Documente Academic

Documente Profesional

Documente Cultură

(LV Dist. Board)

Încărcat de

Farhan SaadatTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

(LV Dist. Board)

Încărcat de

Farhan SaadatDrepturi de autor:

Formate disponibile

8133-1

SECTION - 8133

LOW VOLTAGE (LV) DISTRIBUTION BOARDS

1.0

SCOPE OF WORK

The work under this section consists of design, manufacturing, fabricating,

supplying, installing, connecting, testing, and commissioning of all material and

services of the complete Low Voltage Distribution Boards as specified herein,

shown on the Tender Drawings and stated in the Bill of Quantities.

The Contractor shall discuss the electrical layout with the Engineer and coordinate at site with other services for exact position of the electrical lines and

equipment.

The Low Voltage Distribution Boards shall also comply with the General

specifications for Electrical & Communications Works Section-8001 and with

other relevant provisions of the Tender Documents.

2.0

GENERAL

The Low Voltage Distribution Boards shall be sheet steel fabricated. These shall

be suitable for surface mounting, semi-recessed or recessed in wall mounting.

The Low Voltage Distribution Boards shall be totally enclosed, dust and damp

proof. The Low Voltage Distribution Boards shall be complete in all respects with

material and accessories, factory assembled, tested and finished according to

the Specifications and to the normal requirements.

All components shall be installed on a common mounting plate inside the

enclosure and protected from the front with screwed sheet steel front plate. The

enclosure shall be provided with rubber gasketting and a lockable hinged door

with cam fastener.

The distribution board shall be supplied complete with all installation materials

as recommended by the manufacturer. The incoming and outgoing cable

connections shall be according to the wiring requirements. If required, an

adapter box for accommodating the cables and conduits may be provided. The

box shall be of the same material and finish as the distribution board.

The cabling inside the distribution board shall be suitably harnessed by means

of straps or cords. An earth bar or terminal strips shall be provided for

connection of incoming and outgoing earth conductors. The earth bar or

terminals shall be permanently connected to the body of distribution board at two

points.

The LV Distribution Boards, in general, shall;

-

be suitable for indoor installation & operation

8133-2

3.0

be suitable for operation and maintenance from front side

be suitable for both 415 Volt AC, three phase 4 wire and 230Volt AC,

single phase 2 wire, 50 Hz system

have all components rated for insulation class of 500V minimum for three

phase and 250 Volt for single system

be designed for flush mounting of all instruments on the front

be provided with adequate clearance from live parts so flash overs can

not be caused by switching, vermins, pests, etc.

have incoming/outgoing cable termination arrangements. The power

cables shall be directly connected to the terminals of TP 500V MCCBs of

current ratings of 100 Amps and above. The SP/ TP MCBs and/ or MCCBs

of current ratings upto and including 100 Amps shall be connected to DIN

rail mounted wiring terminals of appropriate ratings, numbers and sizes

for the outgoing wiring cables

be provided with name plate on the front side of door

be provided with pocket inside of door for safe keeping of the detailed asbuilt wiring/ shop diagrams of the switch board

have provisions for incoming and outgoing cables entry, connections and

termination arrangements from top and/ or bottom plates as per site

requirements

have all openable doors grounded with the use of flexible copper

cable/strip of at least 10mm2 cross-sectional area

APPLICABLE STANDARDS/CODES

The latest editions of the following standards and codes shall be applicable for

the materials specified within the scope of this Section :

BS 4752-1 -

Triple Moulded Case Circuit Breaker

IEC 947

Single and Triple Miniature Circuit Breaker

IEC 947

Low Voltage Switch gear and Control gear

IEC 439

Factory Built Assemblies of LV Switch gear

IEC 4752

Switch gear and control gear for Voltages upto & including 1 kV

BS 88

HRC Fuses

8133-3

4.0

IEC 73

Colors for indicator lights and push buttons

IEC 446

Identification of insulated/bare conductors

MATERIAL

4.1

Sheet Metal Work

The Surface mounting Low Voltage Distribution Board shall be fabricated

with 14 SWG sheet steel and the semi-recessed or recessed mounting

type shall be fabricated with 16 SWG sheet steel.

The complete sheet steel metal work of the Low Voltage distribution board

shall be:

4.2

cleaned down to bare shining metal

de-rusted and de-greased

painted with two base coats of anti-corrosive RED oxide paint

Two coats of weather proof powder paint in approved colour

Components

The Low Tension Distribution Board shall be provided with components as

specified in the specifications, mentioned in the Bill of Quantities, as

shown on the Tender Drawings required for the satisfactory operation of

the distribution board and of the electrical system.

