Documente Academic

Documente Profesional

Documente Cultură

Process Control Experiment

Încărcat de

YasserAbyDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Process Control Experiment

Încărcat de

YasserAbyDrepturi de autor:

Formate disponibile

GAS FLOW (AF 922) PLANT CONTROL

1.0

SUMMARY

To identify the important components of the air flow control system

and to mark them in the P&1 Diagram.

To carry out the start-up procedure systematically.

To study gas volumetric flow rate measurement using the orifice plate.

To study gas mass flow rate measurement using the orifice plate and

perfect gas

law to compute the gas density from the pressure and temperature

measurements.

To study gas mass flow rate (Fm) control using PID controller.

To design a PID controller using Ziegler Nichols closed loop method.

2.0 OBJECTIVES

In the gas flow process control system experiment, an equipment model AF

922 will be used. There are six objectives need to achieve which to identify

the important components of the air flow control system and to mark them in

the P&1 Diagram, to carry out the start-up procedure systematically, to study

gas volumetric flow rate measurement using the orifice plate, to study gas

mass flow rate measurement using the orifice plate and perfect gas law to

compute the gas density from the pressure and temperature measurements,

to study gas mass flow rate (Fm) control using PID controller and to design a

PID controller using Ziegler Nichols closed loop method. The experiment will

follow the procedures systematically by follow the lab manual in order to

avoid any error. In this experiment there are two indicators that used in this

experiments which are Control of Gas Flow System and PID Controller Tuning.

All these conditions are needed to test in order to test its function response

whether fast or not. In the theory states that by decreasing the value of PB,

the oscillation will increase and the response damping extremely for the

second trial at 150% compared to 200% of set point. At the last of

1

GAS FLOW (AF 922) PLANT CONTROL

experiments, there are oscillations in the graft and PB was increase until the

oscillation damped out which is about 96 %.

3.0 INTRODUCTION

The air flow process control training system (Model AF922) uses air to

simulate a gas or vapor phase flow process. Gas/vapor volumetric flow can

be measured either by the differential pressure across an orifice or by a

variable

area

flow

meter.

Compensation for pressure and temperature

variation using the Perfect Gas Law can be made to the flow measurement

by the differential pressure measurement.

PID became most useful when a mathematical model of the plant is not

available. There are many different PID tuning rules. The uses of loop tuning

techniques helped make the PID algorithm the most popular of all feedback

control strategies used in industrial applications. The objectives of the

experiment are to identify the important components of the air flow control

system, to study gas volumetric flow rate and gas mass flow rate

measurement using orifice plate. Besides that, to study gas mass flow rate

control using PID controller and to design a PID controller using Ziegler

Nichols closed loop method.

Ziegler and Nichols used the following definition of acceptable stability as a

basis for their controller tuning rules.The ratio of the amplitudes of

subsequent peaks in the same direction (due to a step change of the

disturbance or a step change of the setpoint in the control loop) is

approximately illustrated in Figure 1. (Haugen F., 2010)

GAS FLOW (AF 922) PLANT CONTROL

Figure 1: If A2/A1 1/4 the stability of the system is ok, according to Ziegler

and Nichols

The Ziegler-Nichols closed loop method is based on experiments executed on an

established control loop (a real system or a simulated system) which ilustrated in

Figure 2.

Figure 2: The Ziegler-Nichols closed loop method is executed on an

established control system.

An orifice plate basically a thin plate with a hole in the middle used to

measure the rate of fluid flow. It constricts the flow and measuring the

pressure differential across the constriction gives the flow rate. It used

Bernoullis principle that states, there is a relationship between the pressure

3

GAS FLOW (AF 922) PLANT CONTROL

of the fluid and the velocity of the fluid. When the velocity increases, the

pressure decreases and vice versa that presented in Figure 3. (eFunda, Inc.,

2011)

Figure 3: Orifice Plate Diagram

4.0 RESULTS AND DISCUSSION

Start Up Procedure

The result was shown in a graph form with three colors of lines which is red

line, the green line and the blue line. The red line was representing as the

mass flow rate, the green line represent as the volumetric flowrate and blue

line for TE91 (C). At this stages, MV of FIC91 was set to -6.3% and it was

adjust the manual valve MV900A till the air flow rate is about 50 kg/Hr. After

that, MV was set at 106.3% and change to 50%.

