Documente Academic

Documente Profesional

Documente Cultură

Vibration Analysis Generator Sets

Încărcat de

yzn_hDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Vibration Analysis Generator Sets

Încărcat de

yzn_hDrepturi de autor:

Formate disponibile

! " # $ !

%

&' ( )

* )* '

&+ + + %

% %

.

-/

1 2

"

'

''*

Equipment

The following equipment was used to carry out the vibration analysis:

SKF Microlog:

CMVA60.

Serial No 602995

Accelerometer:

Number: 1

Serial No 222

Dell Notebook Computer

SKF Prism4 Vibration Analysis Software.

Analyst

Mr A Analysit.

Vibration Analysis Report

Oil Company

A Platform

Date:

19/21-9-2007

Introduction

A Vibration Analysis was requested by A National Maintenance Company, on 3 x

Generator sets situated in the engine room of a North Sea Offshore Oil Platform.

The vibration analysis was to identify the cause of the excessive vibration on the

Engine room floor.

During the site visit I was informed the 3 x Caterpillar generator sets were not the

original units, and the vibration had been an issue since they were fitted.

During the vibration analysis two generator sets were constantly running and one

was on standby.

The standby unit was rotated during the analysis, and readings were taken from all

three units during the rotation. This was to check if the vibration on the two running

units was affecting the standby unit, also to see if the two running units affected each

other.

The positions of the readings taken on each unit were:Engine

Non drive end:- Horizontal, Vertical & Axial

Drive end:- Horizontal, Vertical & Axial

Alternator

Drive end:- Horizontal, Vertical & Axial

Non drive end:- Horizontal, Vertical & Axial

Generator Skid

Engine Non drive end:- Horizontal

Engine Drive end:- Horizontal

Alternator Drive end:- Horizontal

Alternator Non drive end:- Horizontal

Resilient Mounts

Engine Non drive end:- Vertical. Top & Bottom Plate

Engine Drive end:- Vertical. Top & Bottom Plate

Alternator Drive end:- Vertical. Top & Bottom Plate

Alternator Non drive end:- Vertical. Top & Bottom Plate

Original Skid

Engine Non drive end:- Vertical

Engine Drive end:- Vertical

Alternator Drive end:- Vertical

Alternator Non drive end:- Vertical

All quoted velocity amplitudes are mm/s RMS.

Overall Values are 30Kcpm frequency length.

Vibration Analysis Report

Oil Company

A Platform

Date:

19/21-9-2007

Report

Fig 1

D2080A Engine Drive End Horizontal

Caterpillar Generator Set No.1

D2080A

Engine

The highest overall vibration recorded on

D2080A engine was 9.49mm/s, with the

1x rotational speed (1800rpm) at

3.36mm/s. This was from the drive end

horizontal position (See Fig 1 D2080A

Engine drive end horizontal).

Unit On Standby

Fig 2

D2080A Alternator Non Drive End Horizontal

Alternator

The highest overall vibration recorded on

D2080A alternator was 12.77mm/s, with

the 1x rotational speed (1800rpm) at

5.46mm/s. This was from the non drive

end horizontal position (See Fig 2

D2080A Alternator non drive end

horizontal).

Unit On Standby

Fig 3

D2080A Generator Skid. Engine Drive End (Left)

Generator Skid

Readings were taken from this skid in

the horizontal direction in line with the

resilient mounts. If viewing the skid from

the engine end, the highest vibration was

on the left hand side of the skid at the

engine position but particularly the drive

end where an overall level of 81.33mm/s

was recorded (See Fig 3 D2080A

Generator Skid Engine drive end). This

vibration was not due to 1x rotational

speed but a frequency of 7,200cpm (See

fig 4 Generator Skid Engine drive end

spectrum).

Unit On Standby

Fig 4

D2080A Generator Skid. Engine Drive End (Left)

Resilient Mounts

Readings were taken from the resilient

mounts in the vertical direction on the top

plate and the bottom plate. The highest

vibration was recorded on the top of the

engine resilient mounts, particularly the

drive end mount which reached an

overall level of 45.6mm/s, again due to a

frequency of 7200cpm.

