Documente Academic

Documente Profesional

Documente Cultură

CT 400 Series: Test Stand For 4-Cylinder Four-Stroke Engines

Încărcat de

sady1967Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CT 400 Series: Test Stand For 4-Cylinder Four-Stroke Engines

Încărcat de

sady1967Drepturi de autor:

Formate disponibile

INTERNAL COMBUSTION ENGINES

CONFIGURATIONS

GP

KIN O

WER

BRA

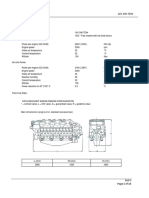

CT 400 SERIES: TEST STAND FOR 4-CYLINDER FOUR-STROKE ENGINES

75 kW

W

CT 400.16

(Sensors)

CT 400

400.01

01

(Petrol engine)

CT 400.17

(Sensors)

CT 400

(Load unit)

CT 400.09

Indicating system

CT 159.02

Exhaust gas

analysis

CT 400

400.02

02

(Diesel engine)

USB

The CT 400 equipment series offers a wide range of

experiments on industrial engines with a power output of

up to 75 kW.

The complete test stand is made up of the

CT 400 load unit and an engine. A choice of two watercooled engines is available:

4 cylinder in-line engine, petrol

4 cylinder in-line engine, diesel

The engine can be connected to the load unit quickly and

easily. The CT 400 load mechanism essentially consists

of an adjustable air-cooled eddy current brake. The

engines can be investigated in two modes:

Torque control: Manual adjustment of braking

torque. The characteristic curve for the brake is

changed, different full load points are approached and

measurements are carried out depending on the

speed.

Speed control: A controller keeps the speed constant,

while the engine torque is increased. This allows

different load points to be approached and

measurements are carried out depending on the load.

An indicating system with software for data acquisition for

the pressure curves in the engines and an exhaust gas

analysis unit are available as accessories.

PC

USB

Learning content/Exercises

Familiarisation with a 4-cylinder petrol engine

Familiarisation with a 4-cylinder diesel engine

Characteristic curves depending on speed

Plotting of torque and power curves

Specific fuel consumption

Volumetric efficiency

Lambda (fuel-air ratio)

Characteristic curves depending on power output

Specific fuel consumption

Volumetric efficiency

Lambda (fuel-air ratio)

Creation of heat balances at full and partial load

Determination of imparted energy, effective

usable power, amount of heat in cooler,

amount of heat in exhaust gas losses, heat

losses due to radiation and convection

Representation in Sankey diagram

Comparison of diesel and petrol engines

In conjunction with other accessories

Exhaust gas analysis with CT 159.02

Electronic indication (CT 400.09) with appropriate

set of sensors for engine (CT 400.16 /.17)

p-V diagram

p-t diagram

Pressure curve over gas cycle

Determination of indicated power

Determination of mechanical efficiency

Minimum configuration

Extending the range of experiments with

CT 400 + engine (CT 400.01 or CT 400.02) including

software for data acquisition

Electronic indication including software for data

acquisition with CT 400.09 and engine-specific

pressure transducer with TDC sensor

(CT 400.16 or CT 400.17)

Exhaust gas analysis

with CT 159.02

SOFTWARE FOR CT 400

Modern LabVIEW software under Windows

with comprehensive visualisation functions

User interface for diesel and petrol

engines with online display of all

measured and calculated variables

Calculated variables

Specific fuel consumption

Intake air volumetric flow

Mechanical power

Efficiency

Volumetric efficiency

Lambda (fuel-air ratio)

Representation of up to four characteristic curves

simultaneously

Characteristic curve representation: freely selectable

assignment of axes

Storage of measured data

Four preselectable languages

Simple connection to PC via USB

187

S-ar putea să vă placă și

- Electronic Control System ComponentsDocument4 paginiElectronic Control System ComponentsThein Htoon lwinÎncă nu există evaluări

- Caterpillar C9 Engine SpecsDocument3 paginiCaterpillar C9 Engine Specsjinxy577991% (11)

- Smart CDIDocument22 paginiSmart CDIjose sousa oliveira100% (1)

- 4 SuperchargingDocument36 pagini4 SuperchargingKaushal Chaudhari100% (4)