Control of Gas Flow System

As for starting of the experiment, the PID controller was start in trial mode

with a specific data input that was shown in Table 1. Based on those trial

modes, the equipment condition can be identifying.

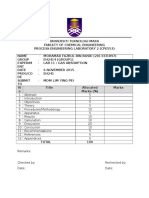

Table 1: The PID Trial Values

4

GAS FLOW (AF 922) PLANT CONTROL

PB1: 200%

TI1: 6 secs

TD1: 0 secs

PB2: 150%

TI2: 6 secs

TD3: 0 secs

PB3: 100%

TI3: 6 secs

TD3: 0 secs

Figure 4: PID trial

Based on Figure 1, the graph shows that the red line was the oscillate

conditions. The red line was representing as the mass flow rate, the green

line represent as the volumetric flowrate. According to the graph, mass flow

rate in the red line is in a proper curve which presented about 95% of value

that was set in the equipment. The equipment was set in manual mode with

with MV = 25% for the first trial and with MV = 30% for the second trial.

Next, mass flow rate in the red line in the second trial presented about 98%

of value. As the result, the red line responds quickly than the green line and

it states that the mass flow rate represent more sensitive than the

volumetric flowrate. By decreasing the value of PB, the oscillation will

increase. The PB corresponding to the constant amplitude oscillation as PB*

ultimate. PB is actually the fractional error change, relative to the error

range, required to produce a 100% change in the proportional term output.

The response damping extremely for the second trial at 150% compared to

200% of set point setting that illustrated in Figure 4.

For this experiment, the PID controller using Ziegler Nichols closed loop

method was used. The point of tuning a PID loop is to adjust how

5

GAS FLOW (AF 922) PLANT CONTROL

aggressively the controller reacts to errors between the measured process

variable and desired setpoint. If the controlled process happens to be

relatively sluggish, the PID algorithm can be configured to take immediate

and dramatic actions whenever a random disturbance changes the process

variable or an operator changes the setpoint. Then the PID algorithm must

apply more conservative corrective efforts over a longer period. The essence

of loop tuning is identifying just how dramatically the process reacts to the

controller efforts and how aggressive the PID algorithm can afford to be as it

tries to eliminate errors.

PID Controller Tuning

PB=100%

T1=

9999sec

(max)

TD=

sec

(min)

For the second experiment which is controller tuning was run to develop

optimizes the closed loop response for process model with the absence of

GAS FLOW (AF 922) PLANT CONTROL

specified disturbance or set-point change. The FIC91 in Manual (M) mode

with the set point SV=25kg/hr.

The PID values was adjusted with PB= about 100%, TI=9999 sec (max) and

TD=0sec (Min). Then, the MV in FIC91 was adjusted until the PV reads close

to the set point 25kg/hr. The FIC91 was transferred to Auto (A) mode. The

controller need to be sure in the Auto mode.

In this step, the set point pulse disturbance was introduced. The Close Loop

Method was repeated with a decreasing PB until uniform (constant

amplitude) oscillation is observed. In this experiment, the value PB was

decrease at 50 % which is constant amplitude. The distance between

adjacent peaks was assumed 2 mm. After the constant amplitude appear,

the Tn need to be calculated by using this formula.

Tn = measured period in mm x 3600 =

Chart speed eg 500mm/hr

1 x 3600 = 7.2

500

TI = Tn = 7.2 = 6

1.2

1.2

So, the PB* = 2 x PB* = 2 x 50 = 100%

Based on the calculation, the new PID value is PB= 100%, TI=6 sec and

TD=0sec (Min). A major control system that makes the effect to the process

is called a closed loop control system. There is feedback to the control

system so it can regulate the process. There are oscillations in the graft and

PB was increase until the oscillation damped out which is about 96 % which

illustrated in Figure 5.

