Supplier Document Requirements SDR GDF

Încărcat de

Fahd Bin RiasatDrepturi de autor:

Formate disponibile

GENERAL SPECIFICATION

SUPPLIER DOCUMENT REQUIREMENTS (SDR)

040305

EvB

Various Changes

DZO

CvB

020703

GvS

Various additions

DZO

CvB

020403

JRO

Change Logo

DZO

CvB

220201

JRO

Change Name

JRO

CvB

120700

JRO

Change Vendor into Supplier, VDR to SDR

and updated.

DZO

CvB

071299

JRO

Issued for enquiry

DZO

CvB

REV.

DATE

ORIG.

DESCRIPTION

CHECKED

APPROVED

Specification

Sheet

Revision

103

1 of 14

GDF PRODUCTION NEDERLAND B.V.

=

TABLE OF CONTENTS

1.

DOCUMENT IDENTIFICATION

2.

LANGUAGE

3.

FORMATS

4.

UNITS OF MEASURE

5.

DOCUMENTS FOR REVIEW

6.

FINAL DOCUMENTS

7.

SUPPLIER DATA BOOKS

8.

NUMBER AND TYPE OF DOCUMENTS

9.

INSTALLATION, MAINTENANCE AND OPERATING MANUAL

10.

MANUFACTURING DATA RECORD

GDF Production Nederland B.V.

Specification 103 Rev. 5.

Page 2 of 14

1.0

DOCUMENT IDENTIFICATION

1.1

All documents shall be properly marked with Buyers Purchase Order number and item/tag number (for

drawings in the title block at the bottom right hand corner).

The SDR Code System shall be used by Supplier to identify information requested by Buyer.

Strict compliance with the SDR Code System is required. Non-conformance may lead to a delayed review

cycle.

1.2

For identical equipment/material, Supplier shall provide typical drawings/documents applicable to each

separate equipment/material.

The correlation between tag number, line number etc. and an equipment/material item number shall be

specified by an index on the drawing/document.

2.0

LANGUAGE

All drawings and documents shall be written in the ENGLISH language.

3.0

FORMATS

Size of drawings shall not exceed A-1 size.

4.0

UNITS OF MEASURE

The international System of Units (SI Units) shall be used throughout, dual units (SI Units with imperial in

parentheses or vice versa) are also permitted. However, with following exceptions:

a.

b.

c.

d.

Nominal pipe/fitting/valve sizes in inches and pressure rating in lbs in accordance with ASME pressure

classes

Pressure in bar

Liquid flow in m3/h

Gas flow in Nm3/h (0C, 1.01325 bara).

5.0

DOCUMENTS FOR REVIEW

5.1

Review by Buyer shall mean that Buyer will retrieve data for its design and will check the document for

interface data. Supplier shall not start fabrication until Buyer has acknowledged such review and possible

comments have been incorporated.

5.2

Documents submitted "For Review" will be returned within three (3) calendar weeks.

5.3

Any document returned to Supplier for revision shall be re-submitted within two (2) calendar weeks complete

with revisions clearly flagged by a triangle showing the latest revisions.

6.0

FINAL DOCUMENTS

All prints of Suppliers documents shall indicate:

a.

b.

c.

that all revisions previously requested by Buyer are included;

that the documents are certified final and that all dimensions and material specifications are identical to

those of the Goods delivered by Supplier;

that no further changes shall be made without Buyers approval.

GDF Production Nederland B.V.

Specification 103 Rev. 5.

Page 3 of 14

7.0

SUPPLIER DATA BOOKS

7.1

Supplier shall ensure that the formats of the Supplier Data Books, i.e.

1.

Installation, Maintenance & Operating Manual (IMO)

2.

Manufacturing Data Record (MDR)

are in accordance with paragraph 9.0 and 10.0. The requirements as described in latter paragraphs are

minimum requirements, which shall be supplemented as necessary to fulfil the requirements and to allow

professional operation and use of the subject equipment. In case of doubt Supplier shall contact Buyer for final

advise. In all cases Supplier to complete the attached SDR.

7.2

All Supplier Data Books shall be bound in A-4 heavy-duty binders with transparent pockets on the cover and

spine and 4 hole ring binder mechanisms. Maximum spine width to be 60 mm.

7.3

Each section shall be separated by using numbered dividers.

8.0

NUMBER AND TYPE OF DOCUMENTS

Required number and type of documents for Buyer shall be as defined hereafter:

9.0

"With Bid" documents

2 prints

"For Review" documents

3 prints

"For Final" documents

3 prints

"Certified as-built" drawings

on disk in AutoCAD version 2000.

Installation, Maintenance &

Operating Manual (IMO)

5 copies (after final review of the master set by Buyer)

Manufacturing Data Record

(MDR)/Certificates

2 copies (after final review of the master set by Buyers

inspector)

INSTALLATION, MAINTENANCE AND OPERATING MANUAL (IMO)

IMO formats shall be compiled according to following format and contents (in so far as appropriate for the

ordered equipment) and shall be applicable for the complete package including deliveries from sub-suppliers:

-

Cover sheet and spine

Contents/index sheet

*

*

*

*

Equipment tag number.

