Documente Academic

Documente Profesional

Documente Cultură

Paul Bakyenga Steel

Încărcat de

akankwasaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Paul Bakyenga Steel

Încărcat de

akankwasaDrepturi de autor:

Formate disponibile

Job Ref.

Project:

a/035/k

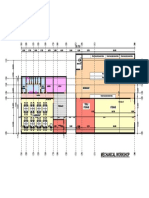

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

P.O BOX 21879,

Date

ak.

Chk'd by

5/5/2016

Date

ak/ 1

App'd by

Date

E.N.

UC COLUMN EXAMLE

STEEL COLUMN DESIGN (EN 1993-1-1)

In accordance with EN1993-1-1:2005 incorporating Corrigenda February 2006 and April 2009 and the UK

national annex

12.5

206.2

12.5

TEDDS calculation version 1.0.11

Column and loading details

Column details

Column section

UKC 203x203x52

System length for buckling about y axis

Ly = 3000 mm

System length for buckling about z axis

Lz = 3000 mm

Sway

The column is not part of a sway frame in the direction of the z axis

The column is not part of a sway frame in the direction of the y axis

Column loading

Axial load

NEd = 590 kN (Compression)

Moment about y axis at end 1

My,Ed1 = 72.0 kNm

Moment about y axis at end 2

My,Ed2 = -55.0 kNm

Moment about z axis at end 1

Mz,Ed1 = 40.0 kNm

Moment about z axis at end 2

Mz,Ed2 = -40.0 kNm

Shear force parallel to z axis

Vz,Ed = 50 kN

Shear force parallel to y axis

Vy,Ed = 40 kN

Double curvature bending about y axis

Double curvature bending about z axis

Material details

Steel grade

S355

Yield strength

fy = 355 N/mm2

Ultimate strength

fu = 470 N/mm2

Modulus of elasticity

E = 210 kN/mm2

Poissons ratio

= 0.3

Shear modulus

G = E / [2 (1 + )] = 80.8 kN/mm2

Buckling length for flexural buckling about y axis

Column stiffness

ky = Iy / Ly = 17529 mm3

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

P.O BOX 21879,

Date

ak.

Chk'd by

5/5/2016

Date

ak/ 2

App'd by

Date

E.N.

At top of column

Column section above

UKC 203x203x52

Length of column above

L1_y = 3000 mm

Column stiffness above

k1_y = Iy1 / L1_y = 17529 mm3

Beam section on side 1

UKB 305x165x46

Length of beam on side 1

L11_y = 4500 mm

Beam stiffness on side 1

k11_y = 0.5 Iy11_y / L11_y = 10999 mm3

Beam section on side 2

UKB 305x165x46

Length of beam on side 2

L12_y = 5000 mm

Beam stiffness on side 2

k12_y = 0.5 Iy12_y / L12_y = 9899 mm3

Distribution factor at top of column

1_y = (ky + k1_y) / (ky + k1_y + k11_y + k12_y) = 0.627

Distribution factor at btm of column (foundation)

2_y = 1.000

Buckling length

Lcr_y = Ly [0.5 + 0.14 (1_y + 2_y) + 0.055 (1_y + 2_y)2]

Lcr_y = 2620 mm

Buckling length for flexural buckling about z axis

Column stiffness

kz = Iz / Lz = 5925 mm3

At top of column

Column section above

UKC 203x203x52

Length of column above

L1_z = 3000 mm

Column stiffness above

k1_z = Iz1 / L1_z = 5925 mm3

Beam section on side 1

UKB 305x165x46

Length of beam on side 1

L11_z = 4500 mm

Beam stiffness on side 1

k11_z = 0.5 Iy11_z / L11_z = 10999 mm3

Beam section on side 2

UKB 305x165x46

Length of beam on side 2

L12_z = 5000 mm

Beam stiffness on side 2

k12_z = 0.5 Iy12_z / L12_z = 9899 mm3

Distribution factor at top of column

1_z = (kz + k1_z) / (kz + k1_z + k11_z + k12_z) = 0.362

Distribution factor at btm of column (foundation)

2_z = 1.000

Buckling length

Lcr_z = Lz [0.5 + 0.14 (1_z + 2_z) + 0.055 (1_z + 2_z)2]

Lcr_z = 2378 mm

Section classification

Web section classification (Table 5.2)

Coefficient depending on fy

= (235 N/mm2 / fy) = 0.814

Depth between fillets

cw = h - 2 (tf + r) = 160.8 mm

Ratio of c/t

ratiow = cw / tw = 20.35

Length of web taken by axial load

lw = min(NEd / (fy tw), cw) =160.8 mm

For class 1 & 2 proportion in compression

= (cw/2 + lw/2) / cw = 1.000

Limit for class 1 web

Limit1w = (396 ) / (13 - 1) = 26.85

The web is class 1

Flange section classification (Table 5.2)

Outstand length

cf = (b - tw) / 2 - r = 88.0 mm

Ratio of c/t

ratiof = cf / tf = 7.04

Conservatively assume uniform compression in flange

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

ak.