Vibration Analysis Report

Oil Company

A Platform

Date:

19/21-9-2007

Report

Fig 5

D2080A Original Skid. Engine Drive End (Left)

Caterpillar Generator Set No.1

D2080A

Original Skid

Readings were taken from this skid in

the vertical direction next to the resilient

mounts. If viewing the skid from the

engine end, the highest vibration was on

the left hand side of the skid at the

engine drive end position. The overall

vibration at this position was 15.50mm/s

(See Fig 5 Original Skid Engine drive

end) this is also due to the 7,200cpm.

Unit On Standby

Summary

Caterpillar Generator Set 1

D2080A

Engine & Alternator

As can be seen in Fig.1 & Fig.2, the vibration on the engine and alternator during the

analysis was at an acceptable level using BS 7698: Part 9:1996.

Generator Skid

As can be seen in Fig.3 & Fig.4 the vibration on the generator skid at the engine drive

end position is excessively high at 81.33mm/s, due to a frequency of 7,200cpm. The

7,200cpm frequency is divisible by the 1x rotational frequency of the engine/alternator

(1800rpm) and could be related to the firing sequence of the engine.

Resilient Mounts

Although the vibration on the top of the engine resilient mounts is high, this is

transmitted from the excessive vibration on the generator skid. It is also worth noting

that although the overall vibration on the top of the mount is 45mm/s the reading at the

base of the engine resilient mounts is 15mm/s, indicating the mount is performing

correctly.

Original Skid

Although the vibration under the engine drive end resilient mount is high (15mm/s),

due to the transmission of the excessive generator skid vibration, the overall level of

vibration collected from other positions around the skid is <8mm/s.

Vibration Analysis Report

Oil Company

A Platform

Date:

19/21-9-2007

Report

Fig 6

D2080C Engine Drive End Horizontal

Caterpillar Generator Set No.2

D2080C

Engine

The highest overall vibration recorded on

D2080C engine was 12.08mm/s, with the

1x rotational speed (1800rpm) at

2.66mm/s. This was from the drive end

horizontal position (See Fig 6 D2080C

Engine drive end horizontal).

Unit On Standby

Fig 7

D2080C Alternator Non Drive End Horizontal

Alternator

The highest overall vibration recorded on

D2080C alternator was 11.12mm/s, with

the 1x rotational speed (1800rpm) at

3.66mm/s. This was from the non drive

end horizontal position (See Fig 7

D2080C Alternator non drive end

horizontal).

Unit On Standby

Fig 8

D2080C Generator Skid. Alternator Drive End

(Left)

Generator Skid

Readings were taken from this skid in

the horizontal direction in line with the

resilient mounts. If viewing the skid from

the engine end, the highest vibration was

on the left hand side of the skid at the

alternator drive end position where an

overall level of 33mm/s was recorded

(See Fig 8 D2080C Generator Skid

Alternator drive end). This vibration was

not due to 1x rotational speed but a

frequency of 7,200cpm.

Unit On Standby

Fig 9

D2080C Engine Non Drive End Resilient Mount

Top Plate

Resilient Mounts

Readings were taken from the resilient

mounts in the vertical direction on the top

plate and the bottom plate. The highest

overall vibration was recorded on the top

of

the

engine

resilient

mounts,

particularly the drive end mount which

reached an overall level of 46mm/s, due

to a frequency of 7200cpm (See Fig 9

Engine non drive end Resilient Mount)

Unit On Standby

Vibration Analysis Report

Oil Company

A Platform

Date:

19/21-9-2007

Report

Fig 10

D2080C Original Skid. Engine Drive End (Left)

Caterpillar Generator Set No.2

D2080C

Original Skid

Readings were taken from this skid in

the vertical direction next to the resilient

mounts. If viewing the skid from the

engine end, the highest vibration was on

the left hand side of the skid at the

engine drive end position. The overall

vibration at this position was 13.34mm/s

(See Fig 10 Original Skid Engine drive

end) this is also due to the 7,200cpm.

Unit On Standby

Summary

Caterpillar Generator Set 2

D2080C

Engine & Alternator

As can be seen in Fig.6 & Fig.7 the vibration on the engine and alternator during the

analysis was at an acceptable level using BS 7698: Part 9:1996.