Equipment description.

Purchase Order number.

Supplier details.

- Section 1

* Introduction

- Scope of supply - manufacturer.

- Sub-Supplier contact list and scope of supply.

- Section 2

* Description of complete equipment/package

- Including Process/Utility diagrams.

- Safety requirements.

GDF Production Nederland B.V.

Specification 103 Rev. 5.

Page 4 of 14

- Section 3

* Installation

- Equipment installation, alignment and replacement procedures.

- Commissioning procedures and checklists.

- Access and lifting.

- Section 4

* Operation

- Operation instructions.

- Functional descriptions.

- Operation and control procedures.

- Instrument set point list.

- Valve numbering drawings.

- Section 5

* Maintenance

- Preventative maintenance schedules/details.

- Routine maintenance.

- Condition monitoring including lube oil analysis/ condemning

limits.

- Routine test procedures.

- Trouble shooting procedures including diagnostic charts.

- Section 6

* Data sheets (completed by manufacturer)

- Mechanical/instrumentation/electrical data sheets.

- Instrument list.

- Section 7

* Drawings

- For type of supply list of applicable drawings including, but not

limited to:

General arrangement drawings and weights

Process and instrumentation diagrams

Cause and Effect diagrams

Piping/Electrical and Instrumentation/Structural

Parts drawings.

- "Certified as-built" drawings.

- Material lists.

- Section 8

* Parts data

- Equipment/package component details (for re-ordering from

original manufacturer, including parts not supplied as spare).

- Completed spare parts list, including all sectional/exploded view

drawings necessary to identify and install the spare parts.

- Section 9

* Special tools

- Schedule and technical description.

- Usage instructions

Section 10

GDF Production Nederland B.V.

Specification 103 Rev. 5.

* Sub-Supplier data

- For all supplied items.

- Marked to show specific type supplied.

- (Operation and maintenance instructions shall be structured as

standard Supplier documentation.)

Page 5 of 14

10.0 MANUFACTURING DATA RECORD (MDR)

MDR formats shall be compiled according to following format and contents (in so far as appropriate for the

ordered equipment):

-

Cover sheet and spine

Contents/index sheet

*

*

*

*

Equipment tag number.

Equipment description.

Purchase Order number.

Supplier details.

- Section 1

* General

- Summary of sub-ordered equipment/material/services with subSupplier details and scope descriptions.

- Section 2

* Data sheets

- Manufacturer's completed data sheets.

- Section 3

* Specification/code references

- Concessions and waivers.

- Non-conformance reports.

- Section 4

* Design Calculations

- Latest revision as reviewed by Buyer.

- Section 5

* Manufacturer's fabrication report

- Manufacturer's certificate of compliance (confirmation that the

package is designed, fabricated and inspected in accordance with

Purchase Order requirements).

- Completed quality control plan.

- Government related documents.

- Inspection release certificates.

- Section 6

* Procedure

- Manufacturing, fabrication, examination and repair procedures.

- Welding procedures WPS.

- Welder qualification records plus welder list with names, stamp,

qualification and WPS.

- NDT operator qualifications and certificates.

- Performance/string test procedures.

- Dimensional control procedure.

- Section 7

* Material certificates

- Certificate index.

- Certificates.

- Heat treatment reports.

GDF Production Nederland B.V.

Specification 103 Rev. 5.

Page 6 of 14

- Section 8

* Inspection/Test Reports

- Material inspection.

- Mechanical inspection.

- Balancing, dynamic and overspeed tests.

- Hydrostatic/leakage test.

- Runouts and clearances inspection.

- Performance test.

- Optional tests, such as:

NPSHR test;

complete unit test;

tandem test;

. gear test;

. helium test;

. sound level test;

spare parts test;

. auxiliary equipment test;

post-test inspection of casing;

. full pressure/full load/full speed test;

post-test inspection of the hydraulic coupling fit.

- Electrical functional test.

- Instrumentation functional test.

- Painting/surface preparation.

- Lifting and weighing.

- Preparation for shipment.

- Section 9

* Drawings

- Index.

- Fabrication and design drawings.

- Weld and NDE identification drawings.

- "Certified as-built" drawings.

- Section 10

* Other relevant documentation

The SDR code(s) selected are shown on following page(s).

GDF Production Nederland B.V.

Specification 103 Rev. 5.

Page 7 of 14

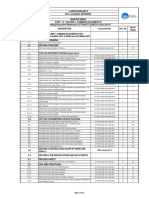

SUPPLIER DOCUMENT REQUIREMENTS (SDR)

DOCUMENTS SHOWN BELOW SHALL BE LISTED ON THE SUPPLIER DOCUMENT REGISTER (SDR CODE

PJ-01). ABBREVIATIONS ARE SHOWN BELOW.

