Documente Academic

Documente Profesional

Documente Cultură

NI 0133 (English)

Încărcat de

Cebrac ItatibaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

NI 0133 (English)

Încărcat de

Cebrac ItatibaDrepturi de autor:

Formate disponibile

-PUBLIC-

N-133

N

REV.. L

ENGLISH

E

02 / 2014

CO

ONTEC

C

Comiss

o de Normalizzao

Tcnica

Weldin

ng

SC-26

Welding

1st Amendm

ment

This is the 1st Ame

endment to PETROBRA

AS N-133 RE

EV. L, and it is used too alter the te

ext of the

Standarrd in the partts indicated below:

b

NOTE 1 The news pages with the

t performe

ed amendments are place

ed in its correesponding po

ositions.

NOTE 2 The amen

nded pages, indicated th

he date of th

he amendme

ent, are placced at the end of this

standard, in chronological order, an

nd shall not be

b used.

CONTE

ENTS OF THE

T

1st AME

ENDMENT - 02/2014

- Table 6

Alteratio

on of the textt of Note 1.

Include of Note 2.

- Subse

ection 5.12.4..2

Alteratio

on of the textt.

PROPE

ERTY OF PETROBRAS

4 pages

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

Welding

Procedure

This Standard replaces and cancels its previous revision.

The CONTEC - Authoring Subcommittee provides guidance on the

interpretation of this Standard when questions arise regarding its contents. The

Department of PETROBRAS that uses this Standard is responsible for adopting

and applying the sections, subsections and enumerates thereof.

CONTEC

Comisso de Normalizao

Tcnica

Technical Requirement: A provision established as the most adequate and

which shall be used strictly in accordance with this Standard. If a decision is

taken not to follow the requirement (non-conformity to this Standard) it shall be

based on well-founded economic and management reasons, and be approved

and registered by the Department of PETROBRAS that uses this Standard. It is

characterized by imperative nature.

Recommended Practice: A provision that may be adopted under the conditions

of this Standard, but which admits (and draws attention to) the possibility of

there being a more adequate alternative (not written in this Standard) to the

particular application. The alternative adopted shall be approved and registered

by the Department of PETROBRAS that uses this Standard. It is characterized

by verbs of a nonmandatory nature. It is indicated by the expression:

[Recommended Practice].

SC - 26

Welding

Copies of the registered non-conformities to this Standard that may contribute

to the improvement thereof shall be submitted to the CONTEC - Authoring

Subcommittee.

Proposed revisions to this Standard shall be submitted to the CONTEC Authoring Subcommittee, indicating the alphanumeric identification and revision

of the Standard, the section, subsection and enumerate to be revised, the

proposed text, and technical/economic justification for revision. The proposals

are evaluated during the work for alteration of this Standard.

This Standard is exclusive property of Petrleo Brasileiro S. A. PETROBRAS, internal application and PETROBRAS Subsidiaries and

shall be used by its suppliers of goods and services under contracts or

similar under the conditions established in Bidding, Contract, Agreement

or similar.

The use of this Standard by other companies / organizations / government

agencies and individuals is the sole responsibility of the users..

Introduction

PETROBRAS Technical Standards are prepared by Working Groups - WG

(consisting specialized of Technical Collaborators from Company and its Subsidiaries), are

commented by Company Units and its Subsidiaries, are approved by the Authoring Subcommittees SCs (consisting of technicians from the same specialty, representing the various Company Units and

its Subsidiaries), and ratified by the Executive Nucleus (consisting of representatives of the Company

Units and its Subsidiaries). A PETROBRAS Technical Standard is subject to revision at any time by its

Authoring Subcommittee and shall be reviewed every 5 years to be revalidated, revised or cancelled.

PETROBRAS Technical Standards are prepared in accordance with PETROBRAS Technical

Standard N-1. For complete information about PETROBRAS Technical Standards see PETROBRAS

Technical Standards Catalog.

PROPERTY OF PETROBRAS

107 pages, Index of Revisions and WG

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

Summary

Foreword................................................................................................................................................ 12

1 Scope................................................................................................................................................. 12

2 Normative References ....................................................................................................................... 12

3 Terms and Definitions........................................................................................................................ 15

4 General Conditions ............................................................................................................................ 17

4.1 General Welding Conditions ................................................................................................ 17

4.2 Welding Documents ............................................................................................................. 18

4.3 Welding Procedure Qualification .......................................................................................... 18

4.4 Personnel Qualification ........................................................................................................ 20

4.4.1 Welder and Welding Operator ..................................................................................... 20

4.4.2 Inspectors ..................................................................................................................... 21

4.4.3 Welding Supervisors or Welding Foremen .................................................................. 22

4.4.4 Certified Welding Specialist Engineer and Certified Welding Technologist................. 22

4.5 Welding Processes and Equipment ..................................................................................... 23

4.6 Welding Technique............................................................................................................... 24

4.7 Consumable ......................................................................................................................... 26

4.8 Environmental Conditions .................................................................................................... 28

4.9 Preheating and Interpass Temperature ............................................................................... 28

4.10 Post-heating ....................................................................................................................... 29

4.11 Inspection and Quality Control ........................................................................................... 29

4.12 Weld Repairs ...................................................................................................................... 30

4.13 Post Weld Heat Treatment (PWHT) ................................................................................... 30

4.14 Auxiliary Assembly Devices ............................................................................................... 31

4.15 Marking of Welded Joints ................................................................................................... 31

4.16 Safety in Welding ............................................................................................................... 32

5 Materials ............................................................................................................................................ 32

5.1 Carbon Steel and Carbon-Manganese Steel ....................................................................... 32

5.1.1 Introduction .................................................................................................................. 32

5.1.2 Weldability .................................................................................................................... 32

2

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

5.1.3 General Welding Technique ........................................................................................ 33

5.1.4 Applicable Welding Processes ..................................................................................... 33

5.1.4.1 SMAW .................................................................................................................. 33

5.1.4.2 GTAW .................................................................................................................. 34

5.1.4.3 GMAW.................................................................................................................. 34

5.1.4.4 FCAW................................................................................................................... 34

5.1.4.5 SAW ..................................................................................................................... 34

5.1.5 Preheating and Interpass Temperature ....................................................................... 34

5.1.6 Post-heating ................................................................................................................. 36

5.1.7 Post Weld Heat Treatment (PWHT)............................................................................. 36

5.1.8 Weld Repair ................................................................................................................. 36

5.1.9 Supplementary Requirements for Maintenance Weld ................................................. 36

5.2 Heat-Treated Low Alloy Steel .............................................................................................. 36

5.2.1 Introduction .................................................................................................................. 36

5.2.2 Weldability .................................................................................................................... 37

5.2.3 General Welding Technique ........................................................................................ 37

