Documente Academic

Documente Profesional

Documente Cultură

Types of Air Motors Vane and Radial

Încărcat de

10rodriguezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Types of Air Motors Vane and Radial

Încărcat de

10rodriguezDrepturi de autor:

Formate disponibile

Selection Guide

Ingersoll Rand offers two basic types of Air Motors:

Vane Motors

Are smaller, lighter and less expensive than piston motors or similar power. Simple in design and construction,

they can be operated in most any position. Vane motors are available in a broad range of speeds, torques and

power and are the most widely used type of air motor.

Radial Piston Motors

Operate at lower speeds than vane motors. Have excellent starting and speed control. Especially good for

"lugging" heavy loads at slow speed. Standard operational position is horizontal.

Reversible / Non-Reversible Air Motors

Non-reversible air motors are rated at slightly higher speeds, torques, and horsepowers than reversible motors

of the same family.

Air Pressure

When selecting air motors, remember that the specification listings show only one set of performance figures,

at a particular pressure 90 psig. Air motors are designed to produce optimum performance at this pressure.

Many other speeds, torques and power can be obtained from the same motor by regulating the pessure, air

supply or exhaust. While they will operate at pessures below 40 psig, their performance may not be consistent.

They can also be operated above 100 psig, but often at the expense of increased maintenance.

A good rule to follow is to size an air motor based on approximately 70% of the lowest available air pressure.

This will allow additional power for starting and possible overloading.

Maximum Power

Ungoverned air motors develop maximum horsepower at approximately 50% of free (unloaded) speed while

governed motors reach their peak horsepower at about 80% of free speed.

Desired Operating Speed

The desired operating speed, not the free and unloaded speed should be considered when selecting air

motors.

Ungoverned air motors should not be run unloaded. The performance curves in this catalog indicate the

maximum speeds at which the motor should be operated. The nameplate stamped speed is present for

identification only.

Required Torque

Equally important as the speed at which an air motor is to be run is the required torque. The combination of the

two factorsspeed and torquedetermine the power of the desired motor. Care should be taken to

differentiate between stall (maximum) and running torques when selecting air motors.

Speed and Torque

Starting torques are approximately 75% of stall torques.

Operating or running torques at any speed can be approximated from motor performance curvesor

calculated using the formula:

Horsepower x 5250

Torque (lb.ft.) = -------------------------------speed (revolutions per minute)

Kilowatts x 9550

Torque (Nm) = -------------------------------speed (revolutions per minute)

Shaft Radial Loads

When an air motor is to be used with a pulley, sprocket, or gear on the shaft, the overhung load (perpendicular

to the shaft), commonly called "shaft radial loading" must be considered. It is shown in the performance curves

and is generally assumed to be applied at the mid-point of the keyway of the shaft.

Air System and Supply

Once an air motor has been selected, it is important to insure that the desired air pressure is available at the

motor, while the motor is operating. A pressure reading at the compressor does not mean that the same

pressure will be available to an operating air motor, because of possible restrictions and friction losses in the

air system. Exhaust restrictions can also affect air motor operation, and are often the cause of performance

problems.

Inlet Controls

When installing reversible air motors, a four-way valve or two three-way valves should be used to prevent

blockage of the secondary Exhaust Port. This is the opposite Rotation Port to that which is being pressurized.

Replacing Electric Motors with Air Motors

Electric motors, with the exception of series wound direct current motors, have entirely different performance

characteristics than air motors. Therefore, their torque and speed curves will not match. Many electric motors

are oversized to allow for overloading and lower power air motors can be used as replacements.

back to top

2014 Ingersoll Rand. All rights reserved.

S-ar putea să vă placă și

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)De la EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Încă nu există evaluări

- Engineering Letter: IntegralmotorsforcentrifugalfansDocument4 paginiEngineering Letter: IntegralmotorsforcentrifugalfansjameeloÎncă nu există evaluări

- Atlas Copco Air Motors GuideDocument76 paginiAtlas Copco Air Motors GuideedinhocadÎncă nu există evaluări

