Documente Academic

Documente Profesional

Documente Cultură

I Beth09gb - e Tdmas4000tec PDF

Încărcat de

haerulamriDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

I Beth09gb - e Tdmas4000tec PDF

Încărcat de

haerulamriDrepturi de autor:

Formate disponibile

IBETH09GB_E

ARRAS MAXEI

OIL TREATMENT

page 1/6

MAS 4000 TEC

TECHNICAL DESCRIPTION

OF THE OIL TREATMENT PLANT MEANT TO TREAT LIVE / OPERATING TRANSFORMERS

TYPE MAS 4000 TEC

PREAMBLE

SUMMARY:

Principle of operation

Main characteristics

Components of the plant

Description of the plant

Flow diagram

Options

The efficient and reliable use

of dielectric fluids in transformers, circuit breakers and

other types of electrical

equipments depends upon

some of their basic characteristics, which in service may

be affected, resulting in reduced operating efficiency of

the electrical equipments.

In order to act as an insulant,

a coolant and an extinguishing medium, dielectric fluids

must have some basic properties, and especially a high

dielectric strength.

Now, in service, the dielectric

fluids basic properties may be

affected by oxidation, condensation and other contaminants such as dissolved gases

and solid impurities.

Working on the principles

of filtration, dehydration,

and vacuum degasification,

MAXEI Industries Electriques oil treatment plants

are particularly recommended to maintain, dry

and fill your transformers

and circuit- breakers.

By removing solid impurities, dissolved moisture and

gases from insulating and

cooling oils, they indeed

enable to restore the oil

dielectric properties, and

thus to extend the useful

life of your electrical equipment.

Used and reknowned all over

the world for their performance, reliability and ease of

operation, our standard

plants have been enriched

with the latest technological

achievements in order to

develop a complete range of

plants meant to treat live /

operating transformers.

As their operation principle

has been approved further to

tests performed in our Quality

and Control platform, ARRAS

MAXEI treatment plants

meant to treat live / operating

transformers ensure a reliable

and safe treatment of the

transformer.

Available with various automation levels, the MAS 4000

TEC and MAS 2000 TEC

plants can operate not only

on live / operating transformers, but also on nonenergized transformers either for their filling-up or

for their traditional mainte-

MAS 4000 TEC on a skid

Treatment of live / operating transformers with MAS 4000 TEC

ARRAS MAXEI MAS 4000 TEC plant has

been especially designed to carry out the

operations of filtration, dehydration and absorption of dissolved gases on a transformer

that is under current or operating. Then, the

transformer is totally available during the

treatment operations that are necessary for

its efficient and safe operation. Furthermore,

the transformer does not need to be stopped

at all during connection with the plant if the

security distance between the transformers

connections and the terminals can be respected.

ARRAS MAXEI MAS 4000 TEC plant has

been designed to treat dielectric oil with a 50

ppm moisture content and a dissolved gas

content of approx. 10% by volume before

being treated. Once the optimal treatment

conditions have been reached, the clean

treated oil goes out after 1 pass at a maximum temperature of 70C with a moisture

content below 5 ppm* and a dissolved gas

content of approximately 0.1% by volume*. This restores the oil dielectric

strength to a value in excess of 75 kV

after treatment. An oil at 20 ppm will go

out at 3 ppm* after 1 pass. These characteristics are given for a distillation curve

of 1.10-2 mbar at 80C. For a treatment

of the active parts of transformer, these

data can vary in function of the state of

the transformer.

Type of transformer to be treated Up to 220 kV

Max. oil quantity

100 000 litres

C o m pa ris o n be twe nn va po r a nd liquid

pha s e s o f m o is ture a nd die le c tric o il

WATER

OIL

10 0 0

10 0

101

0,1

0,01

T C

90

mbars

C et % d'eau

1 000,00

80

Rgulation de temprature

70

Temprature en entre

100,00

60

Temprature en sortie

50

10,00

40

vide

30

1,00

20

10

0

14:33:15

Teneur en eau

0,10

14:49:50

15:06:30

15:23:10

15:39:50

15:56:30

16:13:10

16:29:50

16:46:30

17:03:10

17:19:50

17:36:30

IBETH09GB_E page 2/6

ARRAS MAXEI

OIL TREATMENT

MAS 4000 TEC

Principle of operation

Options

Low speed trailer

Road trailer

The pre-filtered dielectric fluid enters the

plant through an inlet strainer, and then

passes through an inlet oil pump and into

an oil heater, where it is heated by immersion heaters.

