Documente Academic

Documente Profesional

Documente Cultură

Syllabus

Încărcat de

balaguru78Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Syllabus

Încărcat de

balaguru78Drepturi de autor:

Formate disponibile

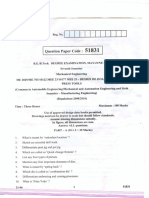

ME6006

DESIGN OF JIGS, FIXTURES AND PRESS TOOLS

LTPC

3003

OBJECTIVES:

To understand the functions and design principles of Jigs, fixtures and press tools

To gain proficiency in the development of required views of the final design.

UNIT I

LOCATING AND CLAMPING PRINCIPLES:

8

Objectives of tool design- Function and advantages of Jigs and fixtures Basic elements

principles of location Locating methods and devices Redundant Location Principles of

clamping Mechanical actuation pneumatic and hydraulic actuation Standard parts Drill

bushes and Jig buttons Tolerances and materials used.

UNIT II

JIGS AND FIXTURES

10

Design and development of jigs and fixtures for given component- Types of Jigs Post,

Turnover, Channel, latch, box, pot, angular post jigs Indexing jigs General principles of

milling, Lathe, boring, broaching and grinding fixtures Assembly, Inspection and Welding

fixtures Modular fixturing systems- Quick change fixtures.

UNIT III PRESS WORKING TERMINOLOGIES AND ELEMENTS OF CUTTING DIES 10

Press Working Terminologies - operations Types of presses press accessories

Computation of press capacity Strip layout Material Utilization Shearing action

Clearances Press Work Materials Center of pressure- Design of various elements of dies

Die Block Punch holder, Die set, guide plates Stops Strippers Pilots Selection of

Standard parts Design and preparation of four standard views of simple blanking, piercing,

compound and progressive dies.

UNIT IV

BENDING AND DRAWING DIES

10

Difference between bending and drawing Blank development for above operations Types of

Bending dies Press capacity Spring back knockouts direct and indirect pressure pads

Ejectors Variables affecting Metal flow in drawing operations draw die inserts draw

beads ironing Design and development of bending, forming, drawing, reverse redrawing and

combination dies Blank development for axisymmetric, rectangular and elliptic parts Single

and double action dies.

UNIT V

OTHER FORMING TECHNIQUES

7

Bulging, Swaging, Embossing, coining, curling, hole flanging, shaving and sizing, assembly, fine

Blanking dies recent trends in tool design- computer Aids for sheet metal forming Analysis

basic introduction - tooling for numerically controlled machines- setup reduction for work holding

Single minute exchange of dies Poka Yoke.

TOTAL: 45 PERIODS

Note: (Use of P S G Design Data Book is permitted in the University examination)

OUTCOMES:

Upon completion of this course, the students can able to design jigs, fixtures and press tools.

TEXT BOOKS:

1. Joshi, P.H. Jigs and Fixtures, Second Edition, Tata McGraw Hill Publishing Co., Ltd., New

Delhi, 2004.

2. Joshi P.H Press tools - Design and Construction, wheels publishing, 1996

REFERENCES:

1. Venkataraman. K., Design of Jigs Fixtures & Press Tools, Tata McGraw Hill, New Delhi,

2005.

2. Donaldson, Lecain and Goold Tool Design, 3rd Edition, Tata McGraw Hill, 2000.

3. Kempster, Jigs and Fixture Design, Third Edition, Hoddes and Stoughton, 1974.

4. Hoffman Jigs and Fixture Design, Thomson Delmar Learning, Singapore, 2004.

5. ASTME Fundamentals of Tool Design Prentice Hall of India.

6. Design Data Hand Book, PSG College of Technology, Coimbatore.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Mech JRF ISRO 2017 v2Document4 paginiMech JRF ISRO 2017 v2balaguru78Încă nu există evaluări

- 2.ISCA RJMatS 2013 002Document5 pagini2.ISCA RJMatS 2013 002balaguru78Încă nu există evaluări

- Vibration AbsorberDocument3 paginiVibration Absorberbalaguru78Încă nu există evaluări

- 2.ISCA RJMatS 2013 002 PDFDocument5 pagini2.ISCA RJMatS 2013 002 PDFbalaguru78Încă nu există evaluări

- An Overview of Development of Fiber Reinforced Polymer Composite Coiled Spring For Automobile ApplicationsDocument14 paginiAn Overview of Development of Fiber Reinforced Polymer Composite Coiled Spring For Automobile Applicationsbalaguru78Încă nu există evaluări