5.2.4 Applicable Welding Processes ..................................................................................... 37

5.2.5 General Conditions for Consumables .......................................................................... 37

5.2.6 Preheating and Interpass ............................................................................................. 38

5.2.7 Post-Heating ................................................................................................................ 38

5.2.8 Post Weld Heat Treatment (PWHT)............................................................................. 38

5.2.9 Maintenance Weld Repair ............................................................................................ 38

5.2.10 Supplementary Requirements for Inspection ............................................................. 38

5.3 Chrome-Molybdenum Steels and Molybdenum Steels ........................................................ 39

5.3.1 Introduction .................................................................................................................. 39

5.3.2 Weldability .................................................................................................................... 39

5.3.3 General Welding Technique ........................................................................................ 40

5.3.4 Applicable Welding Processes ..................................................................................... 40

5.3.4.1 SMAW .................................................................................................................. 40

5.3.4.2 GTAW .................................................................................................................. 40

5.3.4.3 GMAW.................................................................................................................. 40

3

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

5.3.4.4 FCAW-G............................................................................................................... 41

5.3.4.5 SAW ..................................................................................................................... 41

5.3.5 General Conditions for Consumables .......................................................................... 41

5.3.6 Preheating and Interpass Temperature ....................................................................... 43

5.3.7 Post-heating ................................................................................................................. 44

5.3.8 Post Weld Heat Treatment (PWHT)............................................................................. 45

5.3.9 Hardness Test in Homogeneous Joints ....................................................................... 46

5.3.10 Weld Repair ............................................................................................................... 46

5.3.11 Supplementary Requirements for Maintenance Weld ............................................... 46

5.3.12 Supplementary Requirements for Inspection ............................................................. 47

5.4 Nickel Steel .......................................................................................................................... 47

5.4.1 Introduction .................................................................................................................. 47

5.4.2 Weldability .................................................................................................................... 47

5.4.3 General Welding Technique ........................................................................................ 48

5.4.4 Applicable Welding Processes ..................................................................................... 48

5.4.4.1 SMAW .................................................................................................................. 48

5.4.4.2 GTAW .................................................................................................................. 48

5.4.4.3 GMAW.................................................................................................................. 48

5.4.4.4 SAW ..................................................................................................................... 49

5.4.5 General Conditions for Consumables .......................................................................... 49

5.4.6 Preheating and Interpass Temperature ....................................................................... 50

5.4.7 Post-heating ................................................................................................................. 50

5.4.8 Post Weld Heat Treatment (PWHT)............................................................................. 50

5.4.9 Weld Repair ................................................................................................................. 51

5.4.10 Supplementary Requirements for Maintenance Weld ............................................... 51

5.4.11 Supplementary Requirements for Inspection ............................................................. 51

5.5 Austenitic Stainless Steels ................................................................................................... 51

5.5.1 Introduction .................................................................................................................. 51

5.5.2 Weldability .................................................................................................................... 52

5.5.3 General Welding Technique ........................................................................................ 52

5.5.4 Applicable Welding Processes ..................................................................................... 55

4

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

5.5.4.1 SMAW .................................................................................................................. 55

5.5.4.2 GTAW .................................................................................................................. 55

5.5.4.3 GMAW.................................................................................................................. 55

5.5.4.4 FCAW................................................................................................................... 56

5.5.4.5 SAW ..................................................................................................................... 56

5.5.5 General Conditions for Consumables .......................................................................... 56

5.5.6 Preheating and Interpass ............................................................................................. 58

5.5.7 Post-heating ................................................................................................................. 58

5.5.8 Post Weld Heat Treatment (PWHT)............................................................................. 58

5.5.9 Weld Repair ................................................................................................................. 58

5.5.10 Supplementary Requirements for Maintenance Weld ............................................... 58

5.5.11 Supplementary Requirements for Inspection ............................................................. 58

5.6 Superaustenitic Stainless Steels .......................................................................................... 59

5.6.1 Introduction .................................................................................................................. 59

5.6.2 Weldability .................................................................................................................... 59

5.6.3 General Welding Technique ........................................................................................ 59

5.6.4 Applicable Welding Processes ..................................................................................... 60

5.6.4.1 SMAW .................................................................................................................. 60

5.6.4.2 GTAW .................................................................................................................. 60

5.6.4.3 GMAW.................................................................................................................. 60

5.6.5 General Conditions for Consumables .......................................................................... 61

5.6.6 Preheating and Interpass ............................................................................................. 61

5.6.7 Post-heating ................................................................................................................. 62

5.6.8 Post Weld Heat Treatment (PWHT)............................................................................. 62

5.6.9 Heat Treatment of Solubilization .................................................................................. 62

5.6.10 Weld Repair ............................................................................................................... 62

5.6.11 Supplementary Requirements for Maintenance Weld ............................................... 62

5.6.12 Supplementary Requirements for Inspection ............................................................. 62

5.7 Duplex, Superduplex and Hyperduplex Stainless Steels ..................................................... 63

5.7.1 Introduction .................................................................................................................. 63

5.7.2 Weldability .................................................................................................................... 64

5

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

5.7.3 General Welding Technique ........................................................................................ 64

5.7.4 Applicable Welding Processes ..................................................................................... 67

5.7.4.1 SMAW .................................................................................................................. 67

5.7.4.2 GTAW .................................................................................................................. 67

5.7.4.3 GMAW.................................................................................................................. 68

5.7.4.4 SAW ..................................................................................................................... 68

5.7.5 General Conditions for Consumables .......................................................................... 68

5.7.6 Preheating and Interpass ............................................................................................. 68

5.7.7 Post-heating ................................................................................................................. 69

5.7.8 Post Weld Heat Treatment (PWHT)............................................................................. 69

5.7.9 Weld Repair ................................................................................................................. 69

5.7.10 Supplementary Requirements for Maintenance Weld ............................................... 69

5.7.11 Supplementary Requirements for Inspection ............................................................. 69

5.8 Martensitic Stainless Steels ................................................................................................. 69

5.8.1 Introduction .................................................................................................................. 69

5.8.2 Weldability .................................................................................................................... 69

5.8.3 General Welding Technique ........................................................................................ 70

5.8.4 Applicable Welding Processes ..................................................................................... 70

5.8.4.1 SMAW .................................................................................................................. 70

5.8.4.2 GTAW .................................................................................................................. 71

5.8.4.3 GMAW.................................................................................................................. 71

5.8.4.4 FCAW................................................................................................................... 71

5.8.4.5 SAW ..................................................................................................................... 71

5.8.5 General Conditions for Consumables .......................................................................... 71

5.8.6 Preheating and Interpass ............................................................................................. 72

5.8.7 Post-heating ................................................................................................................. 72