Generator Skid & Resilient Mounts

As can be seen in Fig.9 the vibration on the top of the engine resilient mount is

excessively high at 46mm/s, due to a frequency of 7,200cpm. This is then transmitting

through to the generator skid. The 7,200cpm frequency is divisible by the 1x rotational

frequency of the engine/alternator (1800rpm) and could be related to the firing

sequence of the engine.

Original Skid

Although the vibration under the engine drive end resilient mount is high (13.34mm/s),

due to the excessive vibration transmitting through from the top of the resilient mount,

the overall level of vibration collected from other positions around the skid is <7mm/s.

Vibration Analysis Report

Oil Company

A Platform

Date:

19/21-9-2007

Report

Fig 11

D2080B Engine Drive End Horizontal

Caterpillar Generator Set No.4

D2080 B

Engine

The highest overall vibration recorded on

D2080B engine was 10.92mm/s, with the

1x rotational speed (1800rpm) at

1.26mm/s. This was from the drive end

horizontal position (See Fig 11 D2080B

Engine drive end horizontal).

Unit On Standby

Fig 12

D2080B Alternator Drive End Horizontal

Alternator

The highest overall vibration recorded on

D2080B alternator was 10.98mm/s, with

the 1x rotational speed (1800rpm) at

1mm/s. This was from the drive end

horizontal position (See Fig 12 D2080B

Alternator drive end horizontal).

Unit On Standby

Generator Skid

Fig 13

D2080B Generator Skid. Engine Drive End

Spectrum (Left)

Readings were taken from this skid in

the horizontal direction in line with the

resilient mounts. If viewing the skid from

the engine end, the highest vibration was

on the left hand side of the skid at the

engine drive end position where an

overall level of 26.76mm/s was recorded.

This vibration was not due to 1x

rotational speed but split between

frequencies of 3,600cpm, 7,237cpm and

8137cpm (See Fig 13 D2080B Generator

Skid Engine drive end spectrum).

Fig 14

D2080B Alternator Drive End Resilient Mount Top

Plate

Resilient Mounts

Readings were taken from the resilient

mounts in the vertical direction on the top

plate and the bottom plate. The highest

overall vibration was recorded on the top

of the alternator drive end resilient

mounts, which reached an overall level

of 25mm/s, due to a frequency of

7200cpm (See Fig 14 Engine non drive

end Resilient Mount).

Unit On Standby

Vibration Analysis Report

Oil Company

A Platform

Date:

19/21-9-2007

Report

Fig 15

D2080B Original Skid. Engine Drive End (Left)

Caterpillar Generator Set 4

D2080B

Original Skid

Readings were taken from this skid in

the vertical direction next to the resilient

mounts. The highest vibration recorded

on this skid was at the engine drive end

position, the overall vibration at this

position was 8.11mm/s (See Fig 15

D2080B Original Skid Engine drive end).

Unit On Standby

Summary

Caterpillar Generator Set 4

D2080B

Engine & Alternator

As can be seen in Fig.11 & Fig.12 the vibration on the engine and alternator during the

analysis was at an acceptable level using BS 7698: Part 9:1996.

Generator Skid

Although the highest overall vibration on this unit is 26.76mm/s as can be seen in

Fig.13 this is due to various vibration signals.

Resilient Mounts

Although the overall vibration on the top of the alternator drive end resilient mount is

25mm/s the base reading on this resilient mount is 4mm/s, indicating the mount is

performing correctly.

Original Skid

The highest overall level of vibration collected from positions around the skid is

<8mm/s.

Vibration Analysis Report

Oil Company

A Platform

Date:

19/21-9-2007

Recommended Action

Caterpillar Generator Set 1

D2080A

The analysis on this unit highlighted a problem on the left side of the generator skid (if

viewed from the engine end) due to an excessive vibration of 81.33mm/s caused by

7,200cpm.

This high vibration will be due to either a resonance or structural weakness in the

beam, which is then excited by a 7,200cpm frequency.

