Documente Academic

Documente Profesional

Documente Cultură

Quiz 1 Solution

Încărcat de

Deepak ThiruDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Quiz 1 Solution

Încărcat de

Deepak ThiruDrepturi de autor:

Formate disponibile

Mine Planning 332/532:

309995/12585

WASM Mining Engineering

Quiz 1, Semester 2, 2012

Attendance Mode:

309995 Internal Only

12585 Internal/External

Centre(s):

Kalgoorlie Campus/Bentley Campus/External Supervised

Date: Monday, August 13, 2012

Duration: 1 Hour

Start @ 12:30pm, Reading Time: 10 minutes, End @ 1:40pm

External Supervisors for EXTERNAL STUDENTS must submit

scanned copy of the quiz no later than 1:55pm (i) by email

(waqar.asad@curtin.edu.au) or a copy by fax to +61 8 9088

6151, and (ii) hard original copy by mail to Dr. Mohammad

Waqar ASAD at WASM Mining, Locked Bag 30, Kalgoorlie WA

6433, Australia.

Total Marks: 50 (Weight towards final grade = 10%)

Calculator: Yes

CLOSED BOOK

IMPORTANT INFORMATION:

Possession or use of:

Mobile phones or any device of communication is prohibited during examinations.

Electronic Organizers/PDAs (except calculators) or other devices capable of storing text or restricted

information are prohibited during examination.

Calculators: only university/department approved may be used during examination. Prior to

commencement of examination, calculators will be checked for compliance by the examiner.

Any breach of examination regulations will be considered cheating and appropriate action will be

taken in accordance with university policy.

Student Name: _______________________

Student Signature: ________________

Supervisor Name: ____________________

Supervisor Signature: ______________

Page 1 of 6

Mine Planning 332/532:

309995/12585

Topic: Mine planning process:

1. (Marks = 3) Long-term mine planning refers to:

a. Pushback design.

b. Strategic planning that looks into all aspects from establishing resources and

reserves to project closure.

c. Ultimate pit limit design using floating cone algorithm.

2. (Marks = 3) A conceptual study utilizes limited exploration data and its outcome justifies

the potential financial worth of the project without conducting detailed feasibility

studies.

a. True.

b. False.

3. (Marks = 3) A technical risk in an underground coal mining operation includes:

a. Change in coal price and transportation cost to port facilities.

b. Change in quality of coal to an unacceptable limit.

c. Performance of coal shearer below designed rate.

4. (Marks 3) Owing to the material handling costs and an opportunity to increase the life of

operation, a mining company is looking into the possibility of switching its open pit

mining operation to an underground operation. Since, the company has more than 15

years experience working in open pit environment; the development of short-term plan

would be sufficient to accomplish this objective.

a. True.

b. False.

Topic: Block economic values

5. (Marks 3) Given a block grade of 0.43% Cu and mill recovery of 79%, what is the quantity

(kg per tonne of ore) of Cu recovered by mill?

a. 3.397 kg/t.

b. 340 kg/t.

c. 33970 kg/t.

Page 2 of 6

Mine Planning 332/532:

309995/12585

Net Value

($/tonne)

(0.43, 3)

Figure 1:

Cu (%)

(0.25, -2)

6. (Marks 3.5) Given the NV-grade curve in Figure 1, what is the net value of a block with

grade = 0.34%.

a. $2.00/t.

b. $3.5/t.

c. $0.51/t.

Establish a straight line equation. Given, grade = x = 0.34%, net value = $0.51/t.

7. (Marks 3.5) Given the NV-grade curve in Figure 1, what is the breakeven cutoff grade?

a. 3.105%.

b. 0.322%.

c. 0.53%.

Given net value = y = 0, g = 0.322%.

Page 3 of 6

Mine Planning 332/532:

309995/12585

Topic: Open pit optimization

8. (Marks 3.5) Given the ore body model in Figure 2, the cutoff grade is 0.45% and each

block contains 1000 tonnes of material. If all blocks are inside the pit, what is the

stripping ratio?