GAS FLOW (AF 922) PLANT CONTROL

An on/off controller only has two outputs, either full maximum or full

minimum. For this system it has been determined that when the

measurement falls below the set point, the valve must be closed to cause it

to increase. Thus, whenever the signal to the automatic controller is below

the set point, the controller output will be 100%. As the measurement

crosses the set point the controller output goes to 0%. This continuous

oscillation may or may not, be acceptable depending upon the amplitude

and length of the cycle. Rapid cycling causes frequent upsets to the plant

supply system and excessive valve wear. On large capacity process, such as

temperature vats, the large capacity causes a very long time constant.

Therefore, the measurement can change only very slowly. The disadvantages

using Ziegler Nichols tuning method are gives very aggressive tuning, some

trial and error and also process upset. The disadvantages using Ziegler

Nichols tuning method are gives very aggressive, some trial and error and

also tuning process upset.

Figure 5: PID Controller Tuning

5.0

CONCLUSION

GAS FLOW (AF 922) PLANT CONTROL

The experiment consists design a PID controller using Ziegler Nichols closed

loop method, identifying the important components of the air flow control

system and to carry out the start-up procedure systematically in gas flow

control. In addition, there are two indicators that used in this experiments

which are Control of Gas Flow System and PID Controller Tuning. By

decreasing the value of PB, the oscillation will increase and the response

damping extremely for the second trial at 150% compared to 200% of set

point. A major control system that makes the effect to the process is called a

closed loop control system. There is feedback to the control system so it can

regulate the process. There are oscillations in the graft and PB was increase

until the oscillation damped out which is about 96 %. At the end of the

experiments, it was consists important components of the gas flow control

system and achieved to carry out the start up procedures systematically.

6.0 REFERENCES

eFunda, Inc., 2011.Orifice Flowmeter Calculator

[online] Available at:

http://www.efunda.com/formulae/fluids/calc_orifice_flowmeter.cfm

[Accessed 12 October 2011].

Haugen F, 2010. Ziegler-Nichols Closed-Loop Method

[online] Available at:

http://techteach.no/publications/articles/zn_closed_loop_method/zn_closed_lo

op_method.pdf

[Accessed 12 October 2011].

GAS FLOW (AF 922) PLANT CONTROL

7.0 APPENDIXES

GAS FLOW (AF 922) PLANT CONTROL UNIT

10

S-ar putea să vă placă și

- The Four Types of Gaps and How To Play Them PDFDocument17 paginiThe Four Types of Gaps and How To Play Them PDFshaikiftakar100% (2)

- Lab Report Batch ReactorDocument21 paginiLab Report Batch Reactornaneesa_190% (30)

- Experiment 3 Pulsed Column Liquid-Liquid Extraction ColumnDocument13 paginiExperiment 3 Pulsed Column Liquid-Liquid Extraction ColumnFikri IlyasÎncă nu există evaluări

- Adolescents and Career DevelopmentDocument10 paginiAdolescents and Career DevelopmentMasrijah MasirÎncă nu există evaluări

- Lab Report Level MeasurementDocument18 paginiLab Report Level MeasurementNur Ainin SofiaÎncă nu există evaluări

- Lab Report CSTR in SeriesDocument13 paginiLab Report CSTR in SeriesNisha Sharif100% (1)

- Maxwell's Equations and Stoke's TheoremDocument26 paginiMaxwell's Equations and Stoke's TheoremTuya ErdenejargalÎncă nu există evaluări

- Lab Report Process Control - Flow Measure PDFDocument23 paginiLab Report Process Control - Flow Measure PDFcleytonmarques1991100% (1)

- Experiment 7 - Batch ReactorDocument5 paginiExperiment 7 - Batch Reactormythili83% (6)

- CLB21103 Process Instrumentation Experiment 5: Thermocouple RTD MeasurementDocument9 paginiCLB21103 Process Instrumentation Experiment 5: Thermocouple RTD MeasurementSiti Hajar MohamedÎncă nu există evaluări

- EXP 10 - Plate Heat Exchanger Report.Document17 paginiEXP 10 - Plate Heat Exchanger Report.Muhammad Fawwaz50% (2)