- Select the Right Air Motor for Your ApplicationDocument14 paginiSelect the Right Air Motor for Your ApplicationRajeev ValunjkarÎncă nu există evaluări

- Technical Information: Condensed Glossary of Motor and Gearing TermsDocument2 paginiTechnical Information: Condensed Glossary of Motor and Gearing TermsdanieldayettddÎncă nu există evaluări

- Electric Motor Brake Horsepower Calculations 2Document7 paginiElectric Motor Brake Horsepower Calculations 2osamaÎncă nu există evaluări

- Nameplate of InductionDocument6 paginiNameplate of InductionARUNPRASADEEEÎncă nu există evaluări

- Nameplate PDFDocument8 paginiNameplate PDFobida adailehÎncă nu există evaluări

- Matching Power To Pump RequirementsDocument6 paginiMatching Power To Pump RequirementsSabariMechyÎncă nu există evaluări

- Compressor Performance TestDocument9 paginiCompressor Performance TestPartha Pratim GhoshÎncă nu există evaluări

- Energy Answers For MotorsDocument4 paginiEnergy Answers For Motorsdetroit44Încă nu există evaluări

- Pocket Guide Air Motors: Omsl - 9067 - 01.indd 1Document28 paginiPocket Guide Air Motors: Omsl - 9067 - 01.indd 1zranothmanÎncă nu există evaluări

- Fan Fundamentals - Greenheck (May2005)Document24 paginiFan Fundamentals - Greenheck (May2005)jagdishgharoteÎncă nu există evaluări

- Vane Motor PresentationDocument16 paginiVane Motor PresentationJayesh BholeÎncă nu există evaluări

- Torque Curves: Roduct NformationDocument11 paginiTorque Curves: Roduct NformationCandiano PopescuÎncă nu există evaluări

- TURBOCHARGERDocument5 paginiTURBOCHARGERAnand Raju100% (1)

- Air Motors: The Ultimate Power Tools The Ultimate Power ToolsDocument16 paginiAir Motors: The Ultimate Power Tools The Ultimate Power ToolsBe HappyÎncă nu există evaluări

- P1V-S Air MotorsDocument28 paginiP1V-S Air MotorsLakshabir DebnathÎncă nu există evaluări

- Types of Supercharger: Positive DisplacementDocument10 paginiTypes of Supercharger: Positive DisplacementMamdouhAlhanafyÎncă nu există evaluări

- Introduction To FAN SELECTION: Model DesignationDocument5 paginiIntroduction To FAN SELECTION: Model Designationradreamer14Încă nu există evaluări

- Engine and Propeller Performance: Groundschool - Theory of FlightDocument25 paginiEngine and Propeller Performance: Groundschool - Theory of FlightAnonymous 3B9kXrÎncă nu există evaluări

- Siemens - Motor SpecificationsDocument50 paginiSiemens - Motor SpecificationsArtifoxÎncă nu există evaluări

- Lear - 25 GlossaryDocument8 paginiLear - 25 Glossaryniben16Încă nu există evaluări

- Buscar TurboDocument37 paginiBuscar TurboSarah Saida Villanueva GuevaraÎncă nu există evaluări

- How To Read Compressor MapDocument1 paginăHow To Read Compressor MapPepenauta InternautaÎncă nu există evaluări

- Turbocharger and Supercharger ReportDocument18 paginiTurbocharger and Supercharger ReportMayank Burman100% (3)

- Caterpillar Torque Curves PDFDocument11 paginiCaterpillar Torque Curves PDFAlberto Pila Alonso100% (2)

- Air Brake System Using Exhaust Gas PowerPoint PresentationDocument16 paginiAir Brake System Using Exhaust Gas PowerPoint PresentationErole Technologies Pvt ltd Homemade Engineer100% (1)

- Greenheck Fan Fundamentals D299Document24 paginiGreenheck Fan Fundamentals D299mohdnazirÎncă nu există evaluări

- Lecture 3Document33 paginiLecture 3Heleana Faye BundocÎncă nu există evaluări

- Aircraft Design Unit 3Document35 paginiAircraft Design Unit 3Vinoth AeroÎncă nu există evaluări