Typical component specifications are given below:

4.2.1 Bus Bars

The bus bars shall be made of high conductivity electrolytic copper

and shall be completely isolated and mechanically braced for the

specified fault level. The phase identification of bus bars shall be

by colours applied on bus bars and these shall be red, yellow and

blue for phase and white for neutral. The earth bus bar shall be

green.

The bus bars shall be triple pole and neutral and shall be of

appropriate size to meet the electrical and mechanical

requirements of the system. The temperature rise shall not exceed

45 degrees centigrade at rated current.

4.2.2 Moulded Case Circuit Breaker (MCCB)

8133-4

The MCCB shall be moulded case, triple pole, rated for 500 Volt

AC. The Operating current ratings and Rupturing capacities shall

be as mentioned in the relevant items of the Bill of Quantities and

as shown on the drawings. The MCCBs shall have fixed Magnetic

Short circuit and fixed Thermal Overload protections. However, the

short circuit breaking capacities of triple pole moulded case circuit

breaks shall be more than or at least, 25 kA and 50 kA as per IEC

category P2, unless specified elsewhere. All incoming Triple pole

circuit breakers shall be Moulded Case Circuit Breakers.

The Moulded Case Circuit Breakers shall be installed in the LV

switchboards such that the switching lever of the Main Incoming

MCCB shall be accessible from the front of the panel with the front

door in closed position and the switching levers of all outgoing

MCCBs and MCBs are accessible through the front plate inside

the switchboards for operations. Circuit Numbers and Designation

on all circuits shall be clearly marked to facilitate connection and

maintenance.

4.2.3 Miniature Circuit Breaker (MCB)

The MCBs shall be Single pole 250 Volt and Triple pole 500 volts

of current ratings as shown on the drawings. These shall have

fixed magnetic short circuit and fixed thermal overload protections.

The Single pole and Triple pole miniature circuit breakers shall

have a 10 kA short circuit breaking capacity as per International

standards IEC 157 Category P2.

The Miniature Circuit Breakers shall be installed such that their

switching levers are accessible through the front plate inside the

Switch Boards for operations. Circuit Numbers and Designation on

all circuits shall be clearly marked to facilitate connection and

maintenance. These Circuit Breakers shall be suitable for working

on lighting and power circuits.

4.2.4 Push Buttons

Push buttons shall be momentary make break contact type

(normally open/normally close). These shall be suitable for flush

mounting. Distribution board, plastic face plate etc. Push buttons

shall have round/square head.

4.2.5 AC Voltmeters

AC Voltmeters shall be Digital type and shall be suitable for flush

mounting on front door of the Distribution Boards. The front

dimensions shall be 96 mm Wide and 48 mm high. The voltmeters

shall have 3-1/2 digit, 0.55 inch display.

8133-5

4.2.6 Ammeters

AC Ampere meters shall be Digital type and shall be suitable for

flush mounting on front door of the Distribution Boards. The front

dimensions shall be 96 mm wide and 48 mm high. The Ampere

meters shall have 3-1/2 digit, 0.55 inch display.

4.2.7 Voltmeter Selector Switch

The voltmeter selector switch shall be complete with front plate,

grip handle, and RY-YB-BR-OFF-RN positions.

4.2.8 Current Transformers

Air cooled, ring type current transformers shall be provided having

transformation ratio as indicated on the drawings. The current

transformers shall be of suitable burden having accuracy class 1.0

and have 5 amps secondary.

4.2.9 Air Break Magnetic Contactors

The contactors shall be air break, triple pole, 415 Volt suitable for

the type of duty to be performed. The main contacts shall be silver

tipped, butt type with double break per pole. Each contactor shall

be provided with 230 Volt AC single phase operating coil, and

minimum two normally open (NO) and two normally closed (NC)

auxiliary contacts wired up to terminals. The number of working

auxiliary contacts shall be provided according to the system

requirements.

4.2.10 Indicating Lamps

Indicating lamps shall be suitable for flush mounting, complete with

base, either 230 Volt neon or 12 Volt incandescent lamp through

auxiliary transformer and shall have rosettes of suitable colour.

4.2.11 Line up Terminals

5.0

Line up terminals wherever provided for control of lighting, power

and control circuits shall be suitable for voltage and size of

conductors as indicated on drawings and as mentioned in the

respective BOQ items. The line-up terminals shall be suitable for

channel mounting. All necessary accessories such as end-plates,

fixing clips, transparent label holder caps and label sheets with

marking shall be provided.

INSTALLATION

8133-6

The location of distribution boards are shown diagrammatically on the drawings.

The actual location shall be determined at site, keeping in view the site

conditions and in coordination with other equipment.

