Documente Academic

Documente Profesional

Documente Cultură

Pages From Vinidex Design PDF

Încărcat de

ilavarasisDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pages From Vinidex Design PDF

Încărcat de

ilavarasisDrepturi de autor:

Formate disponibile

design

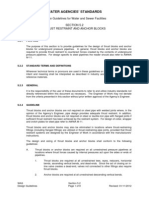

THRUST SUPPORT

Table 3.14 Pressure Thrust at Fittings in kN for each 10 metres Head of Water

An imbalanced thrust is developed

by a pipeline at:

Direction changes (> 10),

e.g. tees and bends.

Changes in pipeline size at

reducers.

Pipeline terminations, e.g. at blank

ends and valves.

Series 1 pipe

Size

DN

Area

(mm2)

BENDS

111/4

221/2

45

90

TEES

ENDS

15

363

0.01

0.01

0.03

0.05

0.04

20

568

0.01

0.02

0.04

0.08

0.06

25

892

0.02

0.03

0.07

0.12

0.09

32

1410

0.03

0.05

0.11

0.20

0.14

40

1840

0.04

0.07

0.14

0.26

0.18

The support system or soil must be

capable of sustaining such thrusts.

50

2870

0.06

0.11

0.22

0.40

0.28

65

4480

0.09

0.17

0.34

0.62

0.44

Pressure thrust results from internal

pressure in the line acting on fittings.

Velocity thrust results from inertial

forces developed by a change in

direction of flow. The latter is

usually insignificant compared to the

former.

80

6240

0.12

0.24

0.47

0.87

0.61

100

10300

0.20

0.39

0.77

1.43

1.01

125

15500

0.30

0.59

1.16

2.15

1.52

150

20200

0.39

0.77

1.52

2.80

1.98

200

40000

0.77

1.53

3.00

5.55

3.92

225

49400

0.95

1.89

3.71

6.85

4.84

250

61900

1.19

2.37

4.65

8.58

6.07

PRESSURE THRUST

300

78400

1.51

3.00

5.88

10.87

7.69

375

126000

2.42

4.82

9.46

17.47

12.36

The pressure thrust developed for

various types of fittings can be

calculated as follows:

Blank ends, tees, valves

F = AP 10-3

Series 2 pipe

Size

DN

Reducers and tapers

F = (A1 -A2)P10-3

Bends

F = 2 A P sin(/2)10-3

where:

F

= resultant thrust force

(kN)

= area of pipe taken at the OD

(mm2)

= design internal pressure

(MPa)

= included angle of bend

Area

(mm2)

BENDS

111/4

221/2

45

90

TEES

ENDS

100

11700

0.23

0.46

0.89

1.65

1.17

150

24800

0.48

0.96

1.89

3.50

2.47

200

42500

0.83

1.65

3.24

5.99

4.24

250

52900

1.04

2.06

4.04

7.47

5.28

300

93700

1.84

3.66

7.17

13.25

9.37

375

142700

2.80

5.57

10.92

20.18

14.27

(degrees)

The design pressure used should be

the maximum pressure, including

water hammer, to be applied to the

line. This will usually be the field

test pressure.

design.44

PVC Pressure Pipe Systems PVC Pressure Pipe Systems PVC Pressure Pipe Systems PVC Pressure Pipe

design

VELOCITY THRUST

Applies only at changes in direction of flow:

F = WAV2 2 sin(/2) 10-9

(kN)

where:

(mm2)

A = cross sectional area of pipe taken at the inside diameter

W = density of fluid (water = 1,000)

(kg/m3)

V = velocity of flow

(m/s)

THRUST BLOCKS

Concrete thrust blocks are usually required to transfer unbalanced forces in

buried pipelines to the surrounding soil. See Installation Guidelines for

construction of thrust blocks.

To determine the bearing area of the thrust block required, divide the

resultant thrust by the bearing capacity of the soil.

The bearing capacity of the soil is dependent on the mode of failure. For

deep situations, compressive characteristics will govern and a guide to the

appropriate design bearing loads is given in Table 3.15.

For shallow cover, shearing slip failure can occur and bearing loads are very

much reduced. For cover less than 600mm, or less than three pipe

diameters, or if the ground is potentially unstable, e.g. embankment

conditions, a complete soil analysis should be carried out.

Slip failure may be avoided by extending the thrust block downwards with

reinforcement against bending loads.