After a first filtration 7 m absolute

through cartridge filter, the dielectric

fluid is sprayed into a vacuum chamber

on a basket of degassing rings.

Finally, after elimination of the air bubbles and filtration 1m absolute, the

clean treated fluid flows through the outlet oil pump.

Main characteristics

Nominal flow* during treatment (l/hr)

4 000

Heating power (kW)

78

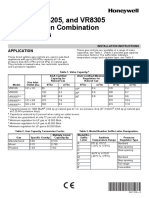

Options

Total power (kW)

88

Tarpaulin

Filtration** by cartridge in absolute m

0,5

Limit vacuum against closed suction (mbar)

0.08

Metallic cover

Vacuum during treatment (mbar)

0.5 to 2

* : Approximate value.

** : Consumable cartridge with filtration expressed in absolute m at 99.9 %.

Our plants are all equipped with tropicalized electrical material

Power supply 400 Volts 3 phases 50 Hz

Auxiliary operation in 220 Volts by transformer.

Components of the plant

Options

Remote control

Continuous moisture content

measurement

Digital recorder

1

1

2

1

1

1

1

1

1

1

1

1

Inlet oil motor-pump.

Direct electrical heater.

Cartridge filters 6 absolute.

Dehydration tank.

Outlet oil vacuum motor-pump.

Trap system of free gases.

Cartridge filter 1 absolute.

Single-staged vacuum motor-pump.

Set measuring, controlling, alarming and regulating apparatus.

Control panel with display and PLC.

Set pipes, valves and accessories for the connection of the plant to the transformer.

Set of 6 hoses with flanges (5 hoses 40 , length : 10 m and 1 hose 40 , length : 2 m ).

In standard presentation, the oil treatment plant is installed on a section iron plate with retention tray and maintenance wheels.

IBETH09GB_E page 3/6

ARRAS MAXEI

OIL TREATMENT

Description of the plant

Inlet oil pump

Maximum flow of pump in l/hr

Pump type

7000

Centrifugal

Discharge rate in mCE

55

Motor power in kW

2.2

Rotation speed in rpm

Pump construction

Continuous control of the temperature of the plant at oil inlet,

before degassing chamber and at oil outlet.

Remote control of the overheating through security thermostat.

Permanent control of the overpressures in the network thanks to

pressostat, security valve and by-pass.

1500

Cast iron/steel

Connection diameter in mm

40

Flows display at inlet, before degassing (regulation and minimum flow) and outlet of the plant.

Continuous control of the oil levels and condensates in the plant.

Oil heating

Total heating power in kW

78

Number of thermo-dippers

10

Power of an element in kW

7.8

Auxiliary heating diameter

40

Filtration 6m absolute

Number of cartridges per filter

Number of filters

Filter construction

Cast iron/steel

Clogging control

Pressostat

Continuous control of the oil level in the transformer.

Automatic regulation of foaming effects.

Tri-filtration through strainer (0.8 mm), filtration before degassing (7m absolute) and fine filtration (1m absolute) at outlet.

Remote control of filters clogging with pressostat.

Vacuum control with Pirani gauge and manometer.

Removal of free gases and air bubbles at the outlet of the plant.

Filtration 1m absolute

Number of cartridges per filter

Filter construction

Cast iron/steel

Clogging control

Pressostat

Detection and automatic draining of free gases at plant outlet.

Running of the plant thanks to an operating system.

Self-operating in compressed air by compressor.