0.23

Figure 2:

1.24

0.29

0.05

0.12

0.25

0.54

1.23

2.14

0.45

0.06

2.51

1.36

0.84

0.65

a. 2.14.

b. 0.67.

c. 2.63.

9. (Marks 2) Problems associated to Floating Cone Algorithm include:

a. It honours the time value of money.

b. It does not allow mutual support among ore blocks.

c. It ensures optimal solution.

d. All of the above.

10. (Marks 3.5) Given the tableau for Whittle 2D in Figure 3, assign arrows to blocks located

at (row i=1, column j=4) and (row i=2, column j=4).

Figure 3:

i

-1

-1

-1

-1

-1

-1

-4

-4

-4

-1

-7

2

3

-1+3 = 2

-4+4 = 0

Production scheduling and Whittle:

11. (Marks 2) Ultimate pit limit design identifies the extent of extraction.

12. (Marks 3) An increase in price of metal results in increase (decrease) in the number of

ore (waste) blocks, thus increases the size of the pit.

13. (Marks 3) Given the range of revenue factors from 0.25 to 2.00 at a step size of 0.025

generates 70 pit shells.

Range = (2.00-0.25) 0.025 = 70.

Page 4 of 6

Mine Planning 332/532:

309995/12585

14. (Marks 2) Open pit production scheduling maximizes the undiscounted future cash flows

and satisfies slope, mining, and processing capacity constraints.

a. True.

b. False.

15. (Marks 2) The worst case schedule mines each bench completely before starting the

next bench. Thus it allows mining from multiple pushbacks simultaneously.

a. True.

b. False.

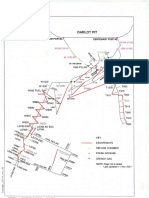

16. (Marks 2) Given the schedule in Figure 4, if minimum and maximum mining rates are

40,000,000 tonnes and 140,000,000 tonnes, respectively, how would you deal with

these two extremes in terms of mining capacity utilization? Your response may not

exceed two lines.

Figure 4:

Extreme stripping in initial years may be contracted out. This will allow smooth mining

capacity during life of operation.

17. (Marks 5) Compare schedules in Figures 4 and 5:

a. What is common in both schedules?

Milling rate.

Page 5 of 6

Mine Planning 332/532:

309995/12585

b. Which one promises higher NPV and why?

Figure 5, deferred stripping.

c. Which one is better in terms of capital cost and why?

Figure 5, less mining capacity 120,000,000 MT < 140,000,000 MT.

Figure 5:

Good Luck.

Page 6 of 6

S-ar putea să vă placă și

- Darlot PlanDocument1 paginăDarlot PlanDeepak ThiruÎncă nu există evaluări

- NamasthaeDocument1 paginăNamasthaeDeepak ThiruÎncă nu există evaluări

- T Q MDocument7 paginiT Q MSalih Al SubaiÎncă nu există evaluări

- Work Design: BY Uma Maheswaran N B E MiningDocument11 paginiWork Design: BY Uma Maheswaran N B E MiningDeepak ThiruÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Uboot Rulebook v1.1 EN PDFDocument52 paginiUboot Rulebook v1.1 EN PDFUnai GomezÎncă nu există evaluări

- 11 Its A Magical World - Bill WattersonDocument166 pagini11 Its A Magical World - Bill Wattersonapi-560386898100% (8)

- MOP Annual Report Eng 2021-22Document240 paginiMOP Annual Report Eng 2021-22Vishal RastogiÎncă nu există evaluări

- Oracle Fusion Global Human Resources Payroll Costing GuideDocument90 paginiOracle Fusion Global Human Resources Payroll Costing GuideoracleappshrmsÎncă nu există evaluări

- Mangalore Electricity Supply Company Limited: LT-4 IP Set InstallationsDocument15 paginiMangalore Electricity Supply Company Limited: LT-4 IP Set InstallationsSachin KumarÎncă nu există evaluări

- Gillette vs. EnergizerDocument5 paginiGillette vs. EnergizerAshish Singh RainuÎncă nu există evaluări