- Marcet BoilerDocument8 paginiMarcet BoilerOjiSofttouchCharlesÎncă nu există evaluări

- Lab Report Distillation Column PDFDocument26 paginiLab Report Distillation Column PDFGebrina RizkiaÎncă nu există evaluări

- Bagi CHAPT 7 TUGAS INGGRIS W - YAHIEN PUTRIDocument4 paginiBagi CHAPT 7 TUGAS INGGRIS W - YAHIEN PUTRIYahien PutriÎncă nu există evaluări

- CKB 20104 Reaction Engineering UniKL MICET Experiment 1a: The Batch Saponification of Ethyl Acetate Full Lab ReportDocument11 paginiCKB 20104 Reaction Engineering UniKL MICET Experiment 1a: The Batch Saponification of Ethyl Acetate Full Lab ReportSiti Hajar Mohamed82% (11)

- Membrane Separation Lab Report - 2018262532 PDFDocument4 paginiMembrane Separation Lab Report - 2018262532 PDFShida ShamÎncă nu există evaluări

- Lab Report (Initial Boiling Point)Document10 paginiLab Report (Initial Boiling Point)nisasoberiÎncă nu există evaluări

- RESULT, DISCUSSION, Calculation, ConclusionDocument11 paginiRESULT, DISCUSSION, Calculation, ConclusionHafizszul Feyzul80% (5)

- Transport Lab Report Experiment 2Document16 paginiTransport Lab Report Experiment 2faranimohamed75% (4)

- Introduction For Batch Reactor ExperimentDocument5 paginiIntroduction For Batch Reactor ExperimentSaints Burner Christopher25% (4)

- Air Flow Process ControlDocument10 paginiAir Flow Process Controlfifie_natasha100% (1)

- CPB30004 Process Dynamics and Control Experiment 2: Liquid Flow Ratio Process Control Lab ReportDocument11 paginiCPB30004 Process Dynamics and Control Experiment 2: Liquid Flow Ratio Process Control Lab ReportSiti Hajar Mohamed100% (1)

- EXPERIMENT 16-Pressure ControlDocument21 paginiEXPERIMENT 16-Pressure ControlQeseraReaÎncă nu există evaluări

- Process Control Lab ReportDocument23 paginiProcess Control Lab ReportAnonymous OWdJRM8C100% (1)

- LAB REPORT FlowmeterDocument31 paginiLAB REPORT Flowmeterahlan wasahlan82% (28)

- Level Measurement Lab ReportDocument21 paginiLevel Measurement Lab ReportRabiyatul Adawiyah80% (5)

- CPE533 Gas Absorption Full Lab ReportDocument30 paginiCPE533 Gas Absorption Full Lab ReportFazsroul83% (12)

- Temperature Control Lab Report MuzDocument18 paginiTemperature Control Lab Report MuzAhmad Muzammil75% (8)

- Transport Lab Report Experiment 3Document18 paginiTransport Lab Report Experiment 3nurul nabilah bt khairul anuar100% (2)

- CPB30004 Process Dynamics and Control Experiment 1: Level Flow Cascade Process Control Lab ReportDocument8 paginiCPB30004 Process Dynamics and Control Experiment 1: Level Flow Cascade Process Control Lab ReportSiti Hajar Mohamed100% (5)

- Experiment 4 - Level Measurement & CalibrationDocument12 paginiExperiment 4 - Level Measurement & CalibrationRobert GilmoreÎncă nu există evaluări

- Lab Report CSTR 1Document16 paginiLab Report CSTR 1Nisha SharifÎncă nu există evaluări

- CPB30004 Process Dynamics and Control Experiment 4: Gas Pressure Process Control Lab ReportDocument18 paginiCPB30004 Process Dynamics and Control Experiment 4: Gas Pressure Process Control Lab ReportSiti Hajar Mohamed100% (19)

- Process Instrumentation Lab Report 4Document4 paginiProcess Instrumentation Lab Report 4Abu Rectify50% (4)