As previously stated the 7,200cpm frequency is divisible by the 1x rotational

frequency, 1,800rpm, and could be related to the firing sequence of the engine.

It is recommend this beam is inspected for structural weakness and corrected.

Caterpillar Generator Set 2

D2080C

The analysis on this unit highlighted a problem between the top of the engine resilient

mounts and the generator skid, due to an excessive vibration caused by 7,200cpm.

The highest overall vibration on the generator skid is 33mm/s but the top plate of the

resilient mount which is bolted to the skid has an overall vibration level of 46mm/s.

It is recommended that the set up and fixing of the engine resilient mounts on this unit

is checked and corrected as necessary.

Caterpillar Generator Set 4

D2080B

During the analysis the overall levels of vibration recorded on this unit when

compared to Set 1 & Set 2 are at an acceptable level.

S-ar putea să vă placă și

- What Is The Difference Between Low Speed Balancing and Dynamic Balancing in Turbine Rotor PerspectiveDocument10 paginiWhat Is The Difference Between Low Speed Balancing and Dynamic Balancing in Turbine Rotor Perspectiveabdulyunus_amir100% (1)

- Diagnostic Reference ChartDocument4 paginiDiagnostic Reference ChartRao ShahbazÎncă nu există evaluări

- Structural Health MonitoringDe la EverandStructural Health MonitoringDaniel BalageasÎncă nu există evaluări

- CAT Engine Vibration Isolation GoodDocument44 paginiCAT Engine Vibration Isolation GoodTheerayootÎncă nu există evaluări

- Signature AnalysisDocument49 paginiSignature AnalysisVirgilio100% (1)

- Basics of VibrationDocument6 paginiBasics of VibrationChetan PrajapatiÎncă nu există evaluări

- Using Time Waveform Analysis To Distinguish Looseness From MisalignmentDocument5 paginiUsing Time Waveform Analysis To Distinguish Looseness From MisalignmentManel Montesinos100% (1)

- ISO Category II (Analysis I)Document5 paginiISO Category II (Analysis I)nspcl o&eÎncă nu există evaluări

- Transient Speed Vibration AnalysisDocument34 paginiTransient Speed Vibration AnalysistylerdurdaneÎncă nu există evaluări

- Machinery Vibration Analysis-Introduction To Advanced TroubleshootingDocument5 paginiMachinery Vibration Analysis-Introduction To Advanced TroubleshootingAbdulrahman AlkhowaiterÎncă nu există evaluări

- Gear VIbDocument355 paginiGear VIbAnderson V. Viana100% (1)

- Vibration Signature of Defected Gear Tooth Using Spectral AnalysisDocument8 paginiVibration Signature of Defected Gear Tooth Using Spectral AnalysisHURRYSTARÎncă nu există evaluări

- Vibration Analysis of Gear Box.5-MilosprokoDocument3 paginiVibration Analysis of Gear Box.5-MilosprokoRavikiran Hegde100% (2)

- Vibration ChartDocument1 paginăVibration Chartairframer1981Încă nu există evaluări

- Advanced Vibration Analysis TechniquesDocument324 paginiAdvanced Vibration Analysis Techniquesharikrishnanpd3327Încă nu există evaluări

- Story of Vibration AnalysisDocument14 paginiStory of Vibration AnalysisCrusherjpÎncă nu există evaluări

- SKF - Tech Associates of CharlotteDocument57 paginiSKF - Tech Associates of Charlotteiatorres100% (4)

- Crankshaft Torsion and Dampers PDFDocument9 paginiCrankshaft Torsion and Dampers PDFjeyaselvanm100% (1)

- Envelope AnalysisDocument9 paginiEnvelope AnalysisrfriosEPÎncă nu există evaluări

- Condition-Based Lubrication Using Ultrasonic Technology PDFDocument4 paginiCondition-Based Lubrication Using Ultrasonic Technology PDFperdid0Încă nu există evaluări

- A Practical Introduction To Condition Monitoring of RollingDocument14 paginiA Practical Introduction To Condition Monitoring of Rollingsatya_chagantiÎncă nu există evaluări

- Electric Motor Diagnostics Defect Frequencies and Data ColleDocument51 paginiElectric Motor Diagnostics Defect Frequencies and Data ColleSubrata Dubey50% (2)