- Annals 2011 3 32Document6 paginiAnnals 2011 3 32balaguru78Încă nu există evaluări

- April May 2014 Design of Jigs and Fixtures Anwer KeyDocument17 paginiApril May 2014 Design of Jigs and Fixtures Anwer Keybalaguru78Încă nu există evaluări

- Nov Dec 2014 Anna Univ Question PaperDocument5 paginiNov Dec 2014 Anna Univ Question Paperbalaguru78Încă nu există evaluări

- ME 6019 Non Destrictive Testing and Materials SyllabusDocument2 paginiME 6019 Non Destrictive Testing and Materials Syllabusbalaguru780% (2)

- Question PaperDocument3 paginiQuestion Paperbalaguru78Încă nu există evaluări

- Nov Dec 2014 Anna Univ Question PaperDocument5 paginiNov Dec 2014 Anna Univ Question Paperbalaguru78Încă nu există evaluări

- Chapter - 7 List of MaterialsDocument2 paginiChapter - 7 List of Materialsbalaguru78Încă nu există evaluări

- 2016 April R2008 Design of Jigs, Fixtures and Press ToolsDocument2 pagini2016 April R2008 Design of Jigs, Fixtures and Press Toolsbalaguru78Încă nu există evaluări

- Strength of Materials Part - A AnswersDocument3 paginiStrength of Materials Part - A Answersbalaguru78Încă nu există evaluări

- Chapter - 8 Cost EstimationDocument1 paginăChapter - 8 Cost Estimationbalaguru78Încă nu există evaluări

- Annals 2011 3 32Document6 paginiAnnals 2011 3 32balaguru78Încă nu există evaluări

- Call For Papers - ICSSCCET 2015Document7 paginiCall For Papers - ICSSCCET 2015balaguru78Încă nu există evaluări

- Injection MoldingDocument66 paginiInjection Moldingbalaguru78100% (2)

- Numerical and Experimental Investigation On Aerodynamic Characteristics of SMA Actuated Smart Wing ModelDocument6 paginiNumerical and Experimental Investigation On Aerodynamic Characteristics of SMA Actuated Smart Wing Modelbalaguru78Încă nu există evaluări

- ACD Lab Manual Spur Gear DesignDocument4 paginiACD Lab Manual Spur Gear Designbalaguru780% (1)

- Synopsis: Magnet, Electromagnet, IR Transmitter and Receiver. The Transmitter andDocument1 paginăSynopsis: Magnet, Electromagnet, IR Transmitter and Receiver. The Transmitter andbalaguru78Încă nu există evaluări

- Page No.: 2.1. Electromagnet Coil 2 2.2. Permanent Magnet 3 2.3. IR Transmitter and Receiver 4Document1 paginăPage No.: 2.1. Electromagnet Coil 2 2.2. Permanent Magnet 3 2.3. IR Transmitter and Receiver 4balaguru78Încă nu există evaluări

- Anna University Chennai SyllabusDocument95 paginiAnna University Chennai SyllabusRAAM MECHÎncă nu există evaluări

- Design of Transmission Systems-May June 2014Document3 paginiDesign of Transmission Systems-May June 2014balaguru78Încă nu există evaluări

- Chapter - 4 Working PrincipleDocument2 paginiChapter - 4 Working Principlebalaguru78Încă nu există evaluări

- List of FiguresDocument2 paginiList of Figuresbalaguru78Încă nu există evaluări

- Chapter - 7 List of MaterialsDocument2 paginiChapter - 7 List of Materialsbalaguru78Încă nu există evaluări

- Chapter - 3 Design of Equipment and Drawing: 3.1. Machine ComponentsDocument6 paginiChapter - 3 Design of Equipment and Drawing: 3.1. Machine Componentsbalaguru78Încă nu există evaluări

- Synopsis: Magnet, Electromagnet, IR Transmitter and Receiver. The Transmitter andDocument1 paginăSynopsis: Magnet, Electromagnet, IR Transmitter and Receiver. The Transmitter andbalaguru78Încă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Method Statement and Risk Assessment For Scaffold ErectionDocument24 paginiMethod Statement and Risk Assessment For Scaffold ErectionBarry Hart50% (2)

- Ekinex® Price List (APRIL 2019)Document7 paginiEkinex® Price List (APRIL 2019)Federico Ungureanu100% (1)