5.8.8 Post Weld Heat Treatment (PWHT)............................................................................. 73

5.8.9 Weld Repair ................................................................................................................. 73

5.8.10 Supplementary Requirements for Inspection ............................................................. 73

5.9 Ferritic Stainless Steels ........................................................................................................ 73

5.9.1 Introduction .................................................................................................................. 73

6

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

5.9.2 Weldability .................................................................................................................... 73

5.9.3 General Welding Technique ........................................................................................ 74

5.9.4 Applicable Welding Processes ..................................................................................... 74

5.9.4.1 SMAW .................................................................................................................. 74

5.9.4.2 GTAW .................................................................................................................. 75

5.9.4.3 GMAW.................................................................................................................. 75

5.9.4.4 FCAW................................................................................................................... 75

5.9.4.5 SAW ..................................................................................................................... 75

5.9.5 General Conditions for Consumables .......................................................................... 75

5.9.6 Preheating and Interpass ............................................................................................. 77

5.9.7 Post-Heating ................................................................................................................ 77

5.9.8 Post Weld Heat Treatment (PWHT)............................................................................. 77

5.9.9 Weld Repair ................................................................................................................. 77

5.9.10 Supplementary Requirements for Inspection ............................................................. 77

5.10 Nickel and Nickel Alloys ..................................................................................................... 78

5.10.1 Introduction ................................................................................................................ 78

5.10.2 Weldability .................................................................................................................. 78

5.10.3 General Welding Technique ...................................................................................... 79

5.10.4 Applicable Welding Processes................................................................................... 80

5.10.4.1 SMAW ................................................................................................................ 80

5.10.4.2 GTAW ................................................................................................................ 80

5.10.4.3 GMAW................................................................................................................ 80

5.10.4.4 FCAW................................................................................................................. 80

5.10.4.5 SAW ................................................................................................................... 81

5.10.5 General Conditions for Consumables ........................................................................ 81

5.10.6 Preheating and Interpass ........................................................................................... 82

5.10.7 Post-heating ............................................................................................................... 82

5.10.8 Post Weld Heat Treatment (PWHT)........................................................................... 82

5.10.9 Weld Repair ............................................................................................................... 82

5.10.10 Supplementary Requirements for Inspection ........................................................... 82

5.11 Copper and Copper Alloys ................................................................................................. 83

7

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

5.11.1 Introduction ................................................................................................................ 83

5.11.2 Weldability .................................................................................................................. 83

5.11.3 General Welding Technique ...................................................................................... 83

5.11.4 Applicable Welding Processes................................................................................... 84

5.11.4.1 SMAW ................................................................................................................ 84

5.11.4.2 GTAW ................................................................................................................ 84

5.11.4.3 GMAW................................................................................................................ 84

5.11.5 General Conditions for Consumables ........................................................................ 85

5.11.6 Preheating and Interpass ........................................................................................... 85

5.11.7 Post-heating ............................................................................................................... 85

5.11.8 Post Weld Heat Treatment (PWHT)........................................................................... 85

5.12 Welding of Metal Sheets and Coated Tubes ..................................................................... 85

5.12.1 Introduction ................................................................................................................ 85

5.12.2 Types of Metal Coatings ............................................................................................ 86

5.12.2.1 Cladded Plate .................................................................................................... 86

5.12.2.2 Plate with Coating Deposited by Welding (Weld Overlay)................................. 86

5.12.2.3 Plate with Lining ................................................................................................. 86

5.12.3 Weldability .................................................................................................................. 86

5.12.4 General Welding Technique ...................................................................................... 86

5.12.5 Applicable Welding Processes................................................................................... 87

5.12.6 General Conditions for Consumables ........................................................................ 88

5.12.7 Preheating and Interpass Temperature ..................................................................... 90

5.12.8 Post-heating ............................................................................................................... 91

5.12.9 Post Weld Heat Treatment (PWHT)........................................................................... 91

5.12.10 Supplementary Requirements for Inspection ........................................................... 91

5.13 Dissimilar Welding .............................................................................................................. 92

5.13.1 Introduction ................................................................................................................ 92

5.13.2 Base Metal ................................................................................................................. 92

5.13.3 General Welding Technique ...................................................................................... 92

5.13.4 General Conditions for Consumables ........................................................................ 92

5.13.5 Preheating and Interpass Temperature ..................................................................... 94

8

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

5.13.6 Post-heating ............................................................................................................... 94

5.13.7 Post Weld Heat Treatment (PWHT)........................................................................... 94

5.13.8 Supplementary Requirements for Inspection ............................................................. 95

Annex A -Instructions for Sampling Inspection on Receipt of Consumables ....................................... 96

A.1 Objective ........................................................................................................................................ 96

A.2 Sampling ........................................................................................................................................ 96

A.3 Guide For Determination of Sample Size and Acceptance and Rejection Limits .......................... 97

Annex B -Hardness Measurement Test [Recommended Practice] ...................................................... 99

B.1 Objective ........................................................................................................................................ 99

B.2 General Conditions ........................................................................................................................ 99

B.2.1 Calibration of Bench and Portable Measurement System ................................................ 99

B.2.2 Personnel Qualification ..................................................................................................... 99

B.2.3 Hardness Measurement in Laboratory ........................................................................... 100

B.2.3.1 Measurement Procedure ........................................................................................ 100

B.2.3.2 Test Reports ........................................................................................................... 100

B.2.3.3 Test Specimen for Welding Procedure Qualification .............................................. 101

B.2.3.4 Hardness Measurement in Welding Procedure Qualification ................................. 101

B.2.4 Hardness Measurement in Field ..................................................................................... 104

B.2.4.1 Measurement Procedure ........................................................................................ 104

B.2.4.2 Test Reports ........................................................................................................... 105

B.2.4.3 Suitability of Field Portable Instruments ................................................................. 105

B.2.4.4 Surface Preparation ................................................................................................ 106

B.2.4.5 Hardness Measurement Test Performance ........................................................... 107

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

Figures

Figure 1 - Detail for Determination of Thickness ................................................................................... 35

Figure 2 - Examples of Solidification Cracks ......................................................................................... 53

Figure 3 - Examples of Torch Outlet Profile .......................................................................................... 53

Figure 4 -

Examples of Contamination Due to Different Concentrations of Oxygen in Purge Gas... 54

Figure 5 - Heat Input and Corrosion Resistance ................................................................................... 66

Figure 6 - Joint Preparation of Coated Plate with Access on Both Sides ............................................. 86

Figure 7 -Preparation of Joint from Coated Plate with Access Only on the Substrate Side ................ 86

Figure A.1 - Application Diagram of a Simple Sampling Plan ............................................................... 98

Figure B.1 - Hardness Profile for Double V Bevel ............................................................................... 102

Figure B.2 - Hardness Profile for V Bevel ........................................................................................... 102