- NCS2-TPGM-FD-3!10!04-SP-024 - Specification For Firewater Pump and Jockey Pump - Rev ACDocument44 paginiNCS2-TPGM-FD-3!10!04-SP-024 - Specification For Firewater Pump and Jockey Pump - Rev ACLongTuanÎncă nu există evaluări

- May/June 2009Document80 paginiMay/June 2009Rodger BlandÎncă nu există evaluări

- C18 Fire Pump 597 BKW 800 BHP 1750 RPM PDFDocument5 paginiC18 Fire Pump 597 BKW 800 BHP 1750 RPM PDFDenis JimenezÎncă nu există evaluări

- MTUDocument16 paginiMTUWira Karya Diesel50% (6)

- Power Power Power: Authorized Kawasaki DealerDocument32 paginiPower Power Power: Authorized Kawasaki DealerPamela ProsserÎncă nu există evaluări

- TP31397-1 700 Ignition IncompleteDocument211 paginiTP31397-1 700 Ignition IncompleteAchim Maximilian Naumann d'Alnoncourt100% (1)

- Engine Testing TechniqueDocument8 paginiEngine Testing TechniqueNur YakhinÎncă nu există evaluări

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDe la EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetÎncă nu există evaluări

- Operation ManualDocument159 paginiOperation Manualphucdc095041Încă nu există evaluări

- cqm13392 7jDocument8 paginicqm13392 7jsunilbholÎncă nu există evaluări

- Siemens Compressor PackageDocument8 paginiSiemens Compressor PackageMilos ObrenovicÎncă nu există evaluări

- Marine Generator Set 3304B DINADocument8 paginiMarine Generator Set 3304B DINACarlos AguiarÎncă nu există evaluări

- G3512 SpecDocument4 paginiG3512 SpecnunkpÎncă nu există evaluări

- Catalogo BaudouinDocument48 paginiCatalogo BaudouinEvelyn HerediaÎncă nu există evaluări

- Ic EngineDocument72 paginiIc Enginekedirabduri88Încă nu există evaluări

- Power Electronics and Electric Drives for Traction ApplicationsDe la EverandPower Electronics and Electric Drives for Traction ApplicationsÎncă nu există evaluări

- Flywheel Housing & AlternatorsDocument9 paginiFlywheel Housing & AlternatorsLukman ChairkiandraÎncă nu există evaluări

- c32-1000 BHP Spec SheetDocument6 paginic32-1000 BHP Spec SheetPeter John Packiaraj100% (1)

- 99 MTU 4000 SeriesDocument6 pagini99 MTU 4000 SeriesMohamed Naser100% (6)

- Erik - Dick Book - TurbomachinesDocument16 paginiErik - Dick Book - TurbomachinesAleksander Petersen0% (1)

- LEBW4971-04 Engine Room VentilationDocument36 paginiLEBW4971-04 Engine Room VentilationBadar Ud Duja100% (1)

- ISO Standards Std. DescriptionDocument21 paginiISO Standards Std. DescriptionrabmusukeÎncă nu există evaluări

- G3608 Spec SheetDocument4 paginiG3608 Spec SheetTu Pham100% (1)

- Mitsubishi Marine Product Guide 2015 PDFDocument108 paginiMitsubishi Marine Product Guide 2015 PDFJORGE MONTESÎncă nu există evaluări

- Caterpillar Gas EngineDocument4 paginiCaterpillar Gas Enginecandra100% (1)

- Valve and Valve Spring SpecificationsDocument21 paginiValve and Valve Spring Specificationsbetoven8437100% (1)

- 3512B 1500RPM 1300KW BrochureDocument4 pagini3512B 1500RPM 1300KW BrochuresalembatopÎncă nu există evaluări

- Esp32 DocumentatieDocument356 paginiEsp32 Documentatiesady1967Încă nu există evaluări

- Variable Speed AC Drives with Inverter Output FiltersDe la EverandVariable Speed AC Drives with Inverter Output FiltersÎncă nu există evaluări

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDe la EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetEvaluare: 2 din 5 stele2/5 (1)

- TCA Project GuideDocument120 paginiTCA Project GuideBarcenas Samir0% (1)

- 16V2000 G83 3B EnglischDocument10 pagini16V2000 G83 3B EnglischDavid GomezÎncă nu există evaluări