Abbreviations Key: A-award (i.e. telefax, letter) P-Purchase Order placement, T-test, D-delivery, '-'-before, '+'-after,

blank - no requirement, R-review by inspector. Example: +4A = four weeks after award, -2D = two weeks, before

delivery.

PURPOSE AND TIMING

SDR

SDR - CODE DESCRIPTION

CODE

With

Bid

For

Review

Data Book(Yes)

IMO

MDR

PROCUREMENT

PC-01

START-UP AND COMMISSIONING SPARE PARTS LIST

- Itemized and priced.

+8P

PC-02

OPERATIONAL SPARE PARTS LIST

Completed/priced spare parts list for 2 years normal operation

complete with drawings, views for identification of spares

+8P

PC-03

SPECIAL TOOLS LIST - Itemized and priced.

+8P

PC-04

PROJECT QUALITY CONTROL & INSPECTION PLAN

Supplier's proposed inspection plan identifying specific quality

control activities, based on Suppliers Quality Manual.

+4P

PC-05

PC-06

PROJECT SCHEDULE

Bar chart identifying Supplier's engineering, procurement,

fabrication and testing schedules including detailed sub-ordered

activities.

+2P

SUB-SUPPLIERS/CONTRACTORS LIST

+8P

GENERAL

GE-01

SUPPLIER DOCUMENT REGISTER

Listing of all documents, identified SDR codes, to be submitted to

satisfy the SDR codes, as per attached format.

+2P

GE-02

CATALOGUE INFORMATION/DESCRIPTIVE LITERATURE

OF MECHANICAL EQUIPMENT

GE-03

TRANSPORT/LIFTING/STORAGE RECOMMENDATIONS

Provide proposed packing, lifting and storage details and

recommendations.

-2D

GE-04

WEIGHT DATA SHEET

Data sheet as contained in the specification completed by Supplier.

+8P

GE-05

NOISE DATA SHEET

Data sheet as contained in the specification completed by Supplier.

+8P

GE-06

LUBRICATION SCHEDULES

List type of lubricants used, sump capacities, change intervals.

-2D

GE-07

INSTALLATION, MAINTENANCE AND OPERATING

MANUAL Format as detailed in paragraph 9.0.

-2D

+2D

GE-08

MANUFACTURING DATA RECORD

Format as detailed in paragraph 10.0

+2D

GE-09

CERTIFICATES

Certificates in accordance with the relevant Specifications.

GE-10

UTILITY CONSUMPTION LIST

Power, air, fuel, etc.

GDF Production Nederland B.V.

Specification 103 Rev. 5.

+6P

Page 8 of 14

SUPPLIER DOCUMENT REQUIREMENTS (SDR)

DOCUMENTS SHOWN BELOW SHALL BE LISTED ON THE SUPPLIER DOCUMENT REGISTER (SDR CODE

PJ-01). ABBREVIATIONS ARE SHOWN BELOW.

Abbreviations Key: A-award (i.e. telefax, letter) P-Purchase Order placement, T-test, D-delivery, '-'-before, '+'-after,

blank - no requirement, R-review by inspector. Example: +4A = four weeks after award, -2D = two weeks, before

delivery.

PURPOSE AND TIMING

SDR

SDR - CODE DESCRIPTION

CODE

With

Bid

For

Review

Data Book(Yes)

IMO

MDR

CIVIL/MARINE

ST-01

FOUNDATION DRAWINGS

Show dimensions, locate supports, weights, inflicted loads

(static/dynamic), size and location of anchor bolts and civil details.

+6P

ST-02

STRUCTURAL FABRICATION DRAWINGS

Tubulars, plate girders, etc.

+8P

ST-03

STRUCTURAL DESIGN CALCULATIONS

+8P

ST-04

STRUCTURAL SUPPORT DRAWINGS

Location, loads and specific requirements.

+8P

ST-05

MANUFACTURING AND TESTING PROCEDURES

Structural steel (tubulars/girders/sections).

+8P

MECHANICAL

ME-01

MECHANICAL UNIT OUTLINE DRAWING

Preliminary general arrangement (foot print) showing sizes, layout

major components, connections.

+4P

ME-02

EQUIPMENT DATA SHEETS

Data sheets as contained in the specification completed by Supplier.

+6P

ME-03

PERFORMANCE DATA AND CURVES

+4P

ME-04

GENERAL

ARRANGEMENT/CROSS

SECTIONAL/ASSEMBLY DRAWING - Shows dimensions, all

components with tag numbers, layout, locations, all connections,

routing and location of piping, valves and instruments and electrical

materials.

+6P

ME-05

PARTS LIST

Identify all materials, make, type, material, quantity.

+6P

ME-06

NOZZLE LOADING

Indicate max. allowable nozzle loadings.

+6P

ME-07

NAME/TAG PLATE LIST - Detail equipment/material name, tag

number, design/operating conditions, inspection authority, etc.

+10P

AUTHORITY/CODE

REQUIREMENTS,

PRESSURE

CONTAINING PARTS - Documents, i.e. calculations, drawings,

manufacturing/test procedures required to meet authority and/or

code requirements.