P.O BOX 21879,

Date

5/5/2016

Chk'd by

Date

ak/ 3

App'd by

Date

E.N.

Limit1f = 9 = 7.32

Limit for class 1 flange

Limit for class 2 flange

Limit2f = 10 = 8.14

Limit for class 3 flange

Limit3f = 14 = 11.39

The flange is class 1

Overall section classification

The section is class 1

Resistance of cross section (cl. 6.2)

Shear parallel to z axis (cl. 6.2.6)

Design shear force

Vz,Ed = 50.0 kN

Shear area

Avz = max((h - 2tf) tw, A - 2 b tf + (tw + 2 r) tf) = 1875

mm2

Vpl,z,Rd = Avz (fy / (3)) / M0 = 384.2 kN

Plastic shear resistance

PASS - Shear resistance parallel to z axis exceeds the design shear force

Vz,Ed <= 0.5Vpl,z,Rd - No reduction in fy required for bending/axial force

Shear parallel to y axis (cl. 6.2.6)

Design shear force

Vy,Ed = 40.0 kN

Shear area

Avy = 2 b tf - (tw + 2 r) tf = 4754 mm2

Vpl,y,Rd = Avy (fy / (3)) / M0 = 974.3 kN

Plastic shear resistance

PASS - Shear resistance parallel to y axis exceeds the design shear force

Vy,Ed <= 0.5Vpl,y,Rd - No reduction in fy required for bending/axial force

Compression (cl. 6.2.4)

Design force

NEd = 590 kN

Design resistance

Nc,Rd = Npl,Rd = A fy / M0 = 2353 kN

PASS - The compression design resistance exceeds the design force

Bending about y axis (cl. 6.2.5)

Design bending moment

My,Ed = max(abs(My,Ed1), abs(My,Ed2)) = 72.0 kNm

Section modulus about y axis

Wy = Wpl.y = 567.4 cm3

Design resistance

Mc,y,Rd = Wy fy / M0 = 201.4 kNm

PASS - The bending design resistance about the y axis exceeds the design moment

Bending about z axis (cl. 6.2.5)

Design bending moment

Mz,Ed = max(abs(Mz,Ed1), abs(Mz,Ed2)) = 40.0 kNm

Section modulus about z axis

Wz = Wpl.z = 264.2 cm3

Design resistance

Mc,z,Rd = Wz fy / M0 = 93.8 kNm

PASS - The bending design resistance about the z axis exceeds the design moment

Combined bending and axial force (cl. 6.2.9)

Ratio design axial to design plastic resistance

n = abs(NEd) / Npl,Rd = 0.251

Ratio web area to gross area

a = min(0.5, (A - 2 b tf) / A) = 0.229

Bending about y axis (cl. 6.2.9.1)

Design bending moment

My,Ed = max(abs(My,Ed1), abs(My,Ed2)) = 72.0 kNm

Plastic design resistance

Mpl,y,Rd = Wpl.y fy / M0 = 201.4 kNm

Modified design resistance

MN,y,Rd = Mpl,y,Rd min(1, (1 - n) / (1 - 0.5 a)) = 170.5 kNm

PASS - Bending resistance about y axis in presence of axial load exceeds design moment

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

ak.

P.O BOX 21879,

Date

Chk'd by

5/5/2016

Date

ak/ 4

App'd by

Date

E.N.

Bending about z axis (cl. 6.2.9.1)

Mz,Ed = max(abs(Mz,Ed1), abs(Mz,Ed2)) = 40.0 kNm

Design bending moment

Plastic design resistance

Mpl,z,Rd = Wpl.z fy / M0 = 93.8 kNm

Modified design resistance

MN,z,Rd = Mpl,z,Rd [1 - ((n - a) / (1 - a))2] = 93.7 kNm

PASS - Bending resistance about z axis in presence of axial load exceeds design moment