Vacuum pump

Flow in m3/hr

170

Limit vacuum in mbar

0.08

Motor power in kW

Rotation speed in rpm

Vacuum accumulator for draining of transformers connections.

Secure connections to the transformer.

4

1450

Automated and rationalized starting sequences.

Oil capacity in litres

Vacuum measurement

Auxiliary vacuum connection

5

Pirani

50

Outlet oil pump

Maximum flow of pump in l/hr

Pump type

4500

Centrifugal

Discharge rate in mCE

40

Motor power in kW

Rotation speed in rpm

Pump building

Connection diameter in mm

Filling of the plant.

Piping put under vacuum.

Filling of the piping.

Treatment in closed circuit.

Treatment on transformer.

Draining of the piping.

Draining of the plant.

Vacuum in the accumulator for the pipes draining.

1500

Cast iron/bronze

40

Comment :

MAS 4000 TEC is also equipped with an additive function in order to treat off line transformers, using the MAS

TEC safeties. Moreover, you can also use it with the

standards safeties used for MAS type treatment plants.

MAS 4000 TEC

IBETH09GB_E page 4/6

MAS 4000 TEC

ARRAS MAXEI

OIL TREATMENT

Control panel

ARRAS MAXEI oil treatment plant type MAS 4000 TEC is

equipped with a watertight panel of industrial type in painted cast

iron, with PLC, contactors, relays, terminal boards, and every cables

necessary for the plant operation.

On the door of the control panel stand the operating desk, the

switches and the warning lights of the different components.

Painting

ARRAS MAXEI oil treatment plant type MAS 4000 TEC is painted in white (RAL9002).

Approximate dimensions

Machine

length

in mm

3450

Width

Heigh

Weight

in mm

2350

Total

length

in mm

in mm

2150

Plant on a platform with metallic

cover

Plant on a skid with tarpaulin

3450

2150

2250

3100

3250

2150

2250

2800

Plant on a skid with metallic cover

3450

2150

2150

3100

Plant on a low speed trailer with

tarpaulin

Plant on a low speed trailer with

metallic cover

Plant on a road trailer with tarpaulin

Plant on a road trailer with metallic

cover

3250

2000

2650

4250*

3000

3300

2150

2450

4250*

3300

3400

2150

2850

5250*

3100

3450

2150

2650

5250*

3500

Plant on a platform with tarpaulin

in kg

2800

* : Dimension with the draw bar

VP1

B7 (JN7)

B2 (JN2)

B8 (JN8)

Contact d'alarme

buchholz : NO

Vanne basse transformateur

Raccord guillemin anti-desserrement

VP2

B1 (JT1,CI1)

V1

RAO1

RAO25

V25

Contact alarme

MAS 4000 TEC

: NO

T1

B5 (JN5)

B4 (JN4)

T2

B3 (JN3)

VP11

VP3

Niveau d'huile

transformateur

CAR2

VP4

V2

G3

T1

F2

V20

V3

V28

V19'

M3D

SCD

Filtration 1 m absolu

M1

P1

CAR3

Entre auxiliaire de remplissage du MAS par ft

ou entre pour traitement traditionnel

V19

CAR1

VP9

CH

BP

V18

Reg

TS

PS2

VP8

SG

VP10

SS1

PS1

V17

T2

V4

Mano 4

G4

V16

NBRT

Rserve

d'huile

NHRT

F1

P2

M2

IC

V5

TE

SCAB

SCNB

SCNH

SCAH

V10

Mano 1

V10'

Sortie auxiliaire de vidange du MAS par ft

ou sortie pour traitement traditionnel

V8

VP5

ID

DEGAZ

Option : teneur en eau en ligne

Filtration 6 m absolu

V15

VP7

DM

RASCH

V15

V11

PT1

Clap

Niveau d'huile

dans gatte du

MAS

V15

NHCS

PIR

PV

VP6

RAO13

NHG

V14'