Low Voltage distribution board for recessed mounting in wall shall be installed

such that the door shall finish flush with the surface of wall. The recess mounted

distribution board shall be installed before the plastering of walls. The DB shall

be protected to avoid any damage due to the civil work.

All loose parts despatched separately with the DB shall be installed as per

manufacturer instructions and all adjustments or setting shall be made, as

required. All screws, nuts and bolts used for fixing the distribution board shall be

galvanized. The distribution boards installation shall include connecting all

incoming and outgoing cables. The cable entry in the boards shall be provided

from top or bottom as required.

The distribution board body shall be connected to earth as per instructions given

in section "Earthing" of these Specifications. The switchboard shall be tested

and commissioned in the presence of the Engineer. The LV distribution boards

shall be tested before energizing as per instructions contained in the article

"Testing" of General Specifications for Electrical Works, Section-8001 of these

Specifications.

6.0

MEASUREMENT AND PAYMENT

6.1

General

The Contractor's bid amount against each item of Bill of Quantities as

given below shall include design, fabrication, supply, installation, testing,

commissioning and completion for all works specified herein and/or as

shown on the Tender Drawing related to the item.

6.2

LV Distribution Board

6.2.1 Measurement

Measurement shall be made for the number of each

type/designation of LV distribution boards acceptably supplied and

installed by the Contractor as a complete job.

6.2.2 Payment

Payment shall be made for the number of each type/designation of

jobs measured, as provided above, at the Contract unit price each

for design, fabricating, supplying, installing, testing, and

commissioning of the LV distribution boards, including fixing

arrangement and accessories for complete installation.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Disassembly & Assembly 4006-8 TRS - KENR6945-00Document180 paginiDisassembly & Assembly 4006-8 TRS - KENR6945-00bagusÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Stairs Design Concrete ACI 318-11 12-02-14Document14 paginiStairs Design Concrete ACI 318-11 12-02-14LuisFernandoMendietaElena100% (2)

- Dynamo PartsDocument25 paginiDynamo Partsdustinguzman17100% (1)

- BOM SampleDocument7 paginiBOM SampleRobles HenryÎncă nu există evaluări

- Detail "B": 90 DEG 180 DEGDocument3 paginiDetail "B": 90 DEG 180 DEGcarlos ramos100% (1)

- En Capacitor Reforming Instructions DDocument14 paginiEn Capacitor Reforming Instructions DAnonymous UihtV75Încă nu există evaluări

- Nidek ARK 730 Autorefractometer Service Manual PDFDocument83 paginiNidek ARK 730 Autorefractometer Service Manual PDFPetrica DascaluÎncă nu există evaluări

- PW24Document2 paginiPW24farid-00526475Încă nu există evaluări

- MDKBL BM BN Parts ManualDocument144 paginiMDKBL BM BN Parts ManualAhung100% (1)

- 8113 Cable TrayDocument5 pagini8113 Cable TrayFarhan SaadatÎncă nu există evaluări

- Tarbela DamDocument4 paginiTarbela Damadeelkhan4340% (1)

- bm9ybWFsdGVzdHJlcG9ydA AspxDocument3 paginibm9ybWFsdGVzdHJlcG9ydA AspxFarhan SaadatÎncă nu există evaluări

- The PMP Exam: Quick Reference Guide, Sixth Edition (Test Prep Series) The PMP Exam: Quick Reference Guide, Sixth Edition (Test Prep Series)Document1 paginăThe PMP Exam: Quick Reference Guide, Sixth Edition (Test Prep Series) The PMP Exam: Quick Reference Guide, Sixth Edition (Test Prep Series)Farhan SaadatÎncă nu există evaluări

- English Catalougue DhakDocument66 paginiEnglish Catalougue DhakFarhan SaadatÎncă nu există evaluări

- Defence Housing Authority Multan Employment Application FormDocument2 paginiDefence Housing Authority Multan Employment Application FormFarhan Saadat0% (1)

- Practices of The 15 of Sha'ban The Night of Freedom From FireDocument3 paginiPractices of The 15 of Sha'ban The Night of Freedom From FireFarhan SaadatÎncă nu există evaluări

- 7 8 PDFDocument1 pagină7 8 PDFFarhan SaadatÎncă nu există evaluări

- 1253 Adeelshah - 14@yahoo - Com ADEEL HAIDERDocument3 pagini1253 Adeelshah - 14@yahoo - Com ADEEL HAIDERFarhan SaadatÎncă nu există evaluări

- Application DossierDocument10 paginiApplication DossierFarhan SaadatÎncă nu există evaluări

- Site Instruction Regarding Electrical ConduitsDocument2 paginiSite Instruction Regarding Electrical ConduitsFarhan SaadatÎncă nu există evaluări

