Documente Academic

Documente Profesional

Documente Cultură

Corrective and Preventative Action Process

Încărcat de

Kristof MCDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Corrective and Preventative Action Process

Încărcat de

Kristof MCDrepturi de autor:

Formate disponibile

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

GE Power Electronics Business

Corrective and Preventative Action Process

Author:

Alessandro Cervone

Technical Manager Component & Reliability

Engineering

Reviewers:

Names

601 Shiloh Road

Plano, Texas 75074

Reviewer Address

Title

Contributors:

Names

Contributor Address

Title

Page 1 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

Table of Contents

1.0

PURPOSE .............................................................................................................................................3

2.0

SCOPE ..................................................................................................................................................3

3.0

DEFINITIONS AND ACRONYMS.........................................................................................................4

4.0

REFERENCE DOCUMENTS ................................................................................................................5

5.0

ROLES AND RESPONSIBILITIES.......................................................................................................5

6.0

PROCEDURE .......................................................................................................................................6

6.1

6.2

6.3

Procedure - Requirements for Corrective Action::::::::::::::::::::::.6

REQUIREMENTS FOR PREVENTIVE ACTION:::::::::::::::::::...::.8

RECORD RETENTION ..........................................................................................................................11

Document Issue History

Issue

1.1

Reason for changes

Initial Release - Compilation of Tyco Power Electronics 402-30

and GEQMS8.5

Date

03/22/2012

Page 2 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

1.0

Purpose

This document defines action to take for effective Corrective and Preventative Action. It should be

used to guide compliance with GEEQMS8.5 (Continuous Improvement) as it pertains to GE Power

Electronics.

The Corrective Action Process is based on the industry standard Kepner/Tregoe concepts and the

Ford Motor Company TOPS (Team Oriented Problem Solving) process which is frequently

referred to as the 8-D Process.

The Preventative Action Process is based on the Six Sigma DMAIC (Define, Measure, Analyze,

Improve and Control) model.

2.0

Scope

The Corrective Action Process is a reactive problem solving process which is intended to describe,

analyze and subsequently determine the root cause(s) of a problem. It is used to solve past

actions than have caused unwanted effects. Generally it takes more time, energy and resources to

correct a problem than to prevent a problem. This process is most effective when utilized by a

small team that is assigned by management to resolve a known problem or nonconformance.

This process should be used when:

There is a gap between the current state and the documented standard

The product does not meet the requirements of the print or the specifications

The process is out of control

Customers require evidence of the resolution of a problem

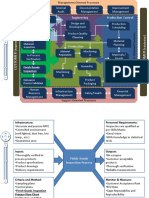

The Preventative Action Process is a proactive process which utilizes the DMAIC approach to

achieve continuous improvement or breakthrough improvement. This process can also be

undertaken to implement plans to prevent the problem from occurring.

Refer to Figure 1.

Page 3 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

Figure 1

3.0

Definitions and Acronyms

Terminology or Acronyms

Corrective Action

Corrective Action Process

Definition

Process that prevents recurrence of a known problem or

nonconformance

A. A reactionary effort that prevents a

nonconformance from reaching a customer and

implements a plan that assures and verifies

permanent corrective action.

B.

The steps in this process are:

1.

Define the concern, organize and plan

2.

Describe the opportunity / problem

3.

Contain the nonconformance to prevent

escapes to the customer

4.

Identify and verify the root cause

5.

Develop the corrective action plan

6.

Implement and verify the corrective action

7.

Prevent recurrence

8.

Celebrate and communicate success

Preventative Action

An improvement plan / action that modifies systems,

Page 4 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

processes or products:

A. To prevent recurrence of a root cause that

produced a nonconformance / problem in one

area within another product or process.

B. Through analysis of historical data, implementing

a plan to prevent a potential problem from

Nonconformance

A product or process that does not meet established

requirements.

Root Cause

The true (original) cause of the nonconformance as verified

through quantifiable data

The recipient of a product or service. This could be the next

operation in the sequence (internal customer) orthe external

customer.