- Manual 012Document60 paginiManual 012Rixwan Bin ShabirÎncă nu există evaluări

- Thrust Reverser For A Mixed Exhaust High Bypass Ratio Turbofan Engine and Its Effect On Aircraft and Engine PerformanceDocument11 paginiThrust Reverser For A Mixed Exhaust High Bypass Ratio Turbofan Engine and Its Effect On Aircraft and Engine PerformancebashirsbaÎncă nu există evaluări

- Supercharging of Diesel EnginesDocument6 paginiSupercharging of Diesel EnginesPolavarapu Srinivasa RaoÎncă nu există evaluări

- Woodward Industrial Turbine ControlDocument16 paginiWoodward Industrial Turbine ControlhrstgaÎncă nu există evaluări

- Engines & SystemsDocument20 paginiEngines & SystemsJosephine TsangÎncă nu există evaluări

- Torque of ThreePhase Induction Motor ExplainedDocument2 paginiTorque of ThreePhase Induction Motor Explainedsaga2000cnÎncă nu există evaluări

- 9 - Propulsion Systems PDFDocument36 pagini9 - Propulsion Systems PDFJosé Edwin RoldánÎncă nu există evaluări

- Nacelle Design and SizingDocument34 paginiNacelle Design and SizingSandeep BandyopadhyayÎncă nu există evaluări

- Supercharger VS TurbochargerDocument25 paginiSupercharger VS TurbochargerAllen CastorÎncă nu există evaluări

- As D CalculatorsDocument14 paginiAs D CalculatorsPatricio TamayoÎncă nu există evaluări

- Actuator Torque Calc PDFDocument12 paginiActuator Torque Calc PDFNishith0% (1)

- Typical NotesDocument13 paginiTypical NotesDevang TripathiÎncă nu există evaluări

- TORQUES Actuator For Ball Valve PDFDocument12 paginiTORQUES Actuator For Ball Valve PDFChaerul AnwarÎncă nu există evaluări

- Improving industrial productivity through energy efficient VSDsDocument4 paginiImproving industrial productivity through energy efficient VSDssayed2846Încă nu există evaluări

- AN Ngineering: Turning Gear and Component Selection GuidelinesDocument2 paginiAN Ngineering: Turning Gear and Component Selection GuidelinesJose Lorenzo ToralÎncă nu există evaluări

- Pplant Lec 2Document6 paginiPplant Lec 2Alyssa SisonÎncă nu există evaluări

- Pneumatic Systems: Plastic Injection MoldingDocument14 paginiPneumatic Systems: Plastic Injection MoldingSino Ba To100% (1)

- VFD FP Calc2Document14 paginiVFD FP Calc2danceÎncă nu există evaluări

- Haskel Air Amplifier Brochure 7 1 1Document12 paginiHaskel Air Amplifier Brochure 7 1 1Manahil KhalilÎncă nu există evaluări

- Course Material On Compressor & PumpDocument59 paginiCourse Material On Compressor & PumpKumar Gaurav SinghÎncă nu există evaluări

- 4 Propeller FundamentalsDocument16 pagini4 Propeller FundamentalsRaul Deonarain100% (1)

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004De la EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Evaluare: 3 din 5 stele3/5 (1)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesDe la EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesEvaluare: 5 din 5 stele5/5 (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDe la EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideEvaluare: 4 din 5 stele4/5 (8)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiDe la EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiÎncă nu există evaluări

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionDe la EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionEvaluare: 4 din 5 stele4/5 (1)

- Seven Recommendations To Ensure Proper Building Operating SequencesDocument5 paginiSeven Recommendations To Ensure Proper Building Operating Sequences10rodriguezÎncă nu există evaluări

- 05 2002Document5 pagini05 2002ozgurdalÎncă nu există evaluări

- Select A Transformer Sizing or Rating For Commercial and IndustrialDocument5 paginiSelect A Transformer Sizing or Rating For Commercial and Industrial10rodriguezÎncă nu există evaluări

- How To Choose High Voltage Cable SizeDocument3 paginiHow To Choose High Voltage Cable Size10rodriguezÎncă nu există evaluări