Figure B.3 Hardness Measurement Points for Profile in V Bevel on Upper Face............................ 103

Figure B.4 Hardness Measurement Points for Profile in V Bevel on Root ....................................... 103

Figure B.5 - Hardness Measurement Points in Profile of Plate with Coating Deposited by Welding

(Weld Overlay) ................................................................................................................ 104

Figure B.6 - Hardness Measurement Points in Welded Joint Surface (Weld Metal, HAZ, and Base

Metal) for Validation of Portable Durometer ................................................................... 106

Figure B.7 - Surface Preparation for Hardness Measurement in Weld ............................................... 106

Figure B.8 - Hardness Measurement Points on Welded Joint Surface ............................................... 107

10

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

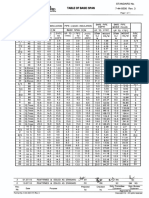

Tables

Table 1 - Diffusible Hydrogen Limit in FCAW Electrodes ...................................................................... 33

Table 2 - Minimum Preheating and Interpass Temperatures Specified for Welding of Carbon Steel and

Carbon-manganese Steel ...................................................................................................... 34

Table 3 - Minimum and Maximum Preheating and Interpass Temperature of Heat-Treated Low Alloy

Steels .................................................................................................................................... 38

Table 4 - Designation of P numbers, According to ASME BPVC Section IX ........................................ 39

Table 5 - Consumables for Molybdenum and Chromium-Molybdenum Steels ..................................... 42

Table 6 - Consumables for Heterogeneous Welding of Molybdenum and Chromium-Molybdenum

Steels .................................................................................................................................... 43

Table 7 - Preheating and Interpass Temperature for Chromium-Molybdenum and Molybdenum Steels ... 44

Table 8 - Post-heating for Chromium-Molybdenum and Molybdenum Steels ...................................... 45

Table 9 - Hardness in Welded and Heat Affected Zone after PWHT .................................................... 46

Table 10 - Electrodes and Rods for Nickel Steel................................................................................... 49

Table 11 - Minimum Preheating and Interpass Temperature for Welding of Steels to Nickel Homogeneous Welding ......................................................................................................... 50

Table 12 - Minimum Preheating and Interpass Temperature for Welding of Steels to Nickel Heterogeneous Welding ...................................................................................................... 50

Table 13 - Consumables of Austenitic Stainless Steels ........................................................................ 57

Table 14 -Coated Electrode, Rod and Solid Wire for Welding of Superaustenitic Stainless Steels .... 61

Table 15 - Chemical Composition (% in Weight) of the Main Duplex Stainless Steels......................... 64

Table 16 - Additional Testing to ASME BPVC Section IX ..................................................................... 67

Table 17 - Consumables of Duplex and Superduplex Stainless Steels ................................................ 68

Table 18 - Electrodes and Rods for Martensitic Stainless Steels ......................................................... 72

Table 19 - Electrodes and Rods for Ferritic Stainless Steels ................................................................ 76

Table 20 - Electrodes, Rods and Solid Wires for Nickel and Nickel Alloys ........................................... 81

Table 21 - Rods for Copper and Copper Alloys .................................................................................... 85

Table 22 - Filler Metals for Coating Deposited by Welding - Weld Overlay - in Carbon Steel or Low

Alloy Base-Plate on Equipment with No Need for PWHT .................................................... 89

Table 23 - Filler Metals for Coating Deposited by Welding - Weld Overlay - in Carbon Steel or Low

Alloy Base-Plate on Equipment Requiring PWHT ............................................................... 90

Table 24 - Consumables, Preheating and Post-Heating Temperatures for Welding of Dissimilar Joints ... 92

Table A.1 - Simple Sampling Plan - Normal Inspection of Consumers Risk 5 % and 10 % ................ 96

11

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

Foreword

This Standard is the English version (issued in 12/2013) of PETROBRAS N-133 REV. L 07/2013. In case

of doubt, the Portuguese version, which is the valid document for all intents and purposes, shall be used.

1 Scope

1.1 This Standard establishes the requirements and recommended practices for fusion welding of

steels and nonferrous alloys, except for 1.1.1 and 1.1.2.

1.1.1 In the event of welding or hot tapping of equipment, industrial pipes and pipelines in operation

with internal fluid, PETROBRAS N-2163 shall be used.

1.1.2 In the event of underwater welding, PETROBRAS N-2036 shall be used.

1.2 This Standard applies to the following materials and conditions:

a) carbon steel and carbon-manganese;

b) heat-treated low alloy steel;

c) chrome-molybdenum steel and molybdenum steel;

d) nickel steel;

e) austenitic stainless steel;

f) super-austenitic stainless steel;

g) duplex, super-duplex and hyper-duplex stainless steels;

h) martensitic stainless steel;

i) ferritic stainless steel;

j) nickel and nickel alloy;

k) copper and copper alloy;

l) coated sheet;

m) dissimilar welding.

1.3 This Standard applies to procedures started as of its date of issuance.

1.4 This Standard contains Technical Requirements and Recommended Practices.

2 Normative References

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document applies.

PETROBRAS N-1438 - Terminologia Soldagem;

PETROBRAS N-1738 - Descontinuidades em Juntas Soldadas, Fundidos, Forjados e Laminados;

PETROBRAS N-1859 - Qualificao de Consumveis de Soldagem;

PETROBRAS N-2036 - Soldagem Subaqutica;

PETROBRAS N-2163 - Soldagem e Trepanao em Equipamentos, Tubulaes Industriais

e Dutos em Operao;

PETROBRAS N-2301 - Elaborao da Documentao Tcnica de Soldagem;

PETROBRAS N-2349 - Segurana nos Trabalhos de Soldagem e Corte;

12

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

ABNT NBR 5425 - Guia para Inspeo por Amostragem no Controle e na Certificao de

Qualidade;

ABNT NBR 5426 - Planos de Amostragem e Procedimentos na Inspeo por Atributos;

ABNT NBR 5427 - Guia para Utilizao da Norma ABNT NBR 5426 - Planos de

Amostragem e Procedimentos na Inspeo por Atributos;

ABNT NBR 14842 - Critrios para a Qualificao e Certificao de Inspetores de Soldagem;

ABNT NBR ISO IEC 17025 - Requisitos Gerais para Competncia de Laboratrios de

Ensaios e Calibrao;

ABNT NBR NM ISO 9712 - Ensaio No Destrutivo - Qualificao e Certificao de Pessoal;

FBTS 007 - Critrios para a Qualificao e Certificao de Engenheiro Especialista em

Soldagem e Tecnlogo de Soldagem;

ISO IEC 17024 - Conformity Assessment - General Requirements for Bodies Operating

Certification of Persons;

ISO GUIDE 65 - General Requirements for Bodies Operating Product Certification Systems;