+6P

ME-09

DESIGN CALCULATIONS, LCSA (Lateral Critical Speed

Analysis).

+6P

ME-10

DESIGN CALCULATIONS, TVA (Torsional Vibration Analysis)

+10P

ME-11

DESIGN CALCULATIONS, PA (Pulsation Analysis)

+10P

ME-08

GDF Production Nederland B.V.

Specification 103 Rev. 5.

Page 9 of 14

SUPPLIER DOCUMENT REQUIREMENTS (SDR)

DOCUMENTS SHOWN BELOW SHALL BE LISTED ON THE SUPPLIER DOCUMENT REGISTER (SDR CODE

PJ-01). ABBREVIATIONS ARE SHOWN BELOW.

Abbreviations Key: A-award (i.e. telefax, letter) P-Purchase Order placement, T-test, D-delivery, '-'-before, '+'-after,

blank - no requirement, R-review by inspector. Example: +4A = four weeks after award, -2D = two weeks, before

delivery.

PURPOSE AND TIMING

SDR

SDR - CODE DESCRIPTION

CODE

With

Bid

For

Review

Data Book(Yes)

IMO

MDR

ME-12

DYNAMIC BALANCING REPORT: ROTATING

COMPONENTS

+10P

ME-13

RUNNING CLEARANCE REPORT

+10P

ME-14

HYDROSTATIC TEST REPORT

ME-15

TEST PROCEDURES

ELECTRICAL

EL-01

ELECTRICAL EQUIPMENT DATA SHEETS

Data sheets as contained in the specification completed by Supplier.

EL-02

+4P

ONE LINE DIAGRAM

Show the electrical distribution system, with branch circuits to the

various consumers. Also show voltage level(s), nominal and short

circuit rating of buses, main components, number of phases,

neutral, PE bus, etc.

+8P

EL-03

BLOCK DIAGRAM

Show various installation units, with all interconnecting cabling.

+6P

EL-04

LOAD LIST

Identify all electrical consumers and provide following data, as

applicable: nameplate rating, power demand, power absorbed from

mains, pf and efficiency at load conditions, simultaneity factor;

under winter as well as summer conditions.

+6P

CABLE LIST

List all cables with identification number, operating voltage, type,

number and size of conductors and installed length.

+8P

DIMENSIONAL DRAWING, INCLUDING WEIGHT LIST

Show overall dimensions, including free space required for

ventilation, operation and for maintenance, location and size of

cable entries or cable entry area, details of bus duct connection,

shipping splits, location of foundation bolts, etc.

+6P

ELEMENTARY/SCHEMATIC DIAGRAM

Show schematic diagram or logic diagram, clarifying the operation

or function of electrical circuitry.

+6P

WIRING DIAGRAMS

Show internal connections up to and including terminals for

connection of external wiring or cabling.

+6P

WIRING DIAGRAM FOR ALL ACCESSORIES

Show wiring/connections up to and including terminals for

connection of external wiring or cabling.

+6P

FRONT OF PANEL ARRANGEMENT - Show position of

switches, meters, nameplates, etc., including identification of the

various components as well as the nameplate engravings.

+10P

EL-05

EL-06

EL-07

EL-08

EL-09

EL-10

GDF Production Nederland B.V.

Specification 103 Rev. 5.

Page 10 of 14

SUPPLIER DOCUMENT REQUIREMENTS (SDR)

DOCUMENTS SHOWN BELOW SHALL BE LISTED ON THE SUPPLIER DOCUMENT REGISTER (SDR CODE

PJ-01). ABBREVIATIONS ARE SHOWN BELOW.

Abbreviations Key: A-award (i.e. telefax, letter) P-Purchase Order placement, T-test, D-delivery, '-'-before, '+'-after,

blank - no requirement, R-review by inspector. Example: +4A = four weeks after award, -2D = two weeks, before

delivery.

PURPOSE AND TIMING

SDR

SDR - CODE DESCRIPTION

CODE

EL-11

With

Bid

For

Review

Data Book(Yes)

IMO

MDR

BATTERY ARRANGEMENT AND RACK/ENCLOSURE

ASSEMBLY DRAWING - Show battery installation arrangement.

Also show and identify make and type of battery cells or blocks,

type and size of intercell connectors and terminal covers.

+10P

EL-12

PARTS LIST List all used components and materials, together

with information regarding make and type.

+6P

EL-13

NAME PLATES DRAWING

+6P

EL-14

ELECTRICAL EQUIPMENT SIZING CALCULATIONS

+6P

EL-15

CHARACTERISTIC CURVES IF/AS SPECIFIED ELSEWHERE

Refer to equipment specification or Purchase Order.

+6P

INSTRUMENTATION

IN-01

INSTRUMENT LIST - Completed list according to provided

example.

IN-02

IN-03

+6P

INSTRUMENT LOCATIONS AND CABLE LAYOUT

Show location of instruments with tag numbers, routing and layout.