- Phase Analysis: Making Vibration Analysis Easier: SearchDocument4 paginiPhase Analysis: Making Vibration Analysis Easier: Searchdillipsh123Încă nu există evaluări

- Effective Use of Statistical Models To Establish and Update Vibration AlarmDocument11 paginiEffective Use of Statistical Models To Establish and Update Vibration AlarmMohammadreza GalebanÎncă nu există evaluări

- Csi Ds TrainingandcertifDocument20 paginiCsi Ds TrainingandcertifElvis Alberto Rodriguez BravoÎncă nu există evaluări

- 3 - Simon MillsDocument35 pagini3 - Simon MillsRajesh PotluriÎncă nu există evaluări

- Training, Class I, Testing, IIb, 1-10Document12 paginiTraining, Class I, Testing, IIb, 1-10luis_hernandez_qÎncă nu există evaluări

- Vibration SchoolDocument194 paginiVibration SchoolHéctor RiveraÎncă nu există evaluări

- Subsynchronous Resonance Analysis: Types OF SSR InteractionDocument4 paginiSubsynchronous Resonance Analysis: Types OF SSR InteractionBhavik PrajapatiÎncă nu există evaluări

- Identification of Torsional Vibration Features in Electrical Powered Rotating EquipmentDocument9 paginiIdentification of Torsional Vibration Features in Electrical Powered Rotating EquipmentHasan PashaÎncă nu există evaluări

- Learning On VibrationDocument42 paginiLearning On VibrationAnkit Shakyawar100% (1)

- VibMatters September 2016 Final DownloadDocument7 paginiVibMatters September 2016 Final DownloadfazzlieÎncă nu există evaluări

- Article Overall Vibration Values For Reliable Wind Turbines PDFDocument4 paginiArticle Overall Vibration Values For Reliable Wind Turbines PDFrrÎncă nu există evaluări

- A Review of Enveloping and Demodulation TechniquesDocument6 paginiA Review of Enveloping and Demodulation TechniquesMohamed WahidÎncă nu există evaluări

- Monitoring and Analysis of Machine VibrationDocument6 paginiMonitoring and Analysis of Machine VibrationAvinashÎncă nu există evaluări

- Condition Monitoring For ElectricalDocument28 paginiCondition Monitoring For ElectricalArindam SamantaÎncă nu există evaluări

- Detection of Ski Slopes in Vibration SpectrumsDocument7 paginiDetection of Ski Slopes in Vibration SpectrumsjeyaselvanmÎncă nu există evaluări

- Advanced Vibration Analysis On Gear Box TrainDocument25 paginiAdvanced Vibration Analysis On Gear Box Trainoded98100% (1)

- Monitoring Gear Boxes With Peakvue: Presentation at Niagara Falls Vibration Institute Chapter January 20, 2005Document60 paginiMonitoring Gear Boxes With Peakvue: Presentation at Niagara Falls Vibration Institute Chapter January 20, 2005eko bagus sunaryo100% (2)

- Envelope BearingDocument14 paginiEnvelope BearingHussein Razaq100% (1)

- Dynamic Absorber DesignDocument14 paginiDynamic Absorber DesignLarry Deem0% (1)

- SDT Lubrication ULTRASONIDO INGLES PDFDocument14 paginiSDT Lubrication ULTRASONIDO INGLES PDFALONSO SOLÍSÎncă nu există evaluări

- Basics of Vibration and Vibration MeasurementDocument38 paginiBasics of Vibration and Vibration MeasurementAnand Kumar100% (4)

- Vibrationreferenceguide PDFDocument2 paginiVibrationreferenceguide PDFAngela Cely100% (1)

- 48 Case HistoryDocument17 pagini48 Case HistorySamir Benabdallah100% (1)

- ISO Standard Vibration Severity ChartsDocument4 paginiISO Standard Vibration Severity ChartsSUNIL TV100% (1)

- Generator VibrationDocument4 paginiGenerator VibrationsatyandaruÎncă nu există evaluări

- Vibration SeverityDocument11 paginiVibration SeverityDr. R. SharmaÎncă nu există evaluări