- CaterpilarDocument4 paginiCaterpilarpangestu66100Încă nu există evaluări

- Caterpillar 3606 2425kVA GensetDocument6 paginiCaterpillar 3606 2425kVA GensetMuhammad Irfan KhanÎncă nu există evaluări

- Cat C280-8Document16 paginiCat C280-8riz506100% (2)

- Shiploader BrochureDocument28 paginiShiploader Brochuremanoj983@gmail.comÎncă nu există evaluări

- Specifications: C280-12 Marine PropulsionDocument4 paginiSpecifications: C280-12 Marine PropulsionRhijal MahdiyÎncă nu există evaluări

- Managing Fleet Performance 1.0Document16 paginiManaging Fleet Performance 1.0sayedmhÎncă nu există evaluări

- Analysis and Experimental Research On The Influence of VVT Point Selection On Exhaust Temperature in Low Speed Operating ConditionsDocument8 paginiAnalysis and Experimental Research On The Influence of VVT Point Selection On Exhaust Temperature in Low Speed Operating Conditionsrosca raulÎncă nu există evaluări

- Cat C280-12 Spec SheetsDocument16 paginiCat C280-12 Spec SheetsThan Htet100% (1)

- Determination of Performance Characteristics of Four Stroke Diesel Engine - Rev1Document12 paginiDetermination of Performance Characteristics of Four Stroke Diesel Engine - Rev1higaneshkumar32Încă nu există evaluări

- Catc280 8MC1Document3 paginiCatc280 8MC1Cater Pillar100% (1)

- Engine Test Bed: SolteqDocument4 paginiEngine Test Bed: SolteqrudolfpeterssonÎncă nu există evaluări

- 1015Document4 pagini1015Martin KratkyÎncă nu există evaluări

- (Lehw0191-00) 3512c (HD) Ataac With DGBDocument4 pagini(Lehw0191-00) 3512c (HD) Ataac With DGBvictor.ciprianiÎncă nu există evaluări

- Ce T200 1D eDocument4 paginiCe T200 1D edassdsr5Încă nu există evaluări

- Radial Turbine: Al.I'J+JcedDocument74 paginiRadial Turbine: Al.I'J+JcedCm EtcmÎncă nu există evaluări

- Continuous Fuel Injection System CFIDocument202 paginiContinuous Fuel Injection System CFIGreg HannaÎncă nu există evaluări

- KX3300 DataSheetDocument5 paginiKX3300 DataSheethadeÎncă nu există evaluări

- 500kVA D.G Set (05.01.09)Document7 pagini500kVA D.G Set (05.01.09)अभिषेक कुमार उपाध्यायÎncă nu există evaluări

- Cat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Document4 paginiCat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Oghale B. E. OmuaborÎncă nu există evaluări

- G3606 - Lehw0039-02 P1Document4 paginiG3606 - Lehw0039-02 P1Martin KratkyÎncă nu există evaluări

- 785 C IntroductionDocument10 pagini785 C IntroductionAngela AllenÎncă nu există evaluări

- Catalogo Generador Cat 3512Document6 paginiCatalogo Generador Cat 3512pamg50% (1)

- Chapter 2: Engine Performance Measures: BAE 517 - Lecture 2Document40 paginiChapter 2: Engine Performance Measures: BAE 517 - Lecture 2datepravinÎncă nu există evaluări

- TCS-PTG Savings With Extra PowerDocument12 paginiTCS-PTG Savings With Extra Powermieszko9888100% (1)

- U 202 eDocument3 paginiU 202 ePatrick SagatwaÎncă nu există evaluări

- Extract Pages From TBMC32Document1 paginăExtract Pages From TBMC32kimoÎncă nu există evaluări

- 1015Document5 pagini1015sdiamanÎncă nu există evaluări

- Cummins 250KVA 1Document4 paginiCummins 250KVA 1Pio Roni100% (2)

- Combustion Data Acquisition and Analysis: Department of Aeronautical and Automotive EngineeringDocument75 paginiCombustion Data Acquisition and Analysis: Department of Aeronautical and Automotive EngineeringKidus DawitÎncă nu există evaluări