+8P

CAUSE AND EFFECT DIAGRAMS

Show causes to system trips/shutdowns, resulting effects and

actions.

+6P

LIST OF ALARM/TRIP SETTINGS

List all instruments initiating an alarm and/or shutdown by tag

number and show conditions where alarm or shutdown is required.

+6P

IN-05

INSTRUMENT TERMINATION DRAWING

Provide full termination details.

+6P

IN-06

INSTRUMENT HOOK-UP DETAILS

Show principle and materials.

+6P

IN-07

FUNCTIONAL LOGIC DIAGRAM

+6P

IN-08

INSTRUMENT MOUNTING DETAILS

Show installation details.

+8P

IN-09

INSTRUMENT PANEL LAYOUT

Show position meters, switches, nameplate engravings, cutouts, etc.

+8P

IN-10

INSTRUMENT CABLE LIST

Provide cables, types, sizes, lengths, termination details, etc.

+6P

IN-11

INSTRUMENT CALCULATIONS

+6P

IN-12

INSTRUMENT DATA SHEETS

Data sheets as contained in the specification completed by Supplier.

+8P

IN-13

WIRING & SCHEMATIC DIAGRAM

Show internal connections up to and including terminals for

connection of external wiring or cabling.

+6P

IN-04

GDF Production Nederland B.V.

Specification 103 Rev. 5.

X

X

Page 11 of 14

SUPPLIER DOCUMENT REQUIREMENTS (SDR)

DOCUMENTS SHOWN BELOW SHALL BE LISTED ON THE SUPPLIER DOCUMENT REGISTER (SDR CODE

PJ-01). ABBREVIATIONS ARE SHOWN BELOW.

Abbreviations Key: A-award (i.e. telefax, letter) P-Purchase Order placement, T-test, D-delivery, '-'-before, '+'-after,

blank - no requirement, R-review by inspector. Example: +4A = four weeks after award, -2D = two weeks, before

delivery.

PURPOSE AND TIMING

SDR

SDR - CODE DESCRIPTION

CODE

With

Bid

For

Review

Data Book(Yes)

IMO

MDR

IN-14

CERTIFIED DIMENSIONAL DRAWINGS

+10P

IN-15

CALIBRATION SHEET

+10P

IN-16

SOFWARE DOCUMENTATION - Configuration, database,

graphics, etc.

+8P

IN-17

INSTRUMENT LOOP DIAGRAMS

+8P

IN-18

NOT APPLICABLE - SEE IN-20

IN-19

DIMENSIONAL DRAWING, INCLUDING WEIGHT LIST

Show overall dimensions, including free space required for

ventilation, operation and for maintenance, location and size of

cable entries or cable entry area, details of bus duct connection,

shipping splits, location of foundation bolts, etc.

+8P

WIRING DIAGRAM FOR ALL ACCESSORIES

Show wiring/connections up to and including terminals for

connection of external wiring or cabling.

+8P

IN-21

PARTS LIST Identify all materials, make, type, material and

quantity

+6P

IN-22

PAINTING/COATING PROCEDURE/REPORT

+4A

IN-23

MATERIAL CERTIFICATES

In accordance with NEN-EN-10204 3.1.

+4A

IN-24

HYDROSTATIC TEST REPORT

+2T

IN-25

TEST PROCEDURES

+6A

IN-26

AUTHORITY/CODE

REQUIREMENTS

PRESSURE

CONTAINING PARTS (ACCORDING TO PED DIRECTIVE)

Documents, i.e. calculations, drawings, manufacturing/test

procedures required to meet authority and/or code requirements.

+4A

EXPLOSION PROOF CERTIFICATE ACCORDING TO ATEX

+4A

PROCESS FLOW DIAGRAM Incl. heat and mass balance.

+4P

PS-02

PROCESS DESCRIPTION

Including start-up and operating mode.

+4P

PS-03

PROCESS/UTILITY ENGINEERING FLOW SCHEMES (PEFS)

+6P

PS-04

PROCESS CALCULATIONS

+6P

PS-05

PROCESS DATA SHEETS

+6P

PI-01

PIPING COMPONENT OUTLINE DRAWING

+8P

PI-02

PARTS LIST - Identify all materials, make, type, material,

quantity.

+8P

IN-20

IN-27

PROCESS

PS-01

PIPING

GDF Production Nederland B.V.

Specification 103 Rev. 5.

Page 12 of 14

SUPPLIER DOCUMENT REQUIREMENTS (SDR)

DOCUMENTS SHOWN BELOW SHALL BE LISTED ON THE SUPPLIER DOCUMENT REGISTER (SDR CODE

PJ-01). ABBREVIATIONS ARE SHOWN BELOW.

Abbreviations Key: A-award (i.e. telefax, letter) P-Purchase Order placement, T-test, D-delivery, '-'-before, '+'-after,

blank - no requirement, R-review by inspector. Example: +4A = four weeks after award, -2D = two weeks, before

delivery.