- Inrush Currents in Latge MV CableDocument6 paginiInrush Currents in Latge MV Cable10rodriguezÎncă nu există evaluări

- Understanding Time Current CurvesDocument4 paginiUnderstanding Time Current Curves10rodriguezÎncă nu există evaluări

- Aspects of Electrical TestingDocument11 paginiAspects of Electrical Testing10rodriguezÎncă nu există evaluări

- CALCULATION FOR 350KVA GENERATOR SIZINGDocument2 paginiCALCULATION FOR 350KVA GENERATOR SIZING10rodriguezÎncă nu există evaluări

- 2017 Arc Flash Game ChangersDocument5 pagini2017 Arc Flash Game Changers10rodriguezÎncă nu există evaluări

- UPS Effect On Arc Flash - Questions and AnswersDocument1 paginăUPS Effect On Arc Flash - Questions and Answers10rodriguezÎncă nu există evaluări

- @practical Guide To Electrical Grounding, 1st Edition, 1999Document131 pagini@practical Guide To Electrical Grounding, 1st Edition, 1999cyong7788100% (15)

- Cable Sizing BasisDocument11 paginiCable Sizing Basis10rodriguezÎncă nu există evaluări

- Background Infornation Changes NEC 2011Document20 paginiBackground Infornation Changes NEC 201110rodriguezÎncă nu există evaluări

- Burndy ReferenceDocument43 paginiBurndy Reference10rodriguezÎncă nu există evaluări

- UPS Effect On Arc Flash - Questions and AnswersDocument1 paginăUPS Effect On Arc Flash - Questions and Answers10rodriguezÎncă nu există evaluări

- Impedance Percent TranformerDocument10 paginiImpedance Percent Tranformer10rodriguezÎncă nu există evaluări

- Resistivity Conductivity and Temperature CoefficientsDocument6 paginiResistivity Conductivity and Temperature Coefficients10rodriguezÎncă nu există evaluări

- Transformador TutorialDocument10 paginiTransformador Tutorial10rodriguezÎncă nu există evaluări

- CAble Ampacity Calculations IEEE ConferenceDocument7 paginiCAble Ampacity Calculations IEEE Conference10rodriguezÎncă nu există evaluări

- Pulling Cable CPADocument44 paginiPulling Cable CPA10rodriguezÎncă nu există evaluări

- Electrical Commissioning ProcessDocument14 paginiElectrical Commissioning Process10rodriguezÎncă nu există evaluări

- Cable Sizing BasisDocument11 paginiCable Sizing Basis10rodriguezÎncă nu există evaluări

- Statical Analisis Diagnostic Short Circuit Cables MVDocument6 paginiStatical Analisis Diagnostic Short Circuit Cables MV10rodriguezÎncă nu există evaluări

- Transformer Phase DisplacementDocument5 paginiTransformer Phase Displacement10rodriguezÎncă nu există evaluări

- Desing and Selectivity LV - GEDocument105 paginiDesing and Selectivity LV - GE10rodriguezÎncă nu există evaluări

- Phasor DiagramDocument10 paginiPhasor Diagram10rodriguezÎncă nu există evaluări

- Cable Sizing BasisDocument11 paginiCable Sizing Basis10rodriguezÎncă nu există evaluări

- Cable Adiabatic Temperature Rise ConstantDocument3 paginiCable Adiabatic Temperature Rise ConstantJesús RodríguezÎncă nu există evaluări

- Understanding Arc Flash HazardsDocument16 paginiUnderstanding Arc Flash Hazards10rodriguezÎncă nu există evaluări

- Wind Cat 2 PrintoutDocument7 paginiWind Cat 2 PrintoutANKURÎncă nu există evaluări

- U.S. Geothermal Industry Overview 2011 01Document44 paginiU.S. Geothermal Industry Overview 2011 01gjervisÎncă nu există evaluări

- TE809-ATS - Instructions Manual - Project v1.1.3 - TECNOELETTRA® PDFDocument36 paginiTE809-ATS - Instructions Manual - Project v1.1.3 - TECNOELETTRA® PDFpevare50% (2)