V13

ACCU

V14

Mano 2

ARRAS MAXEI

OIL TREATMENT

Nous nous rservons

All characteristics

le droit demay

modifier

be modified

les caractristiques

without any prior

techniques

notice.sans pravis

G1

B6 (JT6,CI6)

G2

VP12

CdC

V23

Tresse conductrice

Vanne ouverture pilote

Bague tflon isolante

Raccord guillemin anti-desserrement

Vanne haute transformateur

IBETH09GB_E page 5/6

MAS 4000 TEC

IBETH09GB_E page 6/6

ARRAS MAXEI

OIL TREATMENT

MAS 4000 TEC

Options

Process controls

AUTOMATIC DRAINING OF THE VALVE

This option enables an optimal protection of the vacuum net of the plant.

VOLTMETER / AMMETER

This option will enable you to visualize the power supply of the plant, as well as the strength developed in order to protect the net

and equipment.

REMOTE CONTROL

The remote control enables to be informed of the plant operation through an internal phone line, a TELECOM phone line, or through

the GSM network.

RECORDER

This option enables to record the physical parameters of the degassing process like temperature and vacuum level.

CONTINUOUS MOISTURE CONTENT MEASURING

This option has been designed to carry out on-line moisture content measurement, that means continuously during the oil treatment.

Then you reduce the errors linked to the sampling method and the risks due to hot oil handling.

REGENERATION

This option enables to regenerate the oil and to decrease its acidity thanks to absorbent and colloidal properties product.

Digital recorder

GSM remote control

Presentations

1) LOW SPEED TRAILER

The oil treatment can be installed on a low speed trailer with full tyres (max. speed : 20 km/hr).

2) ROAD TRAILER

The oil treatment plant can be installed on a road trailer. The trailer is equipped with rear lights in accordance with the EU regulations of road code. The whole installation is commissioned by the French government vehicle testing service to be allowed to circulate in France and in the European countries.

3) TARPAULIN PROTECTION

The plant can be equipped with a protection type tarpaulin, which protects it from bad weather.

The tarpaulin can be opened on the four sides thanks to its panels to enable the access to all the components of the plant.

4) METALLIC COVER PROTECTION

The plant can be equipped with a metallic cover type protection, which protects it from bad weather. It is made of aluminium and the

frame is made of iron steel. The side panels open horizontally, close per key and are maintained thanks to gas jacks. The panels enable the access to the components of the plant.

Road trailer with metallic cover

Low speed trailer with tarpaulin

Skid with tarpaulin

S-ar putea să vă placă și

- Comparison of vapor and liquid phases of moisture and dielectric oilDocument12 paginiComparison of vapor and liquid phases of moisture and dielectric oilSimamora Samuel HansenÎncă nu există evaluări

- Maxei Oil VacuumingDocument5 paginiMaxei Oil Vacuumingaanouar77Încă nu există evaluări

- Hanbell Service ManualDocument80 paginiHanbell Service ManualStephen Marcus100% (2)

- Double Stage Vacuum Transformer Oil Filtration MachineDocument34 paginiDouble Stage Vacuum Transformer Oil Filtration MachineTonny Laulate MelgarejoÎncă nu există evaluări

- REXON Lubricating Oil Purifier Series TYADocument24 paginiREXON Lubricating Oil Purifier Series TYApaola guzman ramirezÎncă nu există evaluări

- Vacuum Oil Filling - Degassing - DehydratingDocument3 paginiVacuum Oil Filling - Degassing - Dehydratingraza239100% (1)

- FRAMODocument128 paginiFRAMOFanisKountouris100% (5)

- Nuclear Power Corporation of India LimitedDocument9 paginiNuclear Power Corporation of India LimitedChandan KumarÎncă nu există evaluări

- TECHNICAL SPECIFICATIONS of of Transformer Oil Filter MachineDocument5 paginiTECHNICAL SPECIFICATIONS of of Transformer Oil Filter MachineS.KAMBAN100% (1)

- HV Transformer Oil Filtration Sumesh Instruction ManualDocument68 paginiHV Transformer Oil Filtration Sumesh Instruction Manualfajar9nugraha-2Încă nu există evaluări