API 510 - Pressure Vessel Inspection Code: In-Service Inspection, Rating, Repair, and

Alteration;

API RP 582 - Welding Guidelines for the Chemical, Oil, and Gas Industries;

API RP 934-A - Materials and Fabrication of 2 1/4Cr-1Mo, 2 1/4Cr-1Mo-1/4V, 3Cr-1Mo, and

3Cr-1Mo-1/4V Steel Heavy Wall Pressure Vessels for High-temperature, High-pressure

Hydrogen Service;

API TR 934-B - Fabrication Considerations for Vanadium-Modified Cr-Mo Steel Heavy Wall

Pressure Vessels;

API RP 934-C - Materials and Fabrication of 1 1/4Cr-1/2Mo Steel Heavy Wall Pressure

Vessels for High-pressure Hydrogen Service Operating at or Below 825 F (441 C);

API TR 934-D - Technical Report on the Materials and Fabrication Issues of 11/4Cr-1/2Mo

and 1Cr-1/2Mo Steel Pressure Vessels;

API RP 934-E - Recommended Practice for Materials and Fabrication of 11/4CR-1/2Mo

Steel Pressure Vessels for Service Above 825 F (440 C);

API TR 938-B - Use of 9Cr-1Mo-V (Grade 91) Steel in the Oil Refining Industry;

ASME BPVC - Section II, Part C - Specifications for Welding Rods, Electrodes, and Filler

Metals;

ASME BPVC - Section V - Nondestructive Examination;

ASME BPVC - Section VIII - Division 1 - Rules For Construction of Pressure Vessels;

ASME BPVC - Section IX - Qualification Standard for Welding and Brazing Procedures,

Welders, Brazers, and Welding and Brazing Operators;

ASTM A 262 - Standard Practices for Detecting Susceptibility to Intergranular Attack in

Austenitic Stainless Steels;

13

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

ASTM A 370 - Methods and Definitions for Mechanical Testing of Steel Products;

ASTM A 380 - Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel

Parts, Equipment, and Systems;

ASTM A 1038 - Standard Test Method for Portable Hardness Testing by the Ultrasonic

Contact Impedance Method;

ASTM E 140 - Standard Hardness Conversion Tables for Metals Relationship Among Brinell

Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness,

and Scleroscope Hardness;

ASTM E 340 - Standard Test Method for Macroetching Metals and Alloys;

ASTM E 384 - Standard Test Method for Knoop and Vickers Hardness of Materials;

ASTM E 562 - Standard Test Method for Determining Volume Fraction by Systematic

Manual Point Count;

ASTM G 48 - Standard Test Methods for Pitting and Crevice Corrosion Resistance of

Stainless Steels and Related Alloys by Use of Ferric Chloride Solution;

AWS A3.0 - Standard Welding Terms and Definitions Including Terms for Adhesive Bonding,

Brazing, Soldering, Thermal Cutting, and Thermal Spraying;

AWS A4.2 - Standard Procedures for Calibrating Magnetic Instruments to Measure the Delta

Ferrite Content of Austenitic and Duplex Ferritic-Austenitic Stainless Steel Weld Metal;

AWS A5.01 - Procurement Guidelines for Consumables - Welding and Allied Processes Flux and Gas Shielded Electrical Welding Processes;

AWS A5.1 - Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding;

AWS A5.4 - Specification for Stainless Steel Electrodes for Shielded Metal Arc Welding;

AWS A5.5 - Specification for Low-Alloy Steel Electrodes for Shielded Metal Arc Welding;

AWS A5.6 Specification for Copper and Copper-Alloy Electrodes for Shielded Metal Arc

Welding;

AWS A5.7 - Specification for Copper and Copper-Alloy Bare Welding Rods and Electrodes;

AWS A5.9 - Specification for Bare Stainless Steel Welding Electrodes and Rods;

AWS A5.11 - Specification for Nickel-Alloy Welding Electrodes for Shielded for Metal Arc

Welding;

AWS A5.12 - Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc

Welding and Cutting;

AWS A5.14 - Specification for Nickel and Nickel-Alloy Bare Welding Electrodes and Rods;

AWS A5.17 - Specification for Carbon Steel Electrodes and Fluxes for Submerged Arc

Welding;

AWS A5.18 - Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc

Welding;

AWS A5.22 - Specification for Stainless Steel Flux Cored and Metal Cored Welding

Electrodes and Rods;

14

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

AWS A5.23 - Specification for Low-Alloy Steel Electrodes and Fluxes for Submerged Arc Welding;

AWS A5.28 - Specification for Low-Alloy Steel Electrodes and Rods for Gas Shielded Arc Welding;

AWS A5.29 - Specification for Low-Alloy Steel Electrodes for Flux Cored Arc Welding;

AWS A5.32 - Welding Consumables - Gases and Gas Mixtures for Fusion Welding and

Allied Processes;

AWS A5.34 - Specification for Nickel-Alloy Electrodes for Flux Cored Arc Welding;

AWS A5.36 - Specification for Carbon and Low-Alloy Steel Flux Cored Electrodes for Flux

Cored Arc Welding and Metal Cored Electrodes for Gas Metal Arc Welding;

AWS C5.5 - Recommended Practices for Gas Tungsten Arc Welding;

AWS D1.1 - Structural Welding Code-Steel;

AWS D10.8 - Recommended Practices for Welding of Chromium-Molybdenum Steel Piping

and Tubing;

AWS D10.10 - Recommended Practices for Local Heating of Welds in Piping and Tubing;

NORSOK M-601 - Welding and Inspection of Piping;

WRC 452 - Recommended Practices for Local Heating of Welds in Pressure Vessels.

NOTE

For documents referred in this Standard and for which only the Portuguese version is

available, the PETROBRAS department that uses this Standard should be consulted for any

information required for the specific application.

3 Terms and Definitions

For purposes of this document, the terms and definitions of PETROBRAS N-1438, N-1738, API

RP 582, AWS A3.0 and the following ones are applied.