- Latest Cisco EnsurePass ICND2 200 101 Dumps PDFDocument151 paginiLatest Cisco EnsurePass ICND2 200 101 Dumps PDFkifayatktkÎncă nu există evaluări

- Catalog 1 PDFDocument19 paginiCatalog 1 PDFtoto-gmbhÎncă nu există evaluări

- Msd252coy - YachtsDocument18 paginiMsd252coy - YachtscatalinÎncă nu există evaluări

- Planned Maintainece System For ShipsDocument22 paginiPlanned Maintainece System For ShipsHarshad TallurÎncă nu există evaluări

- 4G Kpi Ibd HPDocument20 pagini4G Kpi Ibd HPYalzlelfÎncă nu există evaluări

- PLC Connection PDFDocument761 paginiPLC Connection PDFKhalid RafiqueÎncă nu există evaluări

- 1.design IoT PDFDocument38 pagini1.design IoT PDFAyush53Încă nu există evaluări

- DSE8610 MKII Installation InstructionsDocument2 paginiDSE8610 MKII Installation InstructionsRafael FernandoÎncă nu există evaluări

- Iskraemeco Mx37y Technical DescriptionDocument38 paginiIskraemeco Mx37y Technical DescriptionmirelaMEÎncă nu există evaluări

- Instructor Materials Chapter 1: WAN Concepts: CCNA Routing and Switching Connecting NetworksDocument29 paginiInstructor Materials Chapter 1: WAN Concepts: CCNA Routing and Switching Connecting NetworksAsy LpanÎncă nu există evaluări

- TDX Manual enDocument28 paginiTDX Manual enJack Duff100% (2)

- Uai B 0214Document4 paginiUai B 0214Jose Puc ManzanillaÎncă nu există evaluări

- Medical Electrical Equipment - Part 2-19: Particular Requirements For The Basic Safety and Essential Performance of Infant IncubatorsDocument46 paginiMedical Electrical Equipment - Part 2-19: Particular Requirements For The Basic Safety and Essential Performance of Infant IncubatorsEver Daniel Castro RodriguezÎncă nu există evaluări

- 047 Project Tendering 2016 - 04 - 01Document12 pagini047 Project Tendering 2016 - 04 - 01kian hong100% (1)

- Pure Racing Performance.: All-New 2019 TVS Apache RTR 180 (BS IV)Document2 paginiPure Racing Performance.: All-New 2019 TVS Apache RTR 180 (BS IV)sandeep sehrawatÎncă nu există evaluări

- Gpcet - Ece Front PapersDocument5 paginiGpcet - Ece Front PapersPraveen kumarÎncă nu există evaluări

- QualysGuard Known Issues 20130311Document32 paginiQualysGuard Known Issues 20130311Rajeev AnandÎncă nu există evaluări

- Coach Maint. Manual PDFDocument204 paginiCoach Maint. Manual PDFDebasis MajhiÎncă nu există evaluări

- IEEE STD 519-1992 Harmonic Limits - 07 - TMBDocument9 paginiIEEE STD 519-1992 Harmonic Limits - 07 - TMBAN.ADAMMSÎncă nu există evaluări

- Ip Voice Recorder: Technical ManualDocument25 paginiIp Voice Recorder: Technical ManualkamalÎncă nu există evaluări

- Mov Specification PDFDocument27 paginiMov Specification PDFpl_arunachalam79Încă nu există evaluări

- Bsen 15112Document39 paginiBsen 15112Elambarithi Kalyanakumar100% (1)

- Cincom L12Document8 paginiCincom L12asilka68Încă nu există evaluări

- Lab 8Document24 paginiLab 8RapacitorÎncă nu există evaluări

- Practical-1: Aim: HistoryDocument23 paginiPractical-1: Aim: HistoryGurprasad SinghÎncă nu există evaluări

- Slides 4 December Ray Mead - Standard For Program ManagementDocument25 paginiSlides 4 December Ray Mead - Standard For Program ManagementtigrotÎncă nu există evaluări

- Advances in Telemedicine Technologies Enabling Factors and ScenariosDocument426 paginiAdvances in Telemedicine Technologies Enabling Factors and ScenariosdoctorcaceresÎncă nu există evaluări

- A Brief History of Project Management: 2570 BC: The Great Pyramid of Giza CompletedDocument6 paginiA Brief History of Project Management: 2570 BC: The Great Pyramid of Giza CompletedKarthikrajavÎncă nu există evaluări