Action taken before permanent corrective action is implemented to

assure that a nonconformance does not escape to the customer.

Customer

Containment Action

4.0

Reference Documents

Document ID

GEEQMS 8.5

EEDI-268

SRCWI 8.5

5.0

Document Title

Continuous Improvement

Technical Analysis Instruction

Continuous Improvement (Sourcing)

Roles and Responsibilities

Role

Corrective Action

Responsibility

A. Individual identifying Nonconformance

This individual has the responsibility for reporting the

nonconformance and providing the data related to the

nonconformance in a documented format. All

characteristics found to be nonconforming shall be

reported so appropriate problem description is

understood.

B. Individual Responsible for Corrective Action

1. This individual assumes ownership or is assigned the

responsibility of resolving the nonconformance. This person

shall analyze the problem or concern and organize the

necessary resources to, as a minimum, implement action to

contain the nonconformance (if necessary), determine and

verify root cause (when applicable) and implement and verify

permanent corrective action. The effort shall be appropriately

Page 5 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

documented.

2. When the nonconformance involves a chronic recurrence

that compromises business goals, the responsible individual

shall organize a corrective action team comprised of

individuals with the knowledge to, as a minimum, implement

action to contain the nonconformance, (if necessary)

determine and verify root cause, and implement and verify

permanent corrective action. The effort shall be appropriately

documented.

Preventive Action

To ensure preventive actions are addressed the following

applies:

A. Action taken to prevent a potential nonconformance

of a product or process is the responsibility of the

function benefiting from prevention of the

nonconformance.

B. Documented process reviews and

manufacturing equipment maintenance

activities should routinely be performed by

suppliers.

C. The review and analysis of customer records,

satisfaction surveys, the quality system and

process and product assessment results, are the

responsibility of the supplier's quality function.

Team Action

It is the responsibility of each member of the team to contribute

to an effective resolution of the nonconformance or potential

nonconformance. The team consists of individuals with the

skills associated with completing the appropriate steps of the

corrective action / preventive action process.

6.0

6.1 Procedure - Requirements for Corrective Action

6.1.1 Corrective actions taken to eliminate the root causes of actual nonconformance(s) shall be to

a degree appropriate to the magnitude of problems and consistent with the risks encountered.

Any corrective action process is an exercise in problem solving. An industry standard for

conducting corrective action adopted at GE Power Electronics involves the 8 Discipline (8D)

method. This method is a formal, documented step by step process which, when implemented

appropriately, will cause permanent corrective and preventive action.

Page 6 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

6.1.2 The 8D Reactive Problem Solving Process. Figure diagrams the 8D process.

Figure 2

6.1.3. The minimum requirements of the 8D reactive problem solving process are summarized

below.

A. All steps of the 8D reactive problem solving process shall be addressed when processing a

complaint or rejection received from GE Power Electronics.

B. The results of corrective actions shall be documented and maintained as a quality record.

6.1.4 GE Power Electronics Reactive Problem Solving Process (8D)

Page 7 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

Problem Solving

Process Step

Desired Outcome

1. Define Concern,

Organize and Plan

2. Describe the

Opportunity/Problem

3. Contain the Problem

4. Identify and Verify

Root Cause

5. Develop Corrective

Action Plan

6.

7. Prevent Recurrence

8. Celebrate and

Communicate

Success

6.2

Concern/problem identified.

Project Plan in place for eliminating the problem and improving the

process including scope, key activities, boundaries, responsibilities,

timeliness, resources, etc.

Problem statement written in terms of gap between as is and desired

state.

Define the nonconformance in term of what is wrong (the defect) with

what (the object.

Determine the quantity, size volume, magnitude, of the nonconformance.

Implement interim actions to shield the customer from the problem.

Selected root cause to work on.

Revised problem statement if required.

Produce list of as many ways as possible to solve the problem.

Decide on optimum corrective ation/solution and plan its implementation.