- Efficient PA purifier system for fuel and oil purificationDocument4 paginiEfficient PA purifier system for fuel and oil purificationRizal Falevy100% (1)

- MAV Lube Oil SystemDocument9 paginiMAV Lube Oil SystemMurali Krishna GbÎncă nu există evaluări

- Solar 5.2MVADocument15 paginiSolar 5.2MVAsohaila7Încă nu există evaluări

- Gen Write-Up 200MWDocument49 paginiGen Write-Up 200MWanon_862746578Încă nu există evaluări

- DROPSADocument27 paginiDROPSAcguillermosmÎncă nu există evaluări

- Rotare Vane PumpsDocument10 paginiRotare Vane PumpsZoran DjurdjevicÎncă nu există evaluări

- INSTRUCTIONOF OIL PURIFIED TURBINE sçÇsîûFúàt+ S++tö¿F ÿÄS 1Document21 paginiINSTRUCTIONOF OIL PURIFIED TURBINE sçÇsîûFúàt+ S++tö¿F ÿÄS 1anon_928723433Încă nu există evaluări

- EAG2020-541 E575R 8000 LPH Paras Pakistan Revision ADocument3 paginiEAG2020-541 E575R 8000 LPH Paras Pakistan Revision AArun BajajÎncă nu există evaluări

- Installation, Commissioning and Maintenance Guidelines: For Electrohydraulic SystemsDocument0 paginiInstallation, Commissioning and Maintenance Guidelines: For Electrohydraulic Systemsanta77100% (1)

- Diesel EnginesDocument15 paginiDiesel EnginesDivyansh kaushalÎncă nu există evaluări

- ZYD S Transformer Oil Decoloring Machine 1Document9 paginiZYD S Transformer Oil Decoloring Machine 1EdgarÎncă nu există evaluări

- VacPumpReq TSB007Document6 paginiVacPumpReq TSB007zosuryantoÎncă nu există evaluări

- PureVent Centrifugal Oil Mist Separator Cleaning Crankcase Gas - 1009Document4 paginiPureVent Centrifugal Oil Mist Separator Cleaning Crankcase Gas - 1009Shivananda PatraÎncă nu există evaluări

- ZYD-50 MóvilDocument10 paginiZYD-50 MóvilDaniel SubelzaÎncă nu există evaluări

- Transformer Oil Filtering, Degassing and Drying UnitDocument16 paginiTransformer Oil Filtering, Degassing and Drying UnitSiba Prasad100% (1)

- Erc Series BrochureDocument4 paginiErc Series Brochurelepoulet0% (1)

- Rotrex Technical Datasheet C30 Range V4.0Document7 paginiRotrex Technical Datasheet C30 Range V4.0Blake Newman0% (1)

- Handout For Training-TurbineDocument30 paginiHandout For Training-TurbineDibyajyoti NandaÎncă nu există evaluări

- Powerroc T50 Start Up and Drilling Setting ProcedureDocument7 paginiPowerroc T50 Start Up and Drilling Setting ProcedurerolandÎncă nu există evaluări

- wrcc20 2015 GBDocument44 paginiwrcc20 2015 GBMohamdÎncă nu există evaluări

- Heimstaedt Smardt PresentationDocument58 paginiHeimstaedt Smardt PresentationChoon Seng100% (1)

- Filter Machine, Vacuum Pump & Oil Tank SpecsDocument1 paginăFilter Machine, Vacuum Pump & Oil Tank SpecsRyan JohnÎncă nu există evaluări

- CatalogDocument4 paginiCatalograjamutyala4uÎncă nu există evaluări

- Operation Manual: L Y S F 型系列陆用油水分离器 LYSF type oil-water separators for use on landDocument12 paginiOperation Manual: L Y S F 型系列陆用油水分离器 LYSF type oil-water separators for use on landarief fardy yuskaÎncă nu există evaluări

- 2011 ABB Tips For TC Operators PDFDocument40 pagini2011 ABB Tips For TC Operators PDFaresobscureÎncă nu există evaluări