- 3612Document6 pagini3612Chandrashekar PatigeÎncă nu există evaluări

- Fang ICE Performance TestingDocument19 paginiFang ICE Performance TestingTim WongÎncă nu există evaluări

- MTU 12V4000 Diesel EngineDocument2 paginiMTU 12V4000 Diesel Enginenastyn-1Încă nu există evaluări

- LetgtinDocument4 paginiLetgtindsoÎncă nu există evaluări

- Chapter 2: Engine Performance Measures: BAE 517 - Lecture 2Document40 paginiChapter 2: Engine Performance Measures: BAE 517 - Lecture 2Siraj BusseÎncă nu există evaluări

- Experimental Engine Test Rig Development and MethodologyDocument16 paginiExperimental Engine Test Rig Development and MethodologyKonem SolutionsÎncă nu există evaluări

- 12V4000G23FDocument10 pagini12V4000G23FZawmin TunÎncă nu există evaluări

- TAD1642GE: Volvo Penta Genset EngineDocument2 paginiTAD1642GE: Volvo Penta Genset EngineroozbehxoxÎncă nu există evaluări

- ThermalDocument40 paginiThermalvijayakumarÎncă nu există evaluări

- Model Predictive Control of High Power Converters and Industrial DrivesDe la EverandModel Predictive Control of High Power Converters and Industrial DrivesÎncă nu există evaluări

- Controller de Zbor Mini QuadDocument3 paginiController de Zbor Mini Quadsady1967Încă nu există evaluări

- Ai Hempadur 15570 English 15570-350deDocument6 paginiAi Hempadur 15570 English 15570-350desady1967Încă nu există evaluări

- KMDocument120 paginiKMsady1967Încă nu există evaluări

- Armfield Test Bed CIDocument4 paginiArmfield Test Bed CIsady1967Încă nu există evaluări

- SimulationDocument18 paginiSimulationsady1967Încă nu există evaluări

- Catalog Edibon 2011Document92 paginiCatalog Edibon 2011sady1967100% (1)

- QDTLDocument3 paginiQDTLsady1967Încă nu există evaluări

- Fuel-Air CycleDocument29 paginiFuel-Air Cycletej patelÎncă nu există evaluări

- S14 SR20DET ECU PinoutDocument1 paginăS14 SR20DET ECU Pinoutpedda meierÎncă nu există evaluări

- Boomer S1 DDocument4 paginiBoomer S1 DArturo Pedro Salgado MedinaÎncă nu există evaluări

- Copyright Letter SeatrackerDocument10 paginiCopyright Letter SeatrackerGordon Frohm0% (1)

- KSMBDocument2 paginiKSMBKrishna KanthÎncă nu există evaluări

- File - YANMAR ItalyDocument22 paginiFile - YANMAR ItalyEdisonNainggolanÎncă nu există evaluări

- SOLAR ENERGY SECRETS OF SILICONE With James DunnDocument61 paginiSOLAR ENERGY SECRETS OF SILICONE With James DunnTedd St RainÎncă nu există evaluări

- SM XR 190L (2017) EngDocument128 paginiSM XR 190L (2017) EngJuan Pablo Rodriguez0% (1)

- XFP SubmersiblePumps E10238Document8 paginiXFP SubmersiblePumps E10238vutrung23113163Încă nu există evaluări

- High Performance Injection System: Installation ManualDocument23 paginiHigh Performance Injection System: Installation ManualJunior SalazarÎncă nu există evaluări

- Maintenance Interval Schedule: When RequiredDocument3 paginiMaintenance Interval Schedule: When Requiredsxturbo100% (1)

- Summary Electronic Engine Control Large EngineDocument1 paginăSummary Electronic Engine Control Large EngineMohammed HamdeenÎncă nu există evaluări

- Catalogo Alzadora SP2254Document430 paginiCatalogo Alzadora SP2254dedaluxsalvaje50% (2)

- 263213.13 20reozkDocument24 pagini263213.13 20reozkbishuddha ranjan paridaÎncă nu există evaluări

- CO2 Fixed Fire Fighting System - Precautions and Procedure To FollowDocument9 paginiCO2 Fixed Fire Fighting System - Precautions and Procedure To FollowOctavian DinuÎncă nu există evaluări