- S No Clause No. Existing Clause/ Description Issues Raised Reply of NHAI Pre-Bid Queries Related To Schedules & DCADocument10 paginiS No Clause No. Existing Clause/ Description Issues Raised Reply of NHAI Pre-Bid Queries Related To Schedules & DCAarorathevipulÎncă nu există evaluări

- Tmc521 Fundamentals of Marriage and Family - Lecture 1Document38 paginiTmc521 Fundamentals of Marriage and Family - Lecture 1Christian NwekeÎncă nu există evaluări

- Development of Modern International Law and India R.P.anandDocument77 paginiDevelopment of Modern International Law and India R.P.anandVeeramani ManiÎncă nu există evaluări

- WFP Specialized Nutritious Foods Sheet: Treating Moderate Acute Malnutrition (MAM)Document2 paginiWFP Specialized Nutritious Foods Sheet: Treating Moderate Acute Malnutrition (MAM)elias semagnÎncă nu există evaluări

- Lecture 1Document12 paginiLecture 1asiaÎncă nu există evaluări

- IMMI S257a (s40) Requirement To Provide PIDsDocument4 paginiIMMI S257a (s40) Requirement To Provide PIDsAshish AshishÎncă nu există evaluări

- Term Paper Air PollutionDocument4 paginiTerm Paper Air Pollutionaflsnggww100% (1)

- Cases 1Document79 paginiCases 1Bechay PallasigueÎncă nu există evaluări

- Berkshire Hathaway Inc.: United States Securities and Exchange CommissionDocument48 paginiBerkshire Hathaway Inc.: United States Securities and Exchange CommissionTu Zhan LuoÎncă nu există evaluări

- Session - 30 Sept Choosing Brand Elements To Build Brand EquityDocument12 paginiSession - 30 Sept Choosing Brand Elements To Build Brand EquityUmang ShahÎncă nu există evaluări

- Active Critical ReadingDocument22 paginiActive Critical ReadingYonn Me Me KyawÎncă nu există evaluări

- CCC Guideline - General Requirements - Feb-2022Document8 paginiCCC Guideline - General Requirements - Feb-2022Saudi MindÎncă nu există evaluări

- A Repurchase AgreementDocument10 paginiA Repurchase AgreementIndu GadeÎncă nu există evaluări

- 3 Longman Academic Writing Series 4th Edition Answer KeyDocument21 pagini3 Longman Academic Writing Series 4th Edition Answer KeyZheer KurdishÎncă nu există evaluări

- Persuasive Writing Exam - Muhamad Saiful Azhar Bin SabriDocument3 paginiPersuasive Writing Exam - Muhamad Saiful Azhar Bin SabriSaiful AzharÎncă nu există evaluări

- Chinese and Korean Art Before 1279 CeDocument67 paginiChinese and Korean Art Before 1279 Ceragunath palaniswamyÎncă nu există evaluări

- CPFContributionRatesTable 1jan2022Document5 paginiCPFContributionRatesTable 1jan2022ysam90Încă nu există evaluări

- Projections GuideDocument28 paginiProjections GuidemkmattaÎncă nu există evaluări

- Leadership and Followership in An Organizational Change Context (Sajjad Nawaz Khan, (Editor) ) (Z-Library)Document381 paginiLeadership and Followership in An Organizational Change Context (Sajjad Nawaz Khan, (Editor) ) (Z-Library)benjaminwong8029Încă nu există evaluări

- Unit 7:: Intellectual PropertyDocument52 paginiUnit 7:: Intellectual Propertyمحمد فائزÎncă nu există evaluări

- Art. 19 1993 P.CR - LJ 704Document10 paginiArt. 19 1993 P.CR - LJ 704Alisha khanÎncă nu există evaluări

- Rizal FamilyDocument3 paginiRizal FamilyPamela MarquezÎncă nu există evaluări

- 4 Secrets Behind Disney's Captivating Marketing StrategyDocument10 pagini4 Secrets Behind Disney's Captivating Marketing StrategyJuan Camilo Giorgi MartinezÎncă nu există evaluări

- Pre Project PlanningDocument13 paginiPre Project PlanningTewodros TadesseÎncă nu există evaluări