PURPOSE AND TIMING

SDR

SDR - CODE DESCRIPTION

CODE

PI-03

With

Bid

For

Review

Data Book(Yes)

IMO

MDR

AUTHORITY/CODE

REQUIREMENTS

PRESSURE

CONTAINING PARTS

Documents, i.e. calculations, drawings, manufacturing/test

procedures required to meet authority and/or code requirements.

+10P

PI-04

DESIGN CALCULATIONS PIPING COMPONENTS

+10P

PI-05

PIPING NOZZLE LOADINGS

+8P

PI-06

NAME/TAG PLATE LIST

+10P

PI-07

CERTIFIED DIMENSIONAL DRAWINGS

+8P

GDF Production Nederland B.V.

Specification 103 Rev. 5.

Page 13 of 14

SUPPLIER DOCUMENT REGISTER (SDR CODE PJ-01)

SDR Code

Document Description

GDF Production Nederland B.V.

Specification 103 Rev. 5.

Document Number

Rev. Number

Page 14 of 14

Issue Date according SDR Code

S-ar putea să vă placă și

- CPM Su 5244cmpDocument70 paginiCPM Su 5244cmpLambertWayne100% (2)

- Taking Off - RC Works (Complete)Document4 paginiTaking Off - RC Works (Complete)Wai LapÎncă nu există evaluări

- Master Document MRB Index Rev RDocument10 paginiMaster Document MRB Index Rev RAdolfo Perez MonteroÎncă nu există evaluări

- Agip KCO: Kashagan Field Development Project Experimental ProgrammeDocument27 paginiAgip KCO: Kashagan Field Development Project Experimental ProgrammeMaffone NumerounoÎncă nu există evaluări

- S-000-5138-302 - B Design Change Procedure PDFDocument6 paginiS-000-5138-302 - B Design Change Procedure PDFMahadevan MahalingamÎncă nu există evaluări

- ABS Buckling Requirements For OffshoreDocument94 paginiABS Buckling Requirements For Offshorecurvedbrain100% (1)

- M 3094 (2013-06)Document17 paginiM 3094 (2013-06)Hatada FelipeÎncă nu există evaluări

- Architects DONEDocument10 paginiArchitects DONEAyu Amrish Gupta0% (1)

- Knorr EBS PDFDocument8 paginiKnorr EBS PDFAbrar HussainÎncă nu există evaluări

- Generation and Control of Supplier Document Requirement Lists and Supplier Document ListsDocument16 paginiGeneration and Control of Supplier Document Requirement Lists and Supplier Document ListsVelmurugan RamamoorthyÎncă nu există evaluări

- Supplier Document Requirements SDR GDF PDFDocument14 paginiSupplier Document Requirements SDR GDF PDFRyanÎncă nu există evaluări

- Manufacturers Data Report (MDR) - Plant Projects EP-08-030-37Document17 paginiManufacturers Data Report (MDR) - Plant Projects EP-08-030-37MekhmanÎncă nu există evaluări

- Elm 02 JGC PM SPC 0008Document25 paginiElm 02 JGC PM SPC 0008Amine GuedjibaÎncă nu există evaluări

- Specification Power Supply LGP42-11P EAY62170101 PDFDocument73 paginiSpecification Power Supply LGP42-11P EAY62170101 PDFaplkduÎncă nu există evaluări

- Vendor Document Register List (VDRL) - Air Diving ServicesDocument1 paginăVendor Document Register List (VDRL) - Air Diving Servicesplatipus_85Încă nu există evaluări

- Sample MRB Index For ENIDocument1 paginăSample MRB Index For ENIAnanthu Krishnan100% (1)

- SBU1 TLD G PR 002 Rev.B Document Control ProcedureDocument49 paginiSBU1 TLD G PR 002 Rev.B Document Control ProcedureAndreas SchlagerÎncă nu există evaluări

- Supplier S Documentation of Equipment PDFDocument32 paginiSupplier S Documentation of Equipment PDFzhangjieÎncă nu există evaluări

- Norsok StandardDocument58 paginiNorsok StandardstephlyonÎncă nu există evaluări

- SOW Fabrikasi C-335-01 - 19.116.1Document1 paginăSOW Fabrikasi C-335-01 - 19.116.1AlfanÎncă nu există evaluări

- Master Document Register ListDocument10 paginiMaster Document Register ListcrysÎncă nu există evaluări

- 3.2 Develop The Material Control PlanDocument9 pagini3.2 Develop The Material Control Planjesus_bs100% (1)

- IQWQ-FT-BSPDS-00-120111 - 0 Packing SpecDocument27 paginiIQWQ-FT-BSPDS-00-120111 - 0 Packing Specjacksonbello34Încă nu există evaluări

- Receiving Material Procedure (Done) (Sudah Direvisi)Document8 paginiReceiving Material Procedure (Done) (Sudah Direvisi)Hardika SambilangÎncă nu există evaluări