- Gearbox Spectral Components Presentation V2Document29 paginiGearbox Spectral Components Presentation V2Asha Venkataram100% (1)

- Balancing of Rotating MachineryDocument38 paginiBalancing of Rotating MachineryThomas AbrahamÎncă nu există evaluări

- Diagnosis of Common Vibration Problems: Prof. Dr. Fawkia RamadanDocument13 paginiDiagnosis of Common Vibration Problems: Prof. Dr. Fawkia Ramadanفرح تامر100% (1)

- Welcome To Modal Testing and Analysis: From Brüel & KjærDocument20 paginiWelcome To Modal Testing and Analysis: From Brüel & KjærAhmed AymanÎncă nu există evaluări

- Vibration Analysis Gt6 Generator LibyaDocument6 paginiVibration Analysis Gt6 Generator LibyaRohit GunerkarÎncă nu există evaluări

- MB 722.9 7GDocument18 paginiMB 722.9 7GSam Park100% (5)

- Testing and Adjusting Hydraulic SystemDocument350 paginiTesting and Adjusting Hydraulic SystemFauziah Hanum100% (7)

- Engine Performance - Test - Engine Speed: Essai Et RéglageDocument2 paginiEngine Performance - Test - Engine Speed: Essai Et RéglageKJDNKJZEFÎncă nu există evaluări

- Service Work Report Replacement Auxiliary Engine and Cleaning GeneratorDocument16 paginiService Work Report Replacement Auxiliary Engine and Cleaning GeneratorBima Surya Utama100% (1)

- Case Study Tuning Out Difficult Torsional Vibration ProblemDocument15 paginiCase Study Tuning Out Difficult Torsional Vibration Problempathakshashank100% (1)

- Torque SpectDocument3 paginiTorque Spectzawmoe aungÎncă nu există evaluări

- Grafica de Medidas para Recesion de Valvulas G3400Document3 paginiGrafica de Medidas para Recesion de Valvulas G3400carlos angelÎncă nu există evaluări

- How Do We Design or Modify A System To Avoid ResonanceDocument4 paginiHow Do We Design or Modify A System To Avoid Resonanceyzn_hÎncă nu există evaluări

- 6270 enDocument8 pagini6270 enyzn_h100% (1)

- A Simple Frequency Response FunctionDocument37 paginiA Simple Frequency Response Functionyzn_hÎncă nu există evaluări

- Balance and Vibration Report SampleDocument11 paginiBalance and Vibration Report Sampleyzn_hÎncă nu există evaluări

- SKF Roller Bearing CatalogueDocument452 paginiSKF Roller Bearing CatalogueDarpanrshah67% (3)

- Bearing Interchange Guide 7536Document395 paginiBearing Interchange Guide 7536Misho IvanovÎncă nu există evaluări

- Va Sample Report Uyahd PDFDocument16 paginiVa Sample Report Uyahd PDFyzn_hÎncă nu există evaluări

- Vibration Pen User Manual English 321505a0 - UM-EnDocument41 paginiVibration Pen User Manual English 321505a0 - UM-Enyzn_hÎncă nu există evaluări

- JM02001 - Introduction Guide To Vibration MonitoringDocument30 paginiJM02001 - Introduction Guide To Vibration MonitoringSachin PanwarÎncă nu există evaluări

- Balance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1Document11 paginiBalance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1FabbroxÎncă nu există evaluări

- Centrifugal PumpDocument33 paginiCentrifugal Pumpyzn_hÎncă nu există evaluări

- For For More Sample Engineering Resumes Go ToDocument2 paginiFor For More Sample Engineering Resumes Go Toyzn_hÎncă nu există evaluări

- Seafrost BD50F Refrigerator SystemDocument7 paginiSeafrost BD50F Refrigerator SystemMathiyazhagan SÎncă nu există evaluări

- Flextronics FINALDocument25 paginiFlextronics FINALAnkit GauravÎncă nu există evaluări

- Roland Sands Design US CatalogDocument56 paginiRoland Sands Design US Catalogsema2210Încă nu există evaluări