PVC Pressure Pipe Systems PVC Pressure Pipe Systems PVC Pressure Pipe Systems PVC Pressure Pipe

design.45

design

Table 3.15 Safe Compressive Bearing Load

USBR Soil

Classification

see ASTM D2478

Soil description

Soil Bearing Strength (kN/m2)

for cover height *h

0.75m

1.0m

1.25m

1.5m

Well graded gravel-sand mixtures, well graded

sands, little or no fines

GW,SW

57

76

95

114

Poorly graded gravels and gravel-sand mixtures,

Poorly graded sands, little or no fines

GP,SP

48

64

80

97

Silty gravels, gravel-sand-silt mixtures, silty

sands, sand-silt mixtures

GM,SM

48

64

80

96

Clayey gravels, gravel-sand-clay mixtures,

Clayey sands, sand-clay mixtures

GC,SC

79

92

105

119

Inorganic clays of low to med plasticity, gravelly clays, sandy

clays, silty clays, lean clays

CL

74

85

95

106

Inorganic silts, very fine sands, rock flour, silty or clayey fine

sands

ML

69

81

93

106

OH

240

240

240

240

Organic clays of medium to high plasticity

Rock

*h=height of soil cover measured from centreline

Example:

VERTICAL THRUSTS

Thrust block design for a DN100 Tee

operating at 120m head in clayey

sand soil, *h=1.0m.

For resultant upward forces, the

mass of the thrust block plus any

soil directly above the pipe can be

taken as the counterbalancing force,

provided the overburden can

reasonably be expected to remain

there for the life time of the pipeline.

It is often better to bury the pipe

deeper than to add more concrete to

counterbalance an upward thrust.

Resultant force = 1.01 x 12 = 12.1kN

(Table 3.14)

Bearing Area = 12.1 / 92 = 0.13m2

(Table 3.15)

That is, a bearing area 0.25m high

and 0.55mm wide would be suitable.

design.46

PVC Pressure Pipe Systems PVC Pressure Pipe Systems PVC Pressure Pipe Systems PVC Pressure Pipe

S-ar putea să vă placă și

- Lecture Notes on Reinforced Concrete DesignDe la EverandLecture Notes on Reinforced Concrete DesignÎncă nu există evaluări

- Sand TrapDocument10 paginiSand TrapKhurram Javed100% (1)

- Design of Rigid Pavements and AnalysisDocument68 paginiDesign of Rigid Pavements and AnalysisJuanithaÎncă nu există evaluări

- Stone ColumnDocument116 paginiStone ColumnNur Farhana Ahmad Fuad100% (1)

- Anchor WorksDocument168 paginiAnchor WorksseamaniacÎncă nu există evaluări

- Well Pile Foundation PDFDocument17 paginiWell Pile Foundation PDFlingamkumarÎncă nu există evaluări

- CompactionDocument64 paginiCompactionRamesh Konakalla100% (1)

- NPTEL Course: Ground ImprovementDocument67 paginiNPTEL Course: Ground ImprovementNurullah Akbulut100% (1)

- Anchorage SDocument31 paginiAnchorage SDiego Alejandro Flores OrtízÎncă nu există evaluări

- Well CasingDocument81 paginiWell Casingsaa6383100% (1)

- Asaoka Method PDFDocument67 paginiAsaoka Method PDFAdriel Elezar100% (1)

- Construction of BridgesDocument104 paginiConstruction of BridgesV Venkata Narayana89% (9)

- Lecture08 Stone Columns PDFDocument69 paginiLecture08 Stone Columns PDFvijjikewlguy7116100% (2)

- Soil Testing and AnalysisDocument21 paginiSoil Testing and AnalysiskhemankarÎncă nu există evaluări

- Dewatering Pumps TrainingDocument31 paginiDewatering Pumps TrainingCHLORINE SHAKE100% (1)

- Cement Concrete Pavement and Interlocking Pavor BlocksDocument67 paginiCement Concrete Pavement and Interlocking Pavor Blocksrupesh417Încă nu există evaluări

- Ground Water ControlDocument36 paginiGround Water ControlHafizah Ayob100% (8)

- Box Culvert NotesDocument3 paginiBox Culvert NotesraghuÎncă nu există evaluări

- C A Over Head Water Tank (Final)Document23 paginiC A Over Head Water Tank (Final)usama buttÎncă nu există evaluări

- Wall Footing DesignDocument102 paginiWall Footing DesignAUNGPSÎncă nu există evaluări

- Methods of Tunneling (Techniques)Document24 paginiMethods of Tunneling (Techniques)Assfachew BeleteÎncă nu există evaluări

- Bill of Quantities: Royal Audit Authority Training Centre, TsirangDocument4 paginiBill of Quantities: Royal Audit Authority Training Centre, TsirangNasir UllahÎncă nu există evaluări