- Determining The Dissociation Constant of A Weak Acid Using The SpectrophotometerDocument23 paginiDetermining The Dissociation Constant of A Weak Acid Using The SpectrophotometerLaila Faeizah100% (7)

- Valuing Construction Variation by Using PWA, FIDIC, ICWMF and CEDA Fluctuation Formula MechanismDocument5 paginiValuing Construction Variation by Using PWA, FIDIC, ICWMF and CEDA Fluctuation Formula MechanismAzman YahayaÎncă nu există evaluări

- Adulteration Lab ReportDocument8 paginiAdulteration Lab ReportchromeÎncă nu există evaluări

- Lab Report Full Air Flow Process ControlDocument22 paginiLab Report Full Air Flow Process ControlMuhammad Asyraf II100% (1)

- CPB30303 Oil and Fat Process Technology UniKL MICET Experiment 4: Lab Scale Soap Production Full Lab ReportDocument15 paginiCPB30303 Oil and Fat Process Technology UniKL MICET Experiment 4: Lab Scale Soap Production Full Lab ReportSiti Hajar MohamedÎncă nu există evaluări

- Lab Report PDC Gas PressureDocument9 paginiLab Report PDC Gas PressureHaziq AzliÎncă nu există evaluări

- Exp 6 Gas Temperature Process ControlDocument13 paginiExp 6 Gas Temperature Process Controlmohamad ashaziq100% (8)

- S-Lab Manual Exp 3 - Air Flow Process ControlDocument12 paginiS-Lab Manual Exp 3 - Air Flow Process Controlarif arifinÎncă nu există evaluări

- Exp - 4 - Pulsed Column Liquid - Liquid ExtractionDocument14 paginiExp - 4 - Pulsed Column Liquid - Liquid ExtractionAdawiyah Al-jufri0% (3)

- Lab Report Process Instrument 4Document6 paginiLab Report Process Instrument 4hellothere50% (6)

- Air Pressure Process Control Lab ManualDocument11 paginiAir Pressure Process Control Lab ManualFaris Putera100% (1)

- Lab Report Ratio ControlDocument15 paginiLab Report Ratio Controlnaneesa_1100% (8)

- CKB 20104 Reaction Engineering UniKL MICET Experiment 4: Reactor Test Rig Full Lab ReportDocument14 paginiCKB 20104 Reaction Engineering UniKL MICET Experiment 4: Reactor Test Rig Full Lab ReportSiti Hajar Mohamed100% (10)

- Properties Measurement PVT ManuscriptDocument5 paginiProperties Measurement PVT ManuscriptAtqh AzmnÎncă nu există evaluări

- Level Control (Our Report)Document31 paginiLevel Control (Our Report)Brishti Anwar100% (1)

- Vle UnitDocument26 paginiVle UnitAhmad Ifwat50% (2)

- Level Flow PCDocument10 paginiLevel Flow PCMurali TharanÎncă nu există evaluări

- Lab Report - Distillation of Bubble CapDocument21 paginiLab Report - Distillation of Bubble Capratish100% (1)

- Full Lab Report ThermoDocument42 paginiFull Lab Report Thermoatiqah75% (4)

- FULL PRACTICAL 5 NadopodDocument5 paginiFULL PRACTICAL 5 NadopodBatrisyia IlhamÎncă nu există evaluări

- Tray Dryer - Lab ReportDocument9 paginiTray Dryer - Lab Reportinurhadi1350% (2)

- Lab Report TPP Experiment 3Document10 paginiLab Report TPP Experiment 3Nurul Najwa100% (1)

- VLE Unit (Complete)Document26 paginiVLE Unit (Complete)hishamÎncă nu există evaluări

- Marcet Boiler ExperimentDocument7 paginiMarcet Boiler ExperimentSeng SoonÎncă nu există evaluări

- Lab 2 Brief DepressurizationDocument6 paginiLab 2 Brief DepressurizationRenissha Nair100% (2)

- Temperature Control TrainerDocument31 paginiTemperature Control TrainerAjeet KumarÎncă nu există evaluări