- Highway Engineering B 1Document8 paginiHighway Engineering B 1Angelica TolentinoÎncă nu există evaluări

- MCT Cable Transit System: Fire Rated, Environmental Cable Sealing SystemsDocument7 paginiMCT Cable Transit System: Fire Rated, Environmental Cable Sealing SystemsRaju ThamkeÎncă nu există evaluări

- ADBCDocument12 paginiADBCJaspal KumarÎncă nu există evaluări

- LiftingLugStress Rev 1.5Document17 paginiLiftingLugStress Rev 1.5mohdshakir bahariÎncă nu există evaluări

- c02 Scrubber User ManualDocument30 paginic02 Scrubber User ManualJomhel CalluengÎncă nu există evaluări

- 010 Zircoat MDocument3 pagini010 Zircoat MvsdeepakchandraÎncă nu există evaluări

- Adjustable Juice Groove Jig: Step 1: Jig Base and Bit DistanceDocument5 paginiAdjustable Juice Groove Jig: Step 1: Jig Base and Bit DistanceRod HyattÎncă nu există evaluări

- Sidewall Framing Elevation @GL.K: Gutter DetailDocument1 paginăSidewall Framing Elevation @GL.K: Gutter DetailLUUVANDONG48XFÎncă nu există evaluări

- TSM SmokeDocument2 paginiTSM SmokeSudin AmatyaÎncă nu există evaluări

- Yousif Alotaibi 01 CVDocument3 paginiYousif Alotaibi 01 CVyousefx20Încă nu există evaluări

- Supplier Run Rate CalculatorDocument9 paginiSupplier Run Rate CalculatordcevipinÎncă nu există evaluări

- Dry ContactsDocument2 paginiDry ContactsDiwakar MishraÎncă nu există evaluări

- LSV-08-2 NCPDocument2 paginiLSV-08-2 NCPishtiaqÎncă nu există evaluări

- Dji Phantom 4 RTK Book F-2Document18 paginiDji Phantom 4 RTK Book F-2Liu Purnomo100% (1)

- NextCloud OnlyOffice PDFDocument89 paginiNextCloud OnlyOffice PDFOmar Gallegos Vazquez100% (1)

- AA Holtz & Kovacs - An Introduction To Geotechnical Engineering PDFDocument746 paginiAA Holtz & Kovacs - An Introduction To Geotechnical Engineering PDFPeterÎncă nu există evaluări

- 03 Transformers CT VTDocument10 pagini03 Transformers CT VTEnrique G.Încă nu există evaluări

- Kuokuang Petrochemicals Executive SummaryDocument40 paginiKuokuang Petrochemicals Executive SummaryKhoh Kai ShengÎncă nu există evaluări

- Stereo Conversion Preamplifier: GeneralDocument2 paginiStereo Conversion Preamplifier: GeneralFRANK NIELE DE OLIVEIRAÎncă nu există evaluări

- Repair Kit Hitachi PlasmaDocument4 paginiRepair Kit Hitachi Plasmacolman123456789100% (1)

- FMS 2009 Question Paper and Answer KeyDocument6 paginiFMS 2009 Question Paper and Answer KeyHarish PotterÎncă nu există evaluări

- Check ListDocument6 paginiCheck ListosersÎncă nu există evaluări

- Q45U Ultrasonic Sensors With Analog Outputs (Short Range) : DatasheetDocument8 paginiQ45U Ultrasonic Sensors With Analog Outputs (Short Range) : DatasheetMohammad IsmailÎncă nu există evaluări

- SOM One Linear PDFDocument88 paginiSOM One Linear PDFDinuSkyÎncă nu există evaluări

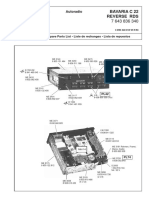

- Bavaria Reverse RdsDocument15 paginiBavaria Reverse RdsDušan JovanovićÎncă nu există evaluări

- High Carbon Steel Shot GritDocument2 paginiHigh Carbon Steel Shot Gritabdulaziz mohammedÎncă nu există evaluări

- Asme eDocument41 paginiAsme eAnonymous wWOWz9UnWÎncă nu există evaluări