Perform pilot test.

Evaluate effectiveness of corrective action/solution.

Document improvements.

Address open issues.

Remove the interim actions and the problem does not re-occur.

Apply permanent fix.

Identify what system, practice or procedure allowed the root cause to

occur.

Modify and monitor to prevent recurrence of problem.

Contributions of everyone involved recognized.

Change or improvements communicated to all individuals who are

affected.

REQUIREMENTS FOR PREVENTIVE ACTION

6.2.1 Preventive action is a proactive effort taken to identify a potential nonconforming product or process.

The preventive action process applies to development of new product or processes, to prevent

potential nonconformance, or to create breakthrough improvements.

6.2.2. Preventive actions resulting from actual nonconformance root cause analysis should be performed

as part of the corrective/preventive action process by the 8D team.

6.2.3. The results of preventive actions shall be documented and maintained as a quality record.

6.2.4. The DMAIC Process

A. The DMAIC (Define, Measure, Analyze, Improve, Control) process is a structured approach for

leading continual and breakthrough improvement initiatives. This structure/model is based on

the Plan, Do, Check, Act cycle.

Page 8 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

B. The GE Power Electronics Six Sigma Operational Excellence initiative utilizes the DMAIC

process, lead by a Black Belt or Green Belt to launch and manage breakthrough improvement.

C. Continual improvement initiatives should follow this same methodology, however, these project teams

are not usually lead by a Black Belt and there may be a less rigorous application of the statistical tools

Page 9 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

Page 10 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

Title and Document ID: Corrective and

Preventative Action Process QP8.5.2+3

Revision: 1.1

Issue Date: 03/22/2012

6.3 Record Retention

Document /

Record

8D or Failure

Analysis Report

Retention

period

7 years

Storage location

Windchill in Material

Context under comcode

Responsible

(if applicable)

Component

Engineering

Page 11 of 11

UNCONTROLLED WHEN PRINTED or Transmitted Electronically

GE Power Electronics, Inc. Proprietary Information

S-ar putea să vă placă și

- Corrective and Preventive ActionsDocument33 paginiCorrective and Preventive ActionsSonam Dhonde100% (2)

- CAPA - IntroductionDocument6 paginiCAPA - IntroductionAshish JoshiÎncă nu există evaluări

- ISO27k Nonconformity Corrective Preventive Action FormDocument3 paginiISO27k Nonconformity Corrective Preventive Action FormJasim's BhaignaÎncă nu există evaluări

- Control of RecordsDocument3 paginiControl of Recordschahi100% (1)

- Corrective and Preventive ActionDocument3 paginiCorrective and Preventive ActionmurugesanÎncă nu există evaluări

- Internal AuditsDocument9 paginiInternal Audits李哲祥100% (1)

- 4.1a - 4.1d Process PlanningDocument2 pagini4.1a - 4.1d Process PlanningFendiÎncă nu există evaluări

- Corrective and Preventive Actıons ProcedureDocument4 paginiCorrective and Preventive Actıons Procedureevrim korı100% (1)

- ISO27k Corrective Action ProcedureDocument2 paginiISO27k Corrective Action Procedurevishnukesarwani67% (3)

- Internal Audit Procedure ExampleDocument4 paginiInternal Audit Procedure Examplestephenb4uÎncă nu există evaluări

- Control of Nonconforming ProductDocument2 paginiControl of Nonconforming ProductAliyantahir100% (2)

- Customer Feedback ProcedureDocument4 paginiCustomer Feedback Procedureomdkhaleel100% (4)

- Corrective and Preventive Action TrainingDocument58 paginiCorrective and Preventive Action TrainingUtkarsh RaiÎncă nu există evaluări

- Procedure For Continuous ImprovementDocument5 paginiProcedure For Continuous ImprovementJobair AlamÎncă nu există evaluări

- CAPA ProcedureDocument6 paginiCAPA ProcedureLove100% (3)