- ITP's and ITR's A Necessary - Monster - PDFDocument5 paginiITP's and ITR's A Necessary - Monster - PDFshastri85Încă nu există evaluări

- CSBP Underground PipingDocument27 paginiCSBP Underground PipingKatamaneni KoteswararaoÎncă nu există evaluări

- EIL Scope of WorkDocument11 paginiEIL Scope of WorkManjunath VenkateshÎncă nu există evaluări

- Annexure - 2 VDRLDocument22 paginiAnnexure - 2 VDRLSeyyed Amir Mohmmadi100% (1)

- Engineering Document Control ProcedureDocument10 paginiEngineering Document Control ProceduretulaskarÎncă nu există evaluări

- WI-SSA-ENGTEC-001-E - 1 - Verification of Process Engineering DocumentsDocument14 paginiWI-SSA-ENGTEC-001-E - 1 - Verification of Process Engineering Documentsanghel_florin82Încă nu există evaluări

- Material Take OffDocument2 paginiMaterial Take OffZaher Mhd Sharaf100% (1)

- Consumable Spec Rev 12Document24 paginiConsumable Spec Rev 12megastar0604Încă nu există evaluări

- Manual de Vaporizadores AmbientalesDocument9 paginiManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoÎncă nu există evaluări

- Fabrication Daily ReportDocument2 paginiFabrication Daily ReportlangcvÎncă nu există evaluări

- MDR 01 r00 27.03.2019Document1 paginăMDR 01 r00 27.03.2019CRISTIAN SILVIU IANUCÎncă nu există evaluări

- VECO-PM-PRO-0006 Document Numbering Procedure, Rev. 0Document6 paginiVECO-PM-PRO-0006 Document Numbering Procedure, Rev. 0hymerchmidtÎncă nu există evaluări

- VDRL Update 5 Aug 2016 TFDocument40 paginiVDRL Update 5 Aug 2016 TFS Dwi NÎncă nu există evaluări

- Shipping Storage and Preservation GuidelineDocument13 paginiShipping Storage and Preservation GuidelinePaul Gianmarco Melendez VasquezÎncă nu există evaluări

- Standard PracticeDocument14 paginiStandard PracticeRomi Abdul RahmanÎncă nu există evaluări

- Technical Query FormatDocument1 paginăTechnical Query Formathamza98Încă nu există evaluări

- Complete PackageDocument105 paginiComplete PackagesarangpuneÎncă nu există evaluări

- Welding MapDocument1 paginăWelding MapSriram Vj100% (1)

- EPCC-5 (MS Block - Octamax Unit) Part-III-Master Index - Volume-1Document10 paginiEPCC-5 (MS Block - Octamax Unit) Part-III-Master Index - Volume-1Structures ProductionÎncă nu există evaluări

- 000 MW SP 0001 Painting SpecificationsDocument74 pagini000 MW SP 0001 Painting Specificationsjcarbajal2013Încă nu există evaluări

- Manufacturing Quality Plan (MQP)Document2 paginiManufacturing Quality Plan (MQP)Ranjit SinghÎncă nu există evaluări

- Mechanical Scope of WorksDocument4 paginiMechanical Scope of WorksidilfitriÎncă nu există evaluări

- PP-CI-GG-005 Civil Inspection and Testing ServicesDocument7 paginiPP-CI-GG-005 Civil Inspection and Testing ServicessiagiandobahÎncă nu există evaluări

- Gen Spec For D Design and Engineering Erd-10-04Document85 paginiGen Spec For D Design and Engineering Erd-10-04kattabommanÎncă nu există evaluări

- Reports - Production - R0Document14 paginiReports - Production - R0talupurumÎncă nu există evaluări

- Supplier's Documentation of EquipmentDocument32 paginiSupplier's Documentation of Equipmentrenjithv_4Încă nu există evaluări

- SOP - 05 - Transportatio ProcedureDocument31 paginiSOP - 05 - Transportatio ProcedureSuci YatiningtiyasÎncă nu există evaluări

- CO-S-004 Document Numbering System Rev.ADocument5 paginiCO-S-004 Document Numbering System Rev.ARanjan KumarÎncă nu există evaluări

- Fabrication and InstallationDocument6 paginiFabrication and Installations33d_2010Încă nu există evaluări

- Construction Check Sheet: Carbon Steel / Cs-Pe / Dss Pipeline PL-201ADocument3 paginiConstruction Check Sheet: Carbon Steel / Cs-Pe / Dss Pipeline PL-201ADaniel MartinezÎncă nu există evaluări

- Responsibility Matrix For Shop Piping WorksDocument5 paginiResponsibility Matrix For Shop Piping WorksRenny DevassyÎncă nu există evaluări

- Content of Project Documentation For Control System v03Document8 paginiContent of Project Documentation For Control System v03Jelenko CrnjakÎncă nu există evaluări

- Supplier Pre-Qualification Document - September 2020Document23 paginiSupplier Pre-Qualification Document - September 2020cephas ventures enterprisesÎncă nu există evaluări