- Alfa Laval PurifiersDocument4 paginiAlfa Laval PurifiersNasim AbbasÎncă nu există evaluări

- Vaccum Dehydrator 1Document7 paginiVaccum Dehydrator 1Simbu ArasanÎncă nu există evaluări

- WQ Submersible Sewage Pump Catalogue-Guomei PumpDocument11 paginiWQ Submersible Sewage Pump Catalogue-Guomei PumpOscarÎncă nu există evaluări

- Liquid Ring PumpDocument48 paginiLiquid Ring Pumpkalyanm203515100% (1)

- Oleum Tek Oil PurifierDocument4 paginiOleum Tek Oil PurifierpramjeeÎncă nu există evaluări

- MARC Steam Turbine PDFDocument20 paginiMARC Steam Turbine PDFctsak0% (1)

- MG6000E IBEDC Nigeria10 2022Document10 paginiMG6000E IBEDC Nigeria10 2022Mubarak AleemÎncă nu există evaluări

- Tb5000 Gas TurbineDocument4 paginiTb5000 Gas TurbinePablo RobuffoÎncă nu există evaluări

- 2011 ABB Tips For TC OperatorsDocument108 pagini2011 ABB Tips For TC Operatorsjohndmariner123100% (1)

- Industrial Steam Turbines PDFDocument20 paginiIndustrial Steam Turbines PDFHerivelto CostaÎncă nu există evaluări

- APH Lube Oil Flushing - RajeevDocument4 paginiAPH Lube Oil Flushing - Rajeevvishal_vajatÎncă nu există evaluări

- Session - 16 - Eliminator - Oil - Filter (Compatibility Mode)Document42 paginiSession - 16 - Eliminator - Oil - Filter (Compatibility Mode)agvass100% (1)

- High VacuumTransformer Oil Purification SystemsDocument5 paginiHigh VacuumTransformer Oil Purification SystemsJicheng PiaoÎncă nu există evaluări

- Since 1970chinaDocument13 paginiSince 1970chinaJohnny QuisbertÎncă nu există evaluări

- Rcoa1806 03 03Document36 paginiRcoa1806 03 03Fernando Sabino100% (1)

- Oil Purification Plants REOIL Regeneration SystemsDocument35 paginiOil Purification Plants REOIL Regeneration SystemsFer PolÎncă nu există evaluări

- Oil Purification Plants REOIL Regeneration SystemsDocument35 paginiOil Purification Plants REOIL Regeneration SystemsFer PolÎncă nu există evaluări

- Workshop Small NewDocument36 paginiWorkshop Small Newesteban marinkovicÎncă nu există evaluări

- Vaccum DehydratorDocument4 paginiVaccum DehydratorSimbu ArasanÎncă nu există evaluări

- Tech Spec Guvnl-NffesDocument9 paginiTech Spec Guvnl-NffesShantanu DasÎncă nu există evaluări

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDe la EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingEvaluare: 5 din 5 stele5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDe la EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesÎncă nu există evaluări

- Demolis Pipe REPORT - Rev1 PDFDocument11 paginiDemolis Pipe REPORT - Rev1 PDFhaerulamriÎncă nu există evaluări

- Sharp Is A Pioneer in Photovoltaics Sharp Solar Modules Have Set Standards For Over 50 YearsDocument2 paginiSharp Is A Pioneer in Photovoltaics Sharp Solar Modules Have Set Standards For Over 50 YearshaerulamriÎncă nu există evaluări

- ArrestorDocument3 paginiArrestorhaerulamriÎncă nu există evaluări

- BRO Combics - Pro e PDFDocument8 paginiBRO Combics - Pro e PDFhaerulamriÎncă nu există evaluări

- List Tabel Berat Besi PDFDocument18 paginiList Tabel Berat Besi PDFhaerulamri100% (1)

- Compact Weighing Terminal & System IndicatorDocument4 paginiCompact Weighing Terminal & System Indicatorhaerulamri100% (1)