3.1

controlled deposition

deposition technique with heat input control of each pass and with ratio between inputs, according to a

predetermined sequence of welding

3.2

EGW - Electrogas Welding

welding process using electro-gas

3.3

ERW - Electrical Resistance Welding

welding process using electrical resistance

3.4

ESW - Electroslag Welding

welding process using electro-slag

3.5

FCAW-G - Gas Shielded Flux Cored Arc-Welding

welding process using gas shielded flux-cored wire

15

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

3.6

FCAW-S - Flux Cored Self-Shielded Arc Welding

welding process using self-shielded flux-cored wire

3.7

GMAW - Gas Metal Arc Welding

arc welding process using shielding gas, with automatic wire feeding. Also known as "MIG/MAG"

3.8

GTAW - Gas Tungsten Arc Welding

arc welding process using shielding gas with non-consumable tungsten electrode. Also known as

"TIG"

3.9

level 2 welding inspector

professional certified by the Sistema Nacional de Qualificao e Certificao - Pessoal (SNQC-PS) as

welding inspector level 2 in the design standard applicable to the service

3.10

high level of diffusible hydrogen in the weld metal

hydrogen level exceeding 16 mL of hydrogen per 100 g of deposited weld metal

3.11

low level of diffusible hydrogen in the weld metal

hydrogen level above 4 mL and of 8 mL or below per 100 g of deposited weld metal (H8)

3.12

extra low level of diffusible hydrogen in the weld metal

hydrogen level exceeding 4 mL of hydrogen per 100 g of deposited weld metal (H4)

3.13

average level of diffusible hydrogen in the weld metal

hydrogen level above 8 mL and of 16 mL or below per 100 g of deposited weld metal (H16)

3.14

oscillating pass

the oscillation of the electrode exceeds in more than three times the diameter of the electrode core

wire

3.15

straight-line pass

straight-line pass with no significant oscillation, in order to ensure specific requirements for corrosion

resistance and toughness. In some cases, depending on the base material, the bead may have a

width up to three times the diameter of the coated electrode core wire

3.16

PAW - Plasma Arc Welding

welding process using plasma

16

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

3.17

welding responsible technician of PETROBRAS

maintenance professional of PETROBRAS Operating Units and technician responsible for welding,

designated by the Operating Unit and qualified to assess the behavior of the welded joint regarding

the application and exposure to the environment. The selection of the Welding Procedure

Specification / Welding Procedure Qualification Record (WPS / RQPS) that best meets the service

conditions will be responsibility of this professional, who shall be registered in the Conselho Regional

de Engenharia e Arquitetura (CREA), have experience and solid background in the welding area

3.18

SAW - Submerged Arc Welding

welding process using submerged arc

3.19

SMAW - Shielded Metal Arc Welding

welding process using coated electrode

3.20

multiple pass welding

fusion weld produced by more than one progression of arc, flame, or the energy source (pass) along

the joint

3.21

welding supervisor or welding foreman

leader of the team of welders, responsible for the team performance based on his/her knowledge

about the qualification criteria of welders and welding operators, WPS, Instruction for Execution and

Welding Inspection (IEIS), welding position, range of thicknesses, welding symbols and terminology,

and technical drawing

3.22

SW - Stud Welding

welding process using studs

4 General Conditions

4.1 General Welding Conditions

4.1.1 This Standard shall be used in conjunction with the design, fabrication, assembly and post

fabrication standards, and with standards of additional requirements relating to the service conditions

of the equipment item or the structure. The conflicting requirements shall be discussed during the

clarification phase in bidding period, with PETROBRASs decision prevailing.

4.1.2 Welding is not permitted without the required qualification of welders and welding procedures,

according to the design code.

4.1.3 The requirements for welding operation are found in this Section, being valid for any of the

materials mentioned and all equipment items or structures made from those materials.

17

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

4.1.4 Section 5 lists the requirements relating to various materials mentioned, such as, for example,

an indication of consumables, welding processes, pre-heating, post-heating and heat treatment

temperatures, and specific conditions for welding technique of the materials.

4.1.5 All welding requirements which depend on the characteristics of the equipment or structure,

such as, for example, details of bevels, adjustment of parts, dimensional tolerances, need for heat

treatment and its application method, requirements for inspection, and evaluation criteria of defects,

are not contained in this standard. This information is defined by design, fabrication, assembly and

post fabrication standards, and with standards of additional requirements relating to the service

conditions of the equipment item or the structure.

4.1.6 The heterogeneous welding shall be avoided, and its performance is mandatorily tied to prior

approval by PETROBRAS.

4.1.7 The autogenous welding shall be avoided, and its performance is mandatorily tied to prior

approval by PETROBRAS.

4.2 Welding Documents

4.2.1 All welding documents shall be prepared in accordance with PETROBRAS N-2301.

4.2.2 Welding documents shall be prepared and qualified in accordance with design, fabrication,

assembly and maintenance designs, as well as with technical specifications and contract

requirements, which may indicate additional testing, based on service or material conditions.

4.2.3 Welding documents shall be approved by the qualified welding professionals, according to

4.4.2.1 or 4.4.4, observing the responsibilities of each certification level, except as described in 4.2.4.

4.2.4 For welding in operation, maintenance or works under management of PETROBRAS' Operating

Units, the IESI may be approved by the welding responsible technician of PETROBRAS.

[Recommended Practice]

4.2.5 The selection of WPS/RQPS for welding operation and maintenance, when done by the welding

professional of the contractor, shall be endorsed by the welding responsible technician of

PETROBRAS.

4.2.6 Prequalified welding procedures provided in AWS D1.1 and the standard procedures specified

in ASME BPVC Section IX are not accepted by PETROBRAS.

4.3 Welding Procedure Qualification

4.3.1 The test specimens shall be identified in the test coupon before being removed, and their

identification shall be maintained until the tests are performed.

18

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

4.3.2 The maximum tensile strength of the deposited weld metal shall be equal to or greater than the

minimum tensile strength specified for the base metal in the homogeneous welding. For dissimilar

welding, the maximum tensile strength of deposited weld metal shall be equal to or greater than the

minimum tensile strength specified for the base metal of lower strength.

4.3.3 In the bend test, the melted and heat affected zones of the joints shall be contained within the

bent portion of the test specimen and show plastic deformation.

4.3.4 Test specimens for mechanical tests shall undergo dimensional and visual inspection before

tests are performed.

NOTE

The dimensional tolerances and finish level of impact test specimens shall comply with

ASTM A 370. The notch inspection of the impact test specimen shall be made in a profile

comparator.

4.3.5 When impact testing on heterogeneous welds and dissimilar joints is required, all zones of

different chemical composition, such as Heat Affected Zone (HAZ) and the fusion zone, shall be

represented by complete set of test specimens with notch located within those zones.

4.3.6 When the design, fabrication or assembly standard requires hardness testing in qualification of

welding procedure, the Annex B of this Standard may be adopted on fusion zone, heat affected zone

and base metal, and its results shall be compatible with the reference standard. [Recommended

Practice]

NOTE

When Annex B is adopted, it shall not be partially applied; it shall be fully applied, as a

normative requirement.

4.3.7 The application method and trademark of protective varnish of bevel shall be evaluated during

the qualification of welding procedure, when its removal before welding is not provided.

4.3.8 For clad plates, a method that proves the complete removal of the coating material shall be

assessed and approved during the welding procedure qualification. This method may not leave

residues that contaminate the weld metal.