- Receiving Material Procedure CoverDocument1 paginăReceiving Material Procedure Covergst ajahÎncă nu există evaluări

- QIR-111-Rotating Equipment Preservation CardDocument2 paginiQIR-111-Rotating Equipment Preservation CardSamer BayatiÎncă nu există evaluări

- Procedure - Asset LabelingDocument4 paginiProcedure - Asset LabelingGiri PrasadÎncă nu există evaluări

- Value Of Work Done A Complete Guide - 2020 EditionDe la EverandValue Of Work Done A Complete Guide - 2020 EditionÎncă nu există evaluări

- Specification 103 Rev. 8 - Supplier Document RequirementsDocument16 paginiSpecification 103 Rev. 8 - Supplier Document RequirementsTadaya KasaharaÎncă nu există evaluări

- 13 - VDDR For MOV (Annexure A)Document1 pagină13 - VDDR For MOV (Annexure A)Anonymous fLgaidVBhzÎncă nu există evaluări

- Std. PR For LT Isolating SwitchDocument10 paginiStd. PR For LT Isolating SwitchJigyesh SharmaÎncă nu există evaluări

- Anubar SpecDocument8 paginiAnubar SpecSHIVAJI CHOUDHURYÎncă nu există evaluări

- 2004 ATRA Seminar Manual ContentsDocument316 pagini2004 ATRA Seminar Manual Contentschoco84100% (2)

- Midas Civil WebinarDocument51 paginiMidas Civil WebinarCHarlesghylonÎncă nu există evaluări

- Oracle IRecruitment - By: Hamdy MohamedDocument49 paginiOracle IRecruitment - By: Hamdy Mohamedhamdy2001100% (1)

- Information: Reading Images - The Grammar of Visual DesignDocument5 paginiInformation: Reading Images - The Grammar of Visual DesignAndang Prasetya Adiwibawa BernardusÎncă nu există evaluări

- HS 30 eDocument9 paginiHS 30 eJayakrishnaÎncă nu există evaluări

- Decrypt SSL and SSH TrafficDocument5 paginiDecrypt SSL and SSH TrafficMinh Luan PhamÎncă nu există evaluări

- ExpertFit Student Version OverviewDocument23 paginiExpertFit Student Version Overviewlucas matheusÎncă nu există evaluări

- Checklist of E/OHS Activities For Asbestos Management: Name of Publication DateDocument20 paginiChecklist of E/OHS Activities For Asbestos Management: Name of Publication DateidahssÎncă nu există evaluări

- SAP LandscapeDocument4 paginiSAP LandscapeSiddharth PriyabrataÎncă nu există evaluări

- HT Motors Data SheetDocument3 paginiHT Motors Data SheetSE ESTÎncă nu există evaluări

- Microreactor P.4-19Document22 paginiMicroreactor P.4-19dheannisrÎncă nu există evaluări

- Pellets Burner 6 00 Manual EnglishDocument22 paginiPellets Burner 6 00 Manual EnglishTasos KachpanisÎncă nu există evaluări

- Volvo Ec35D: Parts CatalogDocument461 paginiVolvo Ec35D: Parts Cataloggiselle100% (1)

- Airtag Wallet Keyword Search-2Document15 paginiAirtag Wallet Keyword Search-2Azhar ShakeelÎncă nu există evaluări

- Multilateral Drilling and Completions - Applications in Practice D. ThemigDocument12 paginiMultilateral Drilling and Completions - Applications in Practice D. ThemigFaiz TalpurÎncă nu există evaluări

- 02 MDB3083 - Lecture1 (B) PDFDocument30 pagini02 MDB3083 - Lecture1 (B) PDFJasmine_lai00Încă nu există evaluări

- Paper GuideDocument77 paginiPaper Guideandhika yudhistiraÎncă nu există evaluări

- Cs - cp56 64 74 Specalog (Qehq1241)Document20 paginiCs - cp56 64 74 Specalog (Qehq1241)firman manaluÎncă nu există evaluări

- DeltaBox Catalogue UK 2021Document37 paginiDeltaBox Catalogue UK 2021Philip G. SantiagoÎncă nu există evaluări

- Ad and AVM l1Document54 paginiAd and AVM l1Rahul Tiwari67% (3)

- CV Kevin Ikhwan Muhammad Pt. Hasakona BinaciptaDocument6 paginiCV Kevin Ikhwan Muhammad Pt. Hasakona BinaciptaKevin MuhammadÎncă nu există evaluări

- Sba 2017 To 2018Document12 paginiSba 2017 To 2018api-383788708Încă nu există evaluări

- CAE Unit 9 Pt. 1Document12 paginiCAE Unit 9 Pt. 1Nguyen TanÎncă nu există evaluări

- My Restaurant API DocumentDocument60 paginiMy Restaurant API DocumentJosé FranciscoÎncă nu există evaluări

- Arduino Water Flow Sensor CodeDocument6 paginiArduino Water Flow Sensor CodeNasruddin AVÎncă nu există evaluări