- Flameproof Weight Indicator for Hazardous AreasDocument2 paginiFlameproof Weight Indicator for Hazardous AreashaerulamriÎncă nu există evaluări

- Compact Weighing Terminal & System IndicatorDocument4 paginiCompact Weighing Terminal & System Indicatorhaerulamri100% (1)

- Electronic Weighbridge PDFDocument2 paginiElectronic Weighbridge PDFhaerulamriÎncă nu există evaluări

- LX 310Document2 paginiLX 310Anastasia NoormaÎncă nu există evaluări

- Grease Trolley PDFDocument4 paginiGrease Trolley PDFhaerulamriÎncă nu există evaluări

- Grease Trolley PDFDocument4 paginiGrease Trolley PDFhaerulamriÎncă nu există evaluări

- cONTACTOR MITSUBISHI PDFDocument89 paginicONTACTOR MITSUBISHI PDFhaerulamriÎncă nu există evaluări

- Rail Scraper PDFDocument1 paginăRail Scraper PDFhaerulamriÎncă nu există evaluări

- Katalog PeralatanDocument438 paginiKatalog PeralatanSurya Kazu MaruÎncă nu există evaluări

- Lifter Storage PDFDocument5 paginiLifter Storage PDFhaerulamriÎncă nu există evaluări

- List Flowmeter Yang Akan Di Kalibrasi PDFDocument1 paginăList Flowmeter Yang Akan Di Kalibrasi PDFhaerulamriÎncă nu există evaluări

- GAMBAR SURVEY LAY OUT PULLING KABEL AREA INJEKSI Rev 1 PDFDocument1 paginăGAMBAR SURVEY LAY OUT PULLING KABEL AREA INJEKSI Rev 1 PDFhaerulamriÎncă nu există evaluări

- Lifter Parking Stand Cut List PDFDocument1 paginăLifter Parking Stand Cut List PDFhaerulamriÎncă nu există evaluări

- Single Line Drawing MCC 10 PDFDocument1 paginăSingle Line Drawing MCC 10 PDFhaerulamriÎncă nu există evaluări

- Schematic Line Diagram Cable Power PDFDocument1 paginăSchematic Line Diagram Cable Power PDFhaerulamriÎncă nu există evaluări

- WTP BoqDocument26 paginiWTP Boqkajale_shrikant2325Încă nu există evaluări

- Electrical Bill of QuantitiesDocument32 paginiElectrical Bill of QuantitiesAbdul RawoofÎncă nu există evaluări

- Drawing Lifter Storage PDFDocument6 paginiDrawing Lifter Storage PDFhaerulamriÎncă nu există evaluări

- WTP BoqDocument26 paginiWTP Boqkajale_shrikant2325Încă nu există evaluări

- E4C-UD Digital Ultrasonic Sensor Brochure PDFDocument8 paginiE4C-UD Digital Ultrasonic Sensor Brochure PDFhaerulamriÎncă nu există evaluări

- MECHANICAL ENGINEER’S MANUAL DEFINEDDocument196 paginiMECHANICAL ENGINEER’S MANUAL DEFINEDYURI G. MELLIZAÎncă nu există evaluări

- Giddings & Lewis Sect08 HydDocument24 paginiGiddings & Lewis Sect08 HydAngel AdautaÎncă nu există evaluări

- Archimedes, Pascal and Bernoulli Practice ProblemsDocument1 paginăArchimedes, Pascal and Bernoulli Practice ProblemsB.r. AnirudhÎncă nu există evaluări

- Pages: 3: Answer Any Two Full QuestionsDocument3 paginiPages: 3: Answer Any Two Full Questionslakshmi dileepÎncă nu există evaluări

- Mechanical Engineering Measurement CourseDocument6 paginiMechanical Engineering Measurement CourseShweta GajbhiyeÎncă nu există evaluări