- P 008 Corrective Preventive Action Process 110414Document8 paginiP 008 Corrective Preventive Action Process 110414adam_3000Încă nu există evaluări

- Corrective & Preventive Action Checklist & NotesDocument3 paginiCorrective & Preventive Action Checklist & NotesHeart Fist100% (1)

- Procedure For TrainingDocument3 paginiProcedure For TrainingSharif Khan100% (1)

- Template of Procedure For Continual ImprovementDocument2 paginiTemplate of Procedure For Continual ImprovementRizaldi Djamil100% (2)

- I. Ii. Iii. Iv. V.: 1 PurposeDocument6 paginiI. Ii. Iii. Iv. V.: 1 Purposemuhamad yasserÎncă nu există evaluări

- Corrective and Preventive ActionDocument6 paginiCorrective and Preventive ActionAmer Rahmah67% (3)

- Corrective Action Response Form With InstructionsDocument3 paginiCorrective Action Response Form With Instructions7twofour100% (3)

- SOP For Corrective Action and Preventive Action (CAPA)Document5 paginiSOP For Corrective Action and Preventive Action (CAPA)Juan Manuel Jaurez100% (5)

- Corrective Action Procedure ExampleDocument6 paginiCorrective Action Procedure ExampleISO 9001 Checklist96% (25)

- Guidance On INTERNAL AUDITSDocument7 paginiGuidance On INTERNAL AUDITSdhir.ankurÎncă nu există evaluări

- Form - Management Review Meeting MinutesDocument6 paginiForm - Management Review Meeting Minutesmgamal1080100% (1)

- Process For Control of Non-Conforming ProductDocument8 paginiProcess For Control of Non-Conforming ProductselvamuthukumarÎncă nu există evaluări

- QMS-SOP-F15 - Procedure For Control of Document InformationDocument4 paginiQMS-SOP-F15 - Procedure For Control of Document InformationPINTU RAJÎncă nu există evaluări

- A6. Control of Nonconforming ProductDocument6 paginiA6. Control of Nonconforming ProductStanley MtamboÎncă nu există evaluări

- 7.4.1 Procedure Supplier Selection With FlowchartDocument3 pagini7.4.1 Procedure Supplier Selection With FlowchartBharath50% (4)

- ISO-Control of Non Conforming ProductsDocument3 paginiISO-Control of Non Conforming Productsnoufal27100% (2)

- Hs Non Conformance Report FormDocument2 paginiHs Non Conformance Report FormMuhammad Hashi100% (2)

- Capa FormDocument3 paginiCapa FormZahid Nazir100% (1)

- CAPA ExampleDocument5 paginiCAPA Examplechemist_tmaÎncă nu există evaluări

- QC Self Inspection Checklist 111Document14 paginiQC Self Inspection Checklist 111yzarvelascoÎncă nu există evaluări

- QMS Work PlanDocument4 paginiQMS Work PlanWael BouabdellahÎncă nu există evaluări

- Management Review Agenda and MinutesDocument6 paginiManagement Review Agenda and MinutesKosomoto100% (2)

- ISO 9001-2015 Supplier Audit Checklist SAMPLEDocument2 paginiISO 9001-2015 Supplier Audit Checklist SAMPLEFaisal0% (1)

- Control of Non-Conformity & Corrective ActionDocument5 paginiControl of Non-Conformity & Corrective ActionAli Kaya83% (6)

- QAS P008 Control of Non-Conforming Processes, Services or Products ProcedureDocument2 paginiQAS P008 Control of Non-Conforming Processes, Services or Products Proceduredanaka007Încă nu există evaluări

- 1.2 Quality ObjectivesDocument1 pagină1.2 Quality ObjectivesIsHq Vishq60% (5)

- QSP 8.3.1 Nonconforming Product - SampleDocument3 paginiQSP 8.3.1 Nonconforming Product - SampleGladys Calvo100% (2)