Biaxial bending

Exponent

= 2.00

Exponent

= max(1, 5 n) = 1.25

Section utilisation at end 1

URCS_1 = [abs(My,Ed1) / MN,y,Rd] + [abs(Mz,Ed1) / MN,z,Rd] = 0.522

Section utilisation at end 2

URCS_2 = [abs(My,Ed2) / MN,y,Rd] + [abs(Mz,Ed2) / MN,z,Rd] = 0.448

PASS - The cross-section resistance is adequate

Buckling resistance (cl. 6.3)

Yield strength for buckling resistance

fy = 355 N/mm2

Flexural buckling about y axis

Elastic critical buckling force

Ncr,y = 2 E Iy / Lcr_y2 = 15882 kN

Non-dimensional slenderness

y = (A fy / Ncr,y) = 0.385

Buckling curve (Table 6.2)

Imperfection factor (Table 6.1)

y = 0.34

Parameter

y = 0.5 [1 + y (y - 0.2) +y2] = 0.606

Reduction factor

y = min(1.0, 1 / [y + (y2 -y2)]) = 0.932

Design buckling resistance

Nb,y,Rd = y A fy / M1 = 2193.1 kN

PASS - The flexural buckling resistance about the y axis exceeds the design axial load

Flexural buckling about z axis

Elastic critical buckling force

Ncr,z = 2 E Iz / Lcr_z2 = 6515 kN

Non-dimensional slenderness

z = (A fy / Ncr,z) = 0.601

Buckling curve (Table 6.2)

Imperfection factor (Table 6.1)

z = 0.49

Parameter

z = 0.5 [1 + z (z - 0.2) +z2] = 0.779

Reduction factor

z = min(1.0, 1 / [z + (z2 -z2)]) = 0.785

Design buckling resistance

Nb,z,Rd = z A fy / M1 = 1846.7 kN

PASS - The flexural buckling resistance about the z axis exceeds the design axial load

Torsional and torsional-flexural buckling (cl. 6.3.1.4)

Torsional buckling length factor

KT = 1.00

Effective buckling length

Lcr_T = KT max(Ly, Lz) = 3000 mm

Distance from shear ctr to centroid along y axis

y0 = 0.0 mm

Distance from shear ctr to centroid along z axis

z0 = 0.0 mm

i0 = (iy2 + iz2 + y02 + z02) = 103.0 mm

T = 1 - (y0 / i0)2 = 1.000

Elastic critical torsional buckling force

Ncr,T = 1 / i02 (G It + 2 E Iw / Lcr_T2) = 6033 kN

Elastic critical torsional-flexural buckling force

Ncr,TF = Ncr,y/(2T)[1+Ncr,T/Ncr,y-[(1-Ncr,T/Ncr,y)2 +

4(y0/i0)2Ncr,T/Ncr,y]]

Ncr,TF = 6033 kN

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

Date

ak.

P.O BOX 21879,

Chk'd by

5/5/2016

Date

ak/ 5

App'd by

Date

E.N.

Non-dimensional slenderness

T = (A fy / min(Ncr,T, Ncr,TF)) = 0.624

Buckling curve (Table 6.2)

Imperfection factor (Table 6.1)

T = 0.49

Parameter

T = 0.5 [1 + T (T - 0.2) +T2] = 0.799

Reduction factor

T = min(1.0, 1 / [T + (T2 -T2)]) = 0.771

Nb,T,Rd = T A fy / M1 = 1813.7 kN

Design buckling resistance

PASS - The torsional/torsional-flexural buckling resistance exceeds the design axial load

Minimum buckling resistance

Nb,Rd = min(Nb,y,Rd, Nb,z,Rd, Nb,T,Rd) = 1813.7 kN

Minimum buckling resistance

PASS - The axial load buckling resistance exceeds the design axial load

Buckling resistance moment (cl.6.3.2.1)

Lateral torsional buckling length factor

KLT = 1.00

Effective buckling length

Lcr_LT = KLT Lz = 3000 mm

End moment factor

= My,Ed2 / My,Ed1 = -0.764

Moment distribution correction factor (Table 6.6)

kc = 1 / (1.33 - 0.33 ) = 0.632

C1 = 1 / kc2 = 2.503

Curvature factor

g = [1 - (Iz / Iy)] = 0.814

Poissons ratio

= 0.3

Shear modulus

G = E / [2 (1 + )] = 80769 N/mm2

Elastic critical buckling moment

Mcr = C1 2 E Iz [Iw / Iz + Lcr_LT2 G It /(2 E

Iz)]/(Lcr_LT2g)

Mcr = 1575.3 kNm

Slenderness ratio for lateral torsional buckling

LT = [Wy fy / Mcr] =0.358

Limiting slenderness ratio

LT,0 = 0.40

Correction factor for rolled sections

r = 0.75

Buckling curve (Table 6.5)