- Bored Tunnels Design and Construction: WEN DazhiDocument80 paginiBored Tunnels Design and Construction: WEN DazhiMelinda GordonÎncă nu există evaluări

- Wk9 Bearing Capacity From Field TestsDocument35 paginiWk9 Bearing Capacity From Field TestsAli Saeed100% (2)

- Thrust BlockingDocument2 paginiThrust Blockingarraghavan100% (2)

- SPE/IADC 119296 Zonal Isolation Achieved in Kashagan Field Through Integrated ApproachDocument11 paginiSPE/IADC 119296 Zonal Isolation Achieved in Kashagan Field Through Integrated ApproachPAOLA ANDREA DUARTE PRADAÎncă nu există evaluări

- 9 Design of Permanent, Final Linings: EM 1110-2-2901 30 May 97Document32 pagini9 Design of Permanent, Final Linings: EM 1110-2-2901 30 May 97Prem Singh RawatÎncă nu există evaluări

- RiGID PAVEMENT DESIGN 20-7-09Document94 paginiRiGID PAVEMENT DESIGN 20-7-09Ma Srinu100% (4)

- Pile Work Presentation at IITK Summer Camp 08Document82 paginiPile Work Presentation at IITK Summer Camp 08praxie0% (1)

- Design of Slabs-on-Grade: CE A433 - RC Design T. Bart Quimby, P.E., Ph.D. Spring 2007Document36 paginiDesign of Slabs-on-Grade: CE A433 - RC Design T. Bart Quimby, P.E., Ph.D. Spring 2007Seifeldin Ali MarzoukÎncă nu există evaluări

- Presentation 14Document19 paginiPresentation 14Claudia DominoniÎncă nu există evaluări

- Ground Improvement Using Stone Column: Rohit Kumar PGRPE 2014Document20 paginiGround Improvement Using Stone Column: Rohit Kumar PGRPE 2014pranja9999Încă nu există evaluări

- Deep Excavation ProcedureDocument26 paginiDeep Excavation ProcedureHuzaifa ZafarÎncă nu există evaluări

- Pile Foundations v1.00 Oct2010Document17 paginiPile Foundations v1.00 Oct2010Munteanu DanÎncă nu există evaluări

- Pile Foundations v1.00 Oct2010Document17 paginiPile Foundations v1.00 Oct2010zuzubettyÎncă nu există evaluări

- Dewatering For ConstructionDocument14 paginiDewatering For ConstructionpabulumzengÎncă nu există evaluări

- Ground Improvement Techniques 01Document57 paginiGround Improvement Techniques 01tharadev2512Încă nu există evaluări

- Proof RollingDocument33 paginiProof Rollingazcomp100% (8)

- CASE STUDY Stone ColumnDocument17 paginiCASE STUDY Stone ColumnNicholas CoteÎncă nu există evaluări

- Comparitive Study of Pile Foundations With Foundations On Stone Column Treated Ground 170704090313Document23 paginiComparitive Study of Pile Foundations With Foundations On Stone Column Treated Ground 170704090313anurag hazarikaÎncă nu există evaluări

- Ground Improvement Techniques ME 3rd SemDocument57 paginiGround Improvement Techniques ME 3rd SemSojil Jain86% (7)

- WellboreDocument18 paginiWellborekeen dela cruz100% (1)

- Rock AnchorDocument49 paginiRock Anchorrajeshri.1664100% (10)

- EC 11SlopeDrainsDocument6 paginiEC 11SlopeDrainstsuakÎncă nu există evaluări

- IRS - Well Pile Foundation Code PDFDocument17 paginiIRS - Well Pile Foundation Code PDFtipsypigÎncă nu există evaluări

- Module 10: Improvement of Rock Mass Responses: 10.4 Underground Supports Steel Arch Support and Steel Ribs & LaggingsDocument12 paginiModule 10: Improvement of Rock Mass Responses: 10.4 Underground Supports Steel Arch Support and Steel Ribs & Laggingsmed AmineÎncă nu există evaluări

- Slabs On GradeDocument36 paginiSlabs On GradeMohan Manickam100% (1)

- All Type of Pile Load TestDocument120 paginiAll Type of Pile Load TestLindsey Smith100% (17)

- AppendixC PDFDocument5 paginiAppendixC PDFkarthickaryanÎncă nu există evaluări

- Rigid Pavements With NEW CODE PDFDocument108 paginiRigid Pavements With NEW CODE PDFdhanush gtÎncă nu există evaluări