- QSP 7.1-03 Control of Organizational Knowledge (Preview)Document4 paginiQSP 7.1-03 Control of Organizational Knowledge (Preview)Centauri Business Group Inc.100% (1)

- Management Review ProcedureDocument1 paginăManagement Review ProcedureBAla83% (6)

- R-11 Intrested PartiesDocument5 paginiR-11 Intrested PartiesSandeep PhatakÎncă nu există evaluări

- ABC ABC Company: Internal Audit PlanDocument1 paginăABC ABC Company: Internal Audit PlanCQMS 5S DivisionÎncă nu există evaluări

- Sop For Handling CCDocument14 paginiSop For Handling CCnataarajan praveenÎncă nu există evaluări

- Process Approach A Complete Guide - 2019 EditionDe la EverandProcess Approach A Complete Guide - 2019 EditionÎncă nu există evaluări

- Internal Audit ProcedureDocument6 paginiInternal Audit ProcedureEric AnastacioÎncă nu există evaluări

- Qa-R-07 Nonconformity and Corrective ActionDocument2 paginiQa-R-07 Nonconformity and Corrective ActionvinothÎncă nu există evaluări

- Management ReviewsDocument9 paginiManagement Reviews李哲祥100% (1)

- MDSAP QMS P0013.004 Continual Improvement Procedure 2019-01-11Document7 paginiMDSAP QMS P0013.004 Continual Improvement Procedure 2019-01-11Tariq Tlafha100% (1)

- Troubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingDe la EverandTroubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingEvaluare: 4.5 din 5 stele4.5/5 (3)

- Root Cause AnalysisDocument47 paginiRoot Cause Analysiskapindra100% (8)

- Root-Cause-Analysis (RCA) Best PracticeDocument8 paginiRoot-Cause-Analysis (RCA) Best PracticeilbbeckÎncă nu există evaluări

- Root Cause Analysis Corrective ActionDocument12 paginiRoot Cause Analysis Corrective ActionAbdulrahman Alkhowaiter100% (2)

- Problem Solving WorksheetDocument10 paginiProblem Solving Worksheetapi-3856433100% (2)

- Entrenamiento 8DDocument23 paginiEntrenamiento 8DRene DurandÎncă nu există evaluări

- Root Cause Corrective Action: Nadcap StyleDocument12 paginiRoot Cause Corrective Action: Nadcap StyleVijay YadavÎncă nu există evaluări

- Aeration Control System Design: A Practical Guide to Energy and Process OptimizationDe la EverandAeration Control System Design: A Practical Guide to Energy and Process OptimizationÎncă nu există evaluări

- 5 Ss Visual ControlDocument57 pagini5 Ss Visual ControlR.BALASUBRAMANIÎncă nu există evaluări

- Lean Six Sigma Leadership 1615402359Document1 paginăLean Six Sigma Leadership 1615402359Kristof MCÎncă nu există evaluări

- 5S Guide: An Introduction To The 5S Method and Practical Tips For Implementation in Any FacilityDocument25 pagini5S Guide: An Introduction To The 5S Method and Practical Tips For Implementation in Any FacilityAndré Luiz LimaÎncă nu există evaluări

- 5Ss 1615573784Document20 pagini5Ss 1615573784Kristof MCÎncă nu există evaluări

- 5S Handbook PDFDocument20 pagini5S Handbook PDFAnonymous iMq2HDvVqÎncă nu există evaluări

- 5Ss 1615573743Document48 pagini5Ss 1615573743Kristof MCÎncă nu există evaluări

- External Auditing and QualityDocument351 paginiExternal Auditing and QualityKristof MC100% (1)

- Black Belt Tollgate Checklist BBv1.1Document12 paginiBlack Belt Tollgate Checklist BBv1.1Kristof MCÎncă nu există evaluări

- Yield GE Wekk48 - 52Document10 paginiYield GE Wekk48 - 52Kristof MCÎncă nu există evaluări

- Business Ethics PDFDocument37 paginiBusiness Ethics PDFtubuiÎncă nu există evaluări