Imperfection factor (Table 6.1)

LT = 0.34

Parameter LT

LT = 0.5 [1 + LT (LT -LT,0) +r LT2] = 0.541

Reduction factor

LT = min(1.0, 1/LT2, 1 / [LT + (LT2 - r LT2)]) = 1.000

Modification factor

f = min(1 - 0.5 (1 - kc) [1 - 2 (LT - 0.8)2], 1) = 0.888

Modified LTB reduction factor - eq 6.58

LT,mod = min(LT / f, 1, 1/LT2) = 1.000

Design buckling resistance moment

Mb,Rd = LT,mod Wy fy / M1 = 201.4 kNm

Design bending moment

My,Ed = max(abs(My,Ed1), abs(My,Ed2)) = 72.0 kNm

PASS - The design buckling resistance moment exceeds the maximum design moment

Combined bending and axial compression (cl. 6.3.3)

Characteristic resistance to normal force

NRk = A fy = 2353 kN

Characteristic moment resistance about y axis

My,Rk = Wpl.y fy = 201.4 kNm

Characteristic moment resistance about z axis

Mz,Rk = Wpl.z fy = 93.8 kNm

y = if(abs(My,Ed1)<=abs(My,Ed2), My,Ed1 / if(My,Ed2>=0 kNm,max(My,Ed2,0.0001 kNm),My,Ed2), My,Ed2 / if(My,Ed1>=0

kNm,max(My,Ed1,0.0001 kNm),My,Ed1)) = -0.764

Moment distribution factor about y axis

y = My,Ed2 / My,Ed1 = -0.764

Moment factor about y axis

Cmy = max(0.4, 0.6 + 0.4 y) = 0.400

Moment distribution factor about z axis

z = Mz,Ed1 / Mz,Ed2 = -1.000

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

P.O BOX 21879,

Date

ak.

5/5/2016

Chk'd by

Date

ak/ 6

App'd by

Date

E.N.

Cmz = max(0.4, 0.6 + 0.4 z) = 0.400

Moment factor about z axis

Moment distribution factor for LTB

LT = My,Ed2 / My,Ed1 = -0.764

Moment factor for LTB

CmLT = max(0.4, 0.6 + 0.4 LT) = 0.400

Interaction factor kyy

kyy = Cmy [1 + min(0.8,y - 0.2) NEd / (y NRk / M1)] = 0.420

Interaction factor kzy

kzy = 1 - min(0.1, 0.1 z)NEd / ((CmLT - 0.25)(z NRk/M1)) =

0.872

Interaction factor kzz

kzz = Cmz [1 + min(1.4, 2 z - 0.6)NEd / (z NRk / M1)] =

0.477

Interaction factor kyz

Section utilisation

kyz = 0.6 kzz = 0.286

URB_1 = NEd / (y NRk / M1) + kyy My,Ed / (LT My,Rk / M1) + kyz Mz,Ed / (Mz,Rk / M1)

URB_1 = 0.541

URB_2 = NEd / (z NRk / M1) + kzy My,Ed / (LT My,Rk / M1) + kzz Mz,Ed / (Mz,Rk / M1)

URB_2 = 0.835

PASS - The buckling resistance is adequate

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

P.O BOX 21879,

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

ak.

Date

5/5/2016

Chk'd by

Date

ak/ 1

App'd by

Date

E.N.

FRAME DESIGN EXAMPLE

STEEL MEMBER ANALYSIS & DESIGN (EN1993-1-1:2005)

In accordance with EN1993-1-1:2005 incorporating Corrigenda February 2006 and April 2009 and the UK

national annex

Tedds calculation version 4.1.00

ANALYSIS

Tedds calculation version 1.0.13

Geometry

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

P.O BOX 21879,

Loading

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

ak.

Date

5/5/2016

Chk'd by

E.N.

Date

ak/ 2

App'd by

Date

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

P.O BOX 21879,

Results

Total deflection

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

ak.

Date

5/5/2016

Chk'd by

E.N.

Date

ak/ 3

App'd by

Date

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

ak.

P.O BOX 21879,

Date

Chk'd by

5/5/2016

E.N.

Node deflections

Load combination: 1.35G + 1.5Q + 1.5RQ (Strength)

Node

Deflection

Rotation

X

(mm)

Z

(mm)

()

-0.11213

0.11213

2.6

0.23478

2.6

-0.23478

4.6

0.20308

4.6

-0.20308

0.17802

-0.17802

0.1

6.6

0.3679

10

-0.1

6.6

-0.3679

Co-ordinate

system

Load combination: 1.0G + 1.0Q + 1.0RQ (Service)

Node

Deflection

Rotation

X

(mm)

Z

(mm)

()

-0.00996

0.00996

1.4

0.01957

1.4

-0.01957

Co-ordinate

system

Date

ak/ 4

App'd by

Date

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Calc. by

Date

ak.

P.O BOX 21879,

Node

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Deflection

Chk'd by

5/5/2016

Rotation

X

(mm)

Z

(mm)

()

2.7

0.15642

-0.15642

2.7

3.6

0.1139

3.6

-0.1139

0.1

4.1

0.24358

10

-0.1

4.1

-0.24358

Date

E.N.

Co-ordinate

system

Total base reactions

Load case/combination

Force

1.35G + 1.5Q + 1.5RQ (Strength)

1.0G + 1.0Q + 1.0RQ (Service)

FX

(kN)

0

0

FZ

(kN)

1178.7

638.4

Element end forces

Load combination: 1.35G + 1.5Q + 1.5RQ (Strength)

Element

Length

(m)

2

3

4

5

3

3

3

3

9

10

5

5

Nodes

Start/End

Axial force Shear force

(kN)

(kN)

Moment

(kNm)

-589.3

9.6

588.3

-9.6

-28.9

-450.4

33.8

-52

449.4

-33.8

-49.3

-300.3

29.6

-45.5

299.3

-29.6

-43.4

-150.1

42

-55

149.1

-42

-70.9

-589.3

-9.6

588.3

9.6

28.9

-450.4

-33.8

52

449.4

33.8

49.3

-300.3

-29.6

45.5

299.3

29.6

43.4

-150.1

-42

55

10

149.1

42

70.9

24.1

-138

80.9

-24.1

-138

-80.9

-4.1

-149.1

94.8

4.1

-149.1

-94.8

-149.1

98.4

-98.4

11

12.3

-12.3

-149.1

12

-42

-149.1

70.9

10

42

-149.1

-70.9

ak/ 5

App'd by

Date

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

Date

ak.

P.O BOX 21879,

Chk'd by

5/5/2016

Date

ak/ 6

App'd by

E.N.

Load combination: 1.0G + 1.0Q + 1.0RQ (Service)

Element

Length

(m)

5

6

3

3

10

11

12

5

5

5

Nodes

Start/End

Axial force Shear force

(kN)

(kN)

Moment

(kNm)

-319.2

0.8

319.2

-0.8

-2.5

-295.2

13.6

-14.7

295.2

-13.6

-26.1

-196.8

20.9

-33.2

196.8

-20.9

-29.6

-98.4

27.5

-35.8

98.4

-27.5

-46.7

-319.2

-0.8

319.2

0.8

2.5

14.7

-295.2

-13.6

295.2

13.6

26.1

-196.8

-20.9

33.2

196.8

20.9

29.6

-98.4

-27.5

35.8

10

98.4

27.5

46.7

12.8

-24

17.2

-12.8

-24

-17.2

7.3

-98.4

59.3

-7.3

-98.4

-59.3

6.6

-98.4

65.5

-6.6

-98.4

-65.5

-27.5

-98.4

46.7

10

27.5

-98.4

-46.7

Partial factors - Section 6.1

Resistance of cross-sections

M0 = 1

Resistance of members to instability

M1 = 1

Resistance of tensile members to fracture

M2 = 1.1

BEAM_1 - Span 1

Section details

Section type

UKB 305x165x46 (Tata Steel Advance)

Steel grade - EN 10025-2:2004

S355

Nominal thickness of element

tnom = max(tf, tw) = 11.8 mm

Nominal yield strength

fy = 355 N/mm2

Nominal ultimate tensile strength

fu = 470 N/mm2

Modulus of elasticity

E = 210000 N/mm2

Date

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

Date

ak.

Chk'd by

Date

App'd by

Date

E.N.

11.8

306.6

11.8

P.O BOX 21879,

5/5/2016

ak/ 7

Lateral restraint

Both flanges have lateral restraint at supports only

Consider Combination 1 - 1.35G + 1.5Q + 1.5RQ (Strength)

Classification of cross sections - Section 5.5

= [235 N/mm2 / fy] = 0.81

Internal compression parts subject to bending - Table 5.2 (sheet 1 of 3)

Width of section

c = d = 265.2 mm

c / tw = 39.6 = 48.6 <= 72

Class 1

Outstand flanges - Table 5.2 (sheet 2 of 3)

c = (b - tw - 2 r) / 2 = 70.6 mm

Width of section

c / tf = 6 = 7.4 <= 9

Class 1

Section is class 1

Check tension - Section 6.2.3

Design tension force

NEd = 24.1 kN

Design resistance of section - eq 6.6

Nt,Rd = Npl,Rd = A fy / M0 = 2085.5 kN

NEd / Nt,Rd = 0.012

PASS - Design tension resistance exceeds design tension

Check design 2500 mm along span

Check bending moment - Section 6.2.5

Design bending moment

My,Ed = 91.6 kNm

Design bending resistance moment - eq 6.13

Mc,y,Rd = Mpl,y,Rd = Wpl.y fy / M0 = 255.6 kNm

My,Ed / Mc,y,Rd = 0.358

PASS - Design bending resistance moment exceeds design bending moment

Slenderness ratio for lateral torsional buckling

Correction factor - Table 6.6

kc = 0.893

C1 = 1 / kc2 = 1.254

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

P.O BOX 21879,

Date

ak.

Chk'd by

5/5/2016

Date

ak/ 8

App'd by

Date

E.N.

Poissons ratio

= 0.3

Shear modulus

G = E / [2 (1 + )] = 80769 N/mm2

Unrestrained effective length

L = 1.0 Lm1_s1_seg1_T = 5000 mm

Elastic critical buckling moment

Mcr = C1 2 E Iz / L2 (Iw / Iz + L2 G It / (2 E Iz)) =

199.4 kNm

Slenderness ratio for lateral torsional buckling

LT = (Wpl.y fy / Mcr) = 1.132

Limiting slenderness ratio

LT,0 = 0.4

LT >LT,0 - Lateral torsional buckling cannot be ignored

Check buckling resistance - Section 6.3.2.1

Buckling curve - Table 6.5

Imperfection factor - Table 6.3

LT = 0.34

Correction factor for rolled sections

= 0.75

LTB reduction determination factor

LT = 0.5 [1 + LT (LT -LT,0) + LT2] = 1.105

LTB reduction factor - eq 6.57

LT = min(1 / [LT + (LT2 - LT2)], 1, 1 /LT2) = 0.619

Modification factor

f = min(1 - 0.5 (1 - kc) [1 - 2 (LT - 0.8)2], 1) = 0.958

Modified LTB reduction factor - eq 6.58

LT,mod = min(LT / f, 1, 1 / LT2) = 0.646

Design buckling resistance moment - eq 6.55

Mb,y,Rd = LT,mod Wpl.y fy / M1 = 165.1 kNm

My,Ed / Mb,y,Rd = 0.554

PASS - Design buckling resistance moment exceeds design bending moment

Check bending and axial force - Section 6.2.9

Bending and axial force check - eq.6.33 & eq.6.34

Ny,lim = min(0.25 Npl,Rd, 0.5 hw tw fy / M0) = 336.6 kN

NEd / Ny,lim = 0.072

Allowance need not be made for the effect of the axial force on the plastic resistance moment about the y-y

axis

Check combined bending and compression - Section 6.3.3

Equivalent uniform moment factors - Table B.3

y = -80.9 kNm / -80.9 kNm = 1.000

y = -80.9 kNm / 91.6 kNm = -0.883

Cmy = 0.95 + 0.05 y = 0.906

LT = -80.9 kNm / -80.9 kNm = 1.000

LT = -80.9 kNm / 91.6 kNm = -0.883

CmLT = 0.95 + 0.05 LT = 0.906

Interaction factors kij for members susceptible to torsional deformations - Table B.2

Characteristic moment resistance

My,Rk = Wpl.y fy = 255.6 kNm

Characteristic moment resistance

Mz,Rk = Wpl.z fy = 58.8 kNm

Characteristic resistance to normal force

NRk = A fy = 2085.5 kN

Interaction factors

kyy = Cmy = 0.906

kzy = 1 = 1.000

Interaction formulae - eq 6.61 & eq 6.62

kyy My,Ed / (LT My,Rk / M1) = 0.524

kzy My,Ed / (LT My,Rk / M1) = 0.579

PASS - Combined bending and compression checks are satisfied

Job Ref.

Project:

a/035/k

PLOTS 522 & 1909, BLOCK 215, KULAMBIRO_PROPOSED

RESIDENTIAL APARTMENTS.

Section

CSEC (U) LTD.

P.O BOX 21879,

Sheet no./rev.

MUHWEZI PAUL BAKYENGA, P.O BOX 21879, KAMPALA.

Calc. by

Date

ak.

Chk'd by

5/5/2016

Date

ak/ 9

App'd by

Date

E.N.

Consider Combination 2 - 1.0G + 1.0Q + 1.0RQ (Service)

Check design 2500 mm along span

Check y-y axis deflection - Section 7.2.1

Maximum deflection

y = 2.7 mm

Allowable deflection

y,Allowable = Lm1_s1 / 360 = 13.9 mm

y / y,Allowable = 0.195

PASS - Allowable deflection exceeds design deflection

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Design of Box Type Line Drain of Size 0.6M and Height Upto 1.5MDocument66 paginiDesign of Box Type Line Drain of Size 0.6M and Height Upto 1.5Mrahul sumanÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Bending Properties of Fillet WeldsDocument2 paginiBending Properties of Fillet Weldsadoc_Încă nu există evaluări

- 11 Slope Stability PDFDocument20 pagini11 Slope Stability PDFMohamed MuayidÎncă nu există evaluări

- RC Design EC2Document70 paginiRC Design EC2Picior Cristian100% (2)

- RCC43 Wide Beams (A & D)Document31 paginiRCC43 Wide Beams (A & D)HambugerLơ.tơ.mơhaynằm.mơăn.tráibơÎncă nu există evaluări

- Rock Quality Designation (RQD) After Twenty YearsDocument101 paginiRock Quality Designation (RQD) After Twenty YearsMINEXPONÎncă nu există evaluări

- CSG DesignDocument97 paginiCSG DesignAndi Priyo Jatmiko100% (1)

- EC5 Timber DesignDocument119 paginiEC5 Timber Designmargitorsi100% (2)

- Footing Design MidasDocument8 paginiFooting Design MidasakankwasaÎncă nu există evaluări

- Footing Design MidasDocument8 paginiFooting Design MidasakankwasaÎncă nu există evaluări

- Fatigue Assessment of Ship StructuresDocument129 paginiFatigue Assessment of Ship StructuresMahdiÎncă nu există evaluări

- Cannot Open GSDDocument8 paginiCannot Open GSDakankwasaÎncă nu există evaluări

- Brian Scheme Design Model (1) 2Document1 paginăBrian Scheme Design Model (1) 2akankwasaÎncă nu există evaluări

- midas RC Beam Serviceability ReportDocument2 paginimidas RC Beam Serviceability ReportakankwasaÎncă nu există evaluări

- Kigumba Workshop WELDINGDocument1 paginăKigumba Workshop WELDINGakankwasaÎncă nu există evaluări

- 452 1Document6 pagini452 1akankwasaÎncă nu există evaluări

- Midas Gen - Integrated Analysis and Design System For Building and General StructuresDocument1 paginăMidas Gen - Integrated Analysis and Design System For Building and General StructuresakankwasaÎncă nu există evaluări

- 160Document6 pagini160akankwasaÎncă nu există evaluări

- 470Document3 pagini470akankwasaÎncă nu există evaluări

- Instrumentation workshop floor planDocument1 paginăInstrumentation workshop floor planakankwasaÎncă nu există evaluări

- Kigumba Workshop WELDINGDocument1 paginăKigumba Workshop WELDINGakankwasaÎncă nu există evaluări

- Kigumba Workshop WELDINGDocument1 paginăKigumba Workshop WELDINGakankwasaÎncă nu există evaluări

- 443Document2 pagini443akankwasaÎncă nu există evaluări

- 38Document6 pagini38akankwasaÎncă nu există evaluări

- 37Document8 pagini37akankwasaÎncă nu există evaluări

- 39Document8 pagini39akankwasaÎncă nu există evaluări

- 434Document8 pagini434akankwasaÎncă nu există evaluări

- Plot 39 - Typical Lintol Sections.Document1 paginăPlot 39 - Typical Lintol Sections.akankwasaÎncă nu există evaluări

- Etabs Lateral Loads.Document10 paginiEtabs Lateral Loads.akankwasaÎncă nu există evaluări

- Protastructure Analysis ResultsDocument8 paginiProtastructure Analysis ResultsakankwasaÎncă nu există evaluări

- Input Data: Notes: HistoryDocument5 paginiInput Data: Notes: HistoryakankwasaÎncă nu există evaluări

- Etabs 2016 16.2Document7 paginiEtabs 2016 16.2akankwasaÎncă nu există evaluări

- Plot 2683 and 2684 Mpererwe Apartments 4-BeamdesDocument13 paginiPlot 2683 and 2684 Mpererwe Apartments 4-BeamdesakankwasaÎncă nu există evaluări

- Elegu Staff Houses. Floor PlansDocument1 paginăElegu Staff Houses. Floor PlansakankwasaÎncă nu există evaluări

- Wind Loads - Analysis in Etabs 2016 16.2Document420 paginiWind Loads - Analysis in Etabs 2016 16.2akankwasaÎncă nu există evaluări

- Childrens Church 1Document1 paginăChildrens Church 1akankwasaÎncă nu există evaluări

- Quick Start Guide Concrete Complete-A2Document7 paginiQuick Start Guide Concrete Complete-A2akankwasaÎncă nu există evaluări

- Wall Types Library Edit Beam Wall Load Wall Types Library Building SetoutDocument3 paginiWall Types Library Edit Beam Wall Load Wall Types Library Building SetoutakankwasaÎncă nu există evaluări

- Flat Slab Training - All Columns and Shear Walls at EdgesDocument5 paginiFlat Slab Training - All Columns and Shear Walls at EdgesakankwasaÎncă nu există evaluări

- An Analysis of Composite Drive Shaft Using Ansys AcpDocument8 paginiAn Analysis of Composite Drive Shaft Using Ansys AcpTJPRC PublicationsÎncă nu există evaluări

- The Theory of Materials FailureDocument3 paginiThe Theory of Materials FailurewidyarahmahÎncă nu există evaluări

- Bia Axial Column DesignDocument85 paginiBia Axial Column Designenvirojspl100% (2)

- Introduction to Prestressed Concrete TechniquesDocument20 paginiIntroduction to Prestressed Concrete TechniquesHezb KhanÎncă nu există evaluări

- Gete 201100024Document11 paginiGete 201100024superwxrÎncă nu există evaluări

- Unit IVDocument42 paginiUnit IVabhijeetchaudhary7779Încă nu există evaluări

- 7 Shear WallDocument33 pagini7 Shear WallHilmy PrasetyoÎncă nu există evaluări

- MDB Lesson 4 Poisson's Ratio-Biaxial and Triaxial DeformationsDocument12 paginiMDB Lesson 4 Poisson's Ratio-Biaxial and Triaxial DeformationsChan MirandaÎncă nu există evaluări

- Mechanism Analysis of Rock Breaking Using Static Cracking Agent (SAC)Document21 paginiMechanism Analysis of Rock Breaking Using Static Cracking Agent (SAC)elwin17175Încă nu există evaluări

- Diltancy AngleDocument7 paginiDiltancy AngleGopal PÎncă nu există evaluări

- Question 1. Define Ductility?: AnswerDocument22 paginiQuestion 1. Define Ductility?: AnswerVivek BajpaiÎncă nu există evaluări

- Chapter 1 - Design of Special BeamsDocument15 paginiChapter 1 - Design of Special BeamsSine EntertaimentÎncă nu există evaluări

- Hetauda Seismic Analysis and InterpretationDocument94 paginiHetauda Seismic Analysis and InterpretationSurendra MaharjanÎncă nu există evaluări

- Phillip Allen DissertationDocument310 paginiPhillip Allen DissertationJustice exposedÎncă nu există evaluări

- Stress Strain Coupons Plastic Instruction Sheet AP 8222Document2 paginiStress Strain Coupons Plastic Instruction Sheet AP 8222kougyoku_15Încă nu există evaluări

- Gullapalli2020 Chapter EffectOfSoilStructureInteractiDocument10 paginiGullapalli2020 Chapter EffectOfSoilStructureInteractiManikanta SharmaÎncă nu există evaluări

- Ebook Huesker.01Document19 paginiEbook Huesker.01Marcos MaÎncă nu există evaluări

- STAS 12313-85 Test On Stand of Concrete Prefabricated Components (En)Document16 paginiSTAS 12313-85 Test On Stand of Concrete Prefabricated Components (En)Gelu-Razvan GimigaÎncă nu există evaluări

- Empirical Curve-Fitting Parameters For A Porewater Pressure Generation Model For Use in 1-D Effective Stress-Based Site Response AnalysisDocument8 paginiEmpirical Curve-Fitting Parameters For A Porewater Pressure Generation Model For Use in 1-D Effective Stress-Based Site Response AnalysisAlejandro Gancedo ToralÎncă nu există evaluări

- ES 13 1920A Problem Set 2Document5 paginiES 13 1920A Problem Set 2Charmaine ColetaÎncă nu există evaluări

- Investigation of Rousselier Model and Gurson-Tvergaard-Needleman Model in Ductile Fracture of API X65 Gas Pipeline SteelDocument23 paginiInvestigation of Rousselier Model and Gurson-Tvergaard-Needleman Model in Ductile Fracture of API X65 Gas Pipeline SteelTerem TebautaÎncă nu există evaluări