- CPE501 - Lab Simulink Control Loop Syste PDFDocument27 paginiCPE501 - Lab Simulink Control Loop Syste PDFJose Heli Vallejos CoronadoÎncă nu există evaluări

- Discussion Tray DryerDocument3 paginiDiscussion Tray DryerIskandar ZulkarnainÎncă nu există evaluări

- Exp 4 Batch Evaporative Crystallization PDFDocument9 paginiExp 4 Batch Evaporative Crystallization PDFmirza farhanÎncă nu există evaluări

- Lab Report LLE LatestDocument7 paginiLab Report LLE Latestnajihah50% (2)

- Air Flow Result DiscussionDocument9 paginiAir Flow Result DiscussionAzura BahrudinÎncă nu există evaluări

- A B&C - List of Residents - VKRWA 12Document10 paginiA B&C - List of Residents - VKRWA 12blr.visheshÎncă nu există evaluări

- Bach Polonaise G Min BWV 119 A4Document1 paginăBach Polonaise G Min BWV 119 A4vincenzovaiaÎncă nu există evaluări

- FBDocument27 paginiFBBenjaminÎncă nu există evaluări

- Transformational Leadership in The UmcDocument17 paginiTransformational Leadership in The Umcapi-202352366Încă nu există evaluări

- PC2000-8 Spec SheetDocument20 paginiPC2000-8 Spec SheetNeeraj ChauhanÎncă nu există evaluări

- Task 3: New - HTMLDocument12 paginiTask 3: New - HTMLGONELA SAI LOKESH (RA2011028010100)Încă nu există evaluări

- Introduction of Woman Role in SocietyDocument12 paginiIntroduction of Woman Role in SocietyApple DogÎncă nu există evaluări

- HH220i - JAN 11Document1 paginăHH220i - JAN 11Achmad GazaliÎncă nu există evaluări

- Po 4458 240111329Document6 paginiPo 4458 240111329omanu79Încă nu există evaluări

- UVEX - Helmets & Eyewear 2009Document19 paginiUVEX - Helmets & Eyewear 2009Ivica1977Încă nu există evaluări

- Ruby Onyinyechi Amanze - Werte Magazine - 2019Document2 paginiRuby Onyinyechi Amanze - Werte Magazine - 2019José LaertonÎncă nu există evaluări

- Lesson 7Document6 paginiLesson 7Jeya Plays YTÎncă nu există evaluări

- RTRT User GuideDocument324 paginiRTRT User GuideAlae Khaoua100% (3)

- 56257375851Document3 pagini56257375851Anneliese FernandesÎncă nu există evaluări

- Pemisah ZirconDocument10 paginiPemisah ZirconLorie Banka100% (1)

- STRESS HealthDocument40 paginiSTRESS HealthHajra KhanÎncă nu există evaluări

- BAB 3 - Follow UpDocument6 paginiBAB 3 - Follow UpDelinda Erutheya NathanÎncă nu există evaluări

- Beyond The Breech Trial. Maggie BanksDocument4 paginiBeyond The Breech Trial. Maggie Bankspurpleanvil100% (2)

- Bluesil Ep 150 A3: Insulator Grade Silicone RubberDocument2 paginiBluesil Ep 150 A3: Insulator Grade Silicone RubberNagendra KumarÎncă nu există evaluări

- My LH Cover LetterDocument3 paginiMy LH Cover LetterAkinde FisayoÎncă nu există evaluări

- Procedure For Non Hazardous Waste ManagementDocument6 paginiProcedure For Non Hazardous Waste ManagementPaddyÎncă nu există evaluări

- Technology For Duck - Fish Integrated Farming System in GoaDocument4 paginiTechnology For Duck - Fish Integrated Farming System in GoagavinilaaÎncă nu există evaluări

- Periodicity Review SL KeyDocument4 paginiPeriodicity Review SL KeyYeyoung ParkÎncă nu există evaluări

- MODULE 1 - Contemporary WorldDocument4 paginiMODULE 1 - Contemporary WorldaapÎncă nu există evaluări

- Month Puzzle Two VariableDocument6 paginiMonth Puzzle Two VariableNayan KaithwasÎncă nu există evaluări