- Suresh SirDocument5 paginiSuresh SirPruthvi PrakashaÎncă nu există evaluări

- Refrigeration & Air Conditioning by W.F. Stoecker & J.W JhonesDocument440 paginiRefrigeration & Air Conditioning by W.F. Stoecker & J.W JhonesJuniel CalixtroÎncă nu există evaluări

- GHTP Coal Handling SystemDocument44 paginiGHTP Coal Handling SystemMuskan GargÎncă nu există evaluări

- Auto 2 - 1 - Measuring InstrumentsDocument66 paginiAuto 2 - 1 - Measuring InstrumentsMalaka UdayangaÎncă nu există evaluări

- 266 Spare PartsDocument16 pagini266 Spare PartsfakhriÎncă nu există evaluări

- 129 Climate Vacum ControlDocument46 pagini129 Climate Vacum ControlGerardo Cuoghi RanzolinÎncă nu există evaluări

- An Investigation of External Gear Pump Efficiency and Stribeck ValuesDocument13 paginiAn Investigation of External Gear Pump Efficiency and Stribeck ValuesFlávio dos Santos Ferreira JuniorÎncă nu există evaluări

- Sop For Boiler Hydro TestDocument4 paginiSop For Boiler Hydro TestHardik ThumarÎncă nu există evaluări

- Different Types of Manometers ExplainedDocument3 paginiDifferent Types of Manometers ExplainedKhairul MuzafarÎncă nu există evaluări

- Crankcase Pressure SM019901095211 - en PDFDocument5 paginiCrankcase Pressure SM019901095211 - en PDFDavy GonzalezÎncă nu există evaluări

- Syllabus Copy R15 II To IVDocument124 paginiSyllabus Copy R15 II To IVJeet Niren ShahÎncă nu există evaluări

- Process Instrumentation Lab Report 4Document4 paginiProcess Instrumentation Lab Report 4Abu Rectify50% (4)

- U-Tube Manometer Lab ReportDocument3 paginiU-Tube Manometer Lab ReportKashif AbbasÎncă nu există evaluări

- Deutscher Kalibrierdienst: Guideline DKD-R 6-2 Calibration of Measuring Devices For VacuumDocument16 paginiDeutscher Kalibrierdienst: Guideline DKD-R 6-2 Calibration of Measuring Devices For VacuumDragan Ilic100% (1)

- Honeywell VR8105 8205 8305 Gas Control InstructionsDocument12 paginiHoneywell VR8105 8205 8305 Gas Control InstructionsAlejandro ObregonÎncă nu există evaluări

- Agriculture MCQs PDFDocument136 paginiAgriculture MCQs PDFjahangir khan100% (1)

- DE-007 Manual TH-4087 PDFDocument7 paginiDE-007 Manual TH-4087 PDFPaola MadrigalÎncă nu există evaluări

- Granville-Phillips® Series 385 Convectron®Document152 paginiGranville-Phillips® Series 385 Convectron®Bruce M SchallerÎncă nu există evaluări

- UCH Compression Project Instrumentation SpecificationDocument46 paginiUCH Compression Project Instrumentation SpecificationHassan Ejaz100% (1)

- Previews-PEI RP030009 PreDocument11 paginiPreviews-PEI RP030009 PreAarthi Kalyan100% (1)

- Wyoming Measuring LawsDocument5 paginiWyoming Measuring LawsJohn KayceeÎncă nu există evaluări

- Documents - Tips - Final Draft Thermo000 PDFDocument222 paginiDocuments - Tips - Final Draft Thermo000 PDFYoshua Martel Candava77% (13)

- Stoecker Jones - Refrigeration Air Conditioning 2nd Ed PDFDocument440 paginiStoecker Jones - Refrigeration Air Conditioning 2nd Ed PDFpascky100% (1)

- Format No SWPL-0221-QA-FRMT-010Document53 paginiFormat No SWPL-0221-QA-FRMT-010Swathy Nath PÎncă nu există evaluări

- Approved Pipeline Chemical Procedure PDFDocument23 paginiApproved Pipeline Chemical Procedure PDFRafeeq Ur Rahman100% (1)