- Gerak Gempur Sains Paper 2Document11 paginiGerak Gempur Sains Paper 2Raymond Cheang Chee-CheongÎncă nu există evaluări

- GIS Based Mapping For Hydropower Plant (IHERF)Document19 paginiGIS Based Mapping For Hydropower Plant (IHERF)Jaime Daliuag100% (1)

- Wind Turbine: Germany TechnologyDocument12 paginiWind Turbine: Germany Technologygoitom01Încă nu există evaluări

- 24kV Pro-MEC ManualDocument20 pagini24kV Pro-MEC Manual0510226445100% (2)

- Sundyne LMV BMP 311 Centrifugal Pump Data SheetDocument2 paginiSundyne LMV BMP 311 Centrifugal Pump Data Sheetmasoud67aÎncă nu există evaluări

- Vortex Bladeless Wind TurbineDocument15 paginiVortex Bladeless Wind TurbineAmol Shankar Devakate100% (2)

- New Microsoft Word DocumentDocument7 paginiNew Microsoft Word DocumentAmr AliÎncă nu există evaluări

- Gas SolubilityDocument59 paginiGas SolubilityAustine Ameh0% (1)

- Vadodara Institute of Engineering: Surging and ChokingDocument16 paginiVadodara Institute of Engineering: Surging and ChokingKorichiKarimÎncă nu există evaluări

- Animal Food Processing PlantDocument30 paginiAnimal Food Processing PlantDaniel OkereÎncă nu există evaluări

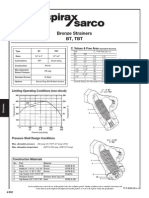

- Bronze Strainers BT, TBT: C Values & Free AreaDocument2 paginiBronze Strainers BT, TBT: C Values & Free AreabuddhansamratÎncă nu există evaluări

- Journal Paper PDFDocument6 paginiJournal Paper PDFsandy66542Încă nu există evaluări

- Daikin VRV Angol Katalógus 2017-2018Document209 paginiDaikin VRV Angol Katalógus 2017-2018Dirt FilterÎncă nu există evaluări

- History of Hydroelectric Power in the PhilippinesDocument3 paginiHistory of Hydroelectric Power in the PhilippinesAdriell David LahayonÎncă nu există evaluări

- RelaysDocument6 paginiRelaysEmilJaredVirayPabustan100% (1)

- MSRX Charge Controller: Product ManualDocument48 paginiMSRX Charge Controller: Product Manualrevle100% (1)

- Installation Guide for Cylinder Head ReplacementDocument5 paginiInstallation Guide for Cylinder Head ReplacementJuan Francisco Canto Diez100% (1)

- Dossier BATERIES enDocument14 paginiDossier BATERIES enNacer Mezghiche100% (1)

- WRV ManualDocument52 paginiWRV ManualJacinto Morales100% (7)

- Science Experiments PDFDocument242 paginiScience Experiments PDFJared MoyaÎncă nu există evaluări

- GET-1008L Distribution Data BookDocument35 paginiGET-1008L Distribution Data BookhramirezpÎncă nu există evaluări

- Technical Seminar on Solar Tree Energy SolutionsDocument10 paginiTechnical Seminar on Solar Tree Energy Solutions4J9 CHANDA VISHNU VARDHAN RAOÎncă nu există evaluări

- Super-II SR+ With P IV+Document145 paginiSuper-II SR+ With P IV+felix3189100% (5)

- EE101 6 Electrical InstallationsDocument8 paginiEE101 6 Electrical InstallationsKasun WerangaÎncă nu există evaluări

- Oceans of Opportunities.Document14 paginiOceans of Opportunities.Uhrin ImreÎncă nu există evaluări

- Financial Services Dumping - Priscilla CarriónDocument2 paginiFinancial Services Dumping - Priscilla CarriónAndrea Carrion100% (2)

- MHI Ammonia Energy Conferce 2021 FinalDocument18 paginiMHI Ammonia Energy Conferce 2021 Finaljonyg01Încă nu există evaluări

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)