- Dmaic Roadmap PDFDocument1 paginăDmaic Roadmap PDFKristof MCÎncă nu există evaluări

- Rakusa Simona PDFDocument147 paginiRakusa Simona PDFjames007spyÎncă nu există evaluări

- LSS Templates - M Cox - v4 Aug 08Document139 paginiLSS Templates - M Cox - v4 Aug 08Kristof MCÎncă nu există evaluări

- Development and Implementatio A Remote Audit Tool For HighDocument92 paginiDevelopment and Implementatio A Remote Audit Tool For HighKristof MCÎncă nu există evaluări

- Policy Deployment X-MatrixDocument12 paginiPolicy Deployment X-MatrixKristof MC100% (1)

- LSS GB Markos 06 - 12Document23 paginiLSS GB Markos 06 - 12Kristof MCÎncă nu există evaluări

- Leadership Today Practices For Personal and Professional PerformanceDocument412 paginiLeadership Today Practices For Personal and Professional PerformanceEstie100% (4)

- Policy Deployment X-MatrixDocument12 paginiPolicy Deployment X-MatrixKristof MC100% (1)

- LSSBBDocument35 paginiLSSBBKristof MCÎncă nu există evaluări

- TPS - Toyota Production System: Built in QualityDocument5 paginiTPS - Toyota Production System: Built in QualityKristof MCÎncă nu există evaluări

- LSSBBDocument35 paginiLSSBBKristof MCÎncă nu există evaluări

- Learn To SeeDocument67 paginiLearn To SeeKristof MCÎncă nu există evaluări

- Akashi Demand LetterDocument1 paginăAkashi Demand LetterKristof MCÎncă nu există evaluări

- Entrenamiento 5WDocument42 paginiEntrenamiento 5WSerchecko JaureguiÎncă nu există evaluări

- Plantilla Modelo Hoshin KanriDocument8 paginiPlantilla Modelo Hoshin KanriJavier NumpaqueÎncă nu există evaluări

- Special Characteristics PDFDocument11 paginiSpecial Characteristics PDFKristof MCÎncă nu există evaluări

- Feleffektsanalys/Failure Mode and Effect Analysis Konstruktion/DesignDocument12 paginiFeleffektsanalys/Failure Mode and Effect Analysis Konstruktion/DesignKristof MCÎncă nu există evaluări

- ISO Checklist of Mandatory Documentation Required by IATF 16949 en YES OKDocument20 paginiISO Checklist of Mandatory Documentation Required by IATF 16949 en YES OKroelly100% (2)

- Attribute Gage RR RidgwayDocument50 paginiAttribute Gage RR RidgwayPradeepÎncă nu există evaluări

- Checklist of Mandatory Documentation Required by IATF 16949 enDocument3 paginiChecklist of Mandatory Documentation Required by IATF 16949 enKristof MC100% (1)

- Rattan Pole BendingDocument21 paginiRattan Pole Bendingcintamore_jos355Încă nu există evaluări

- VCSEL Technology v1Document17 paginiVCSEL Technology v1Vaibhav MathurÎncă nu există evaluări

- 1 Starting Time Calculation 2Document15 pagini1 Starting Time Calculation 2Sankalp MittalÎncă nu există evaluări

- Design of Anchor Bolts Embedded in Concrete MasonryDocument9 paginiDesign of Anchor Bolts Embedded in Concrete MasonryYoesuf DecipherÎncă nu există evaluări

- Classification of Pumps and TurbinesDocument12 paginiClassification of Pumps and TurbinesKarim SayedÎncă nu există evaluări

- GET OA Doc - Batch 2Document3 paginiGET OA Doc - Batch 2Ganesh Sai VelidiÎncă nu există evaluări

- 2015 Jicable - Risk On Failure Based On PD Measurements in Actual MV PILC and XLPE Cables.Document3 pagini2015 Jicable - Risk On Failure Based On PD Measurements in Actual MV PILC and XLPE Cables.des1982Încă nu există evaluări

- Checklist For Buying A Better Used Car in MalaysiaDocument2 paginiChecklist For Buying A Better Used Car in MalaysiaSurendra KumarÎncă nu există evaluări

- Duty Statements Office Technician Typing PDFDocument3 paginiDuty Statements Office Technician Typing PDFremon4hrÎncă nu există evaluări

- Compair Fluid Force 4000 IndonesiaDocument3 paginiCompair Fluid Force 4000 Indonesiaindolube75% (4)

- Cable Sheath Voltage Limiters PresentationDocument8 paginiCable Sheath Voltage Limiters PresentationRaden ArmanadiÎncă nu există evaluări

- IRobot 510 PackBot AccessoriesDocument14 paginiIRobot 510 PackBot AccessoriesMirsad34Încă nu există evaluări

- Kevin Colcomb, Matthew Rymell and Alun Lewis: Very Heavy Fuel Oils: Risk Analysis of Their Transport in Uk WatersDocument12 paginiKevin Colcomb, Matthew Rymell and Alun Lewis: Very Heavy Fuel Oils: Risk Analysis of Their Transport in Uk WatersSidney Pereira JuniorÎncă nu există evaluări

- Zeroing RobotDocument44 paginiZeroing RobotArno BothaÎncă nu există evaluări

- Introduction To Weapon & AmmunitionDocument141 paginiIntroduction To Weapon & Ammunitionk2kkhanna105100% (1)

- Traditional Healer in Carletonville, Germiston, Johannesburg, Krugersdorp South Africa+27782669503Document139 paginiTraditional Healer in Carletonville, Germiston, Johannesburg, Krugersdorp South Africa+27782669503mama shifahÎncă nu există evaluări

- Field Trip Grading RubricDocument1 paginăField Trip Grading Rubricapi-242613835Încă nu există evaluări

- DD FC Basix ConfDocument18 paginiDD FC Basix ConfwstanzlÎncă nu există evaluări

- SUPER Final ImportDocument41 paginiSUPER Final ImportronaldÎncă nu există evaluări

- w170 w190 w230c - 30644gb 123bbDocument20 paginiw170 w190 w230c - 30644gb 123bbJIMISINGÎncă nu există evaluări

- Manual - Submersible PumpDocument4 paginiManual - Submersible PumpcodersriramÎncă nu există evaluări

- MBAM Deployment GuideDocument80 paginiMBAM Deployment GuidePsam Umasankar0% (1)

- Indian CyberSecurity Product Landscape PDFDocument56 paginiIndian CyberSecurity Product Landscape PDFShaik InayathÎncă nu există evaluări

- Mamuli N22Document28 paginiMamuli N22doubeÎncă nu există evaluări

- W667 Job Completion CertificateDocument5 paginiW667 Job Completion CertificateMohamed ShafeeqÎncă nu există evaluări

- RISC Vs CISC - The Post-RISC Era - Jon "Hannibal" StokesDocument26 paginiRISC Vs CISC - The Post-RISC Era - Jon "Hannibal" Stokesjlventigan100% (1)

- Product Data Sheet: Circuit Breaker Compact Ns1600N, 50 Ka at 415 Vac, Micrologic 2.0 Trip Unit, 1600 A, Fixed, 4 Poles 4DDocument3 paginiProduct Data Sheet: Circuit Breaker Compact Ns1600N, 50 Ka at 415 Vac, Micrologic 2.0 Trip Unit, 1600 A, Fixed, 4 Poles 4DAchira DasanayakeÎncă nu există evaluări

- Mechanical ComprehensionDocument14 paginiMechanical Comprehensiondanielhealy100% (6)

- Pressure and Level TRansmitters KLAY INSTRUMENTSDocument6 paginiPressure and Level TRansmitters KLAY INSTRUMENTSFrancisco Mones RuizÎncă nu există evaluări

- Mica PDFDocument2 paginiMica PDFomarÎncă nu există evaluări