4.3.9 For pressure vessel and other equipment with toughness requirements, during the welding

procedure qualification, the test specimens to be submitted to mechanical testing shall undergo a Post

Weld Heat Treatment (PWHT) that simulates all PWHT performed during fabrication and assembly

phases, and an additional one, foreseeing a future repair of equipment.

4.3.10 In PWHT of the test coupon used for procedure qualification, the provisions of 4.13 shall be

observed.

4.3.11 Welding consumables shall be approved according to 4.7.1. In case of welding consumables

are required to be approved by PETROBRAS N-1859, the consumable trademark is not an essential

variable in qualified procedures, unless the trademark is an essential variable required by design

code.

19

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

4.3.12 During fabrication or assembly using materials supplied in quenched and tempered or heatmechanical treatment condition, the welding procedure qualification shall be performed with the

material of the same fabrication and heat treatment process. For enlargement of existing facilities,

maintenance or rehabilitation of pipelines, the materials used shall have their quality certificate issued

by the manufacturer, containing analyzed mechanical and chemical composition properties. In these

cases, hardness shall also be measured. For maintenance services, in the occasional absence of the

manufacturers quality certificate, mechanical tests and chemical analyses shall be performed,

monitored by PETROBRAS, in order to fit in the design standard.

4.3.13 The welding procedure qualification and its tests for mirror tube welded joints shall comply with

the design standard and with API RP 582.

4.3.14 For H2S service, the minimum value of the final qualified range shall be limited to 10 % below

the value recorded by the test coupon presenting the lowest heat input.

4.4 Personnel Qualification

4.4.1 Welder and Welding Operator

4.4.1.1 Welders and welding operators shall be qualified in accordance with the applicable design

standards.

4.4.1.2 The qualification of welders and welding operators shall be documented by the Welding

Record Report (RRS) and the Certificate of Qualification of Welders and Operators (RQS).

4.4.1.3 Qualified welders and welding operators shall bear visible identification including name, the

Brazilian Register of Individual Taxpayers (CPF), the stamp number and qualification. For services

performed abroad, the CPF shall be replaced by code or numbering of the document that

unequivocally identifies the welders and operators.

4.4.1.4 A List of Qualified Welders and Welding Operators (RSQ) shall be issued.

4.4.1.5 Test specimens shall be identified in the test coupon, in order to be maintained traceable. The

identification shall be maintained until the tests are performed.

4.4.1.6 For qualification of the welder or welding operator, the methods for cleaning between weld

passes, removal of craters, and arc strikes in the bevel or auxiliary plate shall be the same as those

specified production welds.

4.4.1.7 The qualification of welder or welding operator shall include visual inspection of test coupon

welds, with the same interpretation criterion of the design, fabrication and assembly standard of

equipment or structure.

20

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

4.4.1.8 The control over performance of welders shall be carried out using the Control Over

Performance of Welders and Welding Operators (CDS) form, according to the calculation

methodology defined in PETROBRAS N-2301. The acceptance criteria listed below shall be included

in the specific procedure of the contractor, which shall be evaluated and approved by PETROBRAS

before starting the services:

a) maintenance in workshop: in radiograph, a total not exceeding 5 % of disapproved films

(a film) in a minimum of twenty radiographed films, or, in ultrasound, the sum of defective

lengths not exceeding 2,0 % (60 mm) in at least 3,0 m of weld inspected in the

development of the welded perimeter;

b) maintenance in field: in radiography, a total not exceeding 15 % of disapproved films (a

film) in a minimum of twenty radiographed films, or, in ultrasound, the sum of defective

lengths not exceeding 5,0 % (150 mm) in at least 3,0 m of weld inspected in the

development of the welded perimeter;

NOTE 1 For radiography, it is understood that the welder shall be disqualified when four films for

welds in field or two films for welds in workshop are disapproved, regardless of reaching the

amount of twenty films in the period.

NOTE 2 For ultrasound, it is understood that the welder shall be disqualified when he/she obtains the

minimum repair length of 60 mm for welds in workshop or 150 mm for welds in field,

regardless of reaching the minimum length to be inspected of 3,0 m.

c) construction and assembly: in radiography, a total not exceeding 10 % of disapproved

films (two films) in a minimum of twenty radiographed films, or, in ultrasound, the sum of

defective lengths not exceeding 2,5% (75 mm) in at least 3 m of weld inspected in the

development of the welded perimeter;

d) fabrication: in radiography, a total not exceeding 10 % of disapproved films (four films) in

a minimum of forty radiographed films, or, in ultrasound, the sum of defective lengths not

exceeding 2,5% (150 mm) in at least 6 m of weld inspected in the development of the

welded perimeter.

4.4.1.9 The periodicity for presentation of CDS shall be sufficient to ensure the required corrections

are done with no difficulty and without compromising the execution term and quality of work or service

in progress. 4.4.1.9 In every case, the periodicity for presentation of CDS shall be previously approved

by PETROBRAS.

4.4.2 Inspectors

4.4.2.1 Welding inspectors shall be qualified in accordance with the Sistema Nacional de Qualificao

e Certificao de Inspetores de Soldagem (SNQC - IS), according to ABNT NBR 14842. The welding

inspector level 2 shall be qualified and certified in the main applicable standard to perform the

attributions provided in ABNT NBR 14842 in relation to welding documentation, monitoring and

approval of qualification tests, supervision of level 1 inspectors, etc. For welding services performed

abroad, welding inspectors shall be qualified and certified by international entities meeting the

requirements of ISO IEC 17024, in which case prior approval by PETROBRAS will be necessary. The

welding inspector level 2 employed abroad shall also be qualified and certified in the main applicable

standard or evidence a minimum of one year of experience working with the mentioned standard.

4.4.2.2 For services performed in Brazil, the qualification and certification of personnel for nondestructive testing shall be made by the Sistema Nacional de Qualificao e Certificao em Ensaios

No Destrutivos (SNQC - END), according to ABNT NBR NM ISO 9712, and the visual testing may

also be performed by welding inspector qualified and certified by SNQC - IS. For inspection services

performed abroad, non-destructive testing inspectors shall be qualified and certified by independent

international entities, accredited by national bodies in their respective countries, which fully meet the

requirements of ISO IEC 17024 and operate in full compliance with ISO 9712.

21

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

4.4.2.3 The monitoring of welding performance activities by certified welding inspectors level 1 and

level 2 shall be made clear in applicable contracts.

4.4.3 Welding Supervisors or Welding Foremen

4.4.3.1 Welding supervisors and foremen shall have the following minimum knowledge:

a) interpret the welding information and parameters of IEIS;

b) know the control methodology of quality, storage and drying of consumables, specified in

the contractors procedure;

c) know the welder qualification limits;

d) know and instruct welders about the required precautions for pre-heating

(homogenization e temperature measuring), interpass temperature control, and

post-heating.