- GIT - A2 KEY & Scheme of ValuationDocument6 paginiGIT - A2 KEY & Scheme of ValuationsantoshÎncă nu există evaluări

- Sewage Disposal Works: Their Design and ConstructionDe la EverandSewage Disposal Works: Their Design and ConstructionÎncă nu există evaluări

- Turf Wall Architecture and Turf Furniture Assembly GuideDe la EverandTurf Wall Architecture and Turf Furniture Assembly GuideÎncă nu există evaluări

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionDe la EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionÎncă nu există evaluări

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!De la EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Evaluare: 5 din 5 stele5/5 (2)

- Simple Plumbing Repairs for the Home and FarmsteadDe la EverandSimple Plumbing Repairs for the Home and FarmsteadÎncă nu există evaluări

- Calculation of Service and Sea Margins: Egill EideDocument104 paginiCalculation of Service and Sea Margins: Egill EideilavarasisÎncă nu există evaluări

- 2015 - Flow Regimes in A Vertical Drop Shaft With A Sharp Edged Intake PDFDocument7 pagini2015 - Flow Regimes in A Vertical Drop Shaft With A Sharp Edged Intake PDFilavarasisÎncă nu există evaluări

- Part VI Chapter 5 Fundamentals of Design Part 1Document176 paginiPart VI Chapter 5 Fundamentals of Design Part 1ilavarasisÎncă nu există evaluări

- A W PP-813 Mechanical RestraintDocument3 paginiA W PP-813 Mechanical RestraintilavarasisÎncă nu există evaluări

- @ - Rubble Mound Structure DesignDocument24 pagini@ - Rubble Mound Structure Designapi-3709579100% (1)

- The Performance Pipe Engineering Manual PDFDocument208 paginiThe Performance Pipe Engineering Manual PDFilavarasis100% (1)

- Empirical Bed Load Transport EquationsDocument9 paginiEmpirical Bed Load Transport EquationsilavarasisÎncă nu există evaluări

- 2015 - Flow Regimes in A Vertical Drop Shaft With A Sharp Edged IntakeDocument7 pagini2015 - Flow Regimes in A Vertical Drop Shaft With A Sharp Edged IntakeilavarasisÎncă nu există evaluări

- The Performance Pipe Engineering Manual PDFDocument208 paginiThe Performance Pipe Engineering Manual PDFilavarasisÎncă nu există evaluări

- 1.7 Espaciamiento y Soportes - Performance Pipe Field HandbookDocument138 pagini1.7 Espaciamiento y Soportes - Performance Pipe Field HandbookHeiner PalaciosÎncă nu există evaluări

- A W PP-813 Mechanical RestraintDocument3 paginiA W PP-813 Mechanical RestraintilavarasisÎncă nu există evaluări

- A W PP-813 Mechanical RestraintDocument3 paginiA W PP-813 Mechanical RestraintilavarasisÎncă nu există evaluări

- A Paper On Stability of Offshore Pipelines PDFDocument12 paginiA Paper On Stability of Offshore Pipelines PDFSampurnanand Pandey100% (1)

- Chapter 2Document31 paginiChapter 2ilavarasisÎncă nu există evaluări

- Thrust Restraint & Anchor BlocksDocument8 paginiThrust Restraint & Anchor BlocksElias BuÎncă nu există evaluări

- HDPE DesignDocument15 paginiHDPE Designalmandhari3380% (5)

- Handbook of Polyethylene Pipe Hvac Applications PDFDocument27 paginiHandbook of Polyethylene Pipe Hvac Applications PDFhappale2002Încă nu există evaluări

- Thrust BlocksDocument2 paginiThrust BlockswespritÎncă nu există evaluări

- Marine and Dredging: July - August 2006Document4 paginiMarine and Dredging: July - August 2006ilavarasisÎncă nu există evaluări

- Joint Restraint Vs Thrust Block EBAA PDFDocument2 paginiJoint Restraint Vs Thrust Block EBAA PDFChristian D. OrbeÎncă nu există evaluări

- Pages From Vinidex DesignDocument3 paginiPages From Vinidex DesignilavarasisÎncă nu există evaluări

- Pages From Vinidex DesignDocument3 paginiPages From Vinidex DesignilavarasisÎncă nu există evaluări

- Mas FurnituressDocument12 paginiMas FurnituressilavarasisÎncă nu există evaluări

- Philips Professional Lighting Price Effective Sept 2013 27.10.14Document1 paginăPhilips Professional Lighting Price Effective Sept 2013 27.10.14ilavarasisÎncă nu există evaluări