- Cover Letter Farhan SaadatDocument1 paginăCover Letter Farhan SaadatFarhan SaadatÎncă nu există evaluări

- Deferral of Studies (Freezing) Form: Form Bsc-4 University of Engineering and Technology LahoreDocument1 paginăDeferral of Studies (Freezing) Form: Form Bsc-4 University of Engineering and Technology LahoreFarhan SaadatÎncă nu există evaluări

- BA GeneralDocument1 paginăBA GeneralFarhan SaadatÎncă nu există evaluări

- S T NS T N: Parks & Horticulture Authority (PHA) FaisalabadDocument4 paginiS T NS T N: Parks & Horticulture Authority (PHA) FaisalabadFarhan SaadatÎncă nu există evaluări

- 53438Document257 pagini53438Farhan Saadat0% (1)

- Power System Generation, Transmission and Distribution Prof. D. P. Kothari Center For Energy Studies Indian Institute of Technology, DelhiDocument20 paginiPower System Generation, Transmission and Distribution Prof. D. P. Kothari Center For Energy Studies Indian Institute of Technology, DelhiFarhan SaadatÎncă nu există evaluări

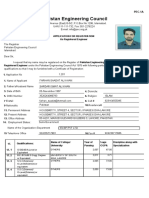

- PecDocument2 paginiPecFarhan SaadatÎncă nu există evaluări

- Attaching Documents To Pak-Identity Application: National Database and Registration AuthorityDocument4 paginiAttaching Documents To Pak-Identity Application: National Database and Registration AuthorityFarhan SaadatÎncă nu există evaluări

- ZWO EAF To GSO Crayford Focuser Installation GuideDocument2 paginiZWO EAF To GSO Crayford Focuser Installation GuideHasanBegzadehÎncă nu există evaluări

- Substation Design 3 Part 1Document32 paginiSubstation Design 3 Part 1Jet FranciscoÎncă nu există evaluări

- W113 EngDocument2 paginiW113 EngStefan PalaghiaÎncă nu există evaluări

- Reseller List v2Document5 paginiReseller List v2AvijitSinharoyÎncă nu există evaluări

- XCFR2.E60425 - Terminal Blocks - Component - UL Product IQDocument187 paginiXCFR2.E60425 - Terminal Blocks - Component - UL Product IQRahul Kumar Singh (IPR and Product Safety Compliance)Încă nu există evaluări

- Soal Latihan Penurunan PondasiDocument24 paginiSoal Latihan Penurunan PondasiKeluarga NainggolanÎncă nu există evaluări

- Stepper MotorDocument8 paginiStepper MotorHassan Muhammad ZahidÎncă nu există evaluări

- AlternatorDocument33 paginiAlternatorG Sandeep KumarÎncă nu există evaluări

- OVR T1-T2 3N 12.5-275s P QSDocument1 paginăOVR T1-T2 3N 12.5-275s P QSDiego PeñaÎncă nu există evaluări

- B 103 06Document12 paginiB 103 06Jesus Melchor Melchor100% (1)

- 7TS16 Annunciation Relay: Function OverviewDocument2 pagini7TS16 Annunciation Relay: Function OverviewVictor Manuel BonettoÎncă nu există evaluări

- HP 8640-1Document40 paginiHP 8640-1k6mayÎncă nu există evaluări

- GE 15312 Sun Smart ManualDocument4 paginiGE 15312 Sun Smart ManualScottstpÎncă nu există evaluări

- Scope of WorksDocument2 paginiScope of WorksBernard QuiboyÎncă nu există evaluări

- Lampu TL - Philips Tms PDFDocument2 paginiLampu TL - Philips Tms PDFmitra perkasa multigunaÎncă nu există evaluări

- ST 2.5-MTt PDFDocument1 paginăST 2.5-MTt PDFsteam100deg8229Încă nu există evaluări

- 0137Q EN WebDocument2 pagini0137Q EN WebDiego SánchezÎncă nu există evaluări

- RCD and Miniature CB Catalog - NHPDocument12 paginiRCD and Miniature CB Catalog - NHPjobpei2Încă nu există evaluări

- Legrand Product CatalogueDocument512 paginiLegrand Product CatalogueSreejith P. Menon100% (1)

- Tyco Rele EC V23078-c1002-A303 DatasheetDocument5 paginiTyco Rele EC V23078-c1002-A303 DatasheetLuis Gustavo Coqueiro LeiteÎncă nu există evaluări

- Human Factors Engineering Dr. Osama Al Meanazel: (Illumination, Luminance and Glare)Document12 paginiHuman Factors Engineering Dr. Osama Al Meanazel: (Illumination, Luminance and Glare)ehab kamalÎncă nu există evaluări