4.4.3.2 It is understood as activities of the welding supervisor or foreman, for example:

a) review the service orders, IEIS, bevel drawings of joints to be welded, so as to:

determine the quantity and type of consumables to be requested;

specify which welding machines and process shall be used in each work front;

assign welders and/or welding operators to adequate fronts;

explain the requirements for bevel preparation, pre/post-heating and inter-pass

temperatures for each work front to welders and/or welding operators;

b) ensure the correct consumables are delivered to each work front;

c) monitor the work fronts in order to ensure that:

every welder or welding operator in service in field/factory has been assigned to a task

within the scope of their certification;

every welding service in field/factory is performed within the requirements of IEIS;

the storage requirements of welding consumables in work fronts are complied with;

d) ensure that joints to be welded in next shift have the correct joint geometry, and, if not,

give feedback to the boiler supervision;

e) monitor the field assembly and adjustment of welding machines, ensuring they are

working properly;

f) at the end of each shift, ensure the consumables that returned to warehouse are duly

handled and stored;

g) manage the workforce under his/her supervision, in order to ensure safety and good

progress of welding services.

4.4.4 Certified Welding Specialist Engineer and Certified Welding Technologist

Welding specialist engineers and technologists shall be certified in accordance with the Fundao

Brasileira de Tecnologia da Soldagem (FBTS), with their attributions defined by FBTS 007.

NOTE

The certification process is being implemented by FBTS and will be available in January

2014.

22

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

4.5 Welding Processes and Equipment

4.5.1 Welding shall be performed using processes permitted by the design, fabrication and assembly

design of equipment or structure.

4.5.2 The insulation of electrode holders and cables shall be in good conditions, without flaws or

unprotected regions, and properly sized for working conditions and personal safety. All welding shall

be performed according to the requirements of PETROBRAS N-2349.

4.5.3 The measurement instruments existing in welding sources shall be calibrated and within the

expiration date.

4.5.3.1 Welding source, cables, clamps, electrode holder, welding guns and torches, wire feeders,

control cables, extension cords, refrigeration unit, auxiliary command and control units coupled to

equipment, high-frequency drive for GTAW process, and others that have direct interference in the

process or are interdependent shall meet the requirements of NEMA (National Electrical

Manufacturers Association) or IEC (International Electrotechnical Commission).

4.5.3.2 For SMAW, GTAW, GMAW, FCAW processes, it is recommended the use of inverter power

sources, mainly for materials in 5.3 and 5.7. [Recommended Practice]

4.5.4 The welding inspector shall ensure that the quantity of current and voltage provided in

WPS/IEIS remains within the qualified limits throughout the welding performance. The voltage shall be

measured as close as possible to the electrode holder, without affecting the operation of welding

service in progress.

4.5.5 The oven for storage or receipt of coated electrodes, bare electrodes, tubular electrodes, rods

and fluxes shall have heating, a thermometer and hygrometer, in order to comply with 4.7.11. Those

ovens shall not be directly connected to welding source.

4.5.6 Ovens for drying coated electrodes and fluxes shall be provided with electrical resistances to

control and maintain the temperature up to 400 C, and have a thermometer, thermostat and vent with

a diameter larger than 10 mm.

4.5.6.1 Oven for drying coated electrodes shall have perforated or grid-shaped shelves at least 25

mm away from the vertical walls.

4.5.6.2 Oven for drying fluxes shall have a shaking device or trays at least 25 mm away from the

vertical walls.

4.5.7 Ovens used for keeping coated electrodes and fluxes dry shall be provided with a thermometer,

thermostat and electrical resistances to control and keep temperatures up to 200 C. Ovens for

keeping coated electrodes dry shall have perforated or grid-shaped shelves.

4.5.8 There shall be at least one storage oven, a drying oven, and an oven for keeping things dry,

which may be fixed or portable.

23

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

4.5.9 The portable oven for keeping low hydrogen coated electrodes dry shall have electrical

resistances to keep the temperature between 80 C and 150 C, and to be of exclusive use for each

welder. The ovens shall be calibrated.

4.5.10 Equipment for pre-heating, post-heating and PWHT shall meet the fabrication and assembly

requirements of the equipment or structure.

4.5.11 Pre-heating, interpass and post-heating temperatures shall be checked by means of optical or

contact pyrometer, taking care so that the instrument adjustment is correlated with the emissivity of

the material. The temperature stick may also be used, as long as it does not conflict with Section 5.

4.5.12 Measuring and testing instruments shall be calibrated in accredited laboratories, according to

ABNT NBR ISO/IEC 17025. It is acceptable that the calibrations are performed using standards traced

by the Rede Brasileira de Calibrao (RBC) or INMETRO. For calibration performed abroad, the

laboratory shall have its metrological system formally recognized as operating in accordance with

ISO/IEC 17025. Calibration of measuring and testing instruments shall follow a Calibration Plan

contained in the Quality System of the unit or contractor.

4.5.13 Tungsten electrodes specified in AWS A5.12 shall be used. The electrode sharpening profile

shall be performed in accordance with AWS C5.5. Sharpening shall be performed longitudinally on the

electrode.

4.5.14 It is recommended the use of tungsten electrodes connected to Cerium (Ce), Lanthanum (La)

and Zirconium (Zr). [Recommended Practice]

4.5.15 For the preparation of the thoriated electrode tips, it shall be used a tungsten sharpener with

container that prevents dispersion in the environment.

4.6 Welding Technique

4.6.1 The use grounding clamps made of copper alloys is not allowed. In addition, there shall be no

contact of between copper pieces (or its alloys) and the areas heated or melted by welding and heat

treatment, except in the case of copper bars for lateral protection of electrogas welding and copper

butt-straps that are not consumable in any process.

4.6.2 The electrical welding arc shall be struck at the bevel or an appendix plate used for that

purpose.

4.6.3 Joints to be welded shall be free of oil, grease, rust, slag, paint, liquid penetrant testing

residues, sand, and soot from gas preheating, in an area of at least 25 mm on each side of the edges,

both internally and externally.

4.6.4 For welding with gas shielding, the bevel and edges shall be cleaned to white metal, in an area

of at least 25 mm on both internal and external sides.

4.6.5 When preparing the bevel, thermal or mechanical cutting irregularities and slag shall be

removed.

24

-PUBLIC-

N-133

REV. L

ENGLISH

07 / 2013

4.6.6 Carbon, slag and copper deposits resulting from carbon electrode cutting operations shall be

mechanically removed to ensure complete removal of HAZ and the contaminants.

4.6.7 Stainless steel, nickel and nickel-alloy materials shall be stored, handled and processed

completely separated from other materials, in order to avoid the risk of contamination.

4.6.8 Slag removal and cleaning tools shall be made